wheel alignment ASTON MARTIN V8 VANTAGE 2010 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 410 of 947

Power Conversion (03.11)

Engine (03.00)3-11-38 Workshop Manual May 2007

3. Position new oil seal (fitted dry). Install oil seal in timing

cover using tool (303-750) (see Figure 3).

Figure 3

4. Remove crankshaft oil seal protector.

5. Install crankshaft pulle y (see Workshop Manual

procedure 03.11.DP Pulley Assembly - Crankshaft

Damper - Renew With Engine Removed).

Crankshaft Rear Oil Seal-Renew (with

Engine Removed

)

Removal

1. Remove engine assembly (see Workshop Manual

procedure 03.00.AA Engi ne Assembly - Renew).

2. Remove bolts (x2), inspection cover to lower crankcase, remove cover.

3. Install tool (303-1185) to restrain flywheel, install and tighten bolts (x2).

4. Remove bolts (x6), clutch cover to flywheel.

5. Release clutch cover from dowels (x3), remove clutch cover, collect drive plate.

6. Remove and discard bolts (x8), flywheel to crankshaft flange.

7. Remove bolts (x2), collect tool (303-1185).

8. Release flywheel from dowel, remove flywheel.

9. Position tool (303-1189) to crankshaft flange, screw in

alignment bolts (x2) 1.5 turns (only).

10. Use tool and pierce holes (x3) in oil seal through holes in special tool for self-tapping screws

11. Install and tighten self-tapping screws (x3) into oil seal.

12. Tighten centre bolt of tool (303-1189) and withdraw crankshaft oil seal.

13. Remove oil seal from special tool, discard oil seal.

Installation

1. Clean oil seal aperture in cylinder block.

2. Ensure that oil seal protector is positioned correctly and install oil seal onto crankshaft flange.

3. Install tool (303-1189) to crankshaft, position nuts on

tool against oil seal.

4. Ensure that oil seal and special are parallel to rear of engine.

5. To install oil seal, tighten nuts alternately on tool (303- 1189) until oil seal correctly seated.

6. Remove special tool from crankshaft.

7. Check that the oil seal is located correctly.

8. Clean flywheel and mating face on crankshaft.

9. Install flywheel, align to dowel on crankshaft flange.

10. Install new bolts (x8), install tool (303-1185) to restrain flywheel. Torque tighten bolts (x8) in the correct

sequence.

11. Clean clutch cover and drive plate.

12. Install clutch assembly on flywheel, align to dowels (x3).

13. Install bolts (x6), install clutch alignment tool, evenly torque tighten bolts (x6) in a diagonal sequence.

Remove clutch alignment tool.

14. Remove bolts (x2), collect tool (303-1185).

15. Install inspection cover, install and torque tighten bolts (x2).

16. Install engine assembly (see Workshop Manual procedure 03.00.AA Engine Assembly - Renew).

Repair Operation Time (ROT)

A0311247

Caution

Do not use any lubricant on cr ankshaft oil seals or seal

protectors. Make sure all co mponents are clean and dry

Caution

Alternate nut tightening to correctly seat the crankshaft rear oil seal.

Page 425 of 947

Issue 6, May 2010 Workshop Manual 1-1-1

Suspension (04.00)

Contents

Road Wheel Alignment (04.00) ............................. 4-0-2Specifications ......................................................... 0-2

Maintenance ........................................................... 0-2All Wheel Alignment .............................................. 0-2

Front Suspension (04.01)....................................... 4-1-1 Description ............................................................. 1-1Suspension Arms .................................................... 1-1

Anti-roll Bar ........................................................... 1-1

Vertical link............................................................ 1-1

Specifications.......................................................... 1-1

Symptoms ............................................................... 1-2

Maintenance ........................................................... 1-3 RH/LH Front Hub and Bearing Assembly

- Renew ................................................................. 1-3

RH/LH Lower Front Suspension Arm Assembly

- Renew ................................................................. 1-4

RH/LH Upper Front Suspension Arm Assembly

- Renew ................................................................. 1-4

Front Anti-Roll Bar - Renew ................................... 1-5

Front Pair Anti-Roll Bar Bushing - Renew................ 1-5

RH/LH Front Anti-Roll Bar Link - Renew ................ 1-5

RH/LH Front Hub Vertical Link - Renew ................ 1-6

Front Suspension Sensor Assembly-Renew ............. 1-7

Rear Suspension (04.02) ........................................ 4-2-1 Description ............................................................. 2-1Suspension Arms .................................................... 2-1

Anti-roll Bar ........................................................... 2-1

Vertical Link........................................................... 2-1

Specifications.......................................................... 2-2

Maintenance ........................................................... 2-2 RH/LH Rear Hub and Bearin g Assembly-Renew ..... 2-2

RH/LH Rear Lower Arm Assembly-Renew .............. 2-2

RH/LH Upper Rear Arm Assembly-Renew .............. 2-3

RH/LH Toe Control Rear Arm Assembly-Renew ..... 2-3

Rear Anti-Roll Bar-Renew ...................................... 2-3

Rear Pair-Anti-Roll Bar Bushing-Renew .................. 2-4

RH/LH Rear Anti-Roll Bar Link-Renew ................... 2-4

RH/LH Rear Hub Vertical Link-Renew.................... 2-4

Rear Suspension Sensor Assembly-Renew .............. 2-5

Shock Absorber System (04.03) ............................. 4-3-1 Description ............................................................. 3-1

Specifications.......................................................... 3-1

Maintenance ........................................................... 3-1Front Spring and Damper Assembly-Pair-Renew .... 3-1

Front Spring-Pair-Renew ........................................ 3-3

Front Damper-Pair-Renew ..................................... 3-4

Rear Spring and Damper Assembly-Pair-Renew...... 3-5

Rear Spring-Pair-Renew ......................................... 3-7

Rear Damper-Pair-Renew ...................................... 3-9

Road Wheels and Tyres (04.04)............................. 4-4-1 Specifications.......................................................... 4-1USA Tyre Gradings................................................. 4-2

Tread Wear ........................................................... 4-2

Traction ................................................................. 4-2 Temperature .......................................................... 4-2

Maintenance ........................................................... 4-3 Safety .................................................................... 4-3

Tyre Replacement and Wheel Interchanging ......... 4-3

Winter (Snow) tyres ................................................ 4-4 Recommended Winter Wheel and

Tyre Combination .................................................. 4-4

Inspection and Verification . ................................... 4-4

Tyre Wear ............................................................. 4-4

Tyre Damage ......................................................... 4-6

Repairs .................................................................. 4-7

Care of Alloy Road Wheels .................................... 4-7

Road Wheel Alignment .......................................... 4-7

Road Wheel and Tyre Balance ............................... 4-8

Torque Tightening of Road Wheel Nuts ................ 4-8

Tyre Pressure Sensing (Option).............................. 4-9 Pressure Sensing with Wint er Wheels and Tyres ..... 4-9

Warnings ............................................................... 4-9

Display Unit ........................................................ 4-10

System Programming ........................................... 4-10

Page 426 of 947

Road Wheel Alignment (04.00)

Suspension (04.00)1-1-2 Workshop Manual Issue 6, May 2010

Suspension (04.00)

Road Wheel Alignment (04.00)

Specifications

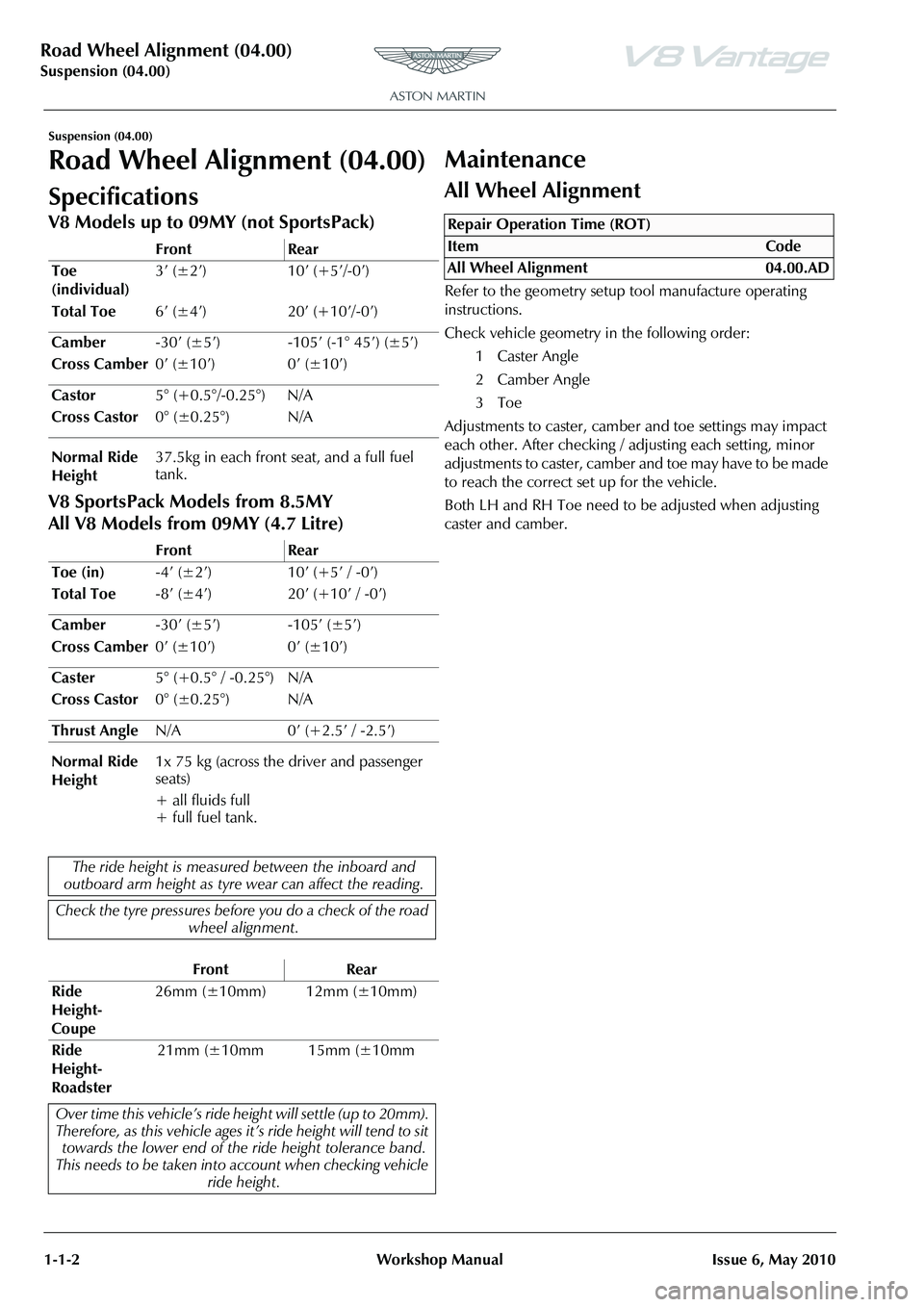

V8 Models up to 09MY (not SportsPack)

V8 SportsPack Models from 8.5MY

All V8 Models from 09MY (4.7 Litre)

Maintenance

All Wheel Alignment

Refer to the geometry setup tool manufacture operating

instructions.

Check vehicle geometry in the following order:

1 Caster Angle

2 Camber Angle

3Toe

Adjustments to caster, camber and toe settings may impact

each other. After checking / adjusting each setting, minor

adjustments to caster, camber and toe may have to be made

to reach the correct set up for the vehicle.

Both LH and RH Toe need to be adjusted when adjusting

caster and camber.

Front Rear

Toe

(individual) 3’ (±2’) 10’ (+5’/-0’)

Total Toe 6’ (±4’) 20’ (+10’/-0’)

Camber -30’ (±5’) -105’ (-1° 45’) (±5’)

Cross Camber 0’ (±10’) 0’ (±10’)

Castor 5° (+0.5°/-0.25°) N/A

Cross Castor 0° (±0.25°) N/A

Normal Ride

Height 37.5kg in each front seat, and a full fuel

tank.

Front Rear

Toe (in) -4

Page 428 of 947

Front Suspension (04.01)

Suspension (04.00)4-1-2 Workshop Manual November 2008

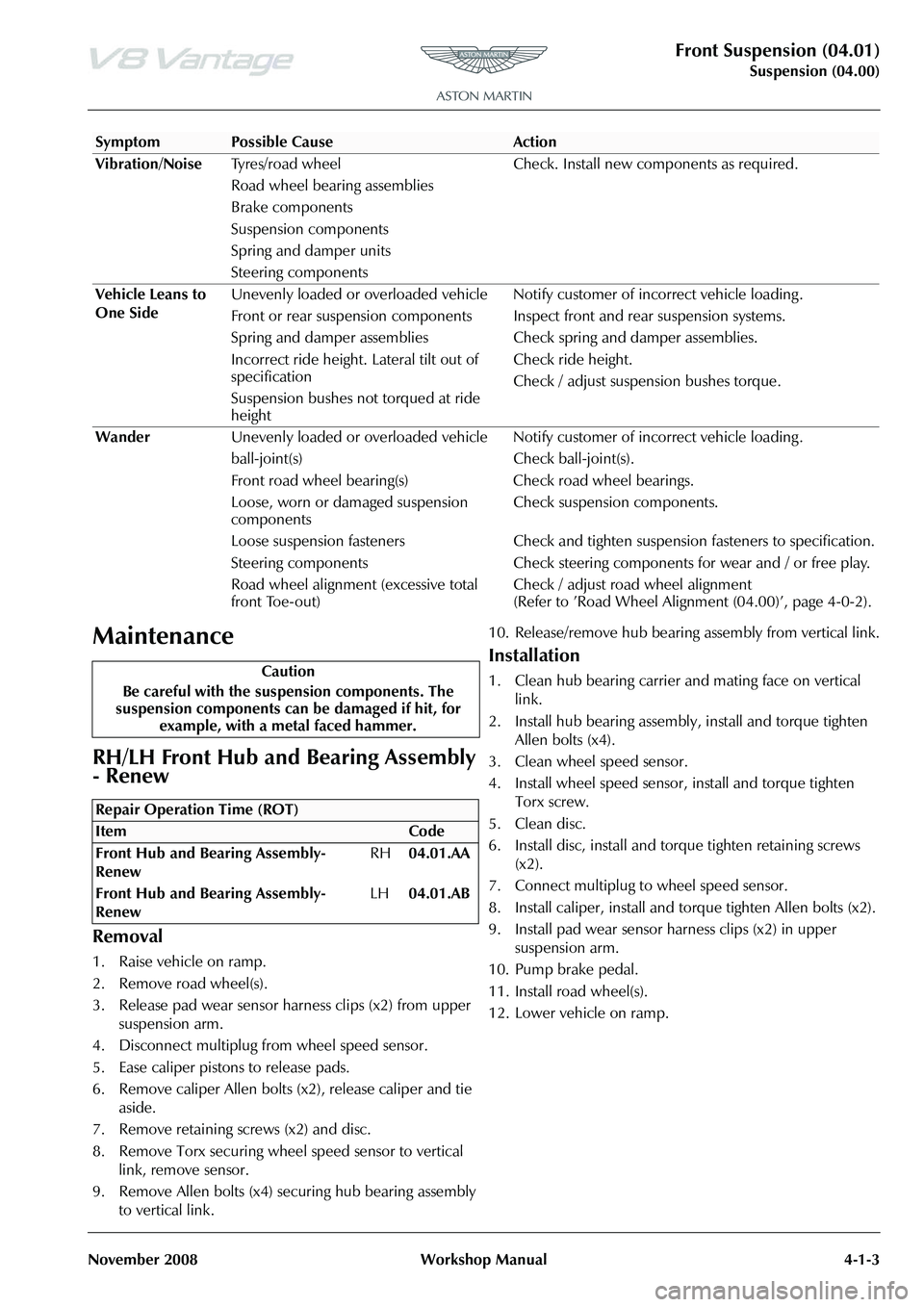

Symptoms

SymptomPossible CauseAction

Crabbing Front or rear suspension components/road

wheel alignment Inspect front and rear suspension systems.

Check / adjust road wheel alignment

Drive axle damaged New drive axle.

Front ‘Bottoming’

or Riding Low Spring(s)

Dampers Check ride height.

Check dampers.

Drift/Pull Unequal tyre pressure Check / adjust tyre pressures.

Inspect tyre for excessive wear.

Incorrect road wheel alignment Check / adjust road wheel alignment.

Tyres Check / adjust tyre pressu res. Inspect tyre for excessive

wear.

Unevenly loaded or overloaded vehicle Not ify customer of incorrect vehicle loading .

Damaged steering components Check steering sy stem for mechanical or hydraulic bias.

Brake drag Check brakes.

Check steering system for mechanical or hydraulic bias.

Rough Ride Spring(s) Check springs.

Shock absorber(s) Check shock absorbers.

Incorrect Tyre

Wear Incorrect tyre pressure Check and adju

st tyre pressure. Inspect tyre for

excessive wear.

Excessive front or rear Toe (rapid inner or

outer edge wear) Check and adjust road wheel alignment (Refer to ’Road

Wheel Alignment (04.00)’, page 4-0-2).

Excessive negative or positive camber

(rapid or outer edge wear) Check and adjust road wheel alignment (Refer to ’Road

Wheel Alignment (04.00)’, page 4-0-2).

Tyres out of balance (tyres cupped or

dished) Balance tyres.

‘Shimmy’ or ‘Road

Wheel Tramp’ Loose road wheel nut(s) Check and tighten road wheel nuts to specification.

Loose front suspension Check and tighten

suspension fixings to specification.

Front road wheel bearing(s) Check road wheel bearings.

Road wheel / tyres Check road wheels / tyres.

Shock absorber(s) Check shock absorbers.

Spring(s) Check springs.

Loose, worn or damaged ball -joint(s) Check ball-joint(s).

Loose, worn or damaged steering

components Check components.

Front road wheel alignment Check and adjust road wheel alignment (Refer to ’Road Wheel Alignment (04.00)’, page 4-0-2).

Worn or damaged suspension bushes Check suspension bushes

Poor ‘Return

ability’ of Steering ball-joints Check ball-joint(s).

Steering components Check for excessive friction in steering system.

Check tyre pressures

Steering Wheel

Off-Centre Unequal front or rear Toe settings Check and adjust road wheel alignment.

Steering components Check and install new components as required.

Sway or Roll Overloaded, unevenly or incorrectly

loaded vehicle Notify customer of incorrect vehicle loading

Loose road wheel nut(s) Check. Tighten road wheel nut(s) to specification

Spring(s) Check. Install new springs as required.

Shock absorber(s) Check. Install new shock absorbers as required.

Loose front stabilizer bar or rear stabilizer

bar Check. Tighten anti-roll bar to specification.

Page 429 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-3

Maintenance

RH/LH Front Hub and Bearing Assembly

- Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Release pad wear sensor harness clips (x2) from upper suspension arm.

4. Disconnect multiplug from wheel speed sensor.

5. Ease caliper pistons to release pads.

6. Remove caliper Allen bolts (x2), release caliper and tie

aside.

7. Remove retaining screws (x2) and disc.

8. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

9. Remove Allen bolts (x4) securing hub bearing assembly to vertical link. 10. Release/remove hub bearing assembly from vertical link.

Installation

1. Clean hub bearing carrier and mating face on vertical

link.

2. Install hub bearing assembly, install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Clean disc.

6. Install disc, install and torque tighten retaining screws (x2).

7. Connect multiplug to wheel speed sensor.

8. Install caliper, install and to rque tighten Allen bolts (x2).

9. Install pad wear sensor harness clips (x2) in upper suspension arm.

10. Pump brake pedal.

11. Install road wheel(s).

12. Lower vehicle on ramp.

Vibration/Noise

Tyres/road wheel

Road wheel bearing assemblies

Brake components

Suspension components

Spring and damper units

Steering components Check. Install new components as required.

Vehicle Leans to

One Side Unevenly loaded or overloaded vehicle Notif

y customer of incorrect vehicle loading .

Front or rear suspension components Inspect front and rear suspension systems.

Spring and damper assemblies Check spring and damper assemblies.

Incorrect ride height. Lateral tilt out of

specification

Suspension bushes not torqued at ride

height Check ride height.

Check / adjust suspension bushes torque.

Wander Unevenly loaded or overloaded vehicle Notif y customer of incorrect vehicle loading .

ball-joint(s) Check ball-joint(s).

Front road wheel bearing(s) Check road wheel bearings.

Loose, worn or damaged suspension

components Check suspension components.

Loose suspension fasteners Check and tighten suspension fasteners to specification.

Steering components Check steering components for wear and / or free play.

Road wheel alignment (excessive total

front Toe-out) Check / adjust road wheel alignment

(Refer to ’Road Wheel Alignment (04.00)’, page 4-0-2).

SymptomPossible CauseAction

Caution

Be careful with the suspension components. The

suspension components can be damaged if hit, for example, with a metal faced hammer.

Repair Operation Time (ROT)

Page 430 of 947

Front Suspension (04.01)

Suspension (04.00)4-1-4 Workshop Manual November 2008

RH/LH Lower Front Suspension Arm

Assembly - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut/washer securing anti-roll bar link to lower suspension, release link from arm.

4. Remove nut/bolt securing damper to lower suspension arm, release damper from mounting.

5. Remove nut securing lower suspension arm ball-joint to vertical link.

6. Install tool (204 - 523) ba ll-joint remover and release

lower suspension ball-joi nt from vertical link.

7. Mark fitted positions of cam washers on lower suspension arm inner fixings to aid assembly purpose.

8. Remove nuts/bolts, cam washers (x2), securing lower suspension arm to subframe.

9. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link and subframe

2. Install lower suspension arm in subframe.

3. Install cam washers, bolts/nuts (x2). Align cam washers to marks. Do not torque tighten at this stage.

4. Install lower suspension arm ball-joint in vertical link. Install and torque tighten nut.

5. Align damper to mounting, install bolt/nut. Do not torque tighten at this stage.

6. Install anti-roll bar link, install washer/nut. Do not torque tighten at this stage.

7. Final tightening of suspen sion components must be

carried out with the suspensi on arms at normal ride

height.

8. Install road wheel(s).

9. Lower vehicle on ramp.

10. Torque tighten suspension nuts/bolts.

11. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check and Adjust).

RH/LH Upper Front Suspension Arm

Assembly - Renew

Removal

1. Raise the vehicle and make it safe.

2. Remove the road wheel for the applicable suspension arm.

3. Disconnect the electrical connector from the ABS sensor.

4. Release the three sensor harness clips from the upper suspension arm and the vertical link.

5. Remove the two Torx screws that attach the engine cross brace to the mounting.

6. Remove the two nuts and two bolts that attach the upper suspension arm to the body.

7. Release the suspension arm from the body.

8. Remove the three nuts that attach the damper top mounting.

9. Remove the mounting for the engine cross brace.

10. Remove the nut and bolt that attaches the damper to its lower mounting.

11. Remove spring/damper assembly.

12. Remove the nut that attaches the ball-joint for the upper suspension arm to the vertical link.

13. Install tool (204 - 523 - ball-joint remover) and release the ball-joint from vertical link.

14. Remove the upper suspension arm assembly.

Installation

1. Clean the upper suspension arm and the mating faces on the body and the vertical link.

2. Install the upper suspension arm to vertical link. Install the nut but do not torque tighten at this step.

3. Install spring/damper assembly.

4. Install the cross-brace support.

5. Install the three nuts but do not torque tighten at this step.

6. Align the damper to the lower mounting, install bolt/nut. Do not torque tighten at this step.

7. Put the upper suspension arm in positionon the body.

8. Install bolts and nuts but do not torque tighten at this step.

9. Connect the electrical connector to the ABS sensor.

Repair Operation Time (ROT)Repair Operation Time (ROT)

ItemCode

Upper Front Suspension Arm

Assembly-Renew RH

04.01.AE

Upper Front Suspension Arm

Assembly-Renew LH

04.01.AF

Caution

Be carefulthat you do not damage the ball-joint rubber

boot when you use the special tool.

Page 431 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-5

10. Install the three sensor harness clips in the upper suspension and the vertical link.

11. Install the road wheel.

12. Lower the vehicle on ramp.

13. Do an all-wheel alignment procedure (Refer to ’All

Wheel Alignment’, page 4-0-2).

14. Torque tighten suspension nuts and bolts.

15. Align engine cross brace to support, install and torque tighten Torx bolts (x2).

Front Anti-Roll Bar - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

4. Remove nuts and washers (x2), anti-roll bar to drop links.

5. Remove bolts (x4), straps (x2).

6. Remove anti-roll bar.

7. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar, bushes and straps.

2. Install bushes (x2) on anti-roll bar.

3. Position anti-roll bar, align bushes (x2), install straps (x2), install bolts (x4). Do not torque tighten.

4. Install drop links to anti-roll bar, install nuts/washers (x2).

Do not torque tighten.

5. Install front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

6. Lower vehicle in ramp.

7. Torque tighten link nuts (x4).

8. Torque tighten bush strap bolts (x4).

Front Pair Anti-Roll Bar Bushing - Renew

Removal

1. Raise vehicle on ramp.

2. Remove front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

3. Remove bolts (x4) securing anti-roll bar bush straps to subframe.

4. Release/remove bush straps.

5. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar and bush straps.

2. Install bushes on to anti-roll bar.

3. Install bush straps (x2), install bolts (x4). Do not torque tighten at this stage.

4. Install front undertray (see Workshop Manual procedure 01.02.NB Undertray - Front - Renew).

5. Lower vehicle on ramp.

6. Torque tighten all suspension nuts/bolts.

RH/LH Front Anti-Roll Bar Link - Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut/bolt securing damper to lower suspension

arm.

4. Release damper from mounting sufficient to remove top anti-roll bar link.

5. Remove nuts and washers (x2) , link to lower suspension

arm and anti-roll bar.

6. Release and remove anti-roll bar link.

Installation

1. Clean anti-roll bar link and mating faces on lower suspension arm and anti-roll bar.

2. Install link to anti-roll bar and lower suspension arm.

3. Install washers (x2) and nuts (x2). Do not torque tighten.

Caution

Do not fully tighten the nuts and bolts on the suspension

components. Only tighten the nuts and bolts of the

suspension components when the suspension arms are

at their usual ride-height and you have adjusted the

geometry. If you do not do this, the suspension bushes

will have too much stress when the suspension is moved

to its maximum upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Page 433 of 947

Front Suspension (04.01)

Suspension (04.00)

November 2008 Workshop Manual 4-1-7

8. Install caliper and Allen bolts (x2) and tighten.

9. Install ABS speed sensor, install and torque tighten.

10. Install sensor multiplug.

11. Install pad wear sensors.

12. Install track rod end to vertical link, install and torque tighten nut.

13. Install road wheel(s).

14. Pump brake pedal.

15. Lower vehicle on ramp.

16. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check & Adjust).

Front Suspension Sensor Assembly-

Renew

Removal

1. Raise vehicle on ramp

2. Remove nut/bolt securing ride height sensor link to

lower suspension arm (see Figure 1).

3. Remove nut/Torx bolt, ride height sensor to subframe.

4. Disconnect ride heig ht sensor multiplug.

5. Remove bolts (x2) securing sensor to sensor bracket.

Installation

1. Align sensor to bracket and install bolts (x2).

2. Connect ride height sensor multiplug.

3. Position sensor to subframe, install and torque tighten nut/Torx bolt.

4. Align sensor link to lower suspension arm, install and torque tighten nut/bolt.

5. Lower vehicle on ramp.

Repair Operation Time (ROT)

Page 435 of 947

Rear Suspension (04.02)

Suspension (04.00)

May 2007 Workshop Manual 4-2-1

Suspension (04.00)

Rear Suspension (04.02)

Description

Anti-roll Bar

An anti-roll bar, mounted on the rear subframe connects to

the LH and RH lower suspension arms via drop links. The

drop links, with a ball joint at either end, transmit vertical

movement of the rear suspension to the anti-roll bar,

minimising body roll.

Vertical Link

The vertical link carries the hub, the cartridge wheel bearing,

the ABS rotor, the wheel speed sensor, the brake caliper, the

hand brake caliper and the brake disc and shield.

A toe control (track-rod) arm secures the rear of the vertical

link to the subframe. The toe control arm is adjustable, on

an eccentric cam, to alter the rear road wheel toe alignment.

04-02-001

Upper Wishbone

Rear Hub Assy

Rear Subframe Lower WishboneAnti Roll Bar LinkAnti Roll Bar

Track Control Arm

Track Control Arm

Page 437 of 947

Rear Suspension (04.02)

Suspension (04.00)

May 2007 Workshop Manual 4-2-3

3. Install bolt and bolts/nuts (x2), lower suspension arm to subframe and vertical link. Do not torque tighten at this

stage.

4. Align damper to lower suspension arm, install bolt. Do not torque tighten at this stage.

5. Align anti-roll bar link to lower suspension arm, install

nut. Do not torque tighten at this stage.

6. Install road wheel(s).

7. Lower vehicle on ramp.

8. Torque tighten suspension nuts/bolts.

9. 4 wheel alignment - check/adjust (see Workshop Manual procedure 04.00.AD 4 Wheel Alignment -

Check and Adjust).

RH/LH Upper Rear Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nuts/bolts (x2), upper suspension arm to subframe.

4. Remove nut/bolt securing upper suspension arm to vertical link.

5. Release and remove upper suspension arm assembly.

Installation

1. Clean upper suspension arm and mating faces on subframe and vertical link.

2. Install upper suspension arm in subframe.

3. Install bolts/nuts (x2), upper suspension arm to subframe. Do not torque tighten at this stage.

4. Install upper suspension arm in vertical link, install bolt/

nut. Do not torque tighten at this stage.

5. Install road wheel(s).

6. Lower vehicle on ramp.

7. Torque tighten nuts/bolts, upper suspension arm to vertical link and subframe.

RH/LH Toe Control Rear Arm Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Release ABS sensor harness clips (x2) from toe control arm.

4. Remove nut/bolt securing toe control arm to subframe.

5. Remove nut/bolt securing toe control arm to vertical link.

6. Release/remove toe control arm.

Installation

1. Clean toe control arm and mating faces on vertical link and subframe.

2. Install toe control arm in vertical link and subframe.

3. Install bolts/nuts (x2). toe control arm to vertical link and subframe. Do not torque tighten at this stage.

4. Install ABS sensor harness clips in toe control arm.

5. Install road wheel(s).

6. Lower vehicle on ramp.

7. 4 wheel alignment - check/adjust(see Workshop Manual procedure 04.00.AD 4 Whee l Alignment - Check and

Adjust).

Rear Anti-Roll Bar-Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear undertray (see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

3. Remove nuts (x2), anti-roll bar links to lower arms.

4. Remove bolts (x4), bush straps (x2), anti-roll bar to subframe.

5. Remove anti-roll bar. Note cut-off section at top.

6. Remove bushes (x2) from anti-roll bar.

7. Remove nuts (x2), washers (x2), remove links from anti- roll bar.

Caution

Final tightening of suspension components must be

carried out with the suspensi on arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Repair Operation Time (ROT)