key ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 325 of 421

Air Conditioning

Refrigerant Recovery and Recycling ^=2?

Recovery Procedure

Hote:

Run the

air-conditioning

system

for

a

few

minutes

before starting the

recovery

procedure as

this will

enable

more refrigerant to be recovered. Turn the

system

off

before

starting

the procedure.

1.

Attach the red (high side) hose oftheunittothe high

side fitting of the system on the vehicle then fit the

blue (low side) fitting to the low side on the vehicle.

Note: Make sure that the Air conditioning

system

has

pressure in it before beginning the recovery

process;

if

there is no

system

pressure there is no refrigerant to

recover.

Also

make sure that the

oil

drain

valve

is

closed.

2. Open both the high and low side valves on the

control panel.

3. Open the red CAS (vapour) valve and the blue

LIQUID valve on the tank.

4.

Turn on the MAIN POWER switch.

5. Press the RECOVERY key on the key-pad. The

display shows that the unit in the RECOVER mode

and AUTOMATIC cycle. After the compressor starts

the display shows the weight of refrigerant being

recovered.

The compressor shuts off automatically

when the recovery is complete and the display

shows the message 'CPL' and the final weight of the

recovered refrigerant.

6. Wait for five minutes and watch the manifold

gauges for a rise above 0. If a rise occurs press the

HOLD/CONT key. Repeat as needed until the

system pressure holds for two minutes.

Note: Drain the oil

separator

after

each

job.

7. Slowly open the oil drain valve and drain the oil

into the oil catch bottle. When all the recovered oil

has completely drained close the valve.

8. Replace oil lost during the recovery procedure by

measuringthe amount of oil inthe catch bottle and

adding the same amount of new oil to the system.

Note:

Dispose

of the

recovered

oil in an approved way.

9. When the recovery tank is full the compressor is

shut off and the display shows the message FULL.

Evacuating and Recycling the Refrigerant

1.

Open the red (high side) and the blue (low side)

valves on the unit and open the red GAS (vapour)

valve and the blue LIQUID valve on the tank.

2.

Enter the required time using the key-pad, press

enter,thedisplayshowstheenteredtime in minutes.

3. Start the vacuum pump by pressing the VACUUM

KEY again. The recycling process begins

approximately five seconds after the vacuum pump

starts and the message RECYCLE is displayed.

Note: If the vacuum pump

has

run for ten hours or

over

without an oil change the

message

OIL

flashes

on the

display.

Change

the pump oil and

then press

the

SHIFT/

RESET key and

the

zero key to

reset the

oil

change

timer

to zero.

The digital display counts down the evacuation

time.

4.

Check for non-condensibles after five minutes

recycling.

Ifthegauge needles are more than lOpsi

apart purge the non-condensibles from the tank by

open

i ng

the purge valve on the back of the

un

it and

continue to bleed until both needles show the same

reading.

The vacuum sequence continues until the

programmed time has elapsed at which point the

message CPL is displayed.

5. If the moisture indicator turns green recharge with

refrigerant.

or

5. If the moisture indicator has not turned green

replace the unit's filter-drier, which is probably

saturated.

Note:

Pressing

any key at this point allows the next

function to be

accessed.

To recycle the refrigerant only without pulling a

vacuum for an indefinite period of time press the

SHIFT/RESET key and the RECYCLE key on the key

pad.

Press the SHIFT/RESET key to cancel.

For vacuum only press the SHIFT/RESET key and

the ENTER key and then press

"1".

Run the vacuum

pump as long as required and then press

"1"

or

press SHIFT/RESET to cancel.

8-48 May 1996

Page 326 of 421

^2?

Air Conditioning

System Recharging / Compressor Oil Check

Recharging the System

1.

Open the high side valve on the unit control panel.

If the messages PROGRAM and CHARGE are not

displayed press the CHG key to enter PROGRAM

mode.

2.

Key in the amount of refrigerant needed to recharge

the system and press ENTER.

3. Press the CHG key; the message AUTOMATIC and

the entered amount of refrigerant wi

11

be displayed.

The display counts down to zero as the charging

process proceeds. When the charging is complete

the message CPL is displayed.

If the refrigerant transfer is too slow the charging

unit emits a signal. If the message CHECK

REFRIGERANT is not displayed, close the high side

valve,

open the low side valve and start the air

conditioning system to pull the remainder of the

charge into the system.

If the refrigerant transfer will not complete and the

message CHECK REFRIGERANT is displayed, press

the HOLD/CONT key to interrupt the cycle then

reset the unit by pressing the RESET key. Recover

the refrigerant already charged into the system by

following the procedure for recovering the

refrigerant, add new refrigerant to the tank and

return to Step 1 to recharge the system.

4.

If the air conditioning system is not running start it

and let it run until the gauge pressure readings

stabilize (compare the gauge readings with the

system manufacturer's specifications).

Note:

Ensure

that the

readings

are accurate by closing

both the high and low side

valves

on the unit's control

panel.

5. Check the evaporator outlet temperature to make

sure that the air conditioning system is operating

properly (refer to the system manufacturer's

specifications for the proper temperature).

Compressor Oil Checic

Data

Special Tools

Sanden oil dipstick JD 149

Torque Figures

Oil filler plug 8-12 Nm

Procedure

Whenever a component has been replaced in the

refrigerator system or there is an obvious oil leak, the

following procedure should be carried out.

A Sanden oil dipstick and angle gauge are required in

order to carry out the check.

1.

Run the compressor for 10 minutes at engine idle

speed.

2.

Depressurise the system.

3. Lay the angle gauge across the flat surfaces of the

two front mounting lobes. Centre the bubble and

note the mounting angle.

4.

Remove the compressor from the vehicle.

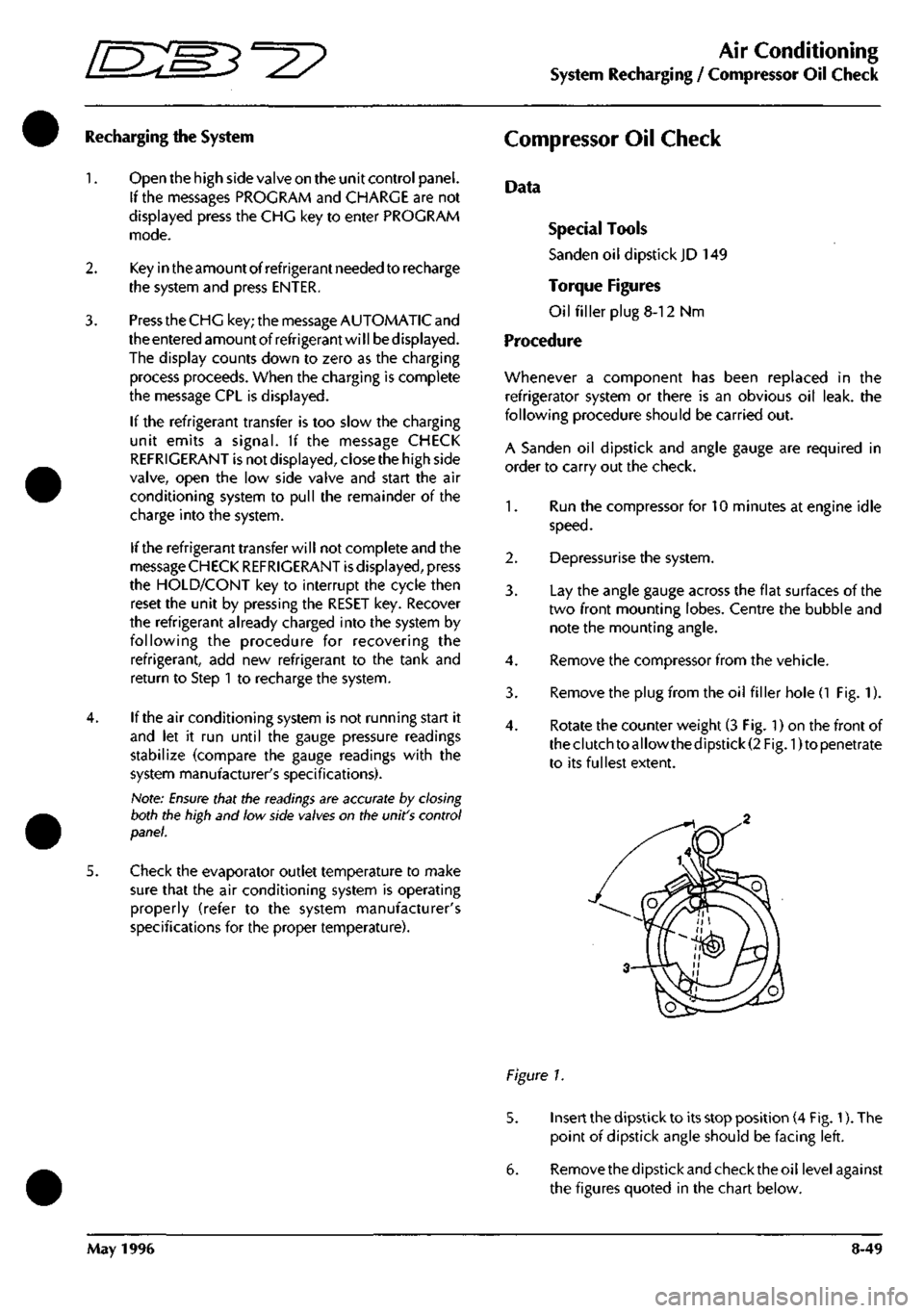

3. Remove the plug from the oil filler hole

(1

Fig. 1).

4.

Rotate the counter weight (3 Fig. 1) on the front of

theclutchtoallowthedipstick(2 Fig. 1)to penetrate

to its fullest extent.

Figure 1.

5. Insert the dipstick to its stop position (4 Fig. 1). The

point of dipstick angle should be facing left.

6. Removethedipstickandchecktheoil levelagainst

the figures quoted in the chart below.

May 1996 8-49

Page 337 of 421

Air Conditioning Repair Procedures

Blower Assembly Renewal o^s^-^?

12.

Disconnect the vacuum pipe from the flap actuator

(Fig.

1-4).

13.

Open the re-circulation flap in the base of the

blower assembly and fit a wedge to retain it in the

open position (Fig. 1-5).

14.

Remove the bolts securing the blower assembly

and ease the blower unit from its location (Fig.

1

-6).

15.

Remove the tape securing the ducting to the

assembly and remove the ducting (Fig.

1

-7).

Note: To remove the blower motor

assembly

from the

vehicle,

the

lower flap must be opened to allow the upper

flap to

disengage

from the upper body

aperture.

8.2.10.1 Blower Assembly Driver/

Passenger Side Overhaul

Note:

Blower

assemblies

under warranty must not be

dismantled.

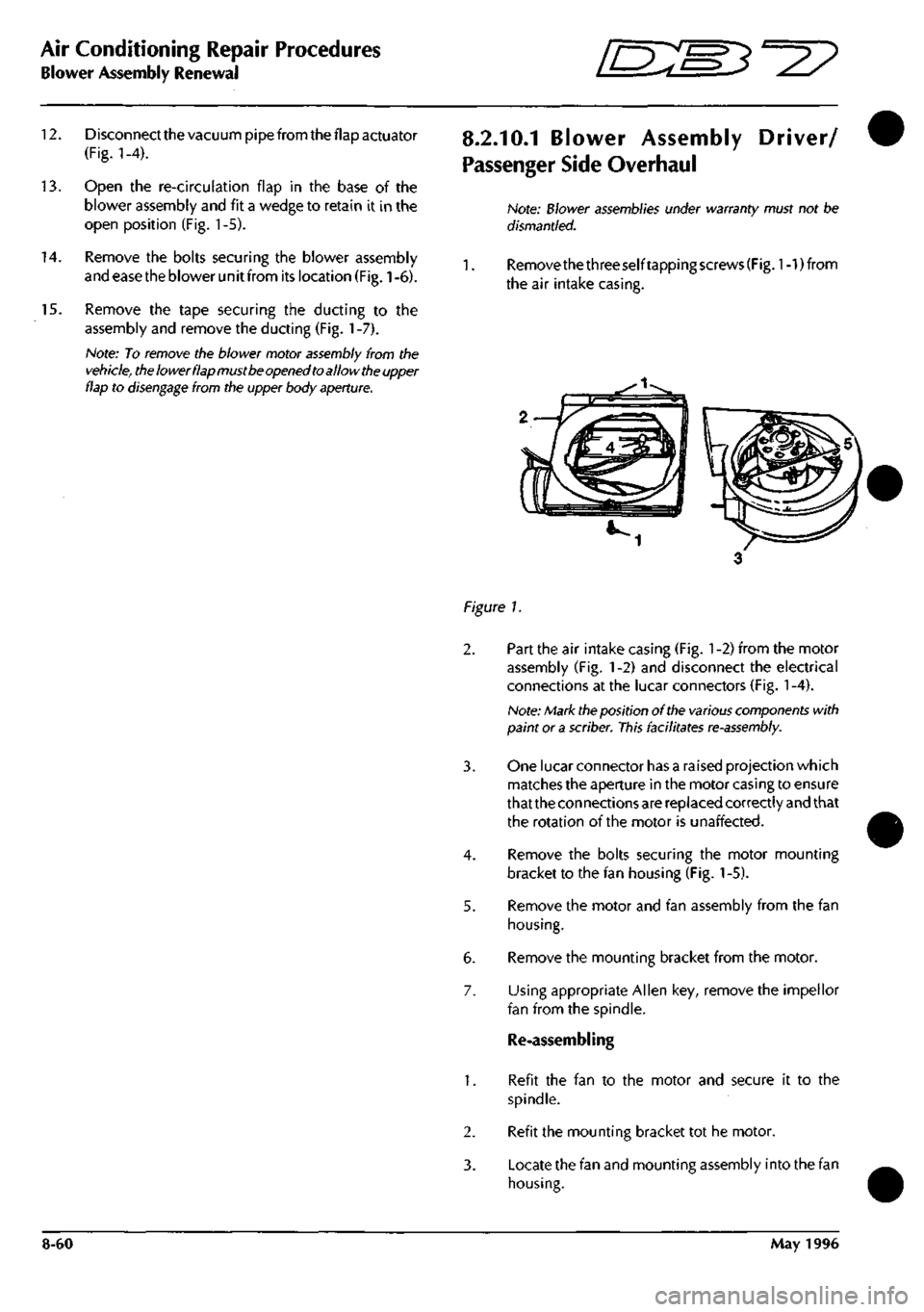

1.

Remove the three selftapping screws

(Fig.

1-1) from

the air intake casing.

Figure 7.

2.

Part the air intake casing (Fig.

1

-2) from the motor

assembly (Fig. 1-2) and disconnect the electrical

connections at the lucar connectors (Fig.

1

-4).

Note: Mark the position of the

various components

with

paint or

a

scriber.

This

facilitates

re-assembly.

3. One lucar connector has a raised projection which

matches the aperture in the motor casing to ensure

that the connections are replaced correctly and that

the rotation of the motor is unaffected.

4.

Remove the bolts securing the motor mounting

bracket to the fan housing (Fig. 1-5).

5. Remove the motor and fan assembly from the fan

housing.

6. Remove the mounting bracket from the motor.

7. Using appropriate Allen key, remove the impellor

fan from the spindle.

Re-assembling

1.

Refit the fan to the motor and secure it to the

spindle.

2.

Refit the mounting bracket tot he motor.

3. Locate the fan and mounting assembly into the fan

housing.

8-60 May 1996

Page 354 of 421

'=^

The Aston Martin Lagonda Diagnostic System

Installation Instructions

12 10

19 22 21 20

VIA A / /^^>^ I B T

A-XA^I'A® QA

13

16

18 29

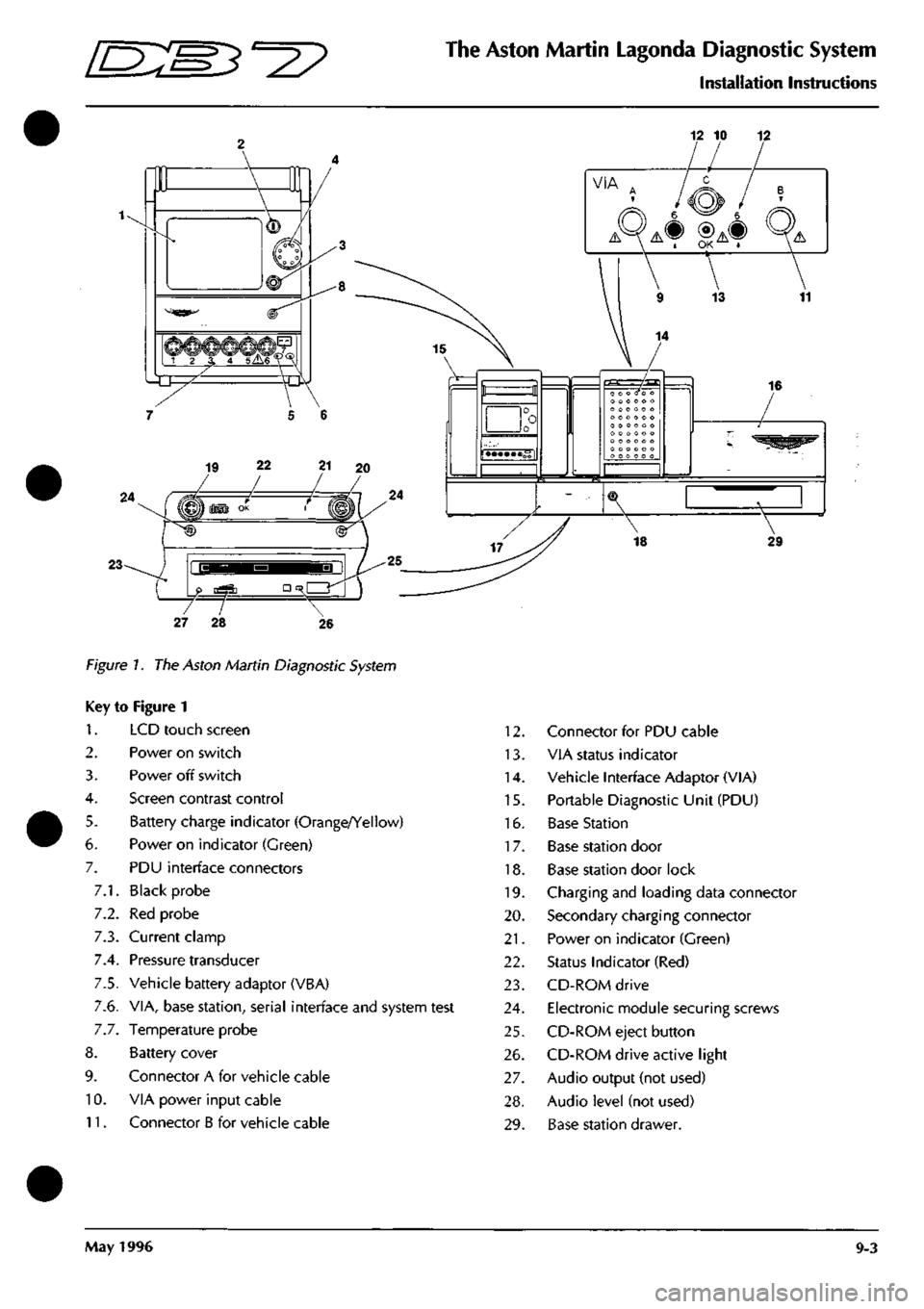

Figure 7. The Aston Martin Diagnostic System

Key to Figure 1

1.

2.

3.

4.

5.

6.

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

8.

9.

10.

11.

LCD touch screen

Power on switch

Power off switch

Screen contrast control

Battery charge indicator (Orange/Yellow)

Power on indicator (Green)

PDU interface connectors

Black probe

Red probe

Current clamp

Pressure transducer

Vehicle battery adaptor (VBA)

VIA, base station, serial interface and system test

Temperature probe

Battery cover

Connector A for vehicle cable

VIA power input cable

Connector B for vehicle cable

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

Connector for PDU cable

VIA status indicator

Vehicle Interface Adaptor (VIA)

Portable Diagnostic Unit (PDU)

Base Station

Base station door

Base station door lock

Charging and loading data connector

Secondary charging connector

Power on indicator (Green)

Status Indicator (Red)

CD-ROM drive

Electronic module securing screws

CD-ROM eject button

CD-ROM drive active light

Audio output (not used)

Audio level (not used)

Base station drawer.

May 1996 9-3

Page 383 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide "^7

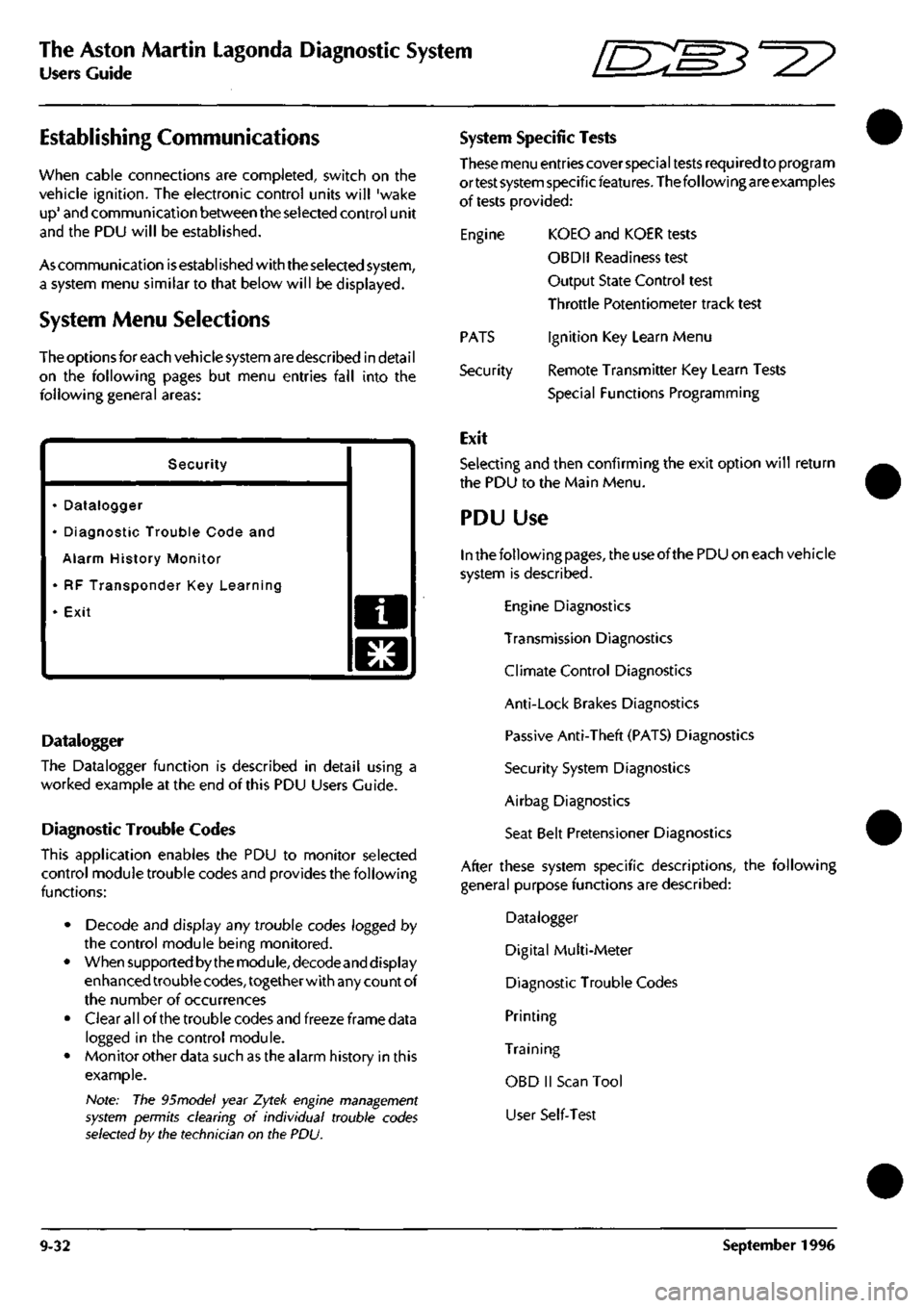

Establishing Communications

when cable connections are completed, switch on the

vehicle ignition. The electronic control units will 'wake

up'

and communication between the selected control unit

and the PDU will be established.

As communication

is

established with the selected system,

a system menu similar to that below will be displayed.

System Menu Selections

The options for each vehicle system are described in detai

I

on the following pages but menu entries fall into the

following general areas:

Security

• Datalogger

• Diagnostic Trouble Code and

Alarm History Monitor

• RF Transponder Key Learning

• Exit a

o

Datalogger

The Datalogger function is described in detail using a

worked example at the end of this PDU Users Guide.

Diagnostic Trouble Codes

This application enables the PDU to monitor selected

control module trouble codes and provides the following

functions:

• Decode and display any trouble codes logged by

the control module being monitored.

• When supported by the module, decodeand display

enhanced trouble

codes,

together with any count of

the number of occurrences

• Clear all of the trouble codes and freeze frame data

logged in the control module.

• Monitor other data such as the alarm history in this

example.

Note: The 95model year Zytek engine management

system permits clearing of individual trouble codes

selected by the technician on the PDU.

System Specific Tests

These menu entries cover special tests required to program

ortest system specificfeatures. The following are examples

of tests provided:

Engine KOEO and KOER tests

OBDII Readiness test

Output State Control test

Throttle Potentiometer track test

Ignition Key Learn Menu

Remote Transmitter Key Learn Tests

Special Functions Programming

PATS

Security

Exit

Selecting and then confirming the exit option will return

the PDU to the Main Menu.

PDU Use

In the following

pages,

the use of the PDU on each vehicle

system is described.

Engine Diagnostics

Transmission Diagnostics

Climate Control Diagnostics

Anti-Lock Brakes Diagnostics

Passive Anti-Theft (PATS) Diagnostics

Security System Diagnostics

Airbag Diagnostics

Seat Belt Pretensioner Diagnostics

After these system specific descriptions, the following

general purpose functions are described:

Datalogger

Digital Multi-Meter

Diagnostic Trouble Codes

Printing

Training

OBD II Scan Tool

User Self-Test

9-32 September 1996

Page 384 of 421

^27

The Aston Martin Lagonda Diagnostic System

Users Guide

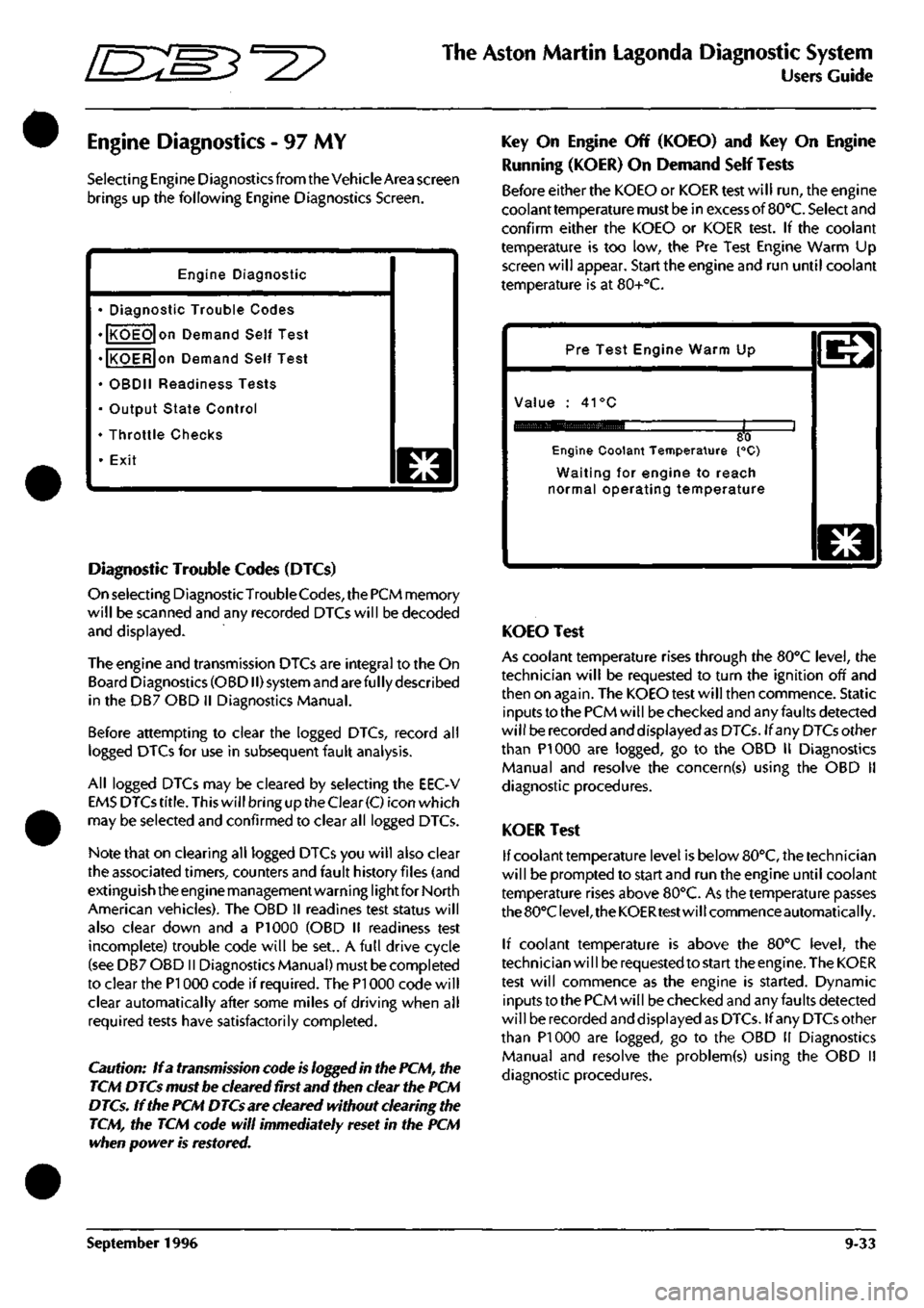

Engine Diagnostics - 97 MY

Selecting Engine Diagnostics from the Vehicle Area screen

brings up the following Engine Diagnostics Screen.

Engine Diagnostic

• Diagnostic Trouble Codes

• KOEO on Demand Self Test

• KOER on Demand Self Test

• OBDII Readiness Tests

• Output State Control

• Throttle Checks

• Exit

o

Diagnostic Trouble Codes (DTCs)

On selecting DiagnosticTrouble

Codes,

the PCM memory

will be scanned and any recorded DTCs will be decoded

and displayed.

The engine and transmission DTCs are integral to the On

Board Diagnostics (OBDII) system and are ful ly described

in the DB7 OBD II Diagnostics Manual.

Before attempting to clear the logged DTCs, record all

logged DTCs for use in subsequent fault analysis.

All logged DTCs may be cleared by selecting the EEC-V

EMS DTCs

title.

This will bring up the Clear

(C)

icon which

may be selected and confirmed to clear all logged DTCs.

Note that on clearing all logged DTCs you will also clear

the associated timers, counters and fault history files (and

extinguish the engine management warning lightfor North

American vehicles). The OBD II readines test status will

also clear down and a PI 000 (OBD II readiness test

incomplete) trouble code will be set.. A full drive cycle

(see DB7 OBD II Diagnostics Manual) must be completed

to clear the PI 000 code if required. The PI 000 code will

clear automatically after some miles of driving when all

required tests have satisfactorily completed.

Caution: If a transmission code is logged in the PCM, the

TCM DTCs must be cleared first and then clear the PCM

DTCs. If the PCM DTCs are cleared without clearing the

TCM, the TCM code will immediately reset in the PCM

when power is restored.

Key On Engine Off (KOEO) and Key On Engine

Running (KOER) On Demand Self Tests

Before either the KOEO or KOER test will run, the engine

coolant temperature must be in excess of

BO'C.

Select and

confirm either the KOEO or KOER test. If the coolant

temperature is too low, the Pre Test Engine Warm Up

screen will appear. Start the engine and run until coolant

temperature is at 80+°C.

Pre Test Engine Warm Up

Value : 41°C

80 Engine Coolant Temperature {°C)

Waiting for engine to reach

normal operating temperature

o

KOEO Test

As coolant temperature rises through the BO'C level, the

technician will be requested to turn the ignition off and

then on again. The KOEO test will then commence. Static

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD II Diagnostics

Manual and resolve the concern(s) using the OBD 11

diagnostic procedures.

KOER Test

If coolant temperature level is below 80°C, the technician

will be prompted to start and run the engine until coolant

temperature rises above 80°C. As the temperature passes

the 80°C

level,

the KOERtest will commence automatically.

If coolant temperature is above the 80°C level, the

technician wi

11

be requested to start the engine. The KOER

test will commence as the engine is started. Dynamic

inputs to the PCM will be checked and any faults detected

will be recorded and displayed as DTCs. If any DTCs other

than PI 000 are logged, go to the OBD 11 Diagnostics

Manual and resolve the problem(s) using the OBD II

diagnostic procedures.

September 1996 9-33

Page 386 of 421

^^2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Output State Control - 97 MY

This menu item provides a quick test of the basic electro

mechanical components controlled by the PCM. These

tests should be performed in a key on engine off state.

The selections available are:

• Low Speed Cooling Fans

• High Speed Cooling Fans

• Set Electromechanical Outputs

Low and High Speed Fans

Selecting and confirming either the low or high speed

cooling fans will run the fans at the selected speed for 5

seconds to verify their operation.

Electromechanical Outputs

This selection will cause the following electromechanical

devices to operate for five seconds

Air Pump

Fuel Pumps

Canister Purge Valve

Idle Air Control Valve

Observing each device in turn as the PCM outputs are

turned 'On' will enable the technician to verify correct

operation.

September 1996 9-35

Page 403 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide [S:S3^2?

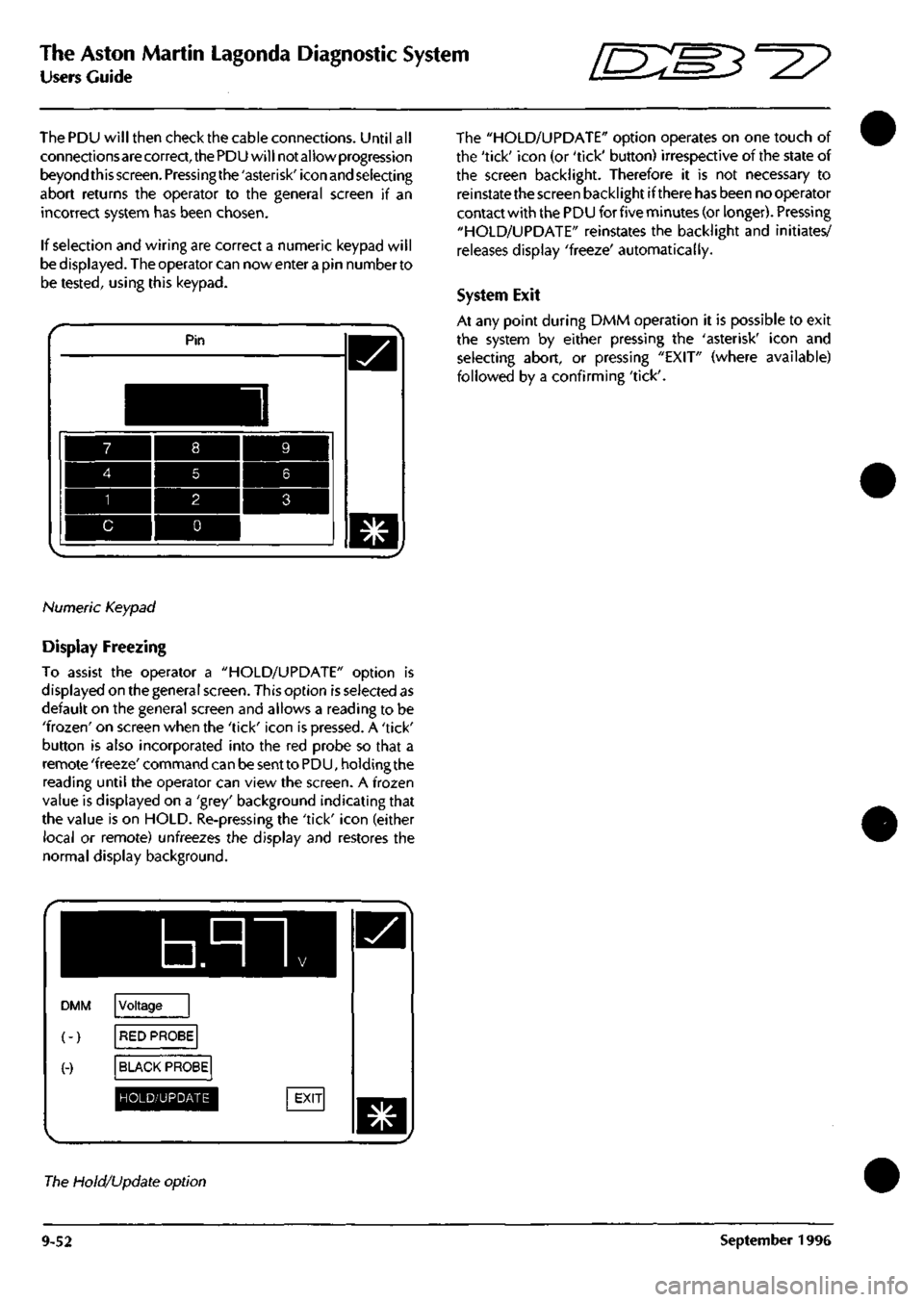

The PDU will then check the cable connections. Until all

connections are correct, the PDU will not allow progression

beyond this

screen.

Pressingthe'asterisk'icon and selecting

abort returns the operator to the general screen if an

incorrect system has been chosen.

If selection and wiring are correct a numeric keypad will

be displayed. The operator can nowenterapin numberto

be tested, using this keypad.

Pin

Numeric Keypad

Display Freezing

To assist the operator a "HOLD/UPDATE" option is

displayed on the general screen. This option is selected as

default on the general screen and allows a reading to be

'frozen'

on screen when the 'tick' icon is pressed. A 'tick'

button is also incorporated into the red probe so that a

remote 'freeze' command can be sent to PDU, holding the

reading until the operator can view the screen. A frozen

value is displayed on a 'grey' background indicating that

the value is on HOLD. Re-pressing the 'tick' icon (either

local or remote) unfreezes the display and restores the

normal display background.

b.nn

DMM

(-)

(-)

Voltage

RED PROBE

BLACK PROBE

HOLD/UPDATE

The "HOLD/UPDATE" option operates on one touch of

the 'tick' icon (or 'tick' button) irrespective of the state of

the screen backlight. Therefore it is not necessary to

reinstate the screen backlight if there has been no operator

contact with the PDU for five minutes (or longer). Pressing

"HOLD/UPDATE" reinstates the backlight and initiates/

releases display 'freeze' automatically.

System Exit

At any point during DMM operation it is possible to exit

the system by either pressing the 'asterisk' icon and

selecting abort, or pressing "EXIT" (where available)

followed by a confirming 'tick'.

The Hold/Update option

9-52 September 1996

Page 418 of 421

in:s3''^

The Aston Martin Lagonda Diagnostic System

Users Guide

#

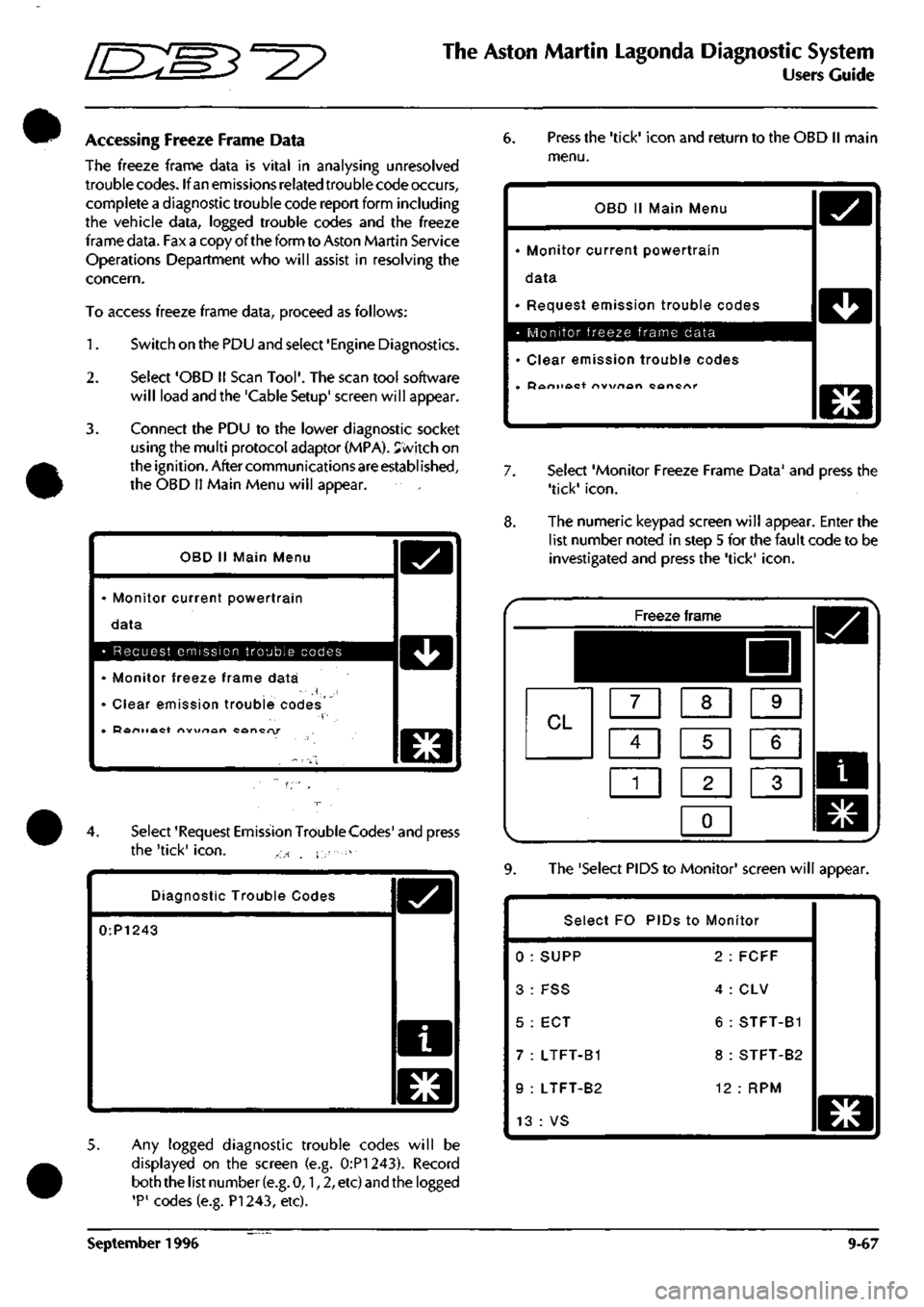

Accessing Freeze Frame Data

The freeze frame data is vital in analysing unresolved

trouble codes. If an emissions related trouble code occurs,

complete a diagnostic trouble code report form including

the vehicle data, logged trouble codes and the freeze

frame data. Fax a copy of the form to Aston Martin Service

Operations Department who will assist in resolving the

concern.

To access freeze frame data, proceed as follows:

1.

Switch on the PDU and select 'Engine Diagnostics.

2.

Select 'OBD II Scan

Tool'.

The scan tool software

will load and the 'Cable Setup' screen will appear.

3. Connect the PDU to the lower diagnostic socket

using the multi protocol adaptor (MPA). Svvitch on

the ignition. After communications are established,

the OBD

11

Main Menu will appear.

OBD

11

Main Menu

• Monitor current powertrain

data

D

• Request emission trouble codes 1 ^^ 1

• Monitor freeze frame data

' Clear emission trouble codes

• Doniiact nw\/rtan concry

O

4.

Select 'Request Emission TroubleCodes' and press

the 'tick'

icon.

, ., - . i-

Diagnostic Trouble Codes

0:P1243

o

5. Any logged diagnostic trouble codes will be

displayed on the screen (e.g. 0:P1243). Record

both the list number

(e.g.

0,1,2, etc) and the logged

'P'

codes (e.g. PI 243, etc).

6. Press the 'tick' icon and return to the OBD II main

menu.

OBD II Main Menu

• Monitor current powertrain

data

• Request emission trouble codes

• Monitor freeze frame data

• Clear emission trouble codes

• Doniioct nvx/nort cancnr

D

D

O

7. Select 'Monitor Freeze Frame Data' and press the

'tick'

icon.

8. The numeric keypad screen will appear. Enter the

list number noted in step 5 for the fault code to be

investigated and press the 'tick'

icon.

Freeze frame

^^HHI

CL m [XI s

ci] s m

1

1 1 2 1 1 3 1

0

1

9. The 'Select PIDS to Monitor' screen will appear.

Select FO PIDs to Monitor

0 : SUPP 2 : FCFF

3: FSS 4:CLV

5 : ECT 6 : STFT-B1

7 : LTFT-B1 8 : STFT-B2

9 : LTFT-B2 12 : RPM

13 : VS

WWWM

o

September 1996 9-67