climate control ASTON MARTIN DB7 1997 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 278 of 421

in:!M3^^?

Air Conditioning

Contents

Contents

General Description 8-5

Specifications 8-5

Climate Control System 8-6

System Description 8-7

Special Servicing Tools and Equipment 8-7

Working Practices 8-8

General 8-8

Handling Refrigerant 8-8

Handling Lubricating Oil 8-8

System Maintenance 8-8

Temperature Distribution System 8-9

Fan Speed Control (Mode Switch) 8-10

Face Level Temperature Differential 8-10

Temperature Rotary Control 8-10

Refrigeration Cycle 8-11

System Protection 8-12

General System Procedures 8-12

Leak Test 8-12

Charge Recovery (System Depressurisation) 8-12

Evacuating the System 8-13

Adding Compressor Lubricating Oil 8-13

Adding Refrigerant 8-14

Functional Check 8-15

System Trouble Shooting 8-1 7

Electronic Control Module (ECM) 8-19

In Car Controls 8-21

Temperature Demand Switch 8-21

Face Level Differential Controller 8-21

Air Conditioning Function Switch 8-22

Fan Speed Control Switch (Mode Switch) 8-23

Temperature Sensors 8-23

Evaporator Sensor 8-24

Motorised In-Car Aspirated Sensor 8-24

Water Temperature Switch 8-25

Blower Motors 8-25

Potentiometers 8-26

Servo Motors 8-27

Vacuum System 8-28

Pressure-Temperature Graphs 8-29

May 1996 8-1

Page 283 of 421

Air Conditioning

General Description 5^^?

climate Control System

Features

Refrigerant R134A (Hydro fluorocarbon), non ozone depletory.

PAG (polyalkylene glycol) synthetic compressor lubricating oil.

Dedicated and improved compressor for Refrigerant R134A.

Quick fit and release self sealing charge and discharge ports.

Triple pressure (Trinary) switch to control the compressor (incorporated into the liquid line).

Clamp retained 'O' ring seals at the expansion valve and evaporator.

All aluminium evaporator matrix and pipe work.

Aluminium receiver-dryer (without sight glass) and HFC dedicated desiccant.

Parallel flow extended height condenser.

Single muffler situated in the suction hose.

Improved electrical system connectors.

Improved system control panel.

System Recognition

Identification Features

Aluminium pipes.

Large diameter, quick release charge and recovery ports.

No sight glass.

8-6 May 1996

Page 352 of 421

^?

The Aston Martin Lagonda Diagnostic System

Contents

Installation Instructions

Introduaion 9-2

The Aston Martin Diagnostic System 9-2

Diagnostic System Cables 9-5

Base Station Installation 9-8

Problem Solving 9-16

Service Centres 9-21

Service and Maintenance 9-22

Technical Specifications 9-24

Operating Instructions

The Aston Martin Lagonda Diagnostic System 9-27

Software 9-29

Cable Setup 9-31

Diagnostic Sockets - 97 MY 9-31

Establishing Communications 9-32

System Menu Selections 9-32

PDU Use 9-32

Engine Diagnostics - 97 MY 9-33

Transmission Diagnostics 9-40

Climate Control Diagnostics 9-43

Anti-Lock Brakes Diagnostics 9-43

Passive Anti-Theft (PATS) Diagnostics 9-44

Airbag System Diagnostics 9-45

Seat Belt Pretensioner Diagnostics 9-47

Print Facility 9-49

Digital Multimeter 9-50

Diagnostic Trouble Codes 9-53

Datalogger 9-55

Datalogger Example 9-63

Training 9-66

OBD II Scan Tool 9-66

System Self Test 9-69

The Asterisk (*) Menu 9-69

System Setup 9-70

May 1996 9-1

Page 379 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide o: "3^^?

PDU Functions

The PDU main menu provides access into the following functions:

Diagnostics

Training

Digital Multimeter

User Self Test

Diagnostics

On selecting'Diagnostics'from the main

menu,

the user will be prompted to enter the features and market specification

of the vehicle to be tested. Use of the diagnostics in each of the above areas is described later in this guide.

Diagnostics Menu - 95 Model Year

Engine

Anti-Lock Braking System

Vlenu - 97 Model Year

Engine Diagnostics

OBD II Scan Tool

Airbag

Seat Belt Pretensioner

•

•

•

•

Transmission

Engine Datalogger

Climate Control

PATS System

Climate Control

Transmission

Anti-Lock Braking System

Security

Digital Multimeter

The Digital Multimeter function provides the capabilityto measure voltage, current, resistance, frequency, pulse width,

pulse period, and duty cycle. These measurements are usually made using the PDU measurement probes. Measurements

may also be made using the module pin selection function on the Teves Mk

II

braking system and on the Air Conditioning

system.

Training

An on-screen programme is provided to train new users in the use of screen icons and in the use of the digital multi

meter and datalogger functions.

User Self Test

In order to prove that the equpment is functioning correctly, a complete user self test is incorporated. The user is directed

to test the PDU and then to progressively connect each part of the PDU system which will be tested by the software.

Any fault identified during the test is notified to the user. If no faults are identified, the user is advised on the correct

functioning of the system.

PDU Power

Power for the PDU is supplied via an internal rechargeable battery pack which can keep the PDU operational for

approximately one hour when disconnected from the base station and the vehicle. In order to preserve PDU battery

charge, power to the screen backlight is automatically cut after five minutes of inactivity. The power ON indicator

remains lit, indicating that the PDU is in 'stand-by' mode. One touch of the screen will restore backlight power.

When connected to the base station, power is supplied to the PDU from the Electronic Module to recharge the PDU

battery pack as necessary.

On 95 MY vehicles, the Vehicle Battery Adaptor (VBA) is used to maintain PDU power.

On 97 MY vehicles, when connected via the MPA to either diagnostic socket on the vehicle, power is supplied via pin

4 (chassis ground) and pin 16 (battery power) to maintain PDU power at all times even when the vehicle ignition is

switched off.

On all model years, when connected to the air conditioning system using the VIA, the vehicle battery adaptor (VBA)

must also be used to maintain PDU power.

9-28 September 1996

Page 381 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide D-^?

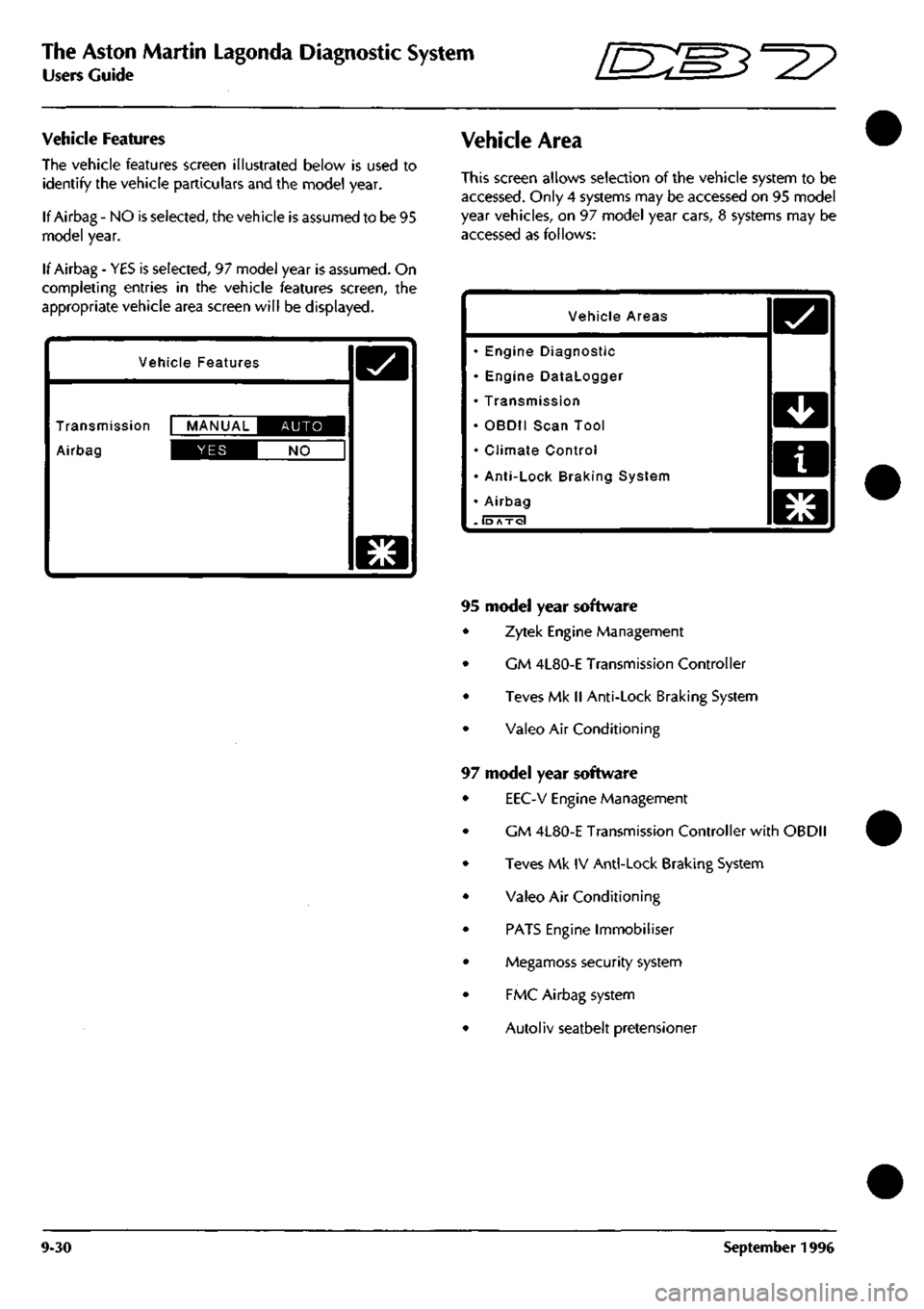

Vehicle Features

The vehicle features screen illustrated below is used to

identify the vehicle particulars and the model year.

If Airbag - NO is selected, the vehicle is assumed to be 95

model year.

If Airbag - YES is selected, 97 model year is assumed. On

completing entries in the vehicle features screen, the

appropriate vehicle area screen will be displayed.

Vehicle Features

Transmission MANUAL IIBIE^^I

Airbag IDS^I NO

D

Vehicle Area

This screen allows selection of the vehicle system to be

accessed.

Only 4 systems may be accessed on 95 model

year vehicles, on 97 model year cars, 8 systems may be

accessed as follows:

Vehicle Areas

• Engine Diagnostic

• Engine Datalogger

• Transmission

• OBDII Scan Tool

• Climate Control

• Anti-Lock Braking System

• Airbag

. lb Axol

o

PI

mLM

n

WLM

El

Ku^

95 model year software

Zytek Engine Management

GM 4L80-E Transmission Controller

Teves Mk II Anti-Lock Braking System

Valeo Air Conditioning

97 model year software

EEC-V Engine Management

CM 4L80-E Transmission Controller with OBDII

Teves Mk IV Anti-Lock Braking System

Valeo Air Conditioning

PATS Engine Immobiliser

Megamoss security system

FMC Airbag system

Autoliv seatbelt pretensioner

9-30 September 1996

Page 383 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide "^7

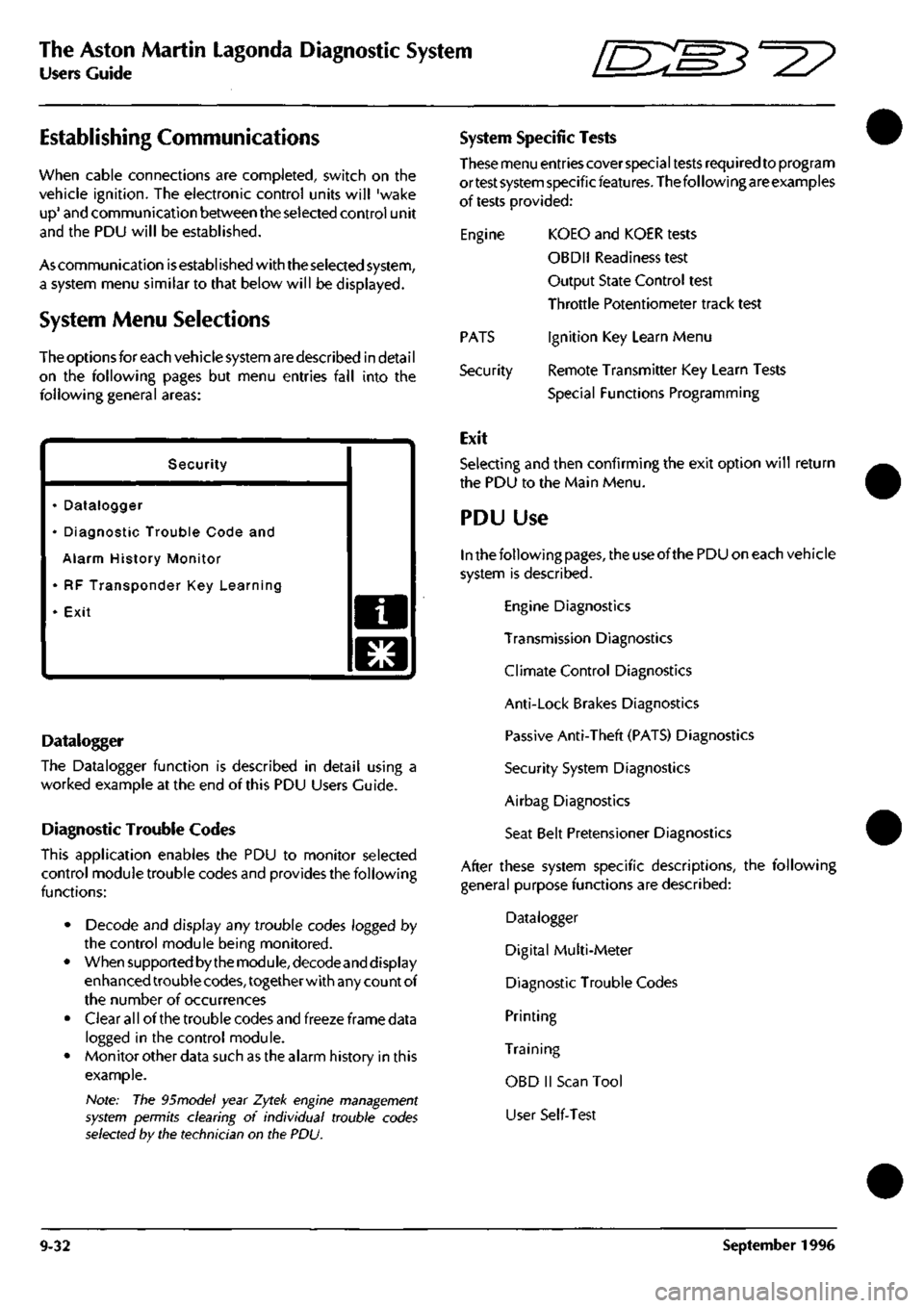

Establishing Communications

when cable connections are completed, switch on the

vehicle ignition. The electronic control units will 'wake

up'

and communication between the selected control unit

and the PDU will be established.

As communication

is

established with the selected system,

a system menu similar to that below will be displayed.

System Menu Selections

The options for each vehicle system are described in detai

I

on the following pages but menu entries fall into the

following general areas:

Security

• Datalogger

• Diagnostic Trouble Code and

Alarm History Monitor

• RF Transponder Key Learning

• Exit a

o

Datalogger

The Datalogger function is described in detail using a

worked example at the end of this PDU Users Guide.

Diagnostic Trouble Codes

This application enables the PDU to monitor selected

control module trouble codes and provides the following

functions:

• Decode and display any trouble codes logged by

the control module being monitored.

• When supported by the module, decodeand display

enhanced trouble

codes,

together with any count of

the number of occurrences

• Clear all of the trouble codes and freeze frame data

logged in the control module.

• Monitor other data such as the alarm history in this

example.

Note: The 95model year Zytek engine management

system permits clearing of individual trouble codes

selected by the technician on the PDU.

System Specific Tests

These menu entries cover special tests required to program

ortest system specificfeatures. The following are examples

of tests provided:

Engine KOEO and KOER tests

OBDII Readiness test

Output State Control test

Throttle Potentiometer track test

Ignition Key Learn Menu

Remote Transmitter Key Learn Tests

Special Functions Programming

PATS

Security

Exit

Selecting and then confirming the exit option will return

the PDU to the Main Menu.

PDU Use

In the following

pages,

the use of the PDU on each vehicle

system is described.

Engine Diagnostics

Transmission Diagnostics

Climate Control Diagnostics

Anti-Lock Brakes Diagnostics

Passive Anti-Theft (PATS) Diagnostics

Security System Diagnostics

Airbag Diagnostics

Seat Belt Pretensioner Diagnostics

After these system specific descriptions, the following

general purpose functions are described:

Datalogger

Digital Multi-Meter

Diagnostic Trouble Codes

Printing

Training

OBD II Scan Tool

User Self-Test

9-32 September 1996

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

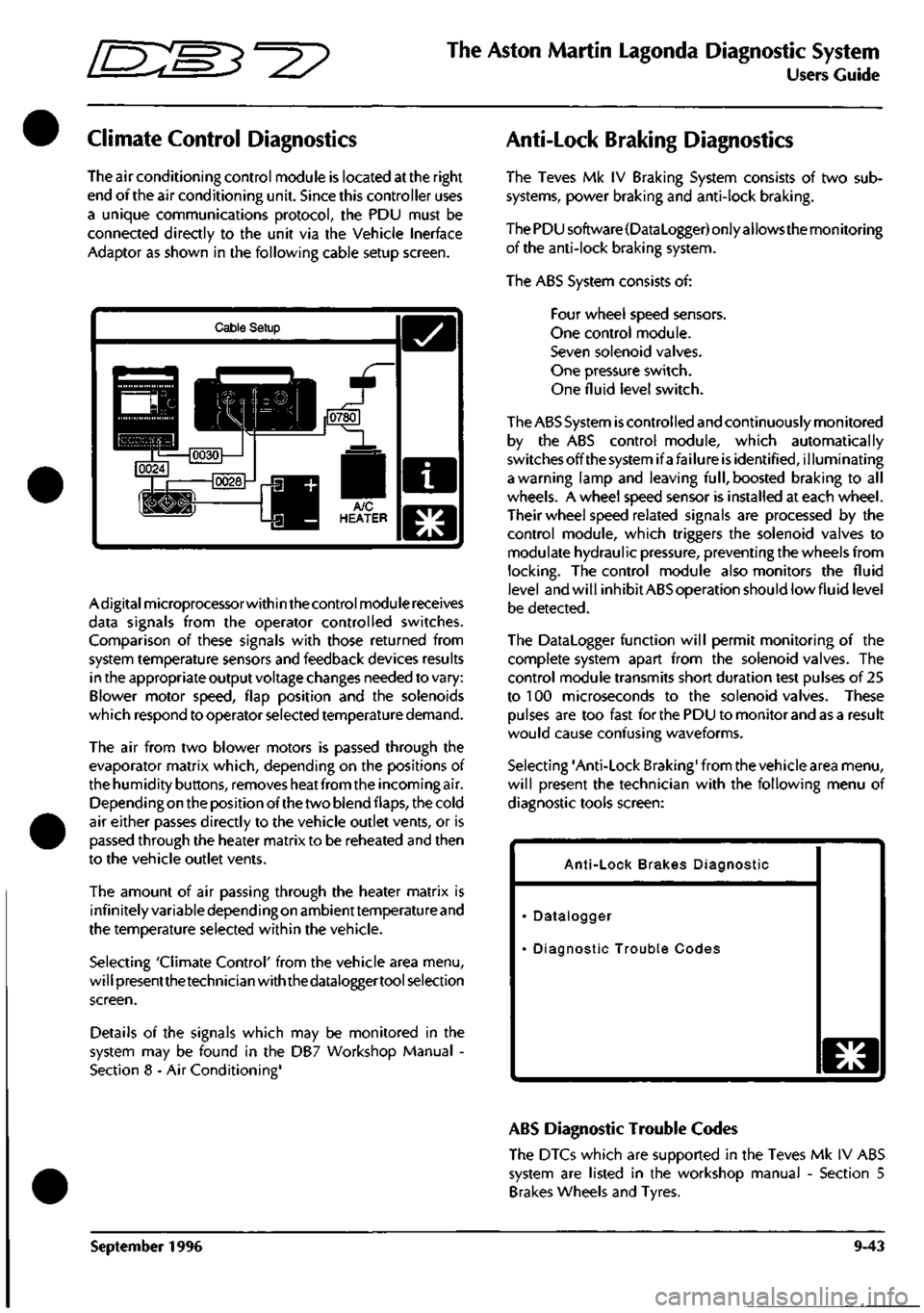

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43