alarm ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 27 of 421

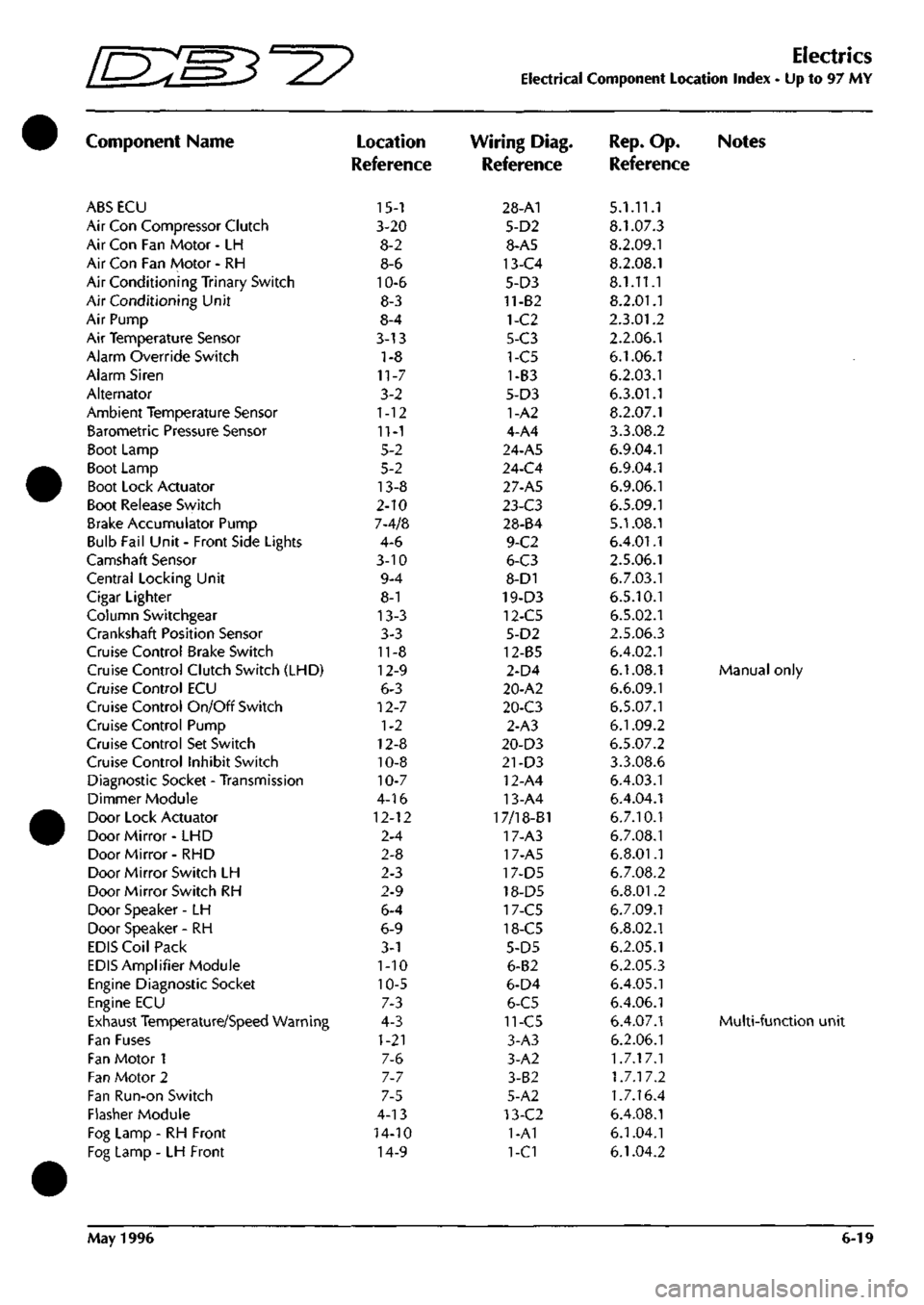

Electrics

Electrical Component Location Index - Up to 97 MY

Component Name

ABS ECU

Air Con Compressor Clutch

Air Con Fan Motor - LH

Air Con Fan Motor - RH

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor

Alarm Override Switch

Alarm Siren

Alternator

Ambient Temperature Sensor

Barometric Pressure Sensor

Boot Lamp

Boot Lamp

Boot Lock Actuator

Boot Release Switch

Brake Accumulator Pump

Bulb Fail Unit - Front Side Lights

Camshaft Sensor

Central Locking Unit

Cigar Lighter

Column Switchgear

Crankshaft Position Sensor

Cruise Control Brake Switch

Cruise Control Clutch Switch (LHD)

Cruise Control ECU

Cruise Control On/Off Switch

Cruise Control Pump

Cruise Control Set Switch

Cruise Control Inhibit Switch

Diagnostic Socket - Transmission

Dimmer Module

Door Lock Actuator

Door Mirror- LHD

Door Mirror- RHD

Door Mirror Switch LH

Door Mirror Switch RH

Door Speaker -LH

Door Speaker - RH

EDIS Coil Pack

EDIS Amplifier Module

Engine Diagnostic Socket

Engine ECU

Exhaust Temperature/Speed Warning

Fan Fuses

Fan Motor 1

Fan Motor 2

Fan Run-on Switch

Flasher Module

Fog Lamp - RH Front

Fog Lamp - LH Front

Location

Reference

15-1

3-20

8-2

8-6

10-6

8-3

8-4

3-13

1-8

11-7

3-2

1-12

11-1

5-2

5-2

13-8

2-10

7-4/8

4-6

3-10

9-4

8-1

13-3

3-3

11-8

12-9

6-3

12-7

1-2

12-8

10-8

10-7

4-16

12-12

2-4

2-8

2-3

2-9

6-4

6-9

3-1

1-10

10-5

7-3

4-3

1-21

7-6

7-7

7-5

4-13

14-10

14-9

Wiring Diag.

Reference

28-A1

5-D2

8-A5

13-C4

5-D3

11-82

1-C2

5-C3

1-C5

1-B3

5-D3

1-A2

4-A4

24-A5

24-C4

27-A5

l-i-C3

28-84

9-C2

6-C3

8-D1

19-D3

12-C5

5-D2

12-85

2-D4

20-A2

20-C3

2-A3

20-D3

21-D3

12-A4

13-A4

17/18-B1

17-A3

17-A5

17-D5

18-D5

17-C5

18-C5

5-D5

6-B2

6-D4

6-C5

11-C5

3-A3

3-A2

3-B2

5-A2

13-C2

1-A1

1-C1

Rep.

Op. Notes

Reference

5.1.11.1

8.1.07.3

8.2.09.1

8.2.08.1

8.1.11.1

8.2.01.1

2.3.01.2

2.2.06.1

6.1.06.1

6.2.03.1

6.3.01.1

8.2.07.1

3.3.08.2

6.9.04.1

6.9.04.1

6.9.06.1

6.5.09.1

5.1.08.1

6.4.01.1

2.5.06.1

6.7.03.1

6.5.10.1

6.5.02.1

2.5.06.3

6.4.02.1

6.1.08.1 Manual only

6.6.09.1

6.5.07.1

6.1.09.2

6.5.07.2

3.3.08.6

6.4.03.1

6.4.04.1

6.7.10.1

6.7.08.1

6.8.01.1

6.7.08.2

6.8.01.2

6.7.09.1

6.8.02.1

6.2.05.1

6.2.05.3

6.4.05.1

6.4.06.1

6.4.07.1 Multi-functio

6.2.06.1

1.7.17.1

1.7.17.2

1.7.16.4

6.4.08.1

6.1.04.1

6.1.04.2

May 1996 6-19

Page 51 of 421

NO COLOUR

PIN

7

B 1 2

8

UR 3

9

UW 4

AREA B2-2

66 Be

NO

COLOUR

PIN

AREA

10 8 I 82-2 11 R/6 2 Bl-i

NO COLOUR

PIN

42

NR 65

4}

N 86

44

R 87 87A

45

N 30

AREA

86 86 C6

C6

NO COLOUR

PIN

46

NB 85

47

W 86

48

U 87 87A

49

N 30

ARtA

C6 C6 ce C6

•M SO 51 52

53

COLOUR

PIN

BR

85

RO

86

BY

87

87A N»

30

mk C6 C6

C3-7

C6

NO COLOUR

PIN

54

8 85

55

U 86

56

UR 87 e7A

57

N 30

AREA C5-8

C6 C6

C6

SIDCLAHP BCLAY

I

87

I

HUCUaP RELAY

NO 1 2 3 4 5 6

COLOUB

08 0 8 NP YS LG

PIN 1 2 3 4 5 6

AREA

C5 C5 82-2 86 86 86

NO COLOUR PIN 40 B U

41

YP w

AREA C3-8 C3-9

NO

COLOUR

PIN

ARET

23 8 I 82-3

24

CR 2 86

5

25

RS 4 C2-4 %^

NO COLOUR

PIN

26

GY A

27

GY B

28

B C

AREA C2-6 C2-6

82-2

IH POIHT |-

nro

COLOUR AREA

I

31 B C3-8

NO

COLOUR

PIN

AREA

32 B I 82-3 2 33 UR 3 86

34

UW 4 86

fRONT

FOG

LAUP RELAY DIP BEAU RELAY

SHEET

2

AREA

CI

ALARM OVERRIDE SWITCM

up)

L.H

HEA0/5IDCLA1«>

NO COLOUB 35

B

36

UR

37

W

38

UW

39

RO

PIN 1 ? 3 4

5 6

AREA C3-8

B6 66 B6 86

NO COLOUR

PIN

58

U 1

59

NR 2

60

N 3 4

AREA

C6 C6 C6

NO COLOUR

PIU

1

0 1

2

08 2 5

AlttA

B3 83

NO COLOUR 4 NP 5 YS 6 LG e UR 9 UW 14 WU 15 RO 17 GW 24 GR 33 UW 34 UR 36 UR 37 W 38 UW 39 RO 42 HR 43 N 44 R 45 N 46 N8 47 W 48 U 49 N 50 BR 51 RO 53 NY 55 U 56 UR 57 N 58 U 59 NR 60 N 62 8 64 YP 67 8 72 YP 78 RS 80 RG 88 B 94 RY 97 GY 98 YP

mi 63 83 B3 A2 A2 A2 A2 Al CI 02 D2 D3 03 03 03 84 84 64 84 84 84 84 84 85 85 85 65 85 85 05 05 05 C3-8 C3-9 C3-8 C5-9 C2-4 Bl-I C3-8 C3-7 C3-6 C3-9

1^:^^-^?

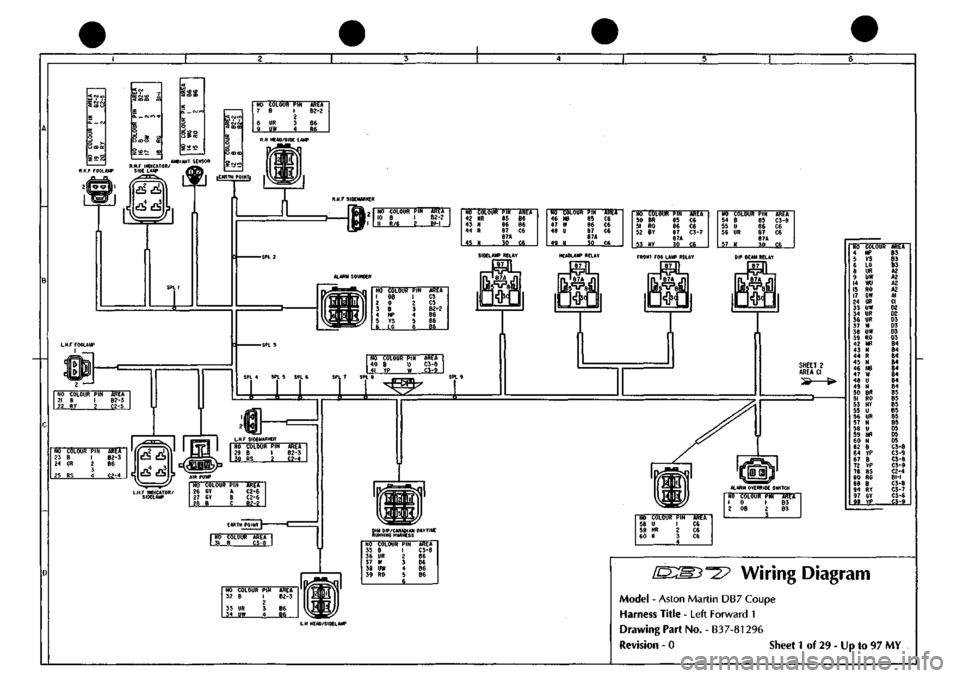

Wiring Diagram

Model - Aston Martin DB7 Coupe

Harness Title - Left Forward 1

Drawing Part No. - B37-81296

Revision - 0 Sheet

1

of 29 - Up to 97 MY

Page 108 of 421

^7

Electrics

Component Index Sheet 1-97 MY

Component

Name

ABS ECU

ABS Wheel Speed Sensor - Front RH

ABS Wheel Speed Sensor - Front LH

ABS Wheel Speed Sensor - Rear RH

ABS Wheel Speed Sensor - Rear LH

Airbag Crash Sensor RH

Airbag Crash Sensor LH

Airbag Diagnostic Monitor

Airbag (Drivers)

Airbag (Passengers)

Airbag Safing Sensor LHD

Air Conditioning Compressor Clutch

Air Conditioning Control

Air Conditioning Trinary Switch

Air Conditioning Unit

Air Pump

Air Temperature Sensor (IAT1)

Air Temperature Sensor (IAT2)

Alarm LED Inverter

Alarm Sounder

Alternator (Generator)

Ambient Temperature Sensor

Barometric Pressure Sensor

Blower Fan LH

Blower Fan RH

Bonnet Switch

Boot Lamp LH

Boot Lamp RH

Boot Lock Actuator

Brake Fluid Level Sensor

Camshaft Sensor (CMP)

Capacitor (Generator)

Catalyst Overtemperature/Speed Warning Module

CD Autochanger

Central Locking Unit '

Cigar Lighter

Column Switchgear Assembly

Coolant Low Level Sensor

Coolant Temperature Sensor (ECT)

Coolant Temperature Sensor - Temp Gauge

Courtesy Light

Crankshaft Position Sensor (CKP)

Cruise Control Clutch Switch (RHD)

Cruise Control Disable and Stop Lamp Switch

Cruise Control On/Off Switch

Cruise Control Servo Unit

Cruise Control Set Switch

Diagnostic Socket - Lower

Diagnostic Socket - Upper

Door Closed Microswitch (Drivers)

Door Closed Microswitch (Passengers)

Door Lock Motor (Drivers)

Door Lock Motor (Passengers)

Door Lock Switch (Drivers)

Component

Location

(Figure No.-ltem No.)

1-5

1-3

1-3

8-1

8-1

2-3

2-3

4-2

9-6

9-1

2-6

9-4

9-2

9-5

9-2

9-3

3-7

3-11

7-8

2-4

3-12

1-1

8-6

10-10

10-4

2-2

10-8

10-6

10-7

16-3

3-2

1-2

4-8

5-5

6-10

6-5

10-5

10-3

3-4

3-3

10-9

3-1

10-2

1-4

6-6

2-8

6-7

11-3

11-3

7-6

7-6

11-6

11-9

11-5

Circuit

Reference

(Sheet No.-Coordinates)

20-A1

20-D2

20-D3

20-B6

20-C6

3-D1

1-C3

11-C6

9-A3

11-C4

12-B4

3-C1

3-D3

3-D1

11-CI

1-C2

5-C1

5-B3

14-B6

1-B2

5-A6

1-A2

4-A4

8-A3

12-C3

1-C5

15-A4

16-D3

16-C6

20-B3

5-C1

5-A5

11-C3 Japan Only

10-B3 Rear of Radio

12-D4

13-A3

9-A2

3-A3

5-B1

5-C1

9-B1

5-A2

3-C5

9-A3

13-A5

2-A6

13-B5

10-A6

10-A5

21-A2

22-A2

21-B1

22-Bl

21-A2

September 1996 6-43

Page 187 of 421

^=2?

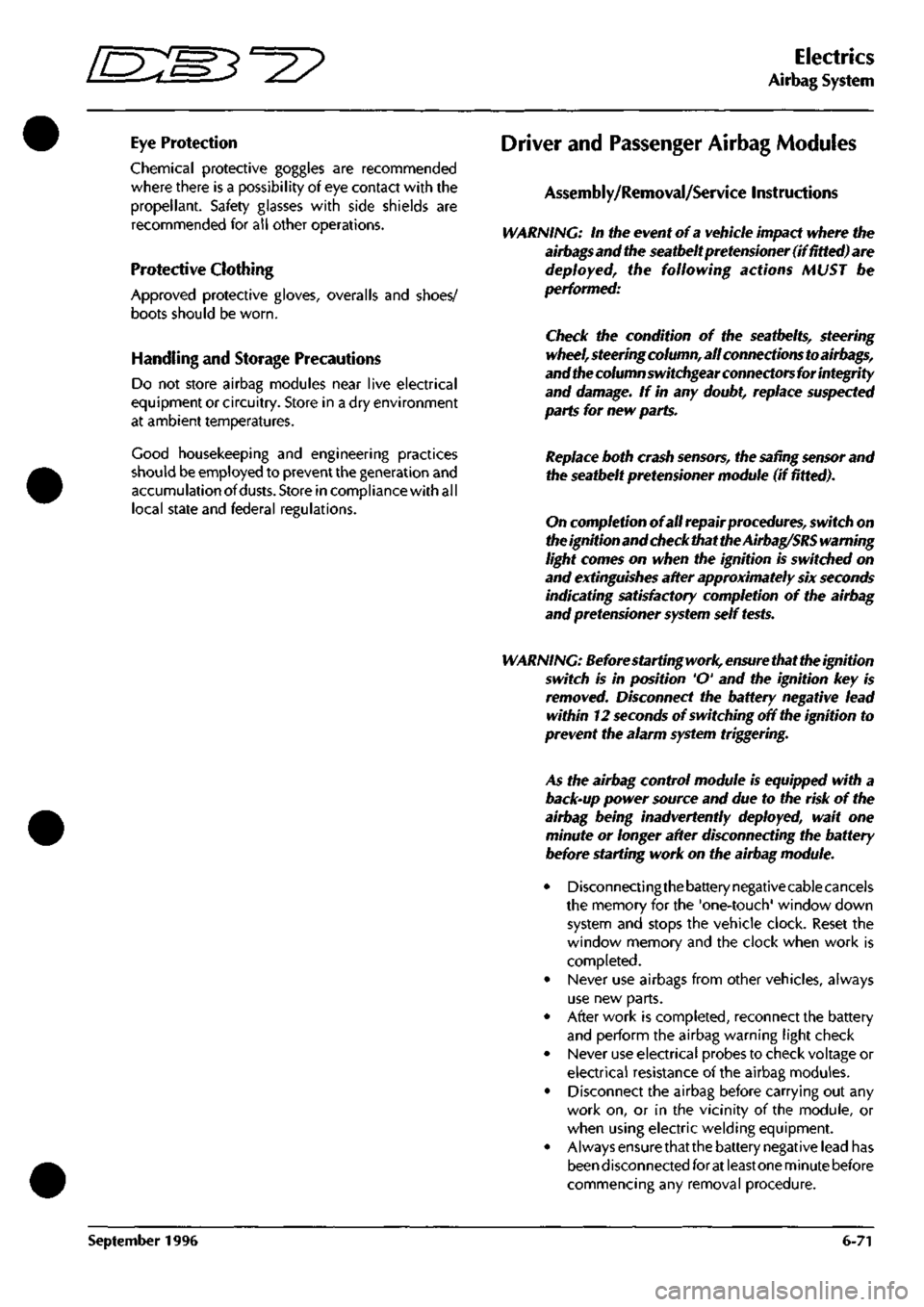

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 191 of 421

'=2?

Electrics

Airbag System

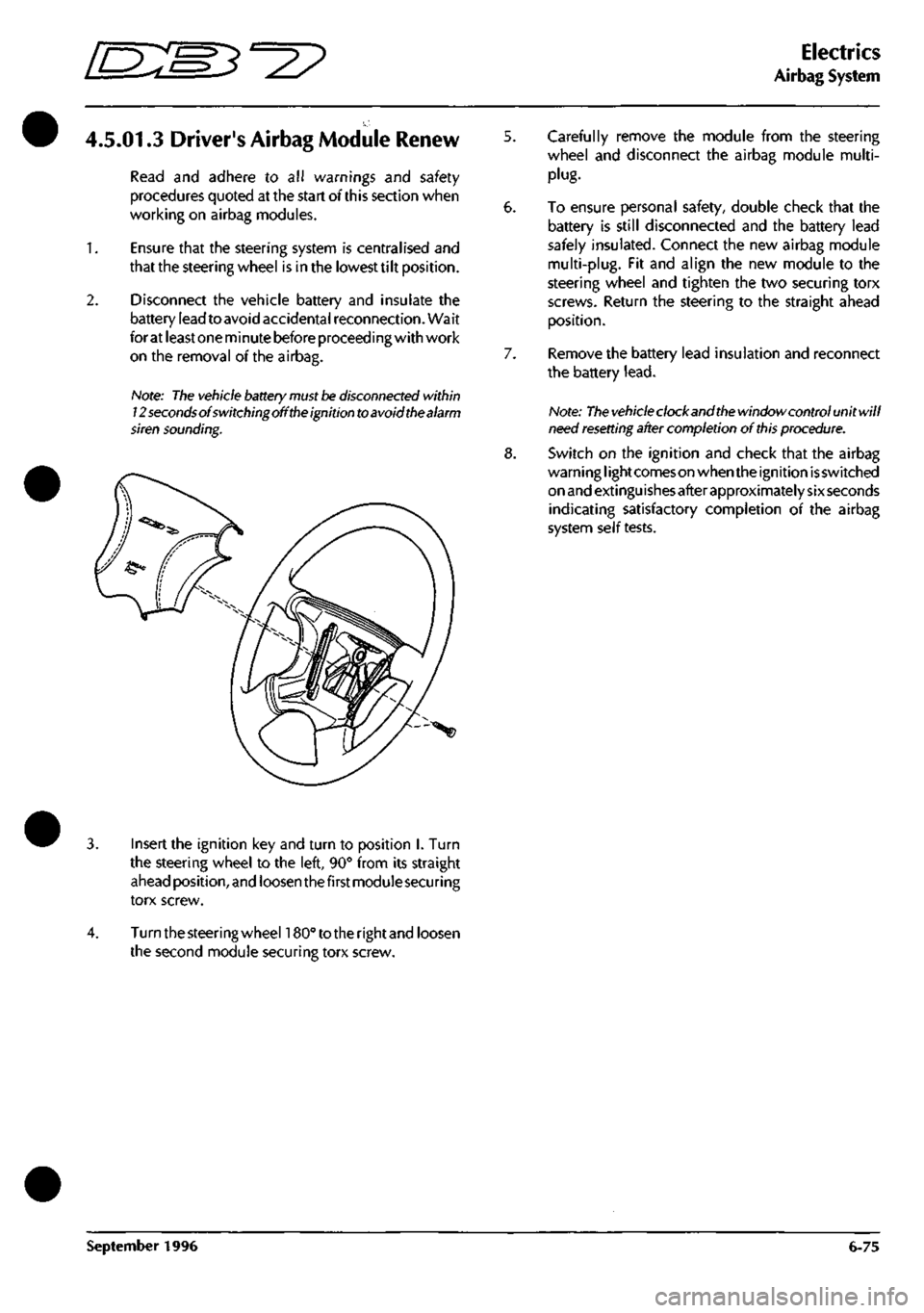

4.5.01.3 Driver's Airbag Module Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on airbag modules.

1.

Ensure that the steering system is centralised and

that the steering wheel is in the lowest tilt position.

2.

Disconnect the vehicle battery and insulate the

battery lead to avoid accidental reconnection. Wait

for at least one minute before proceeding with work

on the removal of the airbag.

Hote: The vehicle battery

must be

disconnected within

12 seconds of switching off

the

ignition to avoid the alarm

siren sounding.

5. Carefully remove the module from the steering

wheel and disconnect the airbag module multi-

plug.

6. To ensure personal safety, double check that the

battery is still disconnected and the battery lead

safely insulated. Connect the new airbag module

multi-plug.

Fit and align the new module to the

steering wheel and tighten the two securing torx

screws. Return the steering to the straight ahead

position.

7. Remove the battery lead insulation and reconnect

the battery

lead.

Note:

The vehicle

clockandthe window control unitwill

need

resetting

after completion of

this

procedure.

8. Switch on the ignition and check that the airbag

warni ng

I

ight comes on when the ignition is switched

on and extinguishes after approximately sixseconds

indicating satisfactory completion of the airbag

system self tests.

Insert the ignition key and turn to position I. Turn

the steering wheel to the left, 90° from its straight

ahead position, and loosen thefirstmoduiesecuring

torx screw.

Turn the steering wheehSO" to the rightand loosen

the second module securing torx screw.

September 1996 6-75

Page 192 of 421

Electrics

Airbag System ^^?

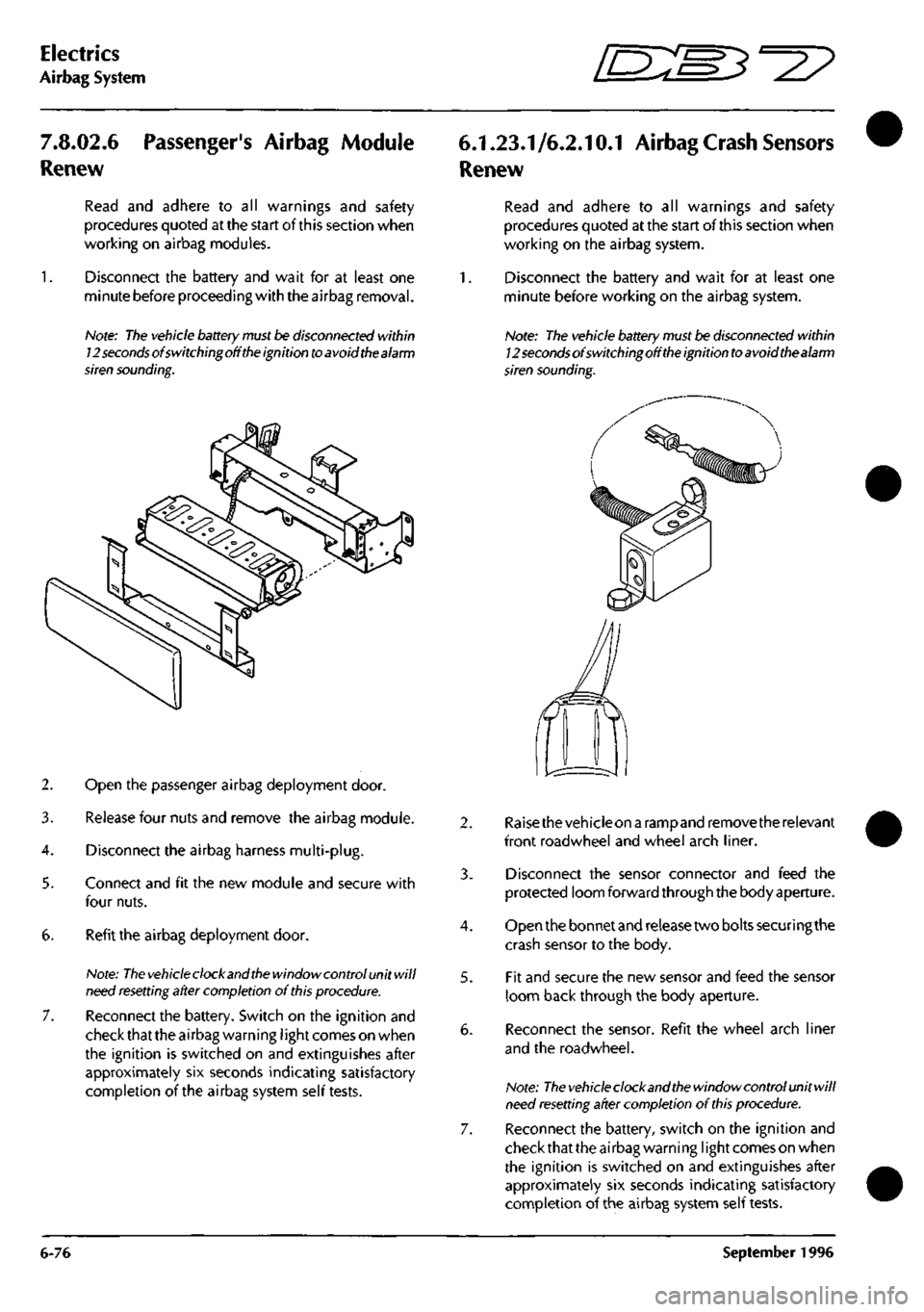

7.8.02.6

Renew

Passenger's Airbag Module

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on airbag modules.

Disconnect the battery and wait for at least one

minute before proceeding with the airbag removal.

Note:

The

vehicle battery

must

be disconnected within

12

seconds

of switchingoff

the

ignition

to

avoid the alarm

siren sounding.

2. Open the passenger airbag deployment door.

3. Release four nuts and remove the airbag module.

4.

Disconnect the airbag harness multi-plug.

5. Connect and fit the new module and secure with

four nuts.

6. Refit the airbag deployment door.

Note:

The vehicle

clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

7. Reconnect the battery. Switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6.1.23.1/6.2.10.1 Airbag

Crash

Sensors

Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

1.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note: The vehicle

battery

must be disconnected within

12

seconds

of switchingoff

the

ignition

to

avoid thealarm

siren sounding.

4.

5.

Raisethevehicleon a rampand remove the relevant

front roadwheel and wheel arch liner.

Disconnect the sensor connector and feed the

protected loom forward through the body aperture.

Open the bonnet and release two bolts securing the

crash sensor to the body.

Fit and secure the new sensor and feed the sensor

loom back through the body aperture.

Reconnect the sensor. Refit the wheel arch liner

and the roadwheel.

Note:

The vehicle

clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

Reconnect the battery, switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6-76 September 1996

Page 193 of 421

^7

Electrics

Airbag System

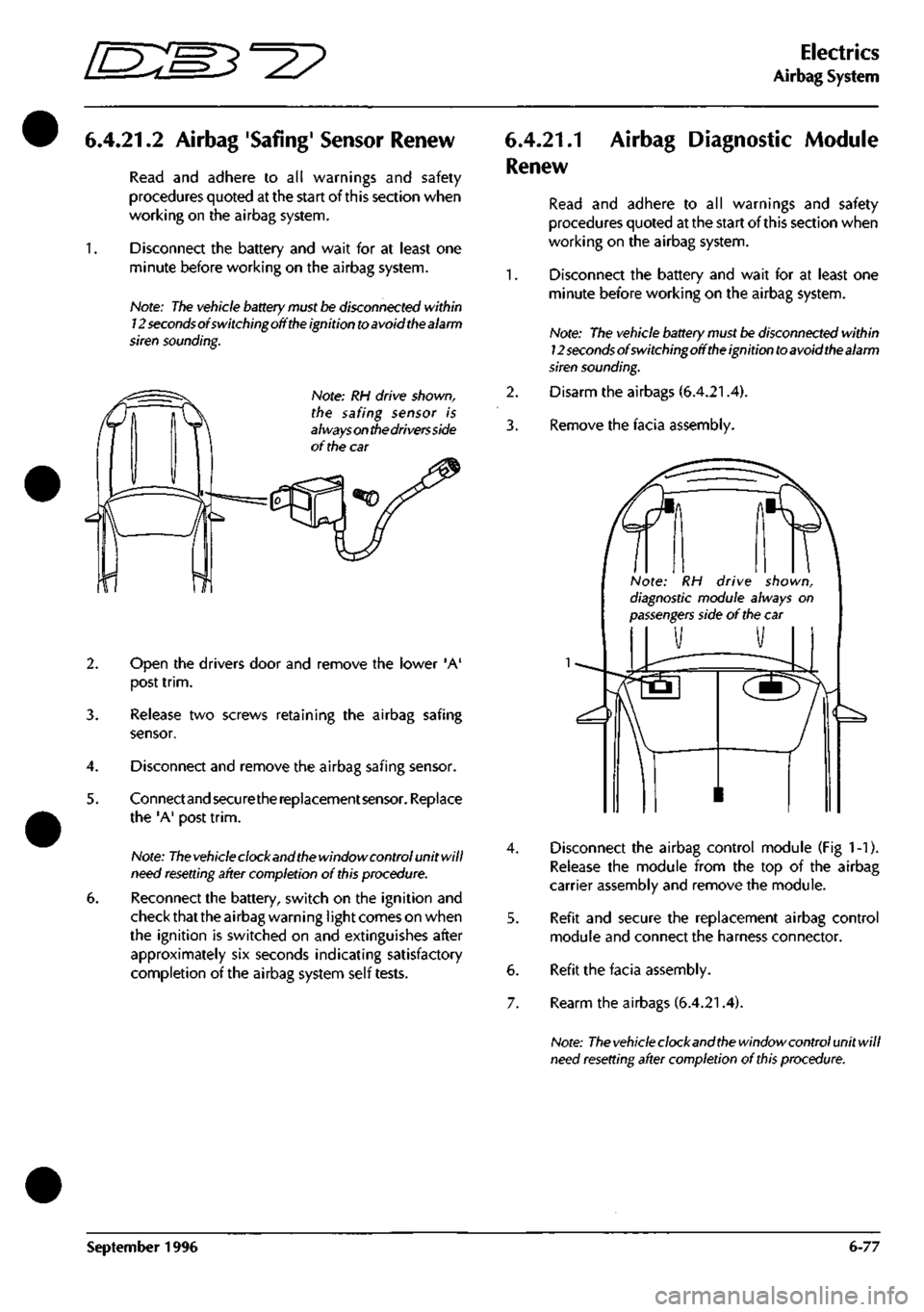

6.4.21.2

Airbag 'Safing' Sensor Renew

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

1.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note:

The

vehicle battery must be disconnected within

12 secondsofswitchingoffthe ignition to avoid the alarm

siren sounding.

^h

Note: RH drive shown,

the safing sensor is

always

on

the drivers side

of the car

2. Open the drivers door and remove the lower 'A'

post

trim.

3. Release two screws retaining the airbag safing

sensor.

4.

Disconnect and remove the airbag safing sensor.

5. Connectand securethe replacement sensor. Replace

the 'A' post

trim.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of

this

procedure.

6. Reconnect the battery, switch on the ignition and

check that the airbag warning

I

ight comes on when

the ignition is switched on and extinguishes after

approximately six seconds indicating satisfactory

completion of the airbag system self tests.

6.4.21.1

Renew

Airbag Diagnostic Module

1.

2.

3.

4.

6.

7.

Read and adhere to all warnings and safety

procedures quoted at the start of this section when

working on the airbag system.

Disconnect the battery and wait for at least one

minute before working on the airbag system.

Note: The vehicle battery must

be

disconnected within

l2secondsofswitchingofftheignitiontoavoidthealarm

siren

sounding.

Disarm the airbags (6.4.21.4).

Remove the facia assembly.

Note: RH drive shown,

diagnostic module always on

passengers

side of

the

car

Disconnect the airbag control module (Fig 1-1).

Release the module from the top of the airbag

carrier assembly and remove the module.

Refit and secure the replacement airbag control

module and connect the harness connector.

Refit the facia assembly.

Rearm the airbags (6.4.21.4).

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

September 1996 6-77

Page 196 of 421

Electrics

Airbag System ^2?

6.4.21.4

Airbag Disarming/Arming

Procedures

WARNINGS AND CAUTIONS:

WARNINGS:

Disarm the airbags by disconnecting the battery

ground (black)

lead,

waiting one minute and then

removing the airbag modules before servicing of

any airbag or steering column component.

After disconnecting the battery ground

lead,

allow

a minimum of one minute delay for the back-up

power supply to discharge before servicing the

airbag system.

The system components are non-serviceable, if

faults are

suspected,

change components for new

items

only.

Failure to observe the above procedures may

result in accidental deployment of the airbags.

Always wear safety

glasses

when working on airbag

equipped vehicles.

Personnel carrying an airbag module must ensure

that the module and trim cover are pointing away

from the

body.

When positioning on a bench or

work surface, ensure that the airbag module and

trim cover face upwards to limit motion on

accidental deployment.

Always wear

gloves

when handling deployed airbag

modules. Deposits of sodium hydroxide may be

presenton the module surface. If sodium hydroxide

contacts any area of the skin, wash the affected

area immediately with mild soap and

water.

Dispose of the deployed airbag using the correct

procedures referred to in this section.

Cautions:

When scrapping vehicles,

ensure

that the

airbags

have

been deployed (see

Scrapping Vehicles

with Live

Airbags).

If a component

has been

renewed and the fault

does

not

clear,

refit the original item and repeat the diagnostic

procedure.

After

servicing,

repeatthe diagnostic

procedures

to ensure

correct

system

operation.

Renew

the airbag module if the surrounding trim

panels

are

damaged.

Do not attempt to repaint trim covers as

paint may

damage

cover material.

Disarming the Airbags

3.

4.

WARNING: Carry out the following disarming

procedure before attempting any work on the

vehicles electrical

systems.

Note: The battery ground (black) lead must be

disconnected within 12 seconds of switching off the

ignition to avoid the alarm siren sounding.

Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

Remove the drivers side airbag module and replace

it with an airbag simulatorfrom the simulator kit (Pt

No.

43.27028).

Remove the passengers airbag module and replace

it with an airbag simulator from the simulator kit.

Reconnect the battery ground.

Rearming the Airbags

WARNING: Carry out the following procedure to

rearm and check the airbags after completing all

work on the vehicles electrical

systems.

Note: The vehicle battery

must be

disconnected within

12

seconds

of switching off

the

ignition

to

avoid the alarm

siren sounding.

^. Disconnect the battery ground

lead.

Allow a

minimum of one minute delay for the back-up

power supply to discharge.

2.

Removethedriverssideairbagsimulatorand replace

it with the drivers airbag module. Secure the airbag

module with the two captive torx screws.

3. Remove the passengers side airbag simulator and

replace it with the passenger side airbag module.

Secure the module with four nuts and washers.

Close the passenger side airbag door.

4.

Reconnect the battery ground.

5. Switch on the ignition and check for correct

indications from the SRS/AIRBAG warning light.

TheSRS/AIRBAC lamp should come on after

a

brief

delay and remain on for approximately six seconds

during the airbag system self check. The lamp will

extinguish upon satisfactory completion of the self

check, or will flash a diagnostic code if an airbag

system fault is detected. Continuous illumination of

the warning lamp may indicate a seatbelt

pretensioner fault

Note:

Reset the

clock and window

ECUs

on completion.

6-80 September 1996

Page 219 of 421

'^^

Electrics

Seat Belt Pretensioner

6.6.26.1

Pretensioner Control Module -

Renew

Read the warnings given in system fault strategy

and service instructions on the previous page before

starting the following procedure.

Procedure

1.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note:

The

vehicle battery must

be

disconnected within

12

seconds

of switching off

the

ignition to avoid the alarm

siren sounding.

2. Motor the right front seat to its rearmost position.

3. Remove the floor carpet and the ECU cover.

4.

Disconnect the pretensioner control module

connector (orange connector with black safety

clip).

5. Remove 3 flange screws securing the module,

noting the position of the earth strap.

6. Fit the new pretensioner control module with the

connector facing to the rear and secure with 3

flange screwsensuringthatthe earth strap is secured

with the outboard rear screw.

7. Connect the orange connector to the control

module.

8. RefitandsecuretheECU cover and the floor carpet.

9. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and the window control unit will

need

resetting

after completion of this procedure.

10.

Switch on the ignition and check that the airbag

warni ng I ight comes on when the ign ition

is

switched

on and extinguishesafterapproximately sixseconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

6.6.24.1

Pretensioner Assembly Renew

Read the warnings given in system fault strategy

and service i nstruaions on the previous page before

starting the following procedure.

1.

2.

4.

Procedure

Motor the drivers seat to its rearmost position.

Disconnect the battery ground (black) lead and

wait at least 10 minutes for the pretensioner power

supply to fully discharge before working on the

pretensioner system.

Note: Disconnect the battery within 12 seconds of

switchingoffthe ignition to avoid the alarm siren sounding.

Remove the pretensioner trim cover. Unbolt the

drivers seat. Tip the seat rearwards and disconnect

the seat and pretensioner squib connectors.

Release one bolt at the

base

of the seat belt

stal k

and

remove the pretensioner assembly.

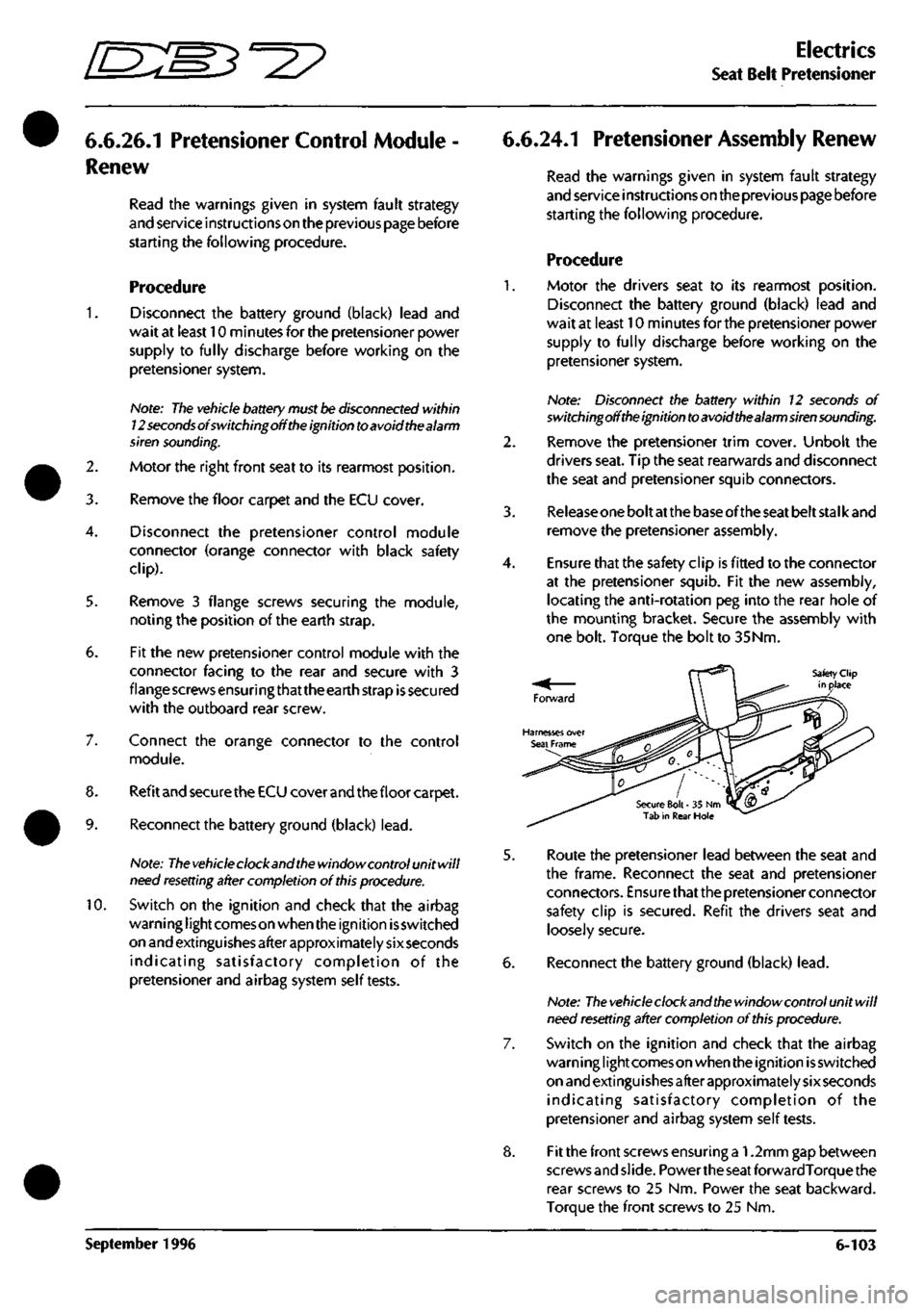

Ensure that the safety clip is fitted to the connector

at the pretensioner squib. Fit the new assembly,

locating the anti-rotation peg into the rear hole of

the mounting bracket. Secure the assembly with

one bolt. Torque the bolt to 35Nm.

Safety Clip in place

5. Route the pretensioner lead between the seat and

the frame. Reconnect the seat and pretensioner

connectors. Ensure that the pretensioner connector

safety clip is secured. Refit the drivers seat and

loosely secure.

6. Reconnect the battery ground (black)

lead.

Note:

The

vehicle clock and

the

window control unit will

need

resetting

after completion of this procedure.

7. Switch on the ignition and check that the airbag

warn i ng I ight comes on when the ignition

is

switched

on and extingu

ishes

after approximately six seconds

indicating satisfactory completion of the

pretensioner and airbag system self tests.

8. Fit the front screws ensuring a 1.2mm gap between

screws and slide. Power the seat forwardTorque the

rear screws to 25 Nm. Power the seat backward.

Torque the front screws to 25 Nm.

September 1996 6-103

Page 227 of 421

3-^?

Electrics

Seat Removal/Replacement 97.5 MY

6.6.03

Seat Removal 97.5 MY

Description

The 97.5 MY front seats are common to the DB7

Coupe

and

Volante

models.

Seat

switch

assembi ies

are located on the outboard side of both driver and

passenger

seats.

The front switch controls fore and

aft movement and the seat height adjustment. The

centre switch controls the recline adjustment. The

rear switch

controls

the

lumbar support adjustment.

The seat

heater switches are mounted on the centre

console, forward of the gear selector

lever.

Only one of

the

slide,

recline or height motors can

be driven under manual control at any one time.

Each seat switch pack is hard wired to the relevant

Seat Control

Module

beneath each

seat.

The

module

outputs are hard wired to the seat motors.

Removal

WARNING -

Seat

belt

Pretensioners

(if fitted):

To avoid the possibility

of

personal

injury

caused

by accidental deployment of the seat belt

pretensioner,

disconnect

the

vehicle battery and

wait at

least

10

minutes

for all

voltages

to fully

discharge

before working on the

pretensioner

system.

This covers the possibility

of

the normal

capacitor

discharge

circuits being inoperative and

failing to discharge the detonator capacitor when

instructed

to

do

so.

Procedure

1.

Motortheseatto

its

maximum forward position and

remove the fixings at the rear of the slides.

2.

Motor the seat to its maximum rearward position

and remove the front seat slide fixings.

3. Disconnect the battery

ground

(black)

lead.

Wait at

least 10 minutes for the pretensioner power supply

to fully discharge before working on the seat if a

pretensioner is fitted.

Note: Disconnect the battery within 12 seconds of

switching off the ignition to avoid the alarm siren sounding.

4.

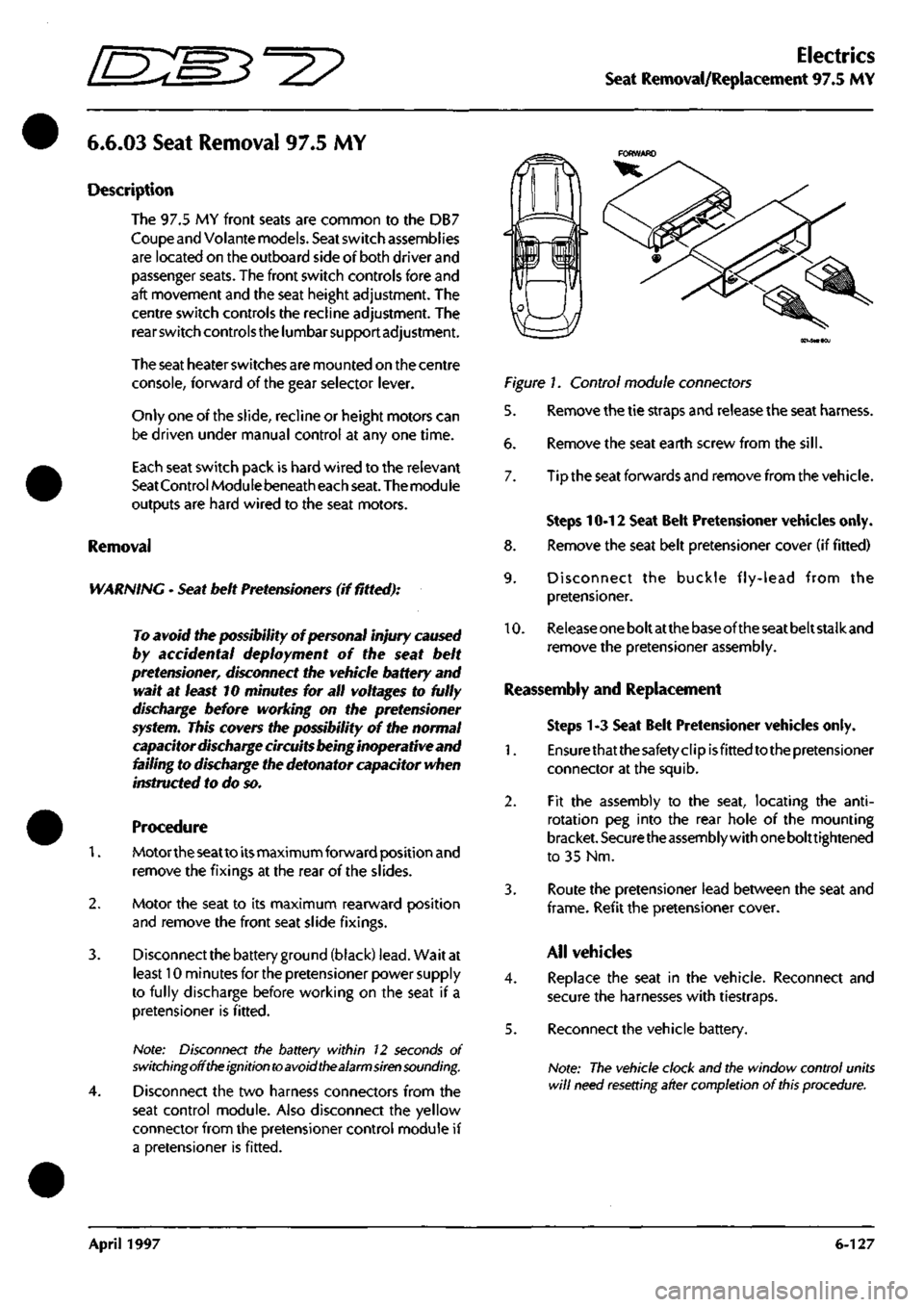

Disconnect the two harness connectors from the

seat control module. Also disconnect the yellow

connector from the pretensioner control module if

a pretensioner is fitted.

Figure 1. Control module connectors

5. Remove the tie straps and release the seat harness.

6. Remove the seat earth screw from the

sill.

7. Tip the seat forwards and remove from the vehicle.

Steps 10-12 Seat Belt Pretensioner vehicles only.

8. Remove the seat belt pretensioner cover (if fitted)

9. Disconnect the buckle fly-lead from the

pretensioner.

10.

Release

one

bolt at

the

base of the

seat

belt stalk and

remove the pretensioner assembly.

Reassembly and Replacement

Steps 1-3 Seat Belt Pretensioner vehicles only.

1.

Ensurethatthesafetyclipisfittedtothepretensioner

connector at the squib.

2.

Fit the assembly to the seat, locating the

anti-

rotation peg into the rear hole of the mounting

bracket.

Securethe

assembly with

one

bolttightened

to 35 Nm.

3. Route the pretensioner lead between the seat and

frame.

Refit the pretensioner

cover.

All vehicles

4.

Replace the seat in the vehicle. Reconnect and

secure the harnesses with tiestraps.

5. Reconnect the vehicle battery.

Note:

The vehicle clock and the window control units

will

need resetting after completion

of

this

procedure.

April 1997 6-127