lock ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 864 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Dual MAF Diagnostic

Dual MAF Hardware

The V8 uses a common dirty air pick-up, which feeds twin air filters and MAF meters before recombining the two air streams in a junction prior to the throttle.

[email protected] AML EOBD Monitors 07 ROC.doc Page 18 of 43

FilterFilter

Filter Filter

Filter Filter

Filter Filter

MAF

meters

Normal Operation Side Wind or Partial

Blockage Backflow

Total Blockage

MAF meters receive an

equal share of the airflow. One MAF meter receives

an airflow greater than the total engine consumption. One MAF meter

receives airflow equal to the total airflow.

MAF meters receive

unequal airflows. This is due to severe side

wind. Fault judgement is

de

pendant on severity.

This can either be due

to a side wind or a partial blockage. One MAF meter will

measure zero airflow and this needs to be

determined to prevent false circuit faults.

Low engine airflow

conditions are

particularly susceptible to side wind. Fault judgement is

dependant on severity.

Fault judgement is

dependant on severity.

Page 865 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 19 of 43

Dual MAF Diagnostic Overview

The dual MAF diagnostic performs 11 separate tests on the measured MAF values. Each test is designed

to identify specific faults many of which, are only applicable to the dual MAF hardware configuration.

Many of the tests compare the measured MAF values to the estimated MAF (calculated from throttle

position, barometric pressure, act and engine speed). The tests are performed continuously (apart from the

conditions outlined later) and are always completed in the same sequence:

Test1 - Does MAF1+MAF2 = estimated MAF

Test2 - Does MAF1 = ½ estimated MAF

Test3 - Does MAF2 = ½ estimated MAF

Test4 - Is MAF1

Test6 - MAF2 low voltage

Test7 - MAF1 high voltage

Test8 - MAF2 high voltage

Test9 - Is MAF1> estimated MAF

Test10 - Is MAF2> estimated MAF

Test11 - Does MAF1 = MAF2

By pass/fail combinations of the above tests a vari ety of conditions can be detected discretely on each

MAF:

Partly blocked MAF

Fully blocked MAF

Electrical short to ground MAF

Electrical short high MAF

Backflow

Failed in range MAF

Page 866 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Fault Matrix

ConditionMAF 1 + MAF 2 = EST

MAF 1 = ½ EST

MAF 2 = ½ EST

MAF 1 < MAF 2

MAF 1 low voltage

MAF 2 low voltage

MAF 1 high voltage

MAF 2 high voltage

MAF 1 > EST

MAF 2 > EST

MAF 1 = MAF 2Air Charge P-codes

Normal operating. YY--------f(maf_raw)

None

MAF 1 partly blocked. N-N----f(maf_raw)

P010F, P0100

MAF 1 fully blocked @ low load.

Y-N---- f(maf_raw)

P010F, P0100

MAF 2 partly blocked. -N-N- - -f(maf_raw)

P010F, P010A

MAF 2 fully blocked @ low load. -Y-N---f(maf_raw)

P010F, P010

AMAF 1 shorted to ground.

-Y-N----f(maf_raw)

P0102

MAF 1 shorted to high. -N-Y----f(maf_raw)

P0103

MAF 1 failed in range. -N-N----f(maf_raw)

P0101

MAF 2 shorted to ground. --Y-N---f(maf_raw)

P010C

MAF 2 shorted high. --N-Y---f(maf_raw)

P010D

MAF 2 failed in range. --N-N---f(maf_raw)

P010B

Estimated value wrong. --

Yf(maf_raw)None

MAF 1 and MAF 2 failed in range. --Nf(fmem)

P0101, P010B

Backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 short to ground MAF 2 failed in rng. -N-f(fmem)

P0102, P010B

MAF 1 shorted high, MAF 2 failed in rng. -NN

YN---f(fmem)

P0103, P010B

Backflow via MAF 2.Y-- f(fmem)

P010E

MAF 1 failed in rng, MAF2 short to ground. N- -f(fmem)

P0101, P010C

MAF 1 failed in rng, MAF 2 shorted high. NNN

Y---f(fmem)

P0101, P010D

MAF 1 & MAF 2 shorted to ground. -YYNN---f(fmem)

P0102, P010C

MAF 1 & MAF 2 shorted high. -NNYY---f(fmem)

P0103, P010D

Severe backflow via MAF 2.Y-- f(fmem)

P010E

MAF 2 fully blocked @ high load N- -f(fmem)

P010F, P010B

Severe backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 fully blocked @ high load. -N-f(fmem)

P010F, P0101

YNNY N

N

NN - NNNN

-

-NYY N

-NYNN

-YNN

Y

N

NY

Y

NN

YN

[email protected] AML EOBD Monitors 07 ROC.doc Page 20 of 43

Page 869 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 23 of 43

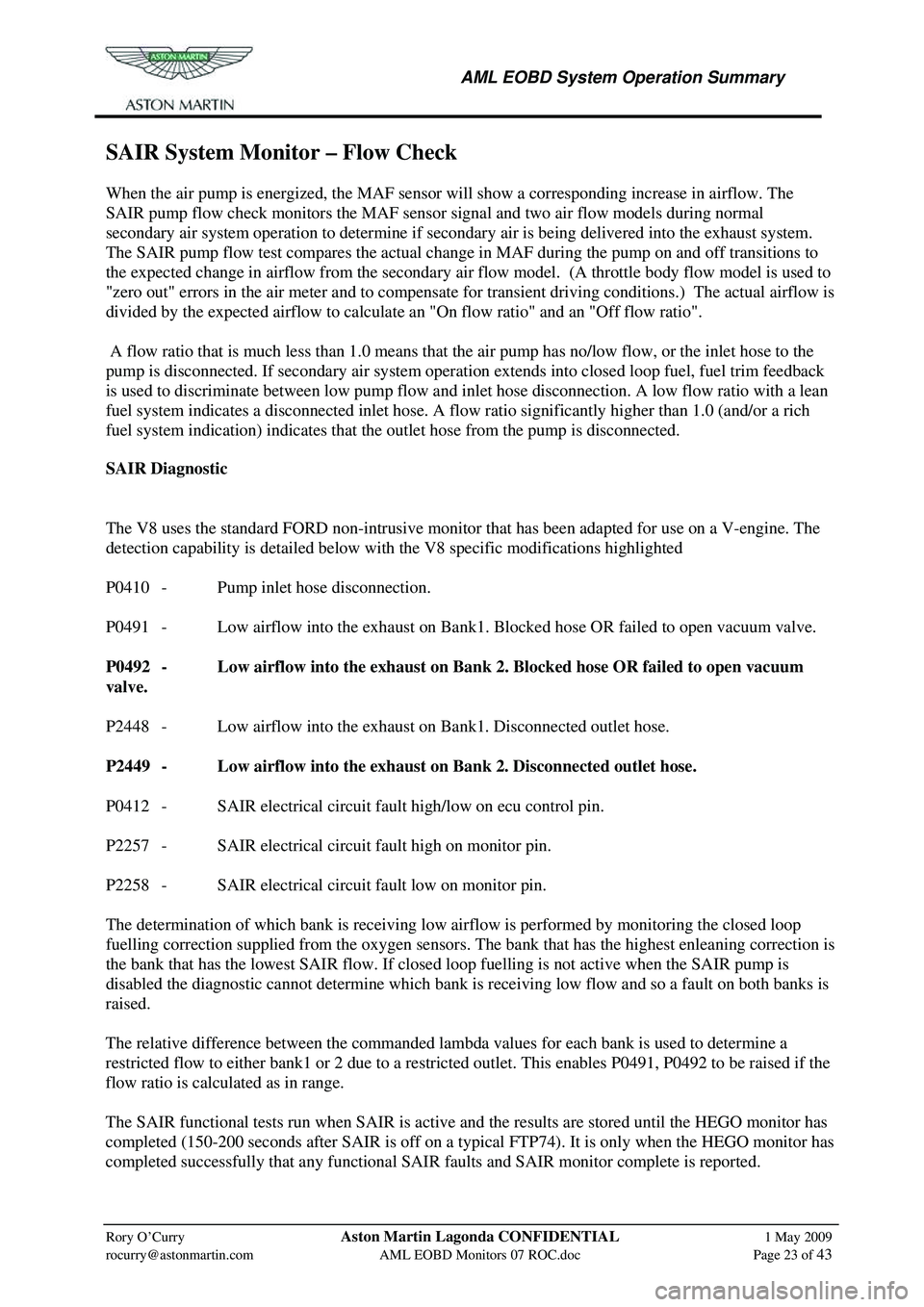

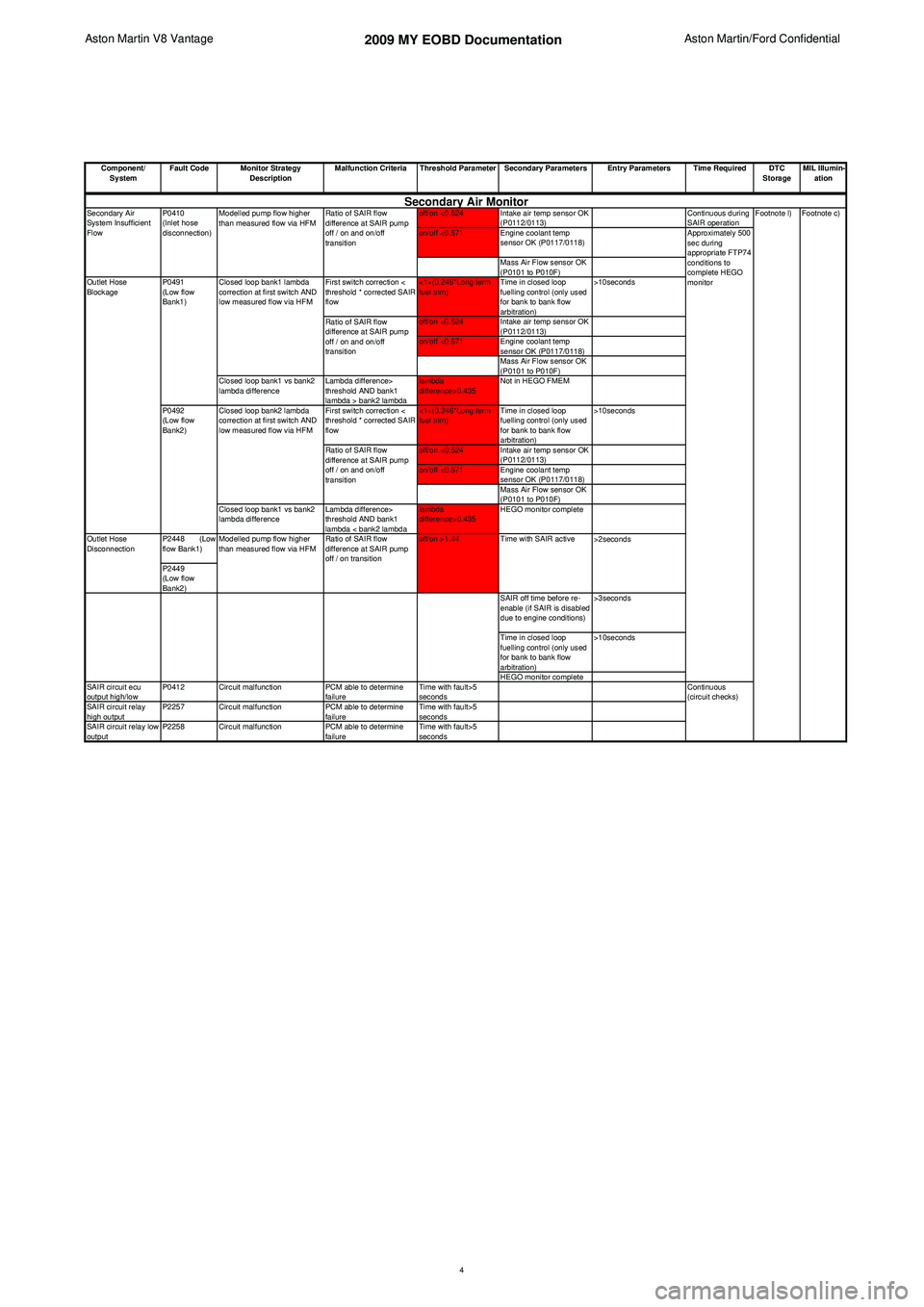

SAIR System Monitor – Flow Check

When the air pump is energized, the MAF sensor will show a corresponding increase in airflow. The

SAIR pump flow check monitors the MAF sensor signal and two air flow models during normal

secondary air system operation to determine if secondary air is being delivered into the exhaust system.

The SAIR pump flow test compares the actual change in MAF during the pump on and off transitions to

the expected change in airflow from the secondary air fl ow model. (A throttle body flow model is used to

"zero out" errors in the air meter and to compensate fo r transient driving conditions.) The actual airflow is

divided by the expected airflow to calculate an "On flow ratio" and an "Off flow ratio".

A flow ratio that is much less than 1.0 means that the air pump has no/low flow, or the inlet hose to the

pump is disconnected. If secondary air system operation ex tends into closed loop fuel, fuel trim feedback

is used to discriminate between low pump flow and in let hose disconnection. A low flow ratio with a lean

fuel system indicates a disconnected inlet hose. A flow ratio significantly higher than 1.0 (and/or a rich

fuel system indication) indicates that th e outlet hose from the pump is disconnected.

SAIR Diagnostic

The V8 uses the standard FORD non-intrusive monitor that has been adapted for use on a V-engine. The

detection capability is detailed below with the V8 specific modifications highlighted

P0410 - Pump inlet hose disconnection.

P0491 - Low airflow into the exhaust on Bank1. Blocked hose OR failed to open vacuum valve.

P0492 - Low airflow into the exhaust on Bank 2. Blocked hose OR failed to open vacuum

valve.

P2448 - Low airflow into the exhaust on Bank1. Disconnected outlet hose.

P2449 - Low airflow into the exhaust on Bank 2. Disconnected outlet hose.

P0412 - SAIR electrical circuit fault high/low on ecu control pin.

P2257 - SAIR electrical circuit fault high on monitor pin.

P2258 - SAIR electrical circuit fault low on monitor pin.

The determination of which bank is receiving low ai rflow is performed by monitoring the closed loop

fuelling correction supplied from the oxygen sensors. The bank that has the highest enleaning correction is

the bank that has the lowest SAIR flow. If closed loop fuelling is not active when the SAIR pump is

disabled the diagnostic cannot determ ine which bank is receiving low flow and so a fault on both banks is

raised.

The relative difference between the commanded lambda values for each bank is used to determine a

restricted flow to either bank1 or 2 due to a restricted outlet. This enables P0491, P0492 to be raised if the

flow ratio is calculated as in range.

The SAIR functional tests run when SAIR is active and the results are stored until the HEGO monitor has

completed (150-200 seconds after SAIR is off on a typical FTP74). It is only when the HEGO monitor has

completed successfully that any functional SAIR fa ults and SAIR monitor complete is reported.

Page 870 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 24 of 43

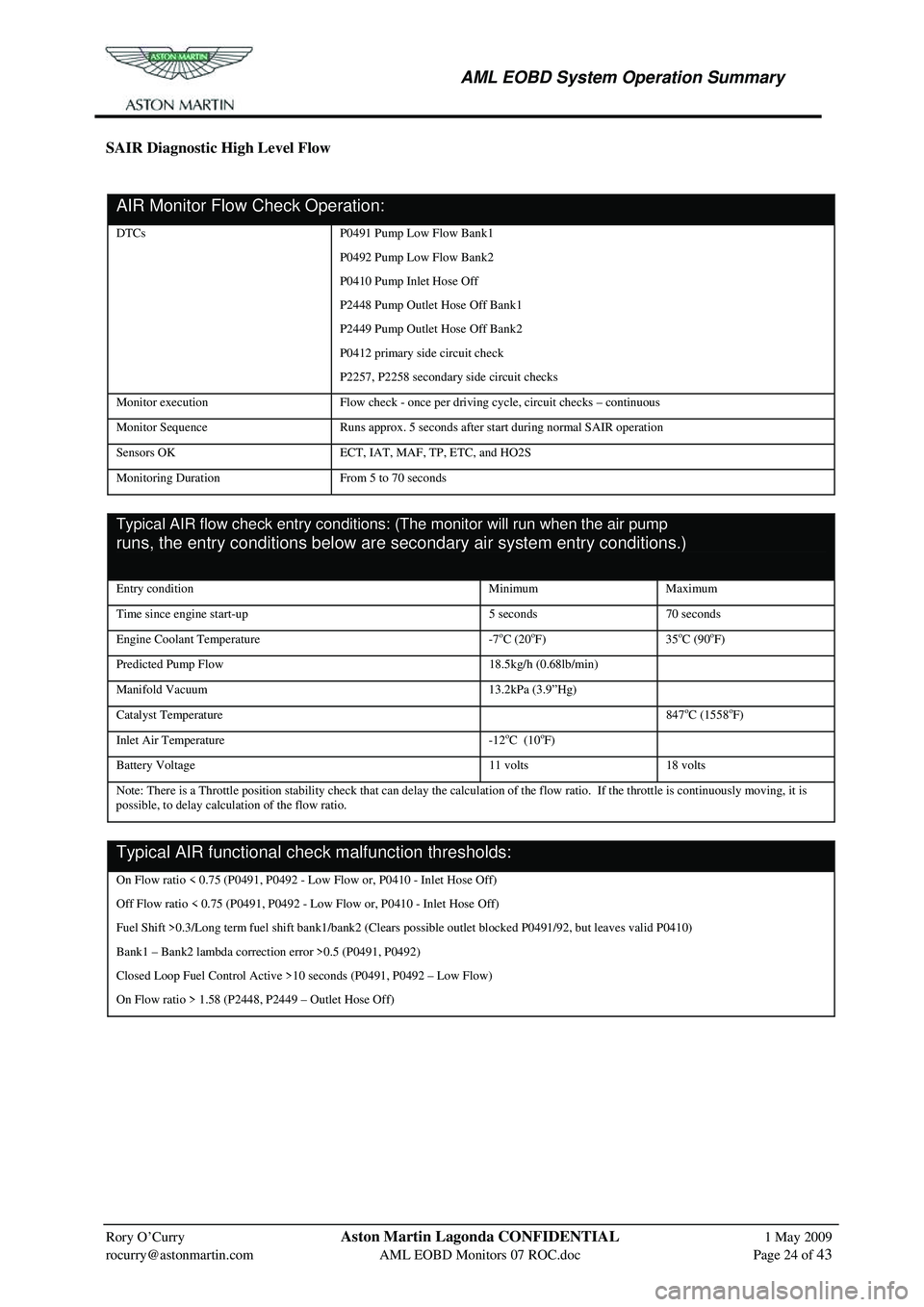

SAIR Diagnostic High Level Flow

AIR Monitor Flow Check Operation: onitor Flow Check Operation:

DTCs P0491 Pump Low Flow Bank1

P0492 Pump Low Flow Bank2

P0410 Pump Inlet Hose Off

P2448 Pump Outlet Hose Off Bank1

P2449 Pump Outlet Hose Off Bank2

P0412 primary side circuit check

P2257, P2258 secondary side circuit checks

Monitor execution Flow check - once per driving cycle, circuit checks – continuous

Monitor Sequence Runs approx. 5 seconds after start during normal SAIR operation

Sensors OK ECT, IAT, MAF, TP, ETC, and HO2S

Monitoring Duration From 5 to 70 seconds

Typical AIR flow check entry conditions: (The monitor will run when the air pump

runs, the entry conditions below are secondary air system entry conditions.) re secondary air

system entry conditions.)

Entry condition Minimum Maximum

Time since engine start-up 5 seconds 70 seconds

Engine Coolant Temperature -7oC (20oF) 35oC (90oF)

Predicted Pump Flow 18.5kg/h (0.68lb/min)

Manifold Vacuum 13.2kPa (3.9”Hg)

Catalyst Temperature 847oC (1558oF)

Inlet Air Temperature -12oC (10oF)

Battery Voltage 11 volts 18 volts

Note: There is a Throttle position stability ch eck that can delay the calculation of the flow ratio. If the throttle is continuously moving, it is

possible, to delay calculation of the flow ratio.

Typical AIR functional check malfunction thresholds:heck malfunction thresholds:

On Flow ratio < 0.75 (P0491, P0492 - Low Flow or, P0410 - Inlet Hose Off)

Off Flow ratio < 0.75 (P0491, P0492 - Lo w Flow or, P0410 - Inlet Hose Off)

Fuel Shift >0.3/Long term fuel shift bank1/bank2 (Clears possible outlet blocked P0491/92, but leaves valid P0410)

Bank1 – Bank2 lambda correcti on error >0.5 (P0491, P0492)

Closed Loop Fuel Control Active >10 seconds (P0491, P0492 – Low Flow)

On Flow ratio > 1.58 (P2448, P2449 – Outlet Hose Off)

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

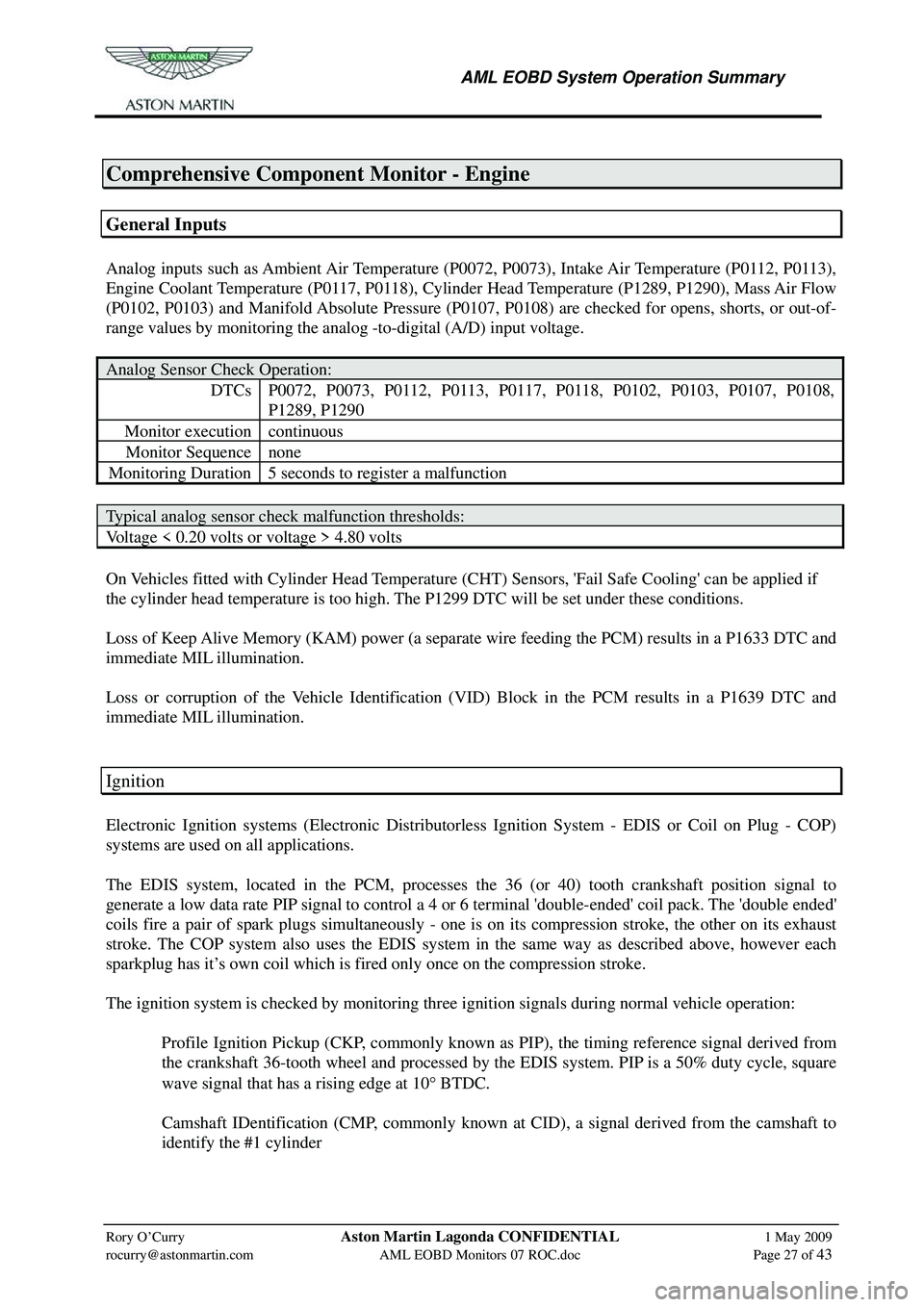

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder

Page 878 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 32 of 43

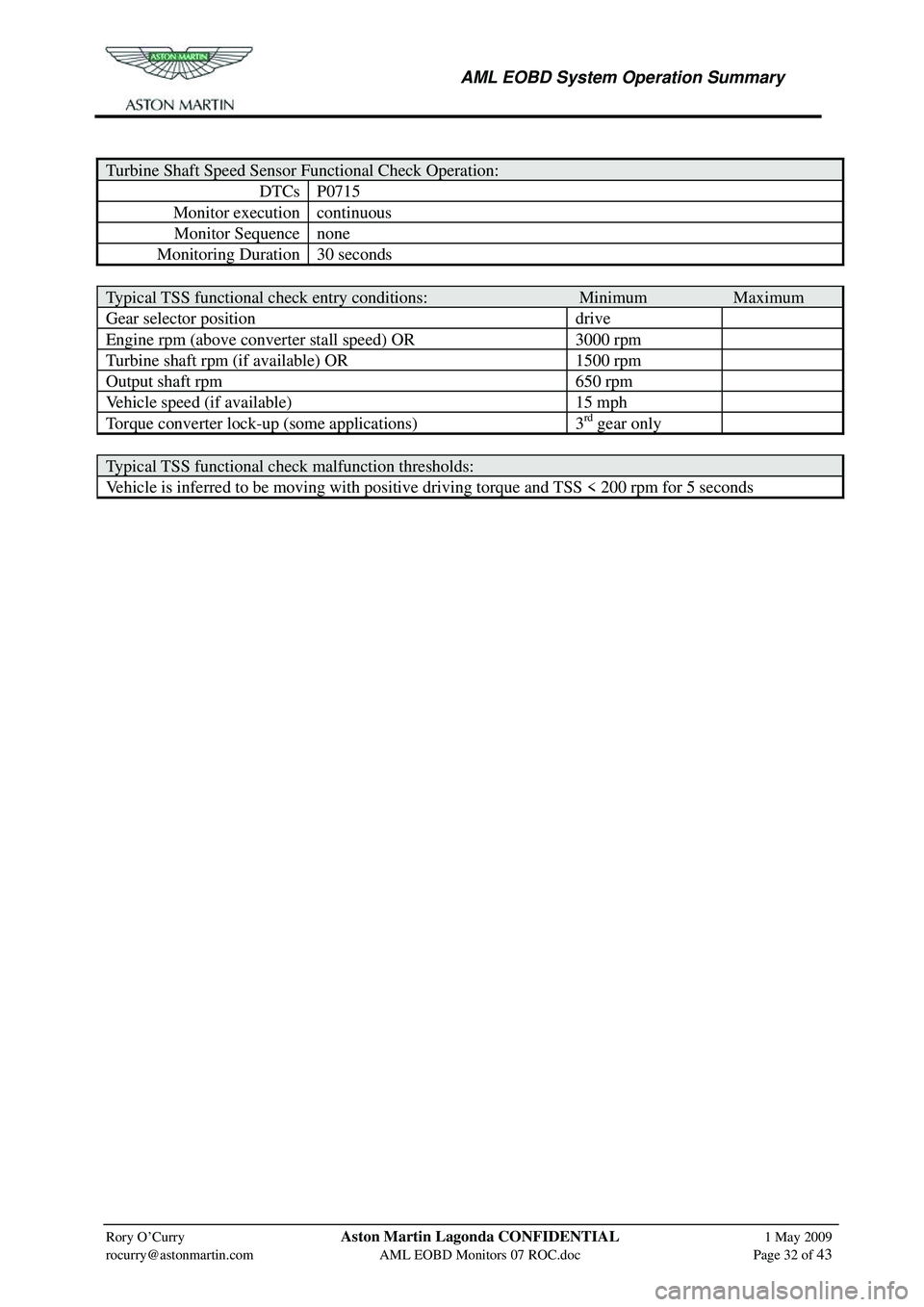

Turbine Shaft Speed Sensor Functional Check Operation:

DTCs P0715

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 30 seconds

Typical TSS functional check entry conditions: Minimum Maximum

Gear selector position drive

Engine rpm (above converter stall speed) OR 3000 rpm

Turbine shaft rpm (if available) OR 1500 rpm

Output shaft rpm 650 rpm

Vehicle speed (if available) 15 mph

Torque converter lock-up (some applications) 3rd gear only

Typical TSS functional check malfunction thresholds:

Vehicle is inferred to be moving with positiv e driving torque and TSS < 200 rpm for 5 seconds

Page 881 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 35 of 43

Inspection Maintenance Readiness Code

I/M readiness information indicates whether a full diagnos tic check has been completed, i.e. the minimum

number of driving cycles necessary for MIL illumination has been completed since computer memory was

last cleared. Information available to the test equi pment or diagnostic tool includes all the non-continuous

monitors. Misfire, Fuel System and CCM monitors are assumed to complete if all the non-continues

monitors have completed.

A P1000 DTC is stored after an OBD reset is performed, until the I/M readiness check is complete.

Tamper Protection

The AML EOBD System shall meet ISO DIS 15031-7 / SAE J2186 - Diagnostic Data Link Security

requirements, to write-protect any re-programmable co mputer code. Additional data will be stored in the

PCM Vehicle Identification Block to enable retrieva l of VIN (although VIN may not be in the VID block

for all vehicles), CALID (CALibration ID identifi es the specific calibration) and CVN (Calibration

Verification Number, similar to an encrypted check sum). CALID and CVN will be tracked for all initial

releases, running changes and field fixes.

To achieve this data retrieva l J1979 Mode 09 will be implemented for VIN, CALD and CVN.

Serial Data Link Connector

The connection between the vehicle and the diagnostic tester shall comply with ISO DIS 15031-3 / SAE

J1962. Whereby the connector will be located in the passenger compartment in the area bounded by the

driver's end of the instrument panel to 300mm beyond the vehicle center line, attached to the instrument

panel and accessible from the driver's seat, and permit one handed / blind insertion of the mating

connector.

Serial Data Link Communication Protocol

The Communication Protocol used by the AML EOBD system will conform to ISO DIS 15031-4 / SAE

J1850, Class B Data Communication Network In terface (41.6kbps) / ISO DIS 15765-4 Diagnostics on

Controller Area Network (CAN).

Basic diagnostic data and bi-directional control inform ation will be provided using the format and units as

described in ISO DIS 15031-5 / SAE J1979 and will be av ailable to Test equipment and diagnostics tools

meeting the requirements of ISO DIS 15031-4 / SAE J1850.

Page 886 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 41 of 43

X P1431 Misfire Monitor Disabled; unable to Learn Trigger Wheel Profile

P1432 Thermostat Heater Control Circuit

P1460 Wide Open Throttle A/C Cut-out Circuit

P1461 A/C Pressure Sensor Circuit High Input

P1462 A/C Pressure Sensor Circuit Low Input

P1463 A/C Pressure Sensor Insufficient Pressure Change

P1464 A/C Demand Out of Self Test Range

P1500 Vehicle Speed Sensor

P1501 Vehicle Speed Sensor Out of Self Test Range

P1549 Intake Manifold Communica tion Control Circuit (Bank 1)

P1572 Brake system input failure (BLS failed then BPS failed)

P1610 Interactive Reprogramming Code – Replace Module

P1611 Interactive Reprogramming Code – Diagnose Further

P1615 Interactive Reprogramming Code – Erase Error

P1616 Interactive Reprogramming Code – Erase Error, Low Voltage

P1617 Interactive Reprogramming Code – Block Program Error

P1618 Interactive Reprogramming Code – Block Program Error, Low Voltage

P1631 Main Relay (Power Hold)

X P1633 Keep Alive Power Voltage too Low

P1635 Tyre/Axle Out of Acceptable Range

P1639 Vehicle Identification (VID) Block Corrupted. Not Programmed

X P1656 CAN Link PCM/PCM Circuit/Network

P1703 Brake switch out of self test range

P1709 Park/Neutral Position Switch Out of Self Test Range

X P2008 Intake Manifold Runner Control Open (Bank 1)

X P2100 Throttle Actuator Control Motor Circuit Open

X P2101 Throttle Actuator Control Motor Circuit Range/Performance

X P2107 Throttle actuator control motor processor

X P2110 Forced limit RPM mode

X P2111 Throttle actuator control system – stuck closed

X P2112 Throttle actuator control system – stuck open

P2121 Pedal position sensor D circuit range/performance

P2122 Pedal position sensor D circuit low input

P2123 Pedal position sensor D circuit high input

P2124 Pedal position sensor D circuit intermittent

P2126 Pedal position sensor E circuit range/performance

P2127 Pedal position sensor E circuit low input

P2128 Pedal position sensor E circuit high input

P2129 Pedal position sensor E circuit intermittent

P2135 Throttle position sensor A/B voltage correlation

P2138 Pedal position sensor D/E voltage correlation

X P2195 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Lean

X P2196 Lack of Heated Oxygen Sensor (Bank 2, Sensor 1) Switches, Sensor Indicates Lean

X P2197 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Rich

X P2198 Lack of Heated Oxygen Sensor (Bank 2, Sensor 1) Switches, Sensor Indicates Rich

Note.

X MIL codes

* Can be non-mil if below EOBD threshold.

Page 892 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

off/on <0.524 Intake air temp sensor OK (P0112/0113) Continuous during

SAIR operation

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda > bank2 lambdalambda

difference>0.435

Not in HEGO FMEM

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda < bank2 lambdalambda

difference>0.435

HEGO monitor complete

P2448 (Low

flow Bank1)

P2449

(Low flow

Bank2) SAIR off time before re-

enable (if SAIR is disabled

due to engine conditions)>3seconds

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

HEGO monitor complete

SAIR circuit ecu

output high/low P0412 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay

high output P2257 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay low

output P2258 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Modelled pump flow higher

than measured flow via HFM

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

>2secondsFootnote c)

Approximately 500

sec during

appropriate FTP74

conditions to

complete HEGO

monitorSecondary Air Monitor

Modelled pump flow higher

than measured flow via HFM Ratio of SAIR flow

difference at SAIR pump

off / on transitionoff/on >1.44

Outlet Hose

Disconnection Footnote l)

Continuous

(circuit checks)

Outlet Hose

Blockage

P0492

(Low flow

Bank2)

P0410

(Inlet hose

disconnection)

Secondary Air

System Insufficient

Flow

Closed loop bank1 lambda

correction at first switch AND

low measured flow via HFM

Closed loop bank2 lambda

correction at first switch AND

low measured flow via HFM

P0491

(Low flow

Bank1)

Time with SAIR active

4