air condition ASTON MARTIN V8 VANTAGE 2010 Manual PDF

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 903 of 947

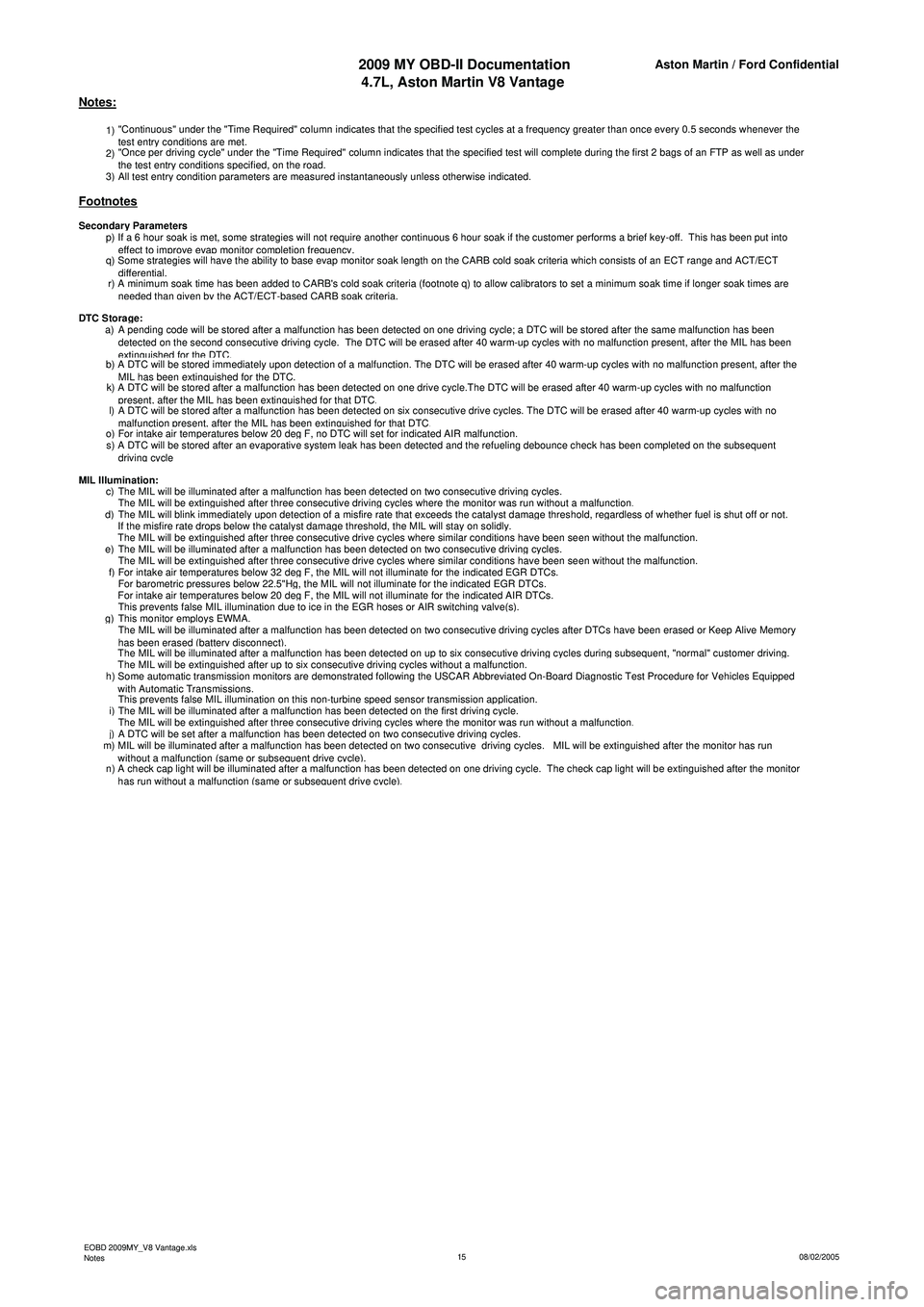

2009 MY OBD-II Documentation4.7L, Aston Martin V8 VantageAston Martin / Ford Confidential

1) "Continuous" under the "Time Required" column indicates that the specified test cycles at a frequency greater than once every 0.5 seconds whenever the

test entry conditions are met.

2) "Once per driving cycle" under the "Time Required" column indicates that the specified test will complete during the first 2 bags of an FTP as well as under

the test entr

y conditions specified, on the road.

3)All test entry condition parameters are measured instantaneously unless otherwise indicated.

p) If a 6 hour soak is met, some strategies will not require another continuous 6 hour soak if the customer performs a brief key-off. This has been put into

effect to improve evap monitor completion frequency.

q) Some strategies will have the ability to base evap monitor soak length on the CARB cold soak criteria which consists of an ECT range and ACT/ECT

differential.

r) A minimum soak time has been added to CARB's cold soak criteria (footnote q) to allow calibrators to set a minimum soak time if longer soak times are

n

eeded than given by the ACT/ECT-based CARB soak criteria.

a) A pending code will be stored after a malfunction has been detected on one driving cycle; a DTC will be stored after the same malfunction has been detected on the second consecutive driving cycle. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been

extinguished for the DTC.b) A DTC will be stored immediately upon detection of a malfunction. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for the DTC.k) A DTC will be stored after a malfunction has been detected on one drive cycle.The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for that DTC.l) A DTC will be stored after a malfunction has been detected on six consecutive drive cycles. The DTC will be erased after 40 warm-up cycles with no malfunction present, after the MIL has been extinguished for that DTC.o)For intake air temperatures below 20 deg F, no DTC will set for indicated AIR malfunction.

s) A DTC will be stored after an evaporative system leak has been detected and the refueling debounce check has been completed on the subsequent

driving cycle

c)The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles.

The MIL will be extinguished after three consecutive driving cycles where the monitor was run without a malfunction.d)The MIL will blink immediately upon detection of a misfire rate that exceeds the catalyst damage threshold, regardless of whether fuel is shut off or not.

If the misfire rate drops below the catalyst damage threshold, the MIL will stay on solidly.

The MIL will be extinguished after three consecutive drive cycles where similar conditions have been seen without the malfunction.e)The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles.

The MIL will be extinguished after three consecutive drive cycles where similar conditions have been seen without the malfunction.f)For intake air temperatures below 32 deg F, the MIL will not illuminate for the indicated EGR DTCs.

For barometric pressures below 22.5"Hg, the MIL will not illuminate for the indicated EGR DTCs.

For intake air temperatures below 20 deg F, the MIL will not illuminate for the indicated AIR DTCs.

This prevents false MIL illumination due to ice in the EGR hoses or AIR switching valve(s).g)This monitor employs EWMA.

The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles after DTCs have been erased or Keep Alive Memory

h

as been erased (battery disconnect).

The MIL will be illuminated after a malfunction has been detected on up to six consecutive driving cycles during subsequent, "normal" customer driving.

The MIL will be extinguished after up to six consecutive driving cycles without a malfunction.

h) Some automatic transmission monitors are demonstrated following the USCAR Abbreviated On-Board Diagnostic Test Procedure for Vehicles Equipped

wi

th Automatic Transmissions.

This prevents false MIL illumination on this non-turbine speed sensor transmission application.

i)The MIL will be illuminated after a malfunction has been detected on the first driving cycle.

The MIL will be extinguished after three consecutive driving cycles where the monitor was run without a malfunction.j)A DTC will be set after a malfunction has been detected on two consecutive driving cycles.

m) MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles. MIL will be extinguished after the monitor has run

wi

thout a malfunction (same or subsequent drive cycle).

n) A check cap light will be illuminated after a malfunction has been detected on one driving cycle. The check cap light will be extinguished after the monitor

h

as run without a malfunction (same or subsequent drive cycle).

MIL Illumination:

Notes:

Footnotes

Secondary Parameters

DTC Stora

ge:

EOBD 2009MY_V8 Vantage.xls

Notes 08/02/2005

15

Page 915 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationMisfire Detected At

Startup P0316 Misfire detected during first

1000 engine revs since start P0316 is set in addition to

P0300 - P0310 DTC 1000 revs

(Continuous)Footnote a) Footnote c)

AICE chip failure in

PCM P0606 NNMM chip to CPU

communication fault Number of attempts 10

Continuous Footnote a) Footnote c)

Camshaft/crankshaft

synchronization

failure P1336 AICE chip reports inability to

synchronize camshaft and

crankshaft signals

(Replaces P1309) Number of attempts > 255

Continuous Footnote a) Footnote c)

Unable to learn

crankshaft profile P0315 Unable to learn stable

crankshaft profile Number of attempts > 6 attempts

Continuous within

profile learning

entry conditionsFootnote a) Footnote c)

ROM checksum error P260F NNP ROM checksum error Checksum from NNP does not equal mainline

strategyNone

Continuous Footnote a) Footnote c)

Fuel System Too

Rich Or Too Lean P0171

(Bank 1 Lean)Excessive long and short term

fuel trim corrections Long term fuel trim cell

currently being utilized

exceeds lean limits> 1.24 * 100 % Engine rpm

600 - 4000 rpmContinuous Footnote a) Footnote c)

Short term fuel trim

exceeds lean limits < 0.96 * 100%

P0172

(Bank 1 Rich) Note: Long term fuel trim

corrections are learned into

an 8x10 cell table as a

function of rpm and load

or

an 8x1 cell table as a function

of rpm and air mass Long term fuel trim cell

currently being utilized

exceeds rich limits

< 0.76 * 100 % Engine air mass 3.4 - 484 g/sec

(0.45 - 63.99 lbs/min)

Short term fuel trim

exceeds rich limits > 1.1 * 100 %

P0174

(Bank 2 Lean) Closed loop fuel, adaptive

fuel learning enabled

(Purge dutycycle = 0 %)Fuel trim learning enabled Fuel trim learning

enabled

P0175

(Bank 2 Rich) Fuel Rail Pressure sensor

OK (P0190/0192/0193)Fuel S

ystem Monitor

4

Page 916 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ationStream 1 (Front) O2

Sensor Signal Stuck

Lean P2195

(Bank 1,

Sensor 1)Lack of HO2S switches

Stage 1:

(Look for short term fuel

trim stuck) Fuel control Closed loop or

Closed loop desiredContinuous Footnote a) Footnote c)

P2197

(Bank 2,

Sensor 1) Short term fuel trim > 1 + 0.3 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 22 * 2 sec Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startu

p)

Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 4

Fuel tank pressure low

enough and sensor OK

(P0451, P0452, P0453) < 2,491 Pa

(< 10 in H2O)

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Stuck sensor recovery

efforts failed

Time entry conditions hav

e

been present > 10 sec

Stream 1 (Front) O2

Sensor Signal Stuck

Rich P2196

(Bank 1,

Sensor 1)Lack of HO2S switches

Stage 1:

(Look for short term fuel

trim stuck) Fuel control

Closed loop or

Closed loop desired Continuous Footnote a) Footnote c)

P2198

(Bank 2,

Sensor 1) Short term fuel trim < 1 - 0.3 * 100% Intake air temp sensor OK

(P0112/0113)

Time with short term fuel

trim at limit > 22 * 2 sec. Engine coolant temp

sensor OK (P0117/0118)

Stage 2:

(Look for HO2S stuck at

startu

p)

Mass Air Flow sensor OK

(P0102/0103)

Cumulative time in test

mode since start up > 30 sec Throttle Position Sensor

OK (P0122/0123)

Number of switches since

start up < 4

Fuel tank pressure low

enough and sensor OK

(P0451, P0452, P0453) < 2,491 Pa

(< 10 in H2O)

Fuel control In FMEM at start up Fuel level above minimum

level > 0.15 * 100 %

Stuck sensor recovery efforts failedTime entry conditions hav

e

been present > 10 sec

HO2S Monitor

5

Page 925 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

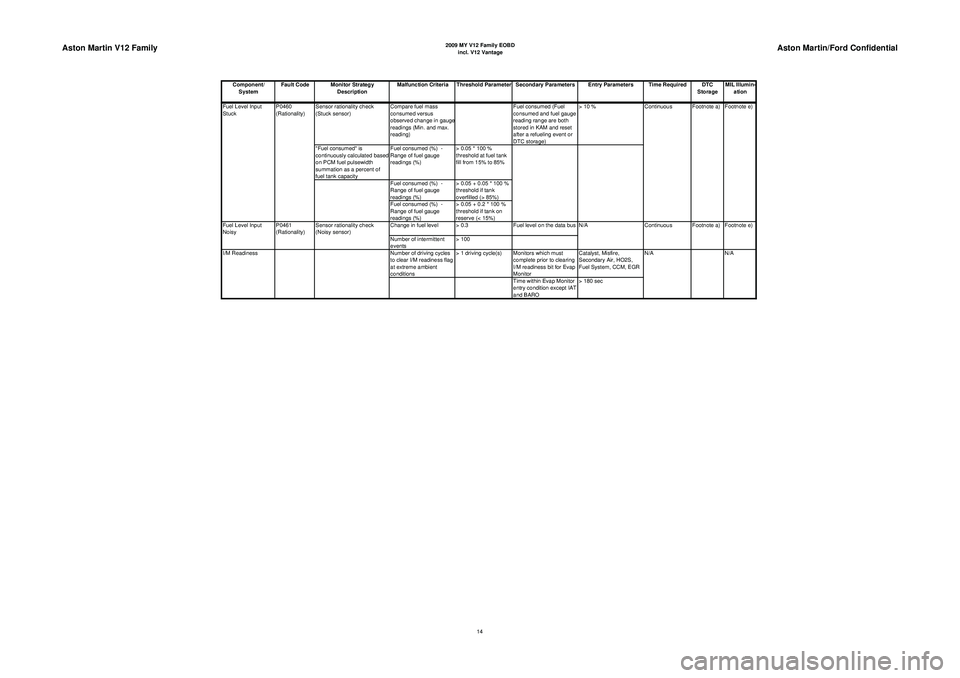

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gaug

e

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refueling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulsewidth

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.05 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.05 + 0.05 * 100 %

threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.05 + 0.2 * 100 %

threshold if tank on

reserve (< 15%)

Change in fuel level > 0.3 Fuel level on the data bus

Number of intermittent

events > 100

Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Monitors which must

complete prior to clearing

I/M readiness bit for Evap

Monitor Catalyst, Misfire,

Secondary Air, HO2S,

Fuel System, CCM, EGR

Time within Evap Monitor

entry condition except IAT

and BARO > 180 sec N/A

I/M Readiness N/AFootnote e)

Fuel Level Input

Noisy P0461

(Rationality)Sensor rationality check

(Noisy sensor) N/A

Continuous Footnote a) Footnote e)

Continuous Footnote a)

Fuel Level Input

Stuck P0460

(Rationality)

14

Page 930 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

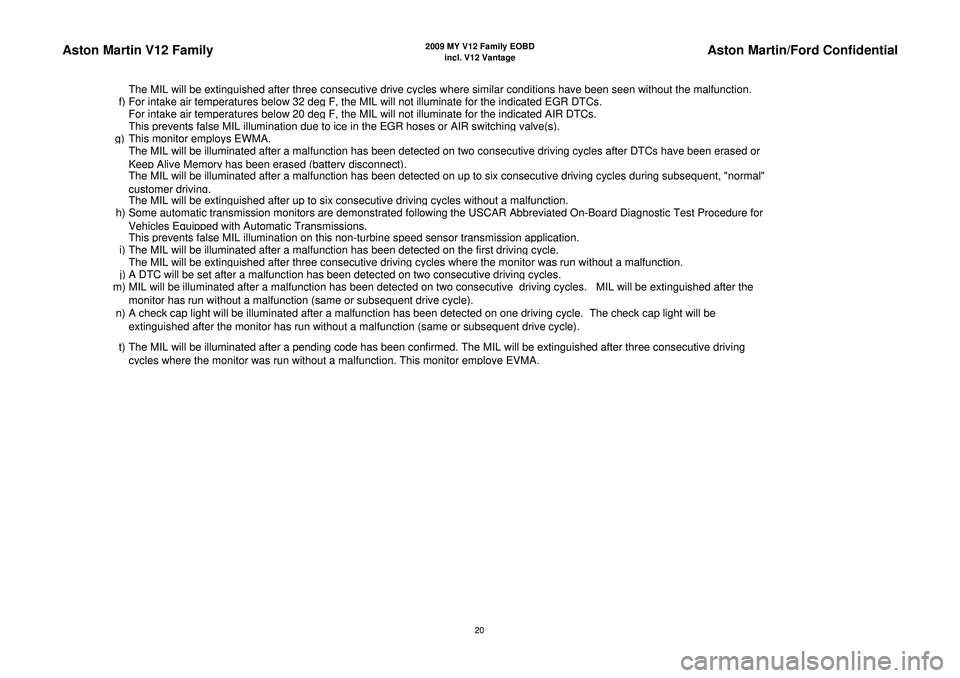

Notes:

1) "Continuous" under the "Time Required" column indicates that the specified test cycles at a frequency greater than once every 0.5

seconds whenever the test entr

y conditions are met.

2) "Once per driving cycle" under the "Time Required" column indicates that the specified test will complete during the first 2 bags of an

FTP as well as under the test entry conditions s

pecified

, on the road.

3

)All test entr

y condition

parameters are measured instantaneousl

y unless otherwise indicated.

Footnotes:Secondar

y Parameters:

p) If a 6 hour soak is met, some strategies will not require another continuous 6 hour soak if the customer performs a brief key-off. This

has been put into effect to im

prove eva

p monitor com

pletion fre

quenc

y.

q) Some strategies will have the ability to base evap monitor soak length on the CARB cold soak criteria which consists of an ECT range

and ACT/ECT differential.

r) A minimum soak time has been added to CARB's cold soak criteria (footnote q) to allow calibrators to set a minimum soak time if

lon

ger soak times are needed than

given b

y the ACT/ECT-based CARB soak criteria.

DTC Stora

ge:

a) A pending code will be stored after a malfunction has been detected on one driving cycle; a DTC will be stored after the same

malfunction has been detected on the second consecutive drivin

g cycle. The DTC will be erased after 40 warm-u

p cycles with no ma

b) A DTC will be stored immediately upon detection of a malfunction. The DTC will be erased after 40 warm-up cycles with no malfunction

present

, after the MIL has been extin

guished for the DTC.

k) A DTC will be stored after a malfunction has been detected on one drive cycle.The DTC will be erased after 40 warm-up cycles with no

malfunction

present

, after the MIL has been extin

guished for that DTC.

l) A DTC will be stored after a malfunction has been detected on six consecutive drive cycles. The DTC will be erased after 40 warm-up

c

ycles with no malfunction

present

, after the MIL has been extin

guished for that DTC.

o

)For intake air tem

peratures below 20 de

g F, no DTC will set for indicated AIR malfunction.

s) A pending code will be stored after a malfunction has been detected on upto the 6th trip depending on the size of the fault deviation; a

DTC will be stored after the same malfunction has been detected on a second driving cycle. The DTC will be erased after 40 warm-up

cycles with no malfunction. This monitor employs EVMA.

MIL Illumination:c)The MIL will be illuminated after a malfunction has been detected on two consecutive drivin

g cycles.

The MIL will be extin

guished after three consecutive drivin

g cycles where the monitor was run without a malfunction.

d) The MIL will blink immediately upon detection of a misfire rate that exceeds the catalyst damage threshold, regardless of whether fuel

is shut off or not.

If the misfire rate dro

ps below the catal

yst dama

ge threshold

, the MIL will sta

y on solidl

y.

The MIL will be extin

guished after three consecutive drive c

ycles where similar conditions have been seen without the malfunction.

e

)The MIL will be illuminated after a malfunction has been detected on two consecutive drivin

g cycles.

19

Page 931 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

The MIL will be extin

guished after three consecutive drive c

ycles where similar conditions have been seen without the malfunction.

f

)For intake air tem

peratures below 32 de

g F, the MIL will not illuminate for the indicated EGR DTCs.

For intake air tem

peratures below 20 de

g F, the MIL will not illuminate for the indicated AIR DTCs.

This

prevents false MIL illumination due to ice in the EGR hoses or AIR switchin

g valve

(s).

g)

This monitor em

ploys EWMA.

The MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles after DTCs have been erased or

Kee

p Alive Memor

y has been erased

(batter

y disconnect

).

The MIL will be illuminated after a malfunction has been detected on up to six consecutive driving cycles during subsequent, "normal"

customer drivin

g.

The MIL will be extin

guished after u

p to six consecutive drivin

g cycles without a malfunction.

h) Some automatic transmission monitors are demonstrated following the USCAR Abbreviated On-Board Diagnostic Test Procedure for

Vehicles E

quipp

ed with Automatic Transmissions.

This

prevents false MIL illumination on this non-turbine s

peed sensor transmission a

pp

lication.

i

)The MIL will be illuminated after a malfunction has been detected on the first drivin

g cycle.

The MIL will be extin

guished after three consecutive drivin

g cycles where the monitor was run without a malfunction.

j)A DTC will be set after a malfunction has been detected on two consecutive drivin

g cycles.

m) MIL will be illuminated after a malfunction has been detected on two consecutive driving cycles. MIL will be extinguished after the

monitor has run without a malfunction

(same or subse

quent drive c

ycle

).

n) A check cap light will be illuminated after a malfunction has been detected on one driving cycle. The check cap light will be

extinguished after the monitor has run without a malfunction (same or subsequent drive cycle).

t) The MIL will be illuminated after a pending code has been confirmed. The MIL will be extinguished after three consecutive driving c

ycles where the monitor was run without a malfunction. This monitor em

ploye EVMA.

20

Page 943 of 947

SB0286V2

December 2009 Page 1 of 5

SERVICE BULLETIN

To: All Dealers

For the attention of: Service Manager/After Sales Manager

Please copy to: The Dealer Principal

Aston Martin Technician(s)

The Parts Manager

Reference

SB0286V2

Issued:

25 December 2009

Model: All Models

VIN Range: All

Subject: Rear Lamp Assembly Condensation Removal and

Repair Procedure Page 1 of 5

Reason for Version 2 of this Service Bulletin (SB0286)

Version 2 of this Service Bulletin has been issued to change the criteria for the quantity of water in the rear lamp,

before you change the lamp. Amendments to this document have a black line against them in the left-side

margin. Please destroy all copies of SB0286 that you have and replace them with this Service Bulletin SB0286V2.

Reason for this Service Bulletin

This Service Bulletin has been issued to give a procedure to dry out and repair a rear lamp assembly (lamp) that

has condensation inside. If a rear lamp has condensation inside, do the Workshop Procedure that follows:

Note: If there is moisture inside the lamp then there must be some damage.

Note: Before you do the Workshop Procedure you must make sure that the lamp unit operates correctly

because it is possible that water can have caused a shor t in the circuitry. It is also possible that if the

unit does not operate correctly, this drying out procedure can

repair the problem.

Workshop Procedure

1. Do a check of the operation of the lamp.

2. If two or more functions of the lamp do not operate correctly, install a new lamp.

3. Do a check for moisture in the rear lamp. If you can s ee water in the rear lamp that is not condensation on

the lens, install a new lamp.

CAUTION: WHEN YOU WORK ON THE LAMP MAKE SURE TH AT IT IS ON A PROTECTIVE SURFACE TO

PREVENT DAMAGE.

4. Remove the rear lamp assembly (Refer to the Workshop Manual procedure 17.02.AA (Left Side) or

17.02.AB (Right Side)).

5. If you do not replace the lamp because of the conditions in steps 2 or 3, do the procedure that follows to

dry the lamp.