airbag disable ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 108 of 421

^7

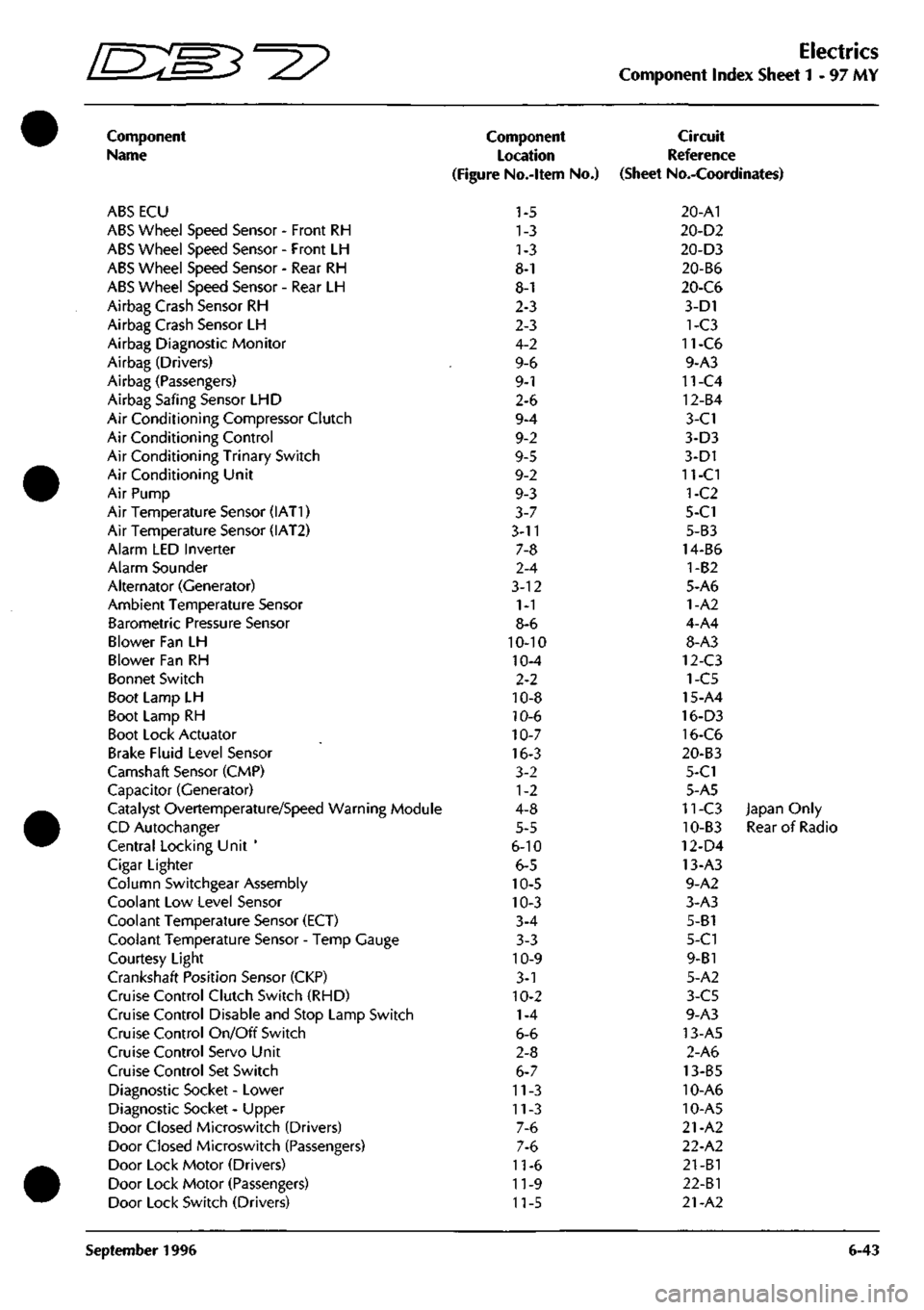

Electrics

Component Index Sheet 1-97 MY

Component

Name

ABS ECU

ABS Wheel Speed Sensor - Front RH

ABS Wheel Speed Sensor - Front LH

ABS Wheel Speed Sensor - Rear RH

ABS Wheel Speed Sensor - Rear LH

Airbag Crash Sensor RH

Airbag Crash Sensor LH

Airbag Diagnostic Monitor

Airbag (Drivers)

Airbag (Passengers)

Airbag Safing Sensor LHD

Air Conditioning Compressor Clutch

Air Conditioning Control

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor (IAT1)

Air Temperature Sensor (IAT2)

Alarm LED Inverter

Alarm Sounder

Alternator (Generator)

Ambient Temperature Sensor

Barometric Pressure Sensor

Blower Fan LH

Blower Fan RH

Bonnet Switch

Boot Lamp LH

Boot Lamp RH

Boot Lock Actuator

Brake Fluid Level Sensor

Camshaft Sensor (CMP)

Capacitor (Generator)

Catalyst Overtemperature/Speed Warning Module

CD Autochanger

Central Locking Unit '

Cigar Lighter

Column Switchgear Assembly

Coolant Low Level Sensor

Coolant Temperature Sensor (ECT)

Coolant Temperature Sensor - Temp Gauge

Courtesy Light

Crankshaft Position Sensor (CKP)

Cruise Control Clutch Switch (RHD)

Cruise Control Disable and Stop Lamp Switch

Cruise Control On/Off Switch

Cruise Control Servo Unit

Cruise Control Set Switch

Diagnostic Socket - Lower

Diagnostic Socket - Upper

Door Closed Microswitch (Drivers)

Door Closed Microswitch (Passengers)

Door Lock Motor (Drivers)

Door Lock Motor (Passengers)

Door Lock Switch (Drivers)

Component

Location

(Figure No.-ltem No.)

1-5

1-3

1-3

8-1

8-1

2-3

2-3

4-2

9-6

9-1

2-6

9-4

9-2

9-5

9-2

9-3

3-7

3-11

7-8

2-4

3-12

1-1

8-6

10-10

10-4

2-2

10-8

10-6

10-7

16-3

3-2

1-2

4-8

5-5

6-10

6-5

10-5

10-3

3-4

3-3

10-9

3-1

10-2

1-4

6-6

2-8

6-7

11-3

11-3

7-6

7-6

11-6

11-9

11-5

Circuit

Reference

(Sheet No.-Coordinates)

20-A1

20-D2

20-D3

20-B6

20-C6

3-D1

1-C3

11-C6

9-A3

11-C4

12-B4

3-C1

3-D3

3-D1

11-CI

1-C2

5-C1

5-B3

14-B6

1-B2

5-A6

1-A2

4-A4

8-A3

12-C3

1-C5

15-A4

16-D3

16-C6

20-B3

5-C1

5-A5

11-C3 Japan Only

10-B3 Rear of Radio

12-D4

13-A3

9-A2

3-A3

5-B1

5-C1

9-B1

5-A2

3-C5

9-A3

13-A5

2-A6

13-B5

10-A6

10-A5

21-A2

22-A2

21-B1

22-Bl

21-A2

September 1996 6-43

Page 202 of 421

Electrics

Airbag System ^2?

Airbag DM Fault Code 13

Airbag circuit short to ground

Normal Operation

The diagnostic modu

le

measures the voltage at pins

2-5 and 2-6. The voltage at these pins is dependant

on charging system voltage as shown in the table

belovi-.

'in 2-5

2.3V

2.4 V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Pin 2-6

2.3V

2.4V

2.5V

2.7V

2.8V

3.0V

3.1V

3.2V

3.4V

3.5V

3.7V

3.8V

4.0V

4.1V

4.3V

Charge Volts

9.0V

9.5V

lO.OV

10.5V

11.OV

11.5V

12.0V

12.5V

13.0V

13.5V

14.0V

14.5V

15.0V

15.5V

16.0V

If the diagnostic monitor measures a voltage of 2.0

volts or less on pins 2-5 and 2-6, a fau It code 13 will

be generated and flashed to the instrument pack to

be signalled on the airbag warning lamp. Voltages

as low as 2.0 volts indicate a possible short to

ground in these circuits.

When generating a code 13 the diagnostic module

also generates a signal to blow its own internal

thermal fuse. This action disables the airbag

deployment circuit. The airbag diagnostic module

fuse is non-repairable and the module must be

replaced after repairing the short circuit, if the

voltage at pins 2-5 and 2-6 returns to normal, fault

code 51 (blown thermal fuse) will be stored in

memory.

6.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag

system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4)

Disconnect the airbag diagnostic module. Switch

on the ignition.

Measure the continuity to ground at the following

pins on the diagnostic module harness connector:

2-2 Passenger airbag feed

2-3 Passenger airbag return

2-4 Drivers airbag return

2-5 Drivers airbag feed

2-11 Safing sensor feed

If no short circuit is detected, go to step 4.

If

a

short circuit is detected, disconnect the relevant

airbag simulator or the safing sensor and repeat the

continuity measurement to isolate the circuit fault.

Service the wiring or replace the safing sensor as

necessary. Fit a new airbag diagnostic module and

rearm the airbags (6.4.21.4).

Check for intermittent short circuits in the cable

reel cassette. Monitor the continuity to ground at

pins 2-4 and 2-5 whilst rotating the steering from

lock to lock in both directions.

If no short circuit is detected, go to step 5.

If a short circuit is detected, replace the column

switchgear assembly. Fit a new airbag diagnostic

module and rearm the airbags (6.4.21.4).

WARNING: Do not attempt to make any electrical

measurements on the airbag

modules.

Any induced

voltage can

cause

the airbag

to

deploy with the

risk

of personal

injury.

Fit a replacement diagnostic module and

replacement airbag modules.

Caution: Do not refit

the

old

airbag

modules.

They may

be faulty and would

damage the

new diagnostic module.

Rearm the airbag system (6.4.21.4).

6-86 September 1996

Page 203 of 421

mxm^^^?

Electrics

Airbag System

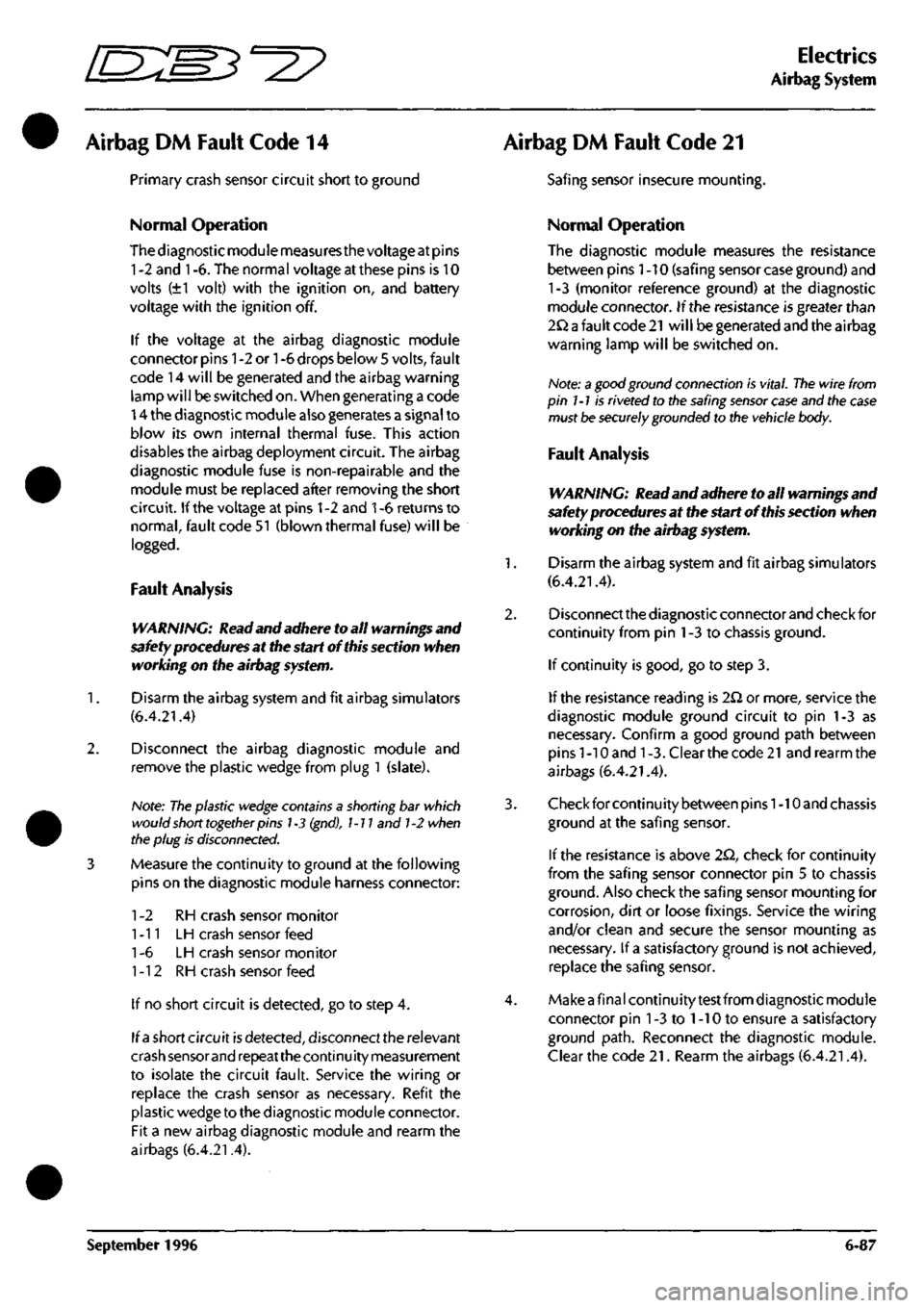

Airbag DM Fault Code 14

Primary crash sensor circuit short to ground

Airbag DM Fault Code 21

Safing sensor insecure mounting.

Normal Operation

The diagnostic module measuresthevoltage at pins

1

-2 and

1

-6. The normal voltage at these pins is 10

volts (±1 volt) with the ignition on, and battery

voltage with the ignition off.

If the voltage at the airbag diagnostic module

connector pins

1

-2 or

1

-6 drops below 5 volts, fault

code 14 will be generated and the airbag warning

lamp will be switched on. When generating a code

14 the diagnostic module also generates a signal to

blow its own internal thermal fuse. This action

disables the airbag deployment circuit. The airbag

diagnostic module fuse is non-repairable and the

module must be replaced after removing the short

circuit. If the voltage at pins 1-2 and 1-6 returns to

normal,

fault code 51 (blown thermal fuse) will be

logged.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of

this

section when

working on the airbag system.

1.

Disarm the airbag system and fit airbag simulators

(6.4.21.4)

2.

Disconnect the airbag diagnostic module and

remove the plastic wedge from plug

1

(slate).

Note:

The

plastic wedge contains a shorting bar which

would

short

together pins

1-3

(gnd),

1-11

and 1-2 when

the plug is disconnected.

3 Measure the continuity to ground at the following

pins on the diagnostic module harness connector:

1-2 RH crash sensor monitor

1-11 LH crash sensor feed

1

-6 LH crash sensor monitor

1-12 RH crash sensor feed

If no short circuit is detected, go to step 4.

If a short circuit

is

detected, disconnect the relevant

crash sensorandrepeatthecontinuity measurement

to isolate the circuit fault. Service the wiring or

replace the crash sensor as necessary. Refit the

plastic wedge to the diagnostic module connector.

Fit a new airbag diagnostic module and rearm the

airbags (6.4.21.4).

Normal Operation

The diagnostic module measures the resistance

between pins

1

-10 (safing sensor case ground) and

1-3 (monitor reference ground) at the diagnostic

module connector. If the resistance is greater than

2Q

a

fault code

21

will be generated and the airbag

warning lamp will be switched on.

Note:

a

good ground connection is vital.

The

wire from

pin

1-1

is riveted to the safing

sensor case

and the

case

must

be securely

grounded to the vehicle

body.

Fault Analysis

WARNING: Read and adhere to all warnings and

safety procedures at the start of this section when

working on the airbag system.

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic connector and check for

continuity from pin 1-3 to chassis ground.

If continuity is good, go to step 3.

If the resistance reading is 2Q or more, service the

diagnostic module ground circuit to pin 1-3 as

necessary. Confirm a good ground path between

pins 1-10 and 1-3.Clearthecode21 and rearm the

airbags (6.4.21.4).

Check for continuity between pins

1

-10 and chassis

ground at the safing sensor.

If the resistance is above 2Q, check for continuity

from the safing sensor connector pin 5 to chassis

ground.

Also check the safing sensor mounting for

corrosion,

dirt or loose fixings. Service the wiring

and/or clean and secure the sensor mounting as

necessary, if a satisfactory ground is not achieved,

replace the safing sensor.

Make

a

final continuity test from diagnostic module

connector pin

1

-3 to

1

-10 to ensure a satisfactory

ground

path.

Reconnect the diagnostic module.

Clear the code

21.

Rearm the airbags (6.4.21.4).

September 1996 6-87

Page 209 of 421

in:m3'^?

Electrics

Airbag System

Airbag DM Fault Code 34

Drivers airbag circuit low resistance or short circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-5 and 2-4 every time the ignition is

switched on. The resistance should be 1.6 to 1.8Q.

This value is made up of the airbag

1

.OQ and the

cable reel cassette windings 0.3-0.4£2 per winding.

If the total resistance in the passengers airbag

circuit falls below 0.7Q, fault code 34 will be

declared and the airbag lamp will be illuminated.

Note: The nominal

resistance

of the airbag simulator is

2.5Q, therefore expect

a

total circuit resistance readingof

3.1 -

3.3£2

with the simulator

fitted.

Caution: The drivers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE THE AIRBAC CONNECTOR

SHORTING BAR UNDER ANY CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated cable reel cassette connector. If

the connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-4 and 2-

5 together.

• Short circuit in the cable reel cassette windings.

• A short across the airbag terminals in the airbag

module.

Fault Analysis

Disarm the airbag system and fit airbag simulators

(6.4.21.4).

Disconnect the diagnostic module and remove the

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-5 and 2-4. The

resistance should be 3.1 - 3.3Q.

If the resistance is 3.1 to 3.3Q, go to step 4.

If the resistance is below 3.1 - 3.3Q, go to step 3.

Disconnect the cable reel cassette connector at the

steering column and remove the plastic wedge.

Measure the resistance from pins 2-4 and 2-5 at the

diagnostic module connector.

If the resistance is infinity, check the cable reel

cassette for short circuits. Replace the column

switchgear assembly if necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 34. Rearm the airbags (6.4.21.4).

If the resistance is less than infinity, replace the

main airbag harness. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

34.

Rearm the airbags (6.4.21.4).

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 34 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 34 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 34 recurs with the airbag modulefitted,

the airbag module is faulty. Replace the drivers

airbag module (4.5.01.3).

September 1996 6-93

Page 210 of 421

Electrics

Airbag System ^^?

Airbag DM Fault Code 35

Passengers airbag circuit low resistance or short

circuit.

Normal Operation

The diagnostic module measures the resistance

across pins 2-2 and 2-3 every time the ignition is

switched on. The resistance should be 0.9 to

1.1Q..

If the total resistance in the passengers airbag

circuit falls below 0.7S2, fault code 35 will be

declared and the airbag lamp will be illuminated.

f^ote:

The

nominal

resistance

of the airbag simulator

is

2.5£2,

therefore expect

a

total circuit

resistance

reading of

2.4 - 2.6Q with the simulator fitted.

Caution: The passengers airbag connector contains

shorting bars which short circuit pins 1 and 3 of

both sides of the connector when disconnected.

DO NOT REMOVE OR DISABLE THE AIRBAG

CONNECTOR SHORTING BAR UNDER ANY

CIRCUMSTANCES.

The airbag harness shorting bar may be temporarily

disabled during the following resistance checks.

Possible Causes

• Poorly mated airbag harness connector. If the

connector is poorly mated, the shorting bars

may not be fully retracted.

• Faulty shorting bar may short circuit 2-2 and 2-

3 together.

• A short across the airbag terminals in the

passengers airbag module.

Fault Analysis

1.

Disarm the airbag system and check the security of

the passengers airbag module connector before

disconnecting.

If the connector is secure, complete the disarming

procedure, fit the airbag simulators (6.4.21.4). Go

to step 2

If the connector is insecure, service as necessary,

clear the code 35, rearm the airbags. Check that

code 35 does not recur.

2.

Disconnectthediagnostic module and removethe

plastic wedge from connector 2 (black). Measure

the resistance between pins 2-2 and 2-3. The

resistance should be 2.4 - 2.6Q.

If the resistance is 2.4 - 2.6Q, go to step 4.

If the resistance is below 2.4 - 2.6fl, go to step 3.

3. Disconnect the airbag simulator at the passengers

airbag module and remove the plastic wedge from

the harness connector. Measure the resistance

between pins 2-2 and 2-3 at the diagnostic module

connector.

If the resistance is infinity, the airbag harness is

good at this time. Swap the airbag simulators at the

drivers and passengers airbag connectors. Repeat

the resistance check. If the resistance is less than

infinity, there is a fault in the passengers airbag

harness connector. Service the connector or replace

the harness as necessary. Refit the plastic wedges.

Reconnect the diagnostic module. Clear the code

35.

Rearm the airbags.

If the resistance is less than infinity, service the

bulkhead harness as necessary. Refit the plastic

wedges. Reconnect the diagnostic module. Clear

the code 35. Rearm the airbags (6.4.21.4).

4.

Since the circuit resistance is in specification, the

fault must lie in the diagnostic module or in the

airbag module.

Substitute a known good diagnostic module. If

code 35 recurs with the airbag simulator fitted,

there is still a fault in the wiring or the simulator.

If the fault code 35 does not recur, rearm the airbags

(6.4.21.4) and retest.

If fault code 35 recurs with the airbag module fitted,

the airbag module is faulty. Replace the passengers

airbag module (7.8.02.6).

6-94 September 1996