spark plugs ASTON MARTIN V8 VANTAGE 2010 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 752 of 947

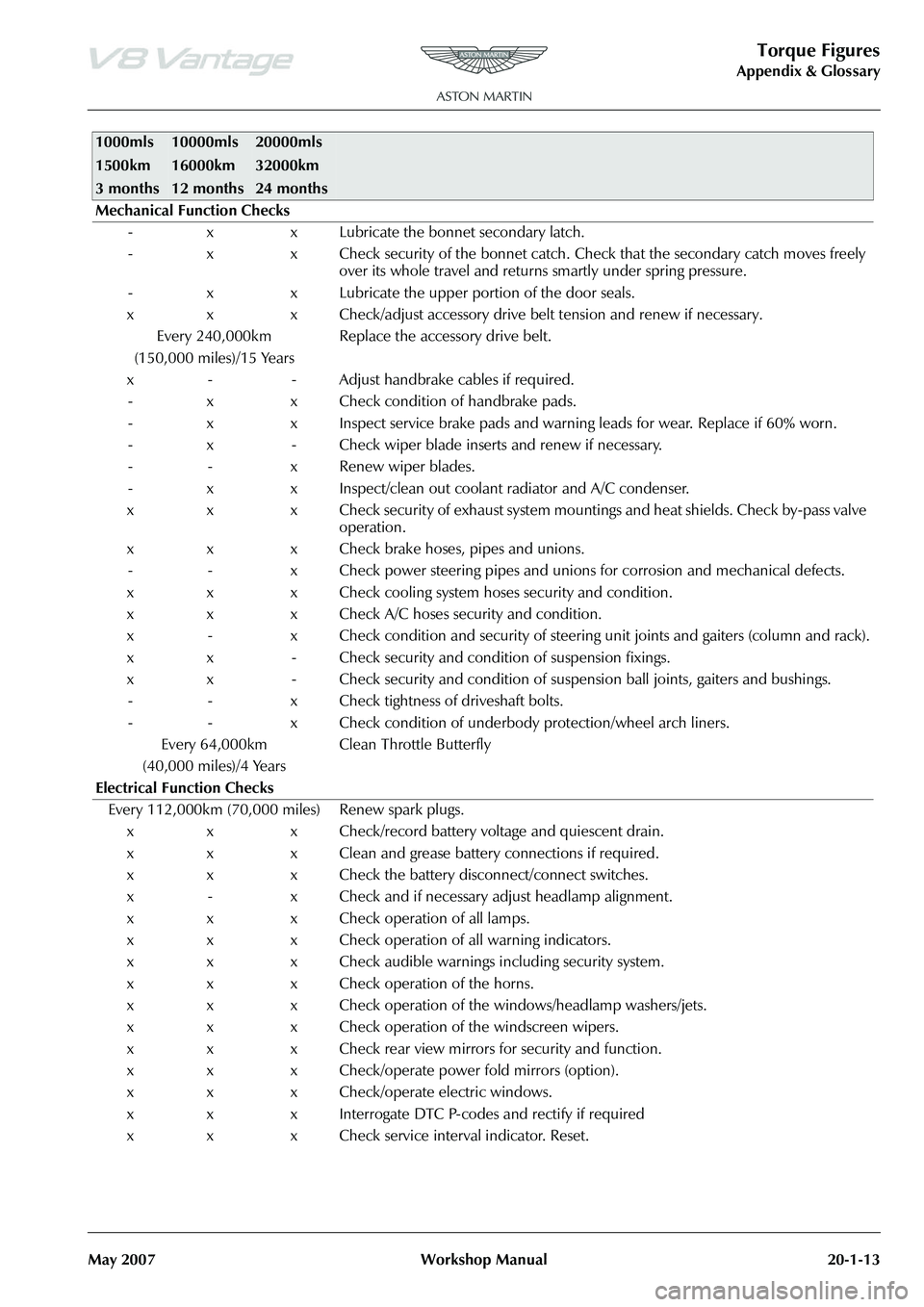

Torque Figures

Appendix & Glossary

May 2007 Workshop Manual 20-1-13

Mechanical Function Checks - x x Lubricate the bonnet secondary latch.

- x x Check security of the bonnet catch. Ch eck that the secondary catch moves freely

over its whole travel and returns smartly under spring pressure.

- x x Lubricate the upper portion of the door seals.

x x x Check/adjust accessory drive belt tension and renew if necessary. Every 240,000km

(150,000 miles)/15 Years Replace the accessory drive belt.

x - - Adjust handbrake cables if required. - x x Check condition of handbrake pads.

- x x Inspect service brake pads and warnin g leads for wear. Replace if 60% worn.

- x - Check wiper blade inserts and renew if necessary.

- - x Renew wiper blades.

- x x Inspect/clean out coolant radiator and A/C condenser.

x x x Check security of exhaust system mountings and heat shields. Check by-pass valve operation.

x x x Check brake hoses, pipes and unions. - - x Check power steering pipes and unions for corrosion and mechanical defects.

x x x Check cooling system hoses security and condition.

x x x Check A/C hoses security and condition.

x - x Check condition and security of steering unit joints and gaiters (column and rack).

x x - Check security and condition of suspension fixings.

x x - Check security and condition of susp ension ball joints, gaiters and bushings.

- - x Check tightness of driveshaft bolts.

- - x Check condition of underbody protection/wheel arch liners.

Every 64,000km

(40,000 miles)/4 Years Clean Throttle Butterfly

Electrical Function Checks Every 112,000km (70,000 miles) Renew spark plugs. x x x Check/record battery voltage and quiescent drain.

x x x Clean and grease battery connections if required.

x x x Check the battery disconnect/connect switches.

x - x Check and if necessary adjust headlamp alignment.

x x x Check operation of all lamps.

x x x Check operation of all warning indicators.

x x x Check audible warnings including security system.

x x x Check operation of the horns.

x x x Check operation of the windows/headlamp washers/jets.

x x x Check operation of the windscreen wipers.

x x x Check rear view mirrors for security and function.

x x x Check/operate power fold mirrors (option).

x x x Check/operate electric windows.

x x x Interrogate DTC P-codes and rectify if required

x x x Check service interval indicator. Reset.

1000mls

1500km

3 months10000mls

16000km

12 months20000mls

32000km

24 months

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

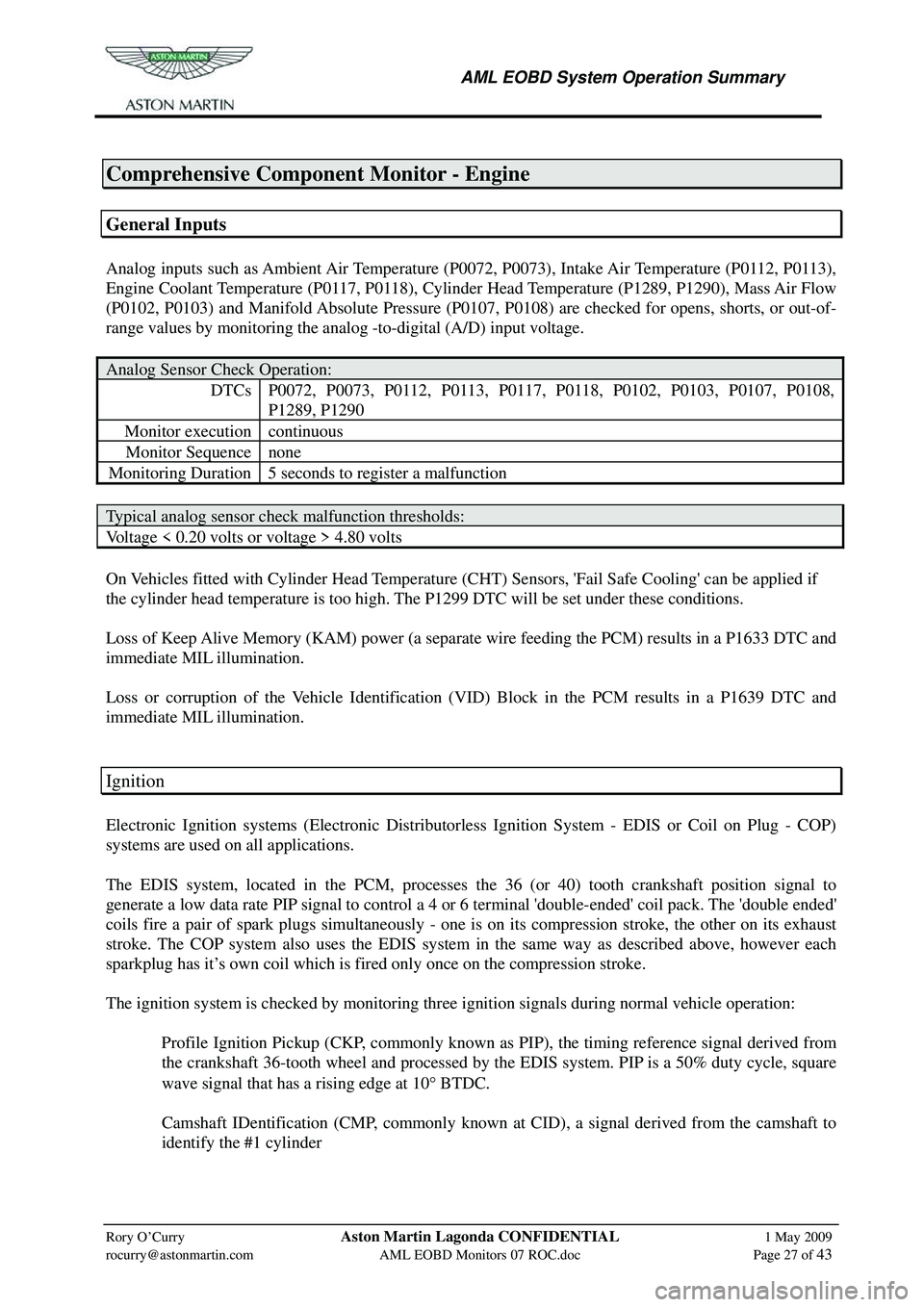

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder