relay ASTON MARTIN V8 VANTAGE 2010 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 693 of 947

Wiring and Circuit Protection (18.01)

Electric Distribution/E lectronic Control (18.00)

18-1-4 Workshop Manual May 2007

How to Read the Circuits

Below is a simple guide to what symbols mean on the circuit

diagrams. For some of the symbols there are descriptions as

to how they function.

Wires

Wires vary in size to allow diffe rent current to be carried. For

example a wire with a diamet er of 0.50mm (This is the

diameter of all the internal copper strands together) will

carry 11A (dependant on ambient temperature) whilst a wire

with a diameter of 2.00mm will carry 25A.

Twisted Wires

The ‘figure of 8’ shown on circuits as below denotes a

twisted wire and shows the wires that are twisted together.

A wire generates a certain amount of ‘electrical noise’ when

a current is passed through it. By twisting the 2 wires

together the ‘electrical noise’ is cancelled out on each wire

by the opposing wire. This is used more on sensors and

audio speakers.

Screened and Twisted Screen Wires

The signals through a wire can be affected by externally

generated electrical noise. To reduce the external

interference the wires are placed inside a conductive sleeve.

One end of the conductive sleeve is always open whilst the

other end can be terminated to a ground, to a component,

or left open.

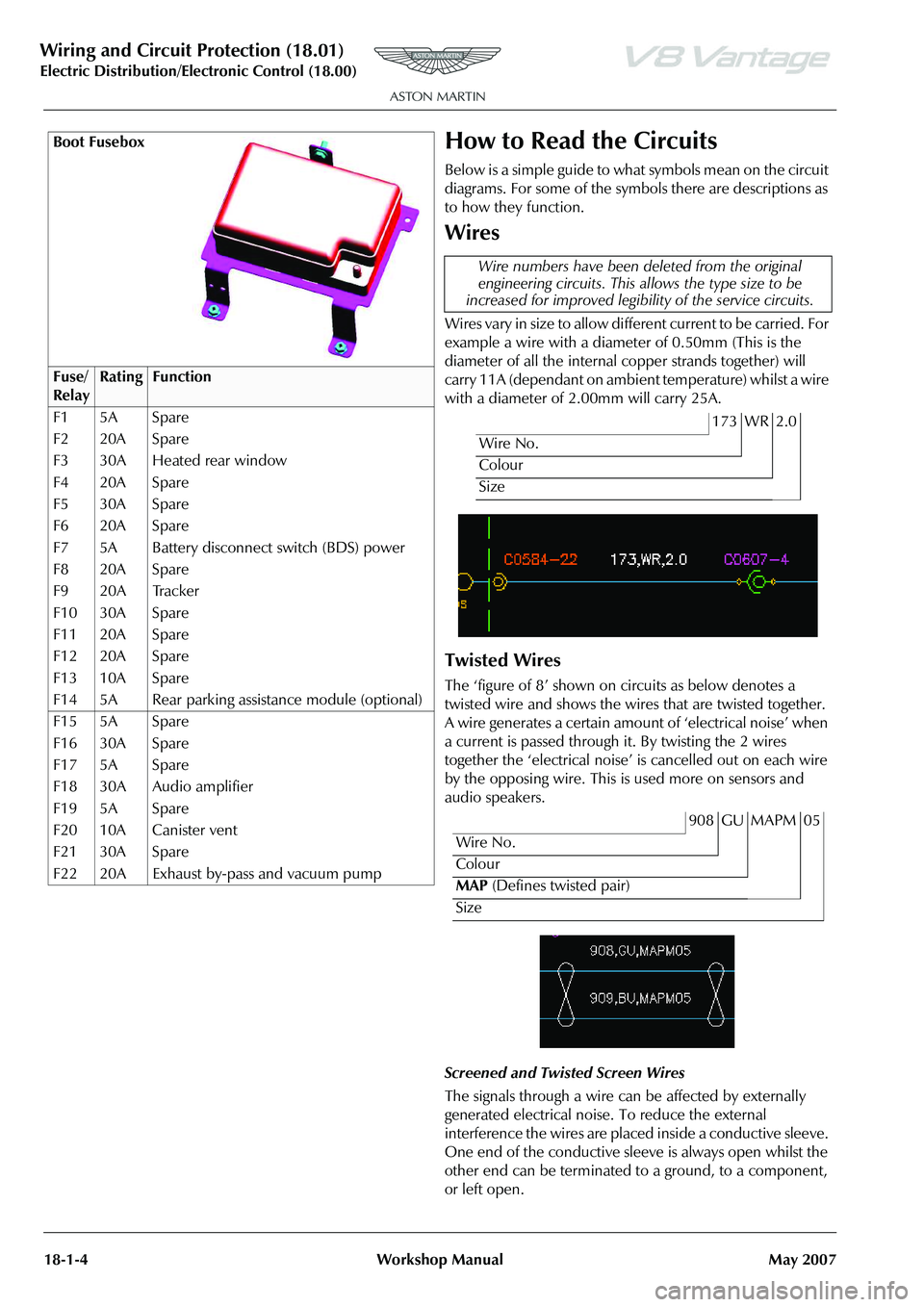

Boot Fusebox

Fuse/

RelayRatingFunction

F1 5A Spare

F2 20A Spare

F3 30A Heated rear window

F4 20A Spare

F5 30A Spare

F6 20A Spare

F7 5A Battery disconnect switch (BDS) power

F8 20A Spare

F9 20A Tracker

F10 30A Spare

F11 20A Spare

F12 20A Spare

F13 10A Spare

F14 5A Rear parking assistance module (optional)

F15 5A Spare

F16 30A Spare

F17 5A Spare

F18 30A Audio amplifier

F19 5A Spare

F20 10A Canister vent

F21 30A Spare

F22 20A Exhaust by-pass and vacuum pump

Wire numbers have been deleted from the original

engineering circuits. This al lows the type size to be

increased for improved legibil ity of the service circuits.

173 WR 2.0

Wire No.

Colour

Size

908 GU MAPM 05

Wire No.

Colour

MAP (Defines twisted pair)

Size

Page 697 of 947

Wiring and Circuit Protection (18.01)

Electric Distribution/E lectronic Control (18.00)

18-1-8 Workshop Manual May 2007

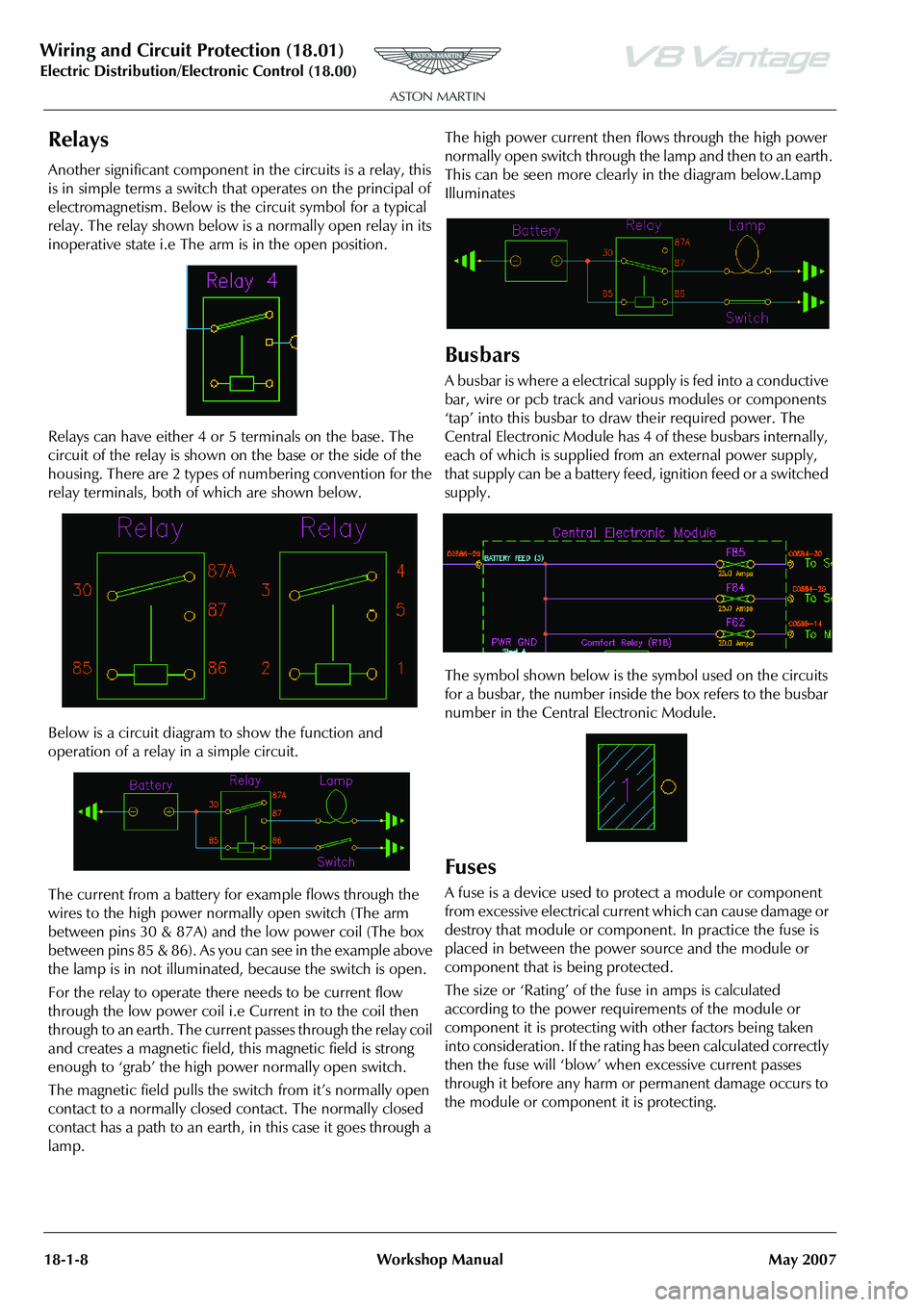

Relays

Another significant component in the circuits is a relay, this

is in simple terms a switch that operates on the principal of

electromagnetism. Below is the circuit symbol for a typical

relay. The relay shown below is a normally open relay in its

inoperative state i.e The arm is in the open position.

Relays can have either 4 or 5 terminals on the base. The

circuit of the relay is shown on the base or the side of the

housing. There are 2 types of numbering convention for the

relay terminals, both of which are shown below.

Below is a circuit diagram to show the function and

operation of a relay in a simple circuit.

The current from a battery for example flows through the

wires to the high power normally open switch (The arm

between pins 30 & 87A) and the low power coil (The box

between pins 85 & 86). As you can see in the example above

the lamp is in not illuminated, because the switch is open.

For the relay to operate there needs to be current flow

through the low power coil i.e Current in to the coil then

through to an earth. The current passes through the relay coil

and creates a magnetic field, this magnetic field is strong

enough to ‘grab’ the high power normally open switch.

The magnetic field pulls the switch from it’s normally open

contact to a normally closed contact. The normally closed

contact has a path to an earth, in this case it goes through a

lamp. The high power current then flows through the high power

normally open switch through the lamp and then to an earth.

This can be seen more clearly in the diagram below.Lamp

Illuminates

Busbars

A busbar is where a electrical

supply is fed into a conductive

bar, wire or pcb track and various modules or components

‘tap’ into this busbar to draw their required power. The

Central Electronic Module has 4 of these busbars internally,

each of which is supplied from an external power supply,

that supply can be a battery feed, ignition feed or a switched

supply.

The symbol shown below is the symbol used on the circuits

for a busbar, the number inside the box refers to the busbar

number in the Central Electronic Module.

Fuses

A fuse is a device used to protect a module or component

from excessive electrical current which can cause damage or

destroy that module or component. In practice the fuse is

placed in between the power source and the module or

component that is being protected.

The size or ‘Rating’ of the fuse in amps is calculated

according to the power requirements of the module or

component it is protecting with other factors being taken

into consideration. If the rating has been calculated correctly

then the fuse will ‘blow’ when excessive current passes

through it before any harm or permanent damage occurs to

the module or component it is protecting.

Page 709 of 947

Wiring and Circuit Protection (18.01)

Electric Distribution/E lectronic Control (18.00)

18-1-20 Workshop Manual May 2007

41. Remove harness/pipe cable ties (see Fig. 22).

42. Disconnect pump multiplug (see Fig. 23).43. Disconnect pump mult

iplug (see Fig. 24).

44. Remove pump relays.

45. Remove end cover (locating tabs x2).

46. Disconnect pump lucar conne ctors (x2) (see Fig. 25).

47. Remove harness from vehicle.

Installation

1. Install harness to approximate route on vehicle.

2. Connect pump lucar connectors.

3. Install pump end cover.

4. Connect pump multiplugs (x2).

5. Install pump relays (x2).

6. Install pump casing and secure velcro.

7. Install harness/pipe cable ties.

8. Install motor and casing under tonneau onto location posts.

9. Install cylinder pivot bracket and connect cylinder to bracket.

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Page 820 of 947

Electronics Training Programme

INPUTS

The Bluetooth system relies on a number of signals it receives either from the car (via hard wiring) or

the users phone (via wireless Bluetooth communication network).

The Bluetooth system will only function if the us ers mobile phone has Bluetooth enabled and it is

‘paired’ to the car. For more information refer to the user’s guide for your mobile phone.

V8 Vantage Power Supplies

Description Supplied From Source Protection

Wakeup signal Central Electronic Module Comfort Relay F68 (5 Amp)

Power supply 1 Central Electronic Module Interior Lights Relay F46 (5Amp)

Power supply 2 Central Electronic Module Interior Lights Relay F46 (5Amp)

DB9 Power Supplies

Description Supplied From Source Protection

Wakeup signal Central Electronic Module Comfort Relay F69 (5 Amp)

Power supply 1 Central Electronic Module Interior Lights Relay F46 (5Amp)

Power supply 2 Central Electronic Module Interior Lights Relay F46 (5Amp)

V8 Vantage Signal Inputs

Input Description Signal Characteristic

MIC In Input signal from microphone Varying current signal direct from microphone

Keypad Steering wheel controls input Variable resistance to earth signal

DB9 Signal Inputs

Input Description Signal Characteristic

MIC In + Input signal from microphone Varying current signal supplied via amplifier

MIC In - Input signal from microphone Varying current signal supplied via amplifier

Keypad Steering wheel controls inpu t Variable resistance to earth

Screens

Some of the signals in and out of the Bluetooth modu le require screening to avoid interference being

picked up. A signal screen is a single wire running along side t he signal wire(s) which will absorb

electro magnetic interference (EMI).

The Bluetooth module on the V8 Vantage features only one screen so as to protect the signal from the

microphone. This screen wire is simply an earth but it is also used as a datum from which to reference

the microphone signal.

The Bluetooth module used on DB9’s features two screens. One is as on the V8 Vantage but is used

only as a screen (because the microphone signal from the amplifie r has two signal wires) and no

datum is required. The second screen on the module is used to screen the ‘Lineout’ signals to the

amplifier. As with the microphone scr een this wire is connected to earth.

15

Page 836 of 947

Electronics Training Programme

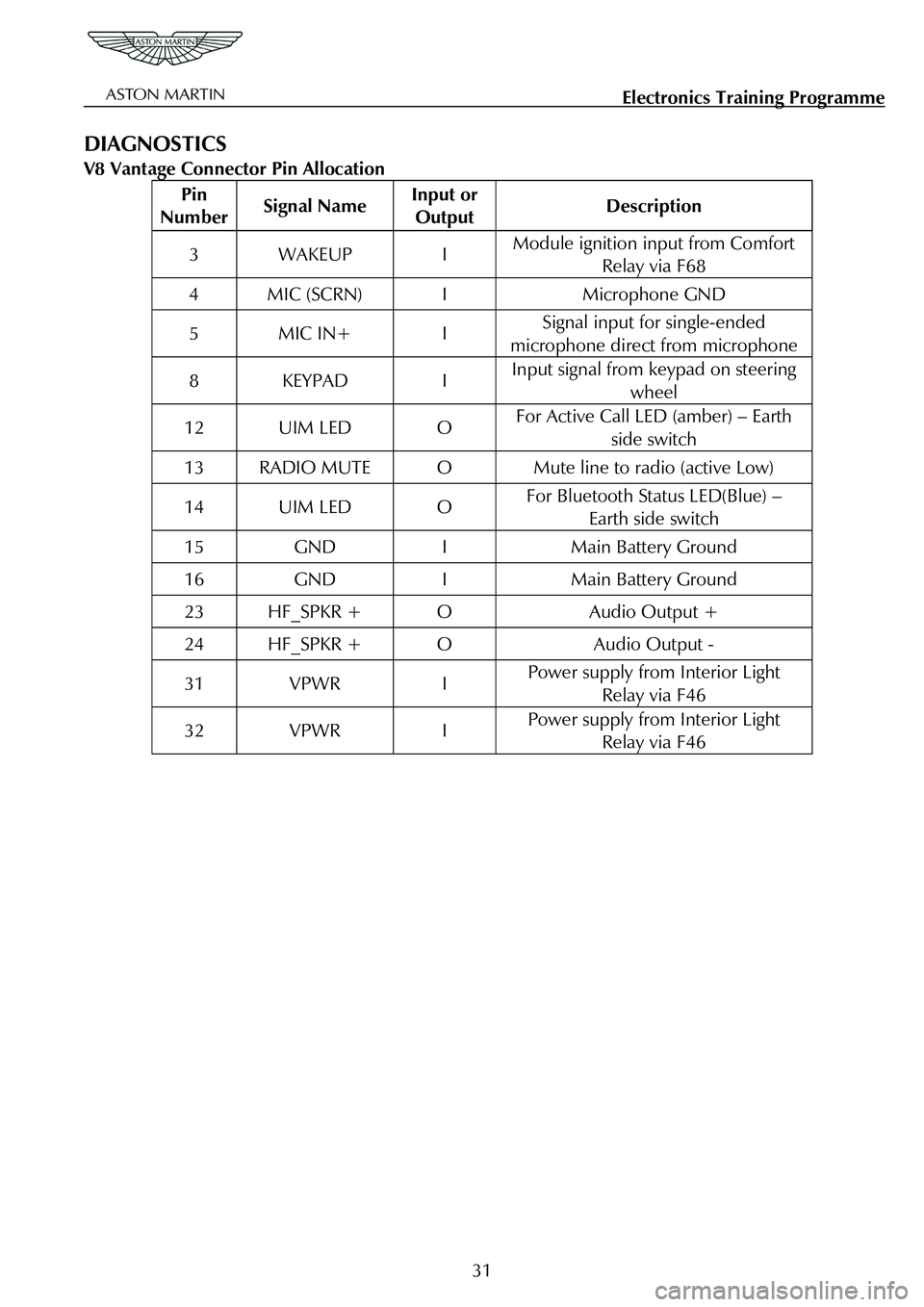

DIAGNOSTICS

V8 Vantage Connector Pin Allocation

Pin

Number Signal Name Input or

Output Description

3 WAKEUP I Module ignition input from Comfort

Relay via F68

4 MIC (SCRN) I Microphone GND

5 MIC IN+ I Signal input for single-ended

microphone direct from microphone

8 KEYPAD I Input signal from keypad on steering wheel

12 UIM LED O For Active Call LED (amber) – Earth

side switch

13 RADIO MUTE O Mute line to radio (active Low)

14 UIM LED O For Bluetooth Status LED(Blue) – Earth side switch

15 GND I Main Battery Ground

16 GND I Main Battery Ground

23 HF_SPKR + O Audio Output +

24 HF_SPKR + O Audio Output -

31 VPWR I Power supply from Interior Light Relay via F46

32 VPWR I Power supply from Interior Light Relay via F46

31

Page 837 of 947

Electronics Training Programme

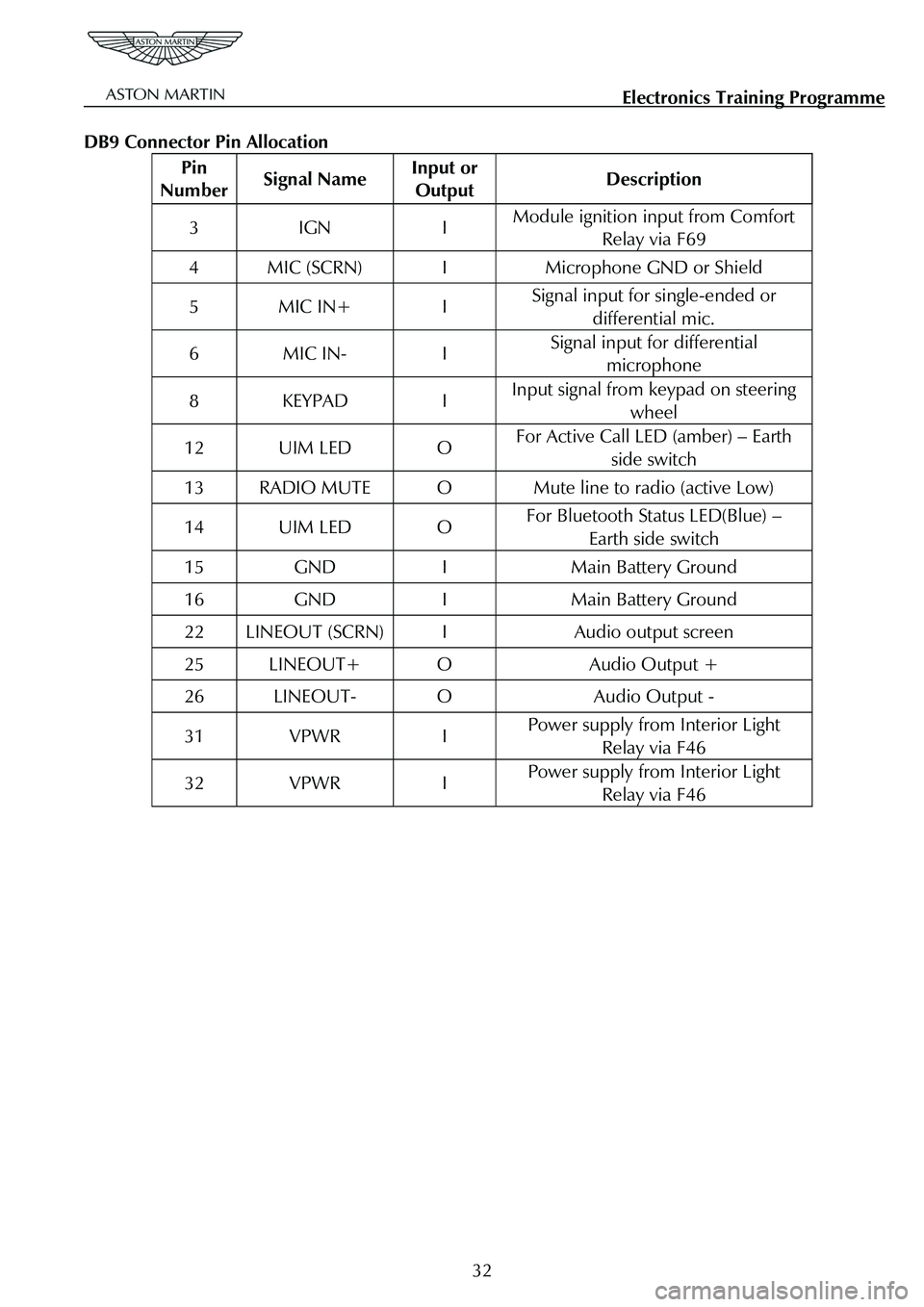

DB9 Connector Pin Allocation

Pin

Number Signal Name Input or

Output Description

3 IGN I Module ignition input from Comfort

Relay via F69

4 MIC (SCRN) I Microphone GND or Shield

5 MIC IN+ I Signal input for single-ended or

differential mic.

6 MIC IN- I Signal input for differential microphone

8 KEYPAD I Input signal from keypad on steering

wheel

12 UIM LED O For Active Call LED (amber) – Earth side switch

13 RADIO MUTE O Mute line to radio (active Low)

14 UIM LED O For Bluetooth Status LED(Blue) – Earth side switch

15 GND I Main Battery Ground

16 GND I Main Battery Ground

22 LINEOUT (SCRN) I Audio output screen

25 LINEOUT+ O Audio Output +

26 LINEOUT- O Audio Output -

31 VPWR I Power supply from Interior Light Relay via F46

32 VPWR I Power supply from Interior Light Relay via F46

32

Page 886 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 41 of 43

X P1431 Misfire Monitor Disabled; unable to Learn Trigger Wheel Profile

P1432 Thermostat Heater Control Circuit

P1460 Wide Open Throttle A/C Cut-out Circuit

P1461 A/C Pressure Sensor Circuit High Input

P1462 A/C Pressure Sensor Circuit Low Input

P1463 A/C Pressure Sensor Insufficient Pressure Change

P1464 A/C Demand Out of Self Test Range

P1500 Vehicle Speed Sensor

P1501 Vehicle Speed Sensor Out of Self Test Range

P1549 Intake Manifold Communica tion Control Circuit (Bank 1)

P1572 Brake system input failure (BLS failed then BPS failed)

P1610 Interactive Reprogramming Code – Replace Module

P1611 Interactive Reprogramming Code – Diagnose Further

P1615 Interactive Reprogramming Code – Erase Error

P1616 Interactive Reprogramming Code – Erase Error, Low Voltage

P1617 Interactive Reprogramming Code – Block Program Error

P1618 Interactive Reprogramming Code – Block Program Error, Low Voltage

P1631 Main Relay (Power Hold)

X P1633 Keep Alive Power Voltage too Low

P1635 Tyre/Axle Out of Acceptable Range

P1639 Vehicle Identification (VID) Block Corrupted. Not Programmed

X P1656 CAN Link PCM/PCM Circuit/Network

P1703 Brake switch out of self test range

P1709 Park/Neutral Position Switch Out of Self Test Range

X P2008 Intake Manifold Runner Control Open (Bank 1)

X P2100 Throttle Actuator Control Motor Circuit Open

X P2101 Throttle Actuator Control Motor Circuit Range/Performance

X P2107 Throttle actuator control motor processor

X P2110 Forced limit RPM mode

X P2111 Throttle actuator control system – stuck closed

X P2112 Throttle actuator control system – stuck open

P2121 Pedal position sensor D circuit range/performance

P2122 Pedal position sensor D circuit low input

P2123 Pedal position sensor D circuit high input

P2124 Pedal position sensor D circuit intermittent

P2126 Pedal position sensor E circuit range/performance

P2127 Pedal position sensor E circuit low input

P2128 Pedal position sensor E circuit high input

P2129 Pedal position sensor E circuit intermittent

P2135 Throttle position sensor A/B voltage correlation

P2138 Pedal position sensor D/E voltage correlation

X P2195 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Lean

X P2196 Lack of Heated Oxygen Sensor (Bank 2, Sensor 1) Switches, Sensor Indicates Lean

X P2197 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Rich

X P2198 Lack of Heated Oxygen Sensor (Bank 2, Sensor 1) Switches, Sensor Indicates Rich

Note.

X MIL codes

* Can be non-mil if below EOBD threshold.

Page 892 of 947

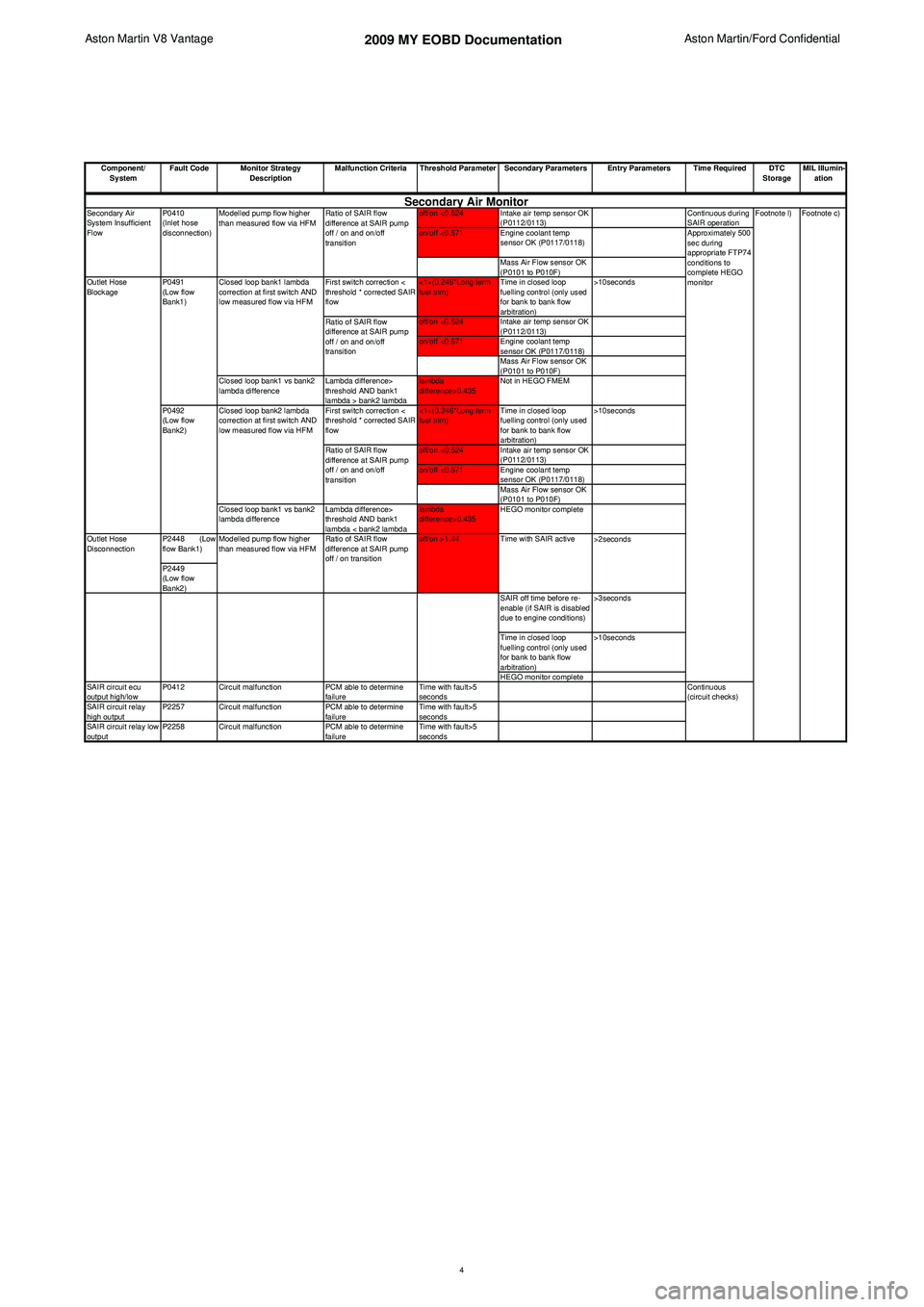

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

off/on <0.524 Intake air temp sensor OK (P0112/0113) Continuous during

SAIR operation

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda > bank2 lambdalambda

difference>0.435

Not in HEGO FMEM

First switch correction <

threshold * corrected SAIR

flow <1+(0.246*Long term

fuel trim)

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

off/on <0.524 Intake air temp sensor OK (P0112/0113)

on/off <0.671 Engine coolant temp sensor OK (P0117/0118)

Mass Air Flow sensor OK

(P0101 to P010F)

Closed loop bank1 vs bank2

lambda difference Lambda difference>

threshold AND bank1

lambda < bank2 lambdalambda

difference>0.435

HEGO monitor complete

P2448 (Low

flow Bank1)

P2449

(Low flow

Bank2) SAIR off time before re-

enable (if SAIR is disabled

due to engine conditions)>3seconds

Time in closed loop

fuelling control (only used

for bank to bank flow

arbitration) >10seconds

HEGO monitor complete

SAIR circuit ecu

output high/low P0412 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay

high output P2257 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

SAIR circuit relay low

output P2258 Circuit malfunction

PCM able to determine

failure Time with fault>5

seconds

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Modelled pump flow higher

than measured flow via HFM

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

Ratio of SAIR flow

difference at SAIR pump

off / on and on/off

transition

>2secondsFootnote c)

Approximately 500

sec during

appropriate FTP74

conditions to

complete HEGO

monitorSecondary Air Monitor

Modelled pump flow higher

than measured flow via HFM Ratio of SAIR flow

difference at SAIR pump

off / on transitionoff/on >1.44

Outlet Hose

Disconnection Footnote l)

Continuous

(circuit checks)

Outlet Hose

Blockage

P0492

(Low flow

Bank2)

P0410

(Inlet hose

disconnection)

Secondary Air

System Insufficient

Flow

Closed loop bank1 lambda

correction at first switch AND

low measured flow via HFM

Closed loop bank2 lambda

correction at first switch AND

low measured flow via HFM

P0491

(Low flow

Bank1)

Time with SAIR active

4

Page 909 of 947

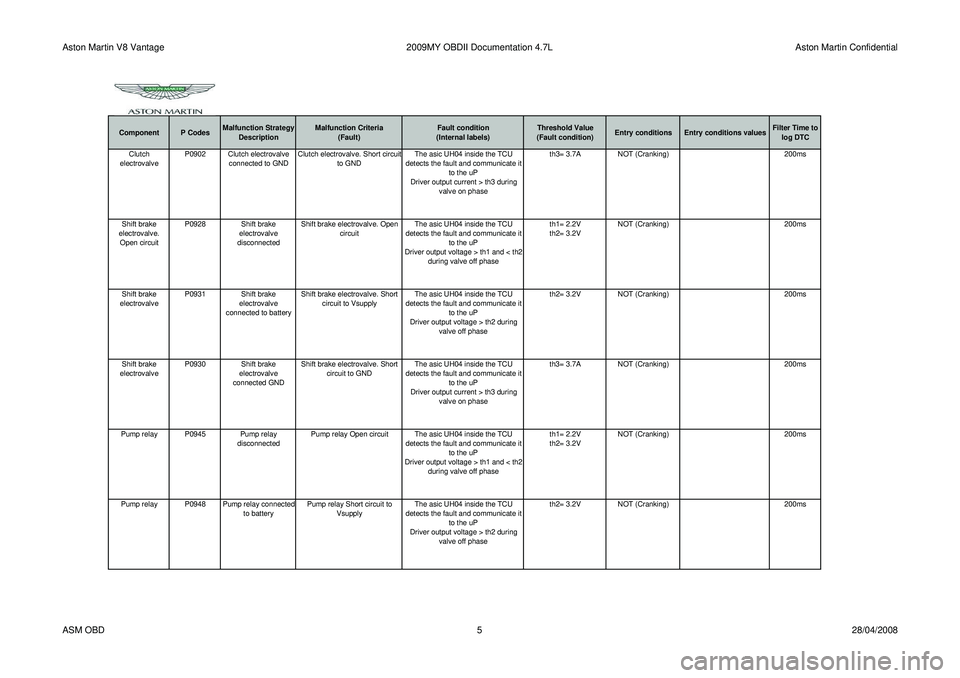

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCClutch

electrovalve P0902 Clutch electrovalve

connected to GND Clutch electrovalve. Short circuit

to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Shift brake

electrovalve. Open circuit P0928 Shift brake

electrovalve

disconnected Shift brake electrovalve. Open

circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Shift brake

electrovalve P0931 Shift brake

electrovalve

connected to battery Shift brake electrovalve. Short

circuit to Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

Shift brake

electrovalve P0930 Shift brake

electrovalve

connected GND Shift brake electrovalve. Short

circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Pump relay P0945 Pump relay disconnectedPump relay Open circuit The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th1 and < th2 during valve off phase th1= 2.2V

th2= 3.2V

NOT (Cranking)

200ms

Pump relay P0948 Pump relay connected to batteryPump relay Short circuit to

Vsupply The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output voltage > th2 during valve off phase th2= 3.2V

NOT (Cranking) 200ms

ASM OBD 528/04/2008

Page 910 of 947

Aston Martin V8 Vantage2009MY OBDII Documentation 4.7L Aston Martin Confidential

Component P CodesMalfunction Strategy

Description Malfunction Criteria

(Fault) Fault condition

(Internal labels) Threshold Value

(Fault condition) Entry conditions Entry conditions values Filter Time to

log DTCPump relay P0947 Pump relay connected GNDPump relay Short circuit to GND The asic UH04 inside the TCU

detects the fault and communicate it to the uP

Driver output current > th3 during valve on phase th3= 3.7A

NOT (Cranking) 200ms

Clutch system P186D Clutch or actuator or valve damagedClutch not opening before gear

shifting Clutch not open in a timeout timeout = 500ms (Gear shifting in

progress) AND

(Clutch opening

Gear Box system P1734 Mechanical or hydraulic problemGear Box. Disengage failed

(mechanical causes) Gear not disengaged in a timeout timeout = 500ms (Gear shifting phase)

AND (disengage phase)

Gear Box system P1701 Mechanical or hydraulic problemGear Box. Wrong gear

engagement The gear which is going to be

engaged is not the requested one (Gear shifting phase)

Hydraulic circuit P0868 Hydraulic leakage Hydraulic circuit. Pressure low Comparison between sensor pressure signal and threshold = f(oil temperature)

pressure < th Th= 25 bar @ -30°C

Th= 40 bar @120°C linear interpolation (Engine ON) AND

NOT (cranking) 200ms

Power grounds P1710 Power grounds. Disconnection both ground pins Power grounds. Disconnection

both ground pins The diagnosis is based on the batter

y

voltage modification during the

activation of the clutch electrovalve. Ubatt < Ubatt0 - DltUbatt Ubatt0 = Ubatt before

starting the testDltUbatt = 2,5V Wake-up phase

ASM OBD

628/04/2008