air condition ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 855 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 9 of 43

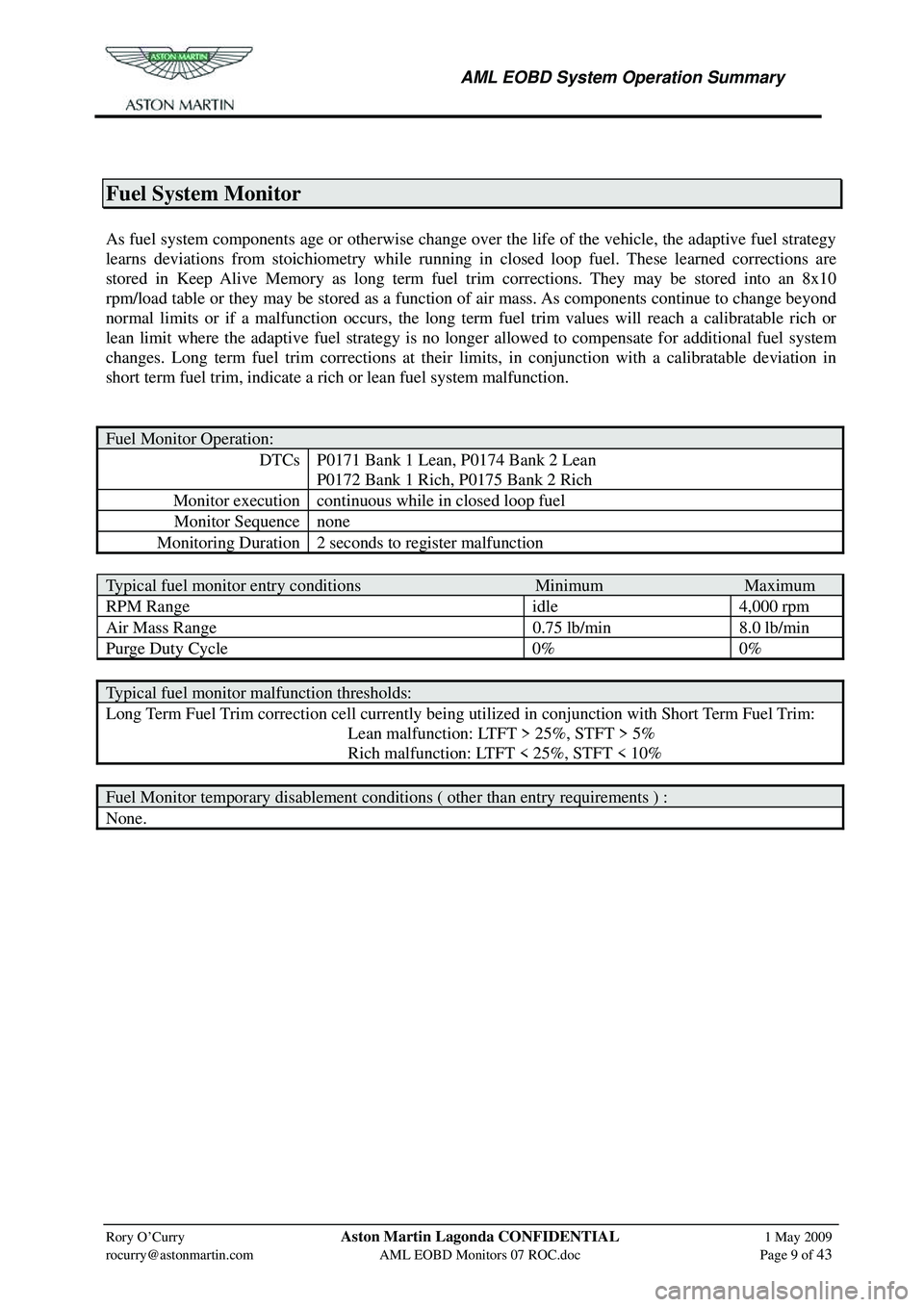

Fuel System Monitor

As fuel system components age or otherwise change over the life of the vehicle, the adaptive fuel strategy

learns deviations from stoichiometry while running in closed loop fuel. These learned corrections are

stored in Keep Alive Memory as long term fuel tr im corrections. They may be stored into an 8x10

rpm/load table or they may be stored as a function of air mass. As components continue to change beyond

normal limits or if a malfunction occurs, the long term fuel trim values will reach a calibratable rich or

lean limit where the adaptive fuel strategy is no longe r allowed to compensate for additional fuel system

changes. Long term fuel trim corrections at their limits, in conjunction with a calibratable deviation in

short term fuel trim, indicate a rich or lean fuel system malfunction.

Fuel Monitor Operation:

DTCs P0171 Bank 1 Lean, P0174 Bank 2 Lean

P0172 Bank 1 Rich, P0175 Bank 2 Rich

Monitor execution continuous while in closed loop fuel

Monitor Sequence none

Monitoring Duration 2 seconds to register malfunction

Typical fuel monitor entry conditions Minimum Maximum

RPM Range idle 4,000 rpm

Air Mass Range 0.75 lb/min 8.0 lb/min

Purge Duty Cycle 0% 0%

Typical fuel monitor malfunction thresholds:

Long Term Fuel Trim correction cell currently being utilized in conjunction with Short Term Fuel Trim:

Lean malfunction: LTFT > 25%, STFT > 5%

Rich malfunction: LTFT < 25%, STFT < 10%

Fuel Monitor temporary disablement conditions ( other than entry requirements ) :

None.

Page 856 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 10 of 43

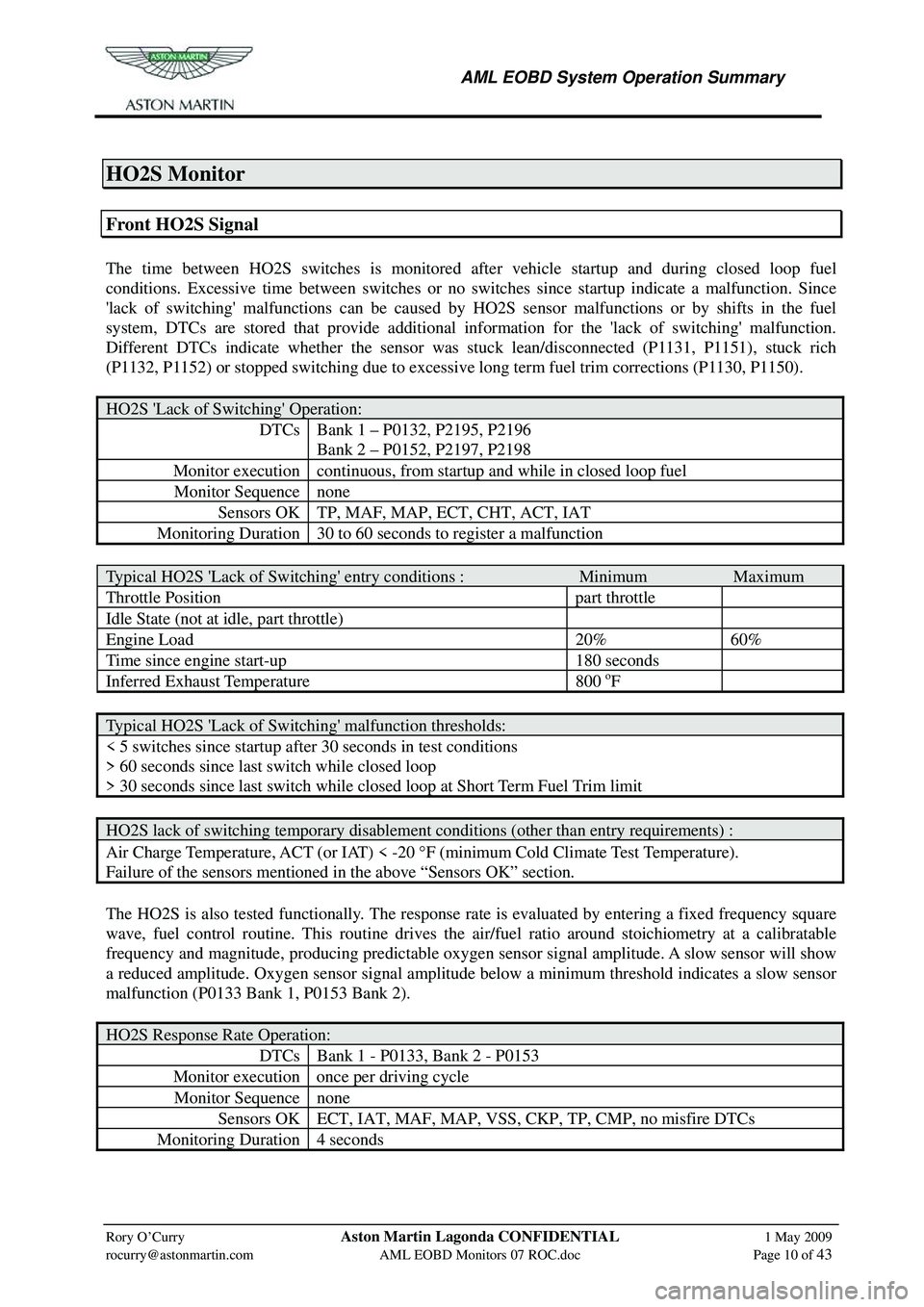

HO2S Monitor

Front HO2S Signal

The time between HO2S switches is monitored after vehicle startup and during closed loop fuel

conditions. Excessive time between switches or no switc hes since startup indicate a malfunction. Since

'lack of switching' malfunctions can be caused by HO2S sensor malfunctions or by shifts in the fuel

system, DTCs are stored that provide additional information for the 'lack of switching' malfunction.

Different DTCs indicate whether the sensor was st uck lean/disconnected (P1131, P1151), stuck rich

(P1132, P1152) or stopped switching due to excessive long term fuel trim corrections (P1130, P1150).

HO2S 'Lack of Switching' Operation:

DTCs Bank 1 – P0132, P2195, P2196

Bank 2 – P0152, P2197, P2198

Monitor execution continuous, from startup and while in closed loop fuel

Monitor Sequence none

Sensors OK TP, MAF, MAP, ECT, CHT, ACT, IAT

Monitoring Duration 30 to 60 seconds to register a malfunction

Typical HO2S 'Lack of Switching' entry conditions : Minimum Maximum

Throttle Position part throttle

Idle State (not at idle, part throttle)

Engine Load 20% 60%

Time since engine start-up 180 seconds

Inferred Exhaust Temperature 800 oF

Typical HO2S 'Lack of Switching' malfunction thresholds:

< 5 switches since startup after 30 seconds in test conditions

> 60 seconds since last switch while closed loop

> 30 seconds since last switch while closed loop at Short Term Fuel Trim limit

HO2S lack of switching temporary disablement conditions (other than entry requirements) :

Air Charge Temperature, ACT (or IAT) < -20 °F (minimum Cold Climate Test Temperature).

Failure of the sensors mentioned in the above “Sensors OK” section.

The HO2S is also tested functionally. The response rate is evaluated by enteri ng a fixed frequency square

wave, fuel control routine. This routine drives the air/fuel ratio around stoichiometry at a calibratable

frequency and magnitude, producing pr edictable oxygen sensor signal amplitude. A slow sensor will show

a reduced amplitude. Oxygen sensor signal amplitude below a minimum threshold indicates a slow sensor

malfunction (P0133 Bank 1, P0153 Bank 2).

HO2S Response Rate Operation:

DTCs Bank 1 - P0133, Bank 2 - P0153

Monitor execution once per driving cycle

Monitor Sequence none

Sensors OK ECT, IAT, MAF, MAP, VSS, CKP, TP, CMP, no misfire DTCs

Monitoring Duration 4 seconds

Page 857 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 11 of 43

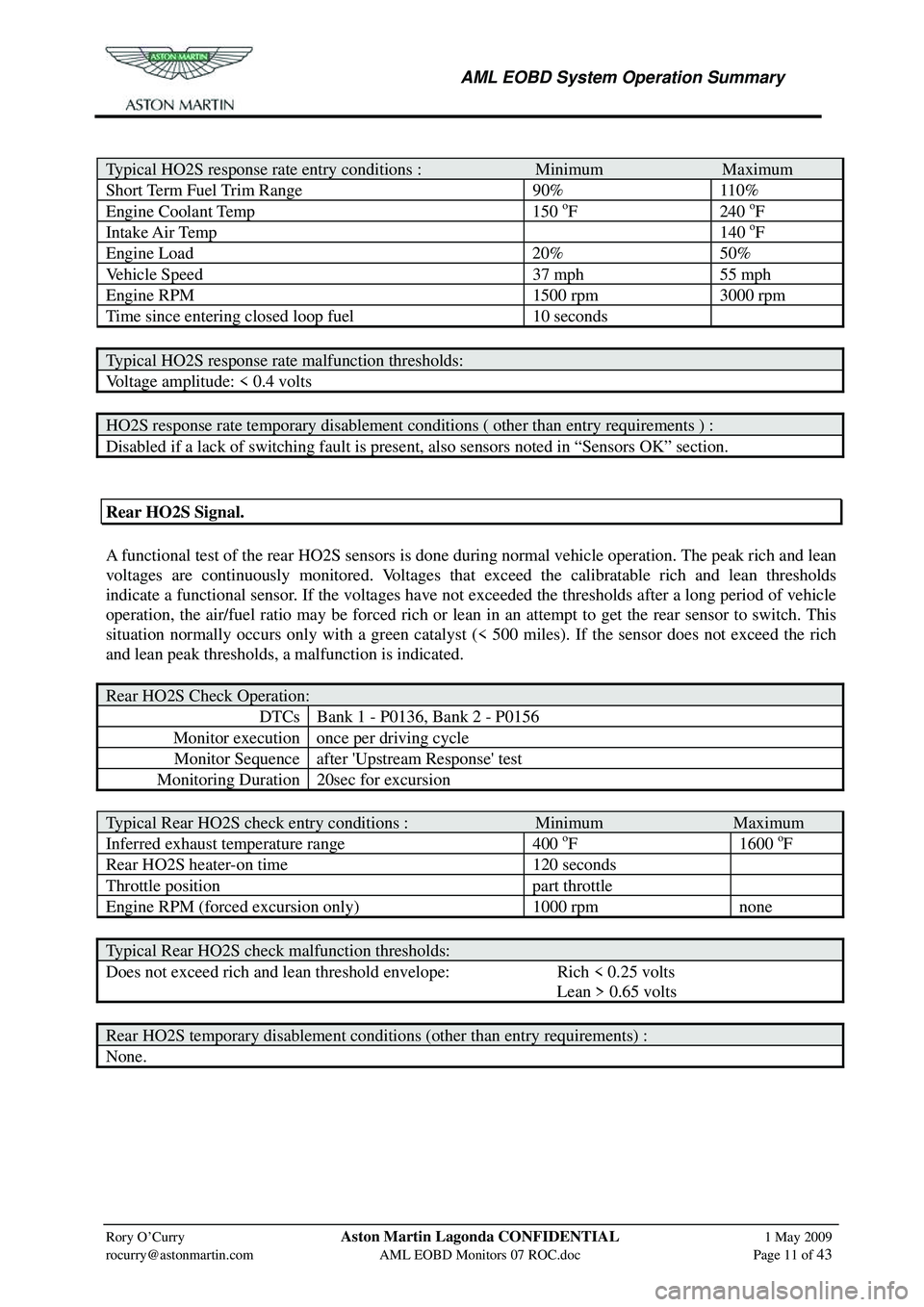

Typical HO2S response rate entry conditions : Minimum Maximum

Short Term Fuel Trim Range 90% 110%

Engine Coolant Temp 150 oF 240 oF

Intake Air Temp 140 oF

Engine Load 20% 50%

Vehicle Speed 37 mph 55 mph

Engine RPM 1500 rpm 3000 rpm

Time since entering closed loop fuel 10 seconds

Typical HO2S response rate malfunction thresholds:

Voltage amplitude: < 0.4 volts

HO2S response rate temporary disablement conditions ( other than entry requirements ) :

Disabled if a lack of switching fault is present, also sensors noted in “Sensors OK” section.

Rear HO2S Signal.

A functional test of the rear HO2S sensors is done dur ing normal vehicle operation. The peak rich and lean

voltages are continuously monitored. Voltages that exceed the calibratable rich and lean thresholds

indicate a functional sensor. If the voltages have not ex ceeded the thresholds after a long period of vehicle

operation, the air/fuel ratio may be forced rich or lean in an attempt to get the rear sensor to switch. This

situation normally occurs only with a green catalyst (< 500 miles). If the sensor does not exceed the rich

and lean peak thresholds, a malfunction is indicated.

Rear HO2S Check Operation:

DTCs Bank 1 - P0136, Bank 2 - P0156

Monitor execution once per driving cycle

Monitor Sequence after 'Upstream Response' test

Monitoring Duration 20sec for excursion

Typical Rear HO2S check entry conditions : Minimum Maximum

Inferred exhaust temperature range 400 oF 1600 oF

Rear HO2S heater-on time 120 seconds

Throttle position part throttle

Engine RPM (forced excursion only) 1000 rpm none

Typical Rear HO2S check malfunction thresholds:

Does not exceed rich and lean threshold envelope: Rich < 0.25 volts

Lean > 0.65 volts

Rear HO2S temporary disablement conditions (other than entry requirements) :

None.

Page 860 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 14 of 43

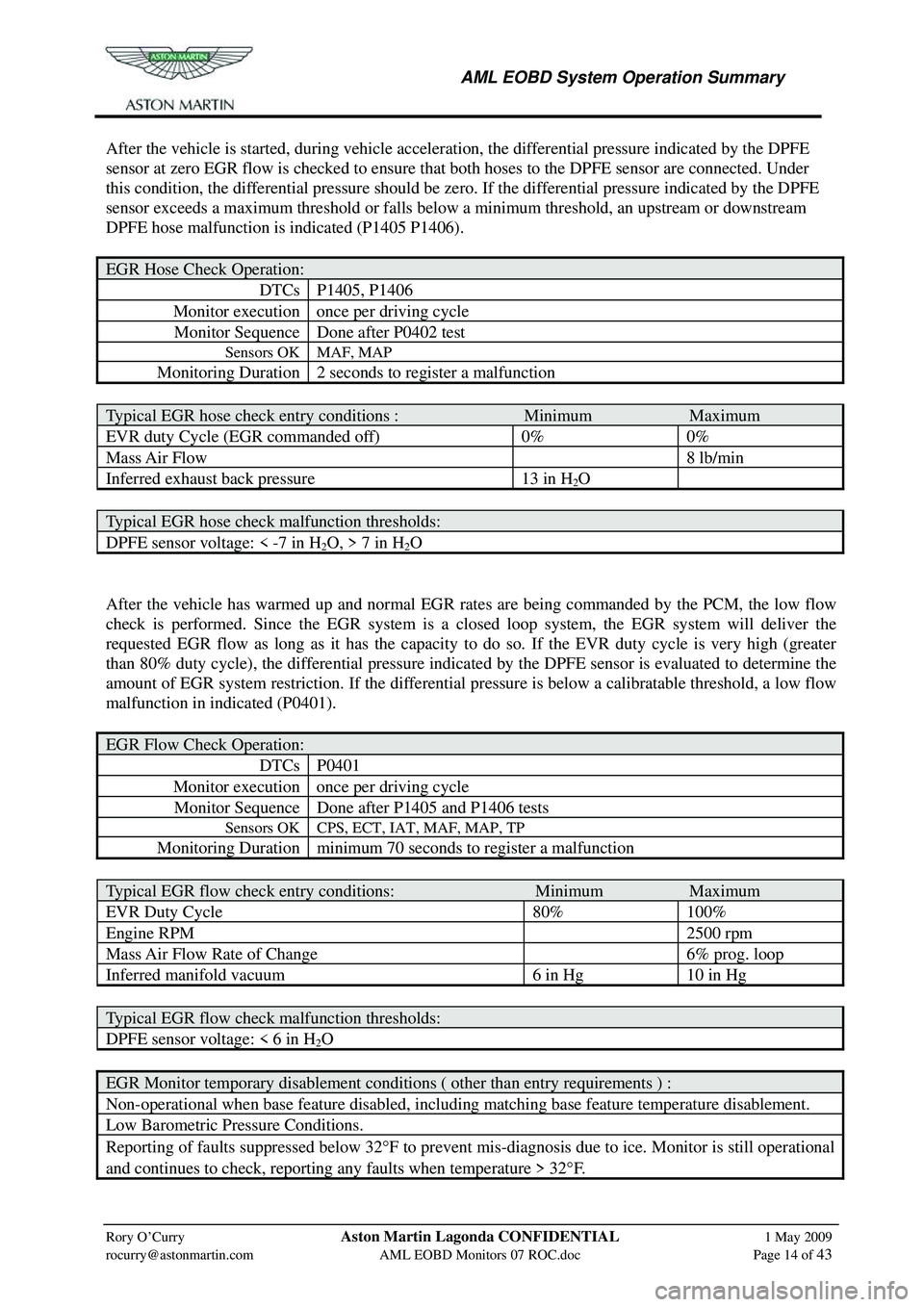

After the vehicle is started, during vehicle acceleration, the differential pressure indicated by the DPFE

sensor at zero EGR flow is checked to ensure that both hoses to the DPFE sensor are connected. Under

this condition, the differential pressure should be zer o. If the differential pressure indicated by the DPFE

sensor exceeds a maximum threshold or falls below a minimum threshold, an upstream or downstream

DPFE hose malfunction is indicated (P1405 P1406).

EGR Hose Check Operation:

DTCs P1405, P1406

Monitor execution once per driving cycle

Monitor Sequence Done after P0402 test

Sensors OK MAF, MAP

Monitoring Duration 2 seconds to register a malfunction

Typical EGR hose check entry conditions : Minimum Maximum

EVR duty Cycle (EGR commanded off) 0% 0%

Mass Air Flow 8 lb/min

Inferred exhaust back pressure 13 in H2O

Typical EGR hose check malfunction thresholds:

DPFE sensor voltage: < -7 in H2O, > 7 in H2O

After the vehicle has warmed up and normal EGR rates are being commanded by the PCM, the low flow

check is performed. Since the EGR system is a closed loop system, the EGR system will deliver the

requested EGR flow as long as it has the capacity to do so. If the EVR duty cycle is very high (greater

than 80% duty cycle), the differential pressure indicated by the DPFE sensor is evaluated to determine the

amount of EGR system restriction. If the differential pr essure is below a calibratable threshold, a low flow

malfunction in indicated (P0401).

EGR Flow Check Operation:

DTCs P0401

Monitor execution once per driving cycle

Monitor Sequence Done after P1405 and P1406 tests

Sensors OK CPS, ECT, IAT, MAF, MAP, TP

Monitoring Duration minimum 70 seconds to register a malfunction

Typical EGR flow check entry conditions: Minimum Maximum

EVR Duty Cycle 80% 100%

Engine RPM 2500 rpm

Mass Air Flow Rate of Change 6% prog. loop

Inferred manifold vacuum 6 in Hg 10 in Hg

Typical EGR flow check malfunction thresholds:

DPFE sensor voltage: < 6 in H2O

EGR Monitor temporary disablement conditions ( other than entry requirements ) :

Non-operational when base feature disabled, including matching base feature temperature disablement.

Low Barometric Pressure Conditions.

Reporting of faults suppressed below 32° F to prevent mis-diagnosis due to ice. Monitor is still operational

and continues to check, reporting any faults when temperature > 32 °F.

Page 864 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Dual MAF Diagnostic

Dual MAF Hardware

The V8 uses a common dirty air pick-up, which feeds twin air filters and MAF meters before recombining the two air streams in a junction prior to the throttle.

[email protected] AML EOBD Monitors 07 ROC.doc Page 18 of 43

FilterFilter

Filter Filter

Filter Filter

Filter Filter

MAF

meters

Normal Operation Side Wind or Partial

Blockage Backflow

Total Blockage

MAF meters receive an

equal share of the airflow. One MAF meter receives

an airflow greater than the total engine consumption. One MAF meter

receives airflow equal to the total airflow.

MAF meters receive

unequal airflows. This is due to severe side

wind. Fault judgement is

de

pendant on severity.

This can either be due

to a side wind or a partial blockage. One MAF meter will

measure zero airflow and this needs to be

determined to prevent false circuit faults.

Low engine airflow

conditions are

particularly susceptible to side wind. Fault judgement is

dependant on severity.

Fault judgement is

dependant on severity.

Page 866 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

Fault Matrix

ConditionMAF 1 + MAF 2 = EST

MAF 1 = ½ EST

MAF 2 = ½ EST

MAF 1 < MAF 2

MAF 1 low voltage

MAF 2 low voltage

MAF 1 high voltage

MAF 2 high voltage

MAF 1 > EST

MAF 2 > EST

MAF 1 = MAF 2Air Charge P-codes

Normal operating. YY--------f(maf_raw)

None

MAF 1 partly blocked. N-N----f(maf_raw)

P010F, P0100

MAF 1 fully blocked @ low load.

Y-N---- f(maf_raw)

P010F, P0100

MAF 2 partly blocked. -N-N- - -f(maf_raw)

P010F, P010A

MAF 2 fully blocked @ low load. -Y-N---f(maf_raw)

P010F, P010

AMAF 1 shorted to ground.

-Y-N----f(maf_raw)

P0102

MAF 1 shorted to high. -N-Y----f(maf_raw)

P0103

MAF 1 failed in range. -N-N----f(maf_raw)

P0101

MAF 2 shorted to ground. --Y-N---f(maf_raw)

P010C

MAF 2 shorted high. --N-Y---f(maf_raw)

P010D

MAF 2 failed in range. --N-N---f(maf_raw)

P010B

Estimated value wrong. --

Yf(maf_raw)None

MAF 1 and MAF 2 failed in range. --Nf(fmem)

P0101, P010B

Backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 short to ground MAF 2 failed in rng. -N-f(fmem)

P0102, P010B

MAF 1 shorted high, MAF 2 failed in rng. -NN

YN---f(fmem)

P0103, P010B

Backflow via MAF 2.Y-- f(fmem)

P010E

MAF 1 failed in rng, MAF2 short to ground. N- -f(fmem)

P0101, P010C

MAF 1 failed in rng, MAF 2 shorted high. NNN

Y---f(fmem)

P0101, P010D

MAF 1 & MAF 2 shorted to ground. -YYNN---f(fmem)

P0102, P010C

MAF 1 & MAF 2 shorted high. -NNYY---f(fmem)

P0103, P010D

Severe backflow via MAF 2.Y-- f(fmem)

P010E

MAF 2 fully blocked @ high load N- -f(fmem)

P010F, P010B

Severe backflow via MAF 1. -

Y-f(fmem)

P0104

MAF 1 fully blocked @ high load. -N-f(fmem)

P010F, P0101

YNNY N

N

NN - NNNN

-

-NYY N

-NYNN

-YNN

Y

N

NY

Y

NN

YN

[email protected] AML EOBD Monitors 07 ROC.doc Page 20 of 43

Page 867 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 21 of 43

Dual MAF Diagnostic Operation:

DTCs P0100 – Mass Air Flow A Circuit

P0101 – Mass Air Flow A Circuit Range/Performance

P0102 – Mass Air Flow A Circuit Low Input

P0103 – Mass Air Flow A Circuit High Input

P0104 – Mass Air Flow A Circuit Intermittent/Erratic

P010A – Mass Air Flow B Circuit

P010B – Mass Air Flow B Circuit Range/Performance

P010C – Mass Air Flow B Circuit Low Input

P010D – Mass Air Flow B Circuit High Input

P010E – Mass Air Flow B Circuit Intermittent/Erratic

P010F – Mass Air Flow Sensors A/B Correlation

Monitor execution Continuous (exceptions below)

Monitor Sequence Continuous (exceptions below)

Sensors/Components OK No Throttle Position Failure

No Vehicle Speed Failure

Monitoring Duration Continuous (exceptions below)

Global Entry Conditions

Entry condition Minimum Maximum

Battery Voltage 11 volts 18 volt

Global Abort Conditions

SAIR monitor running

Abort Conditions for P0100,P0101,P010A,P010B,P010F

Throttle position < 3 degrees & Vehicle Speed > 15mph

Page 869 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 23 of 43

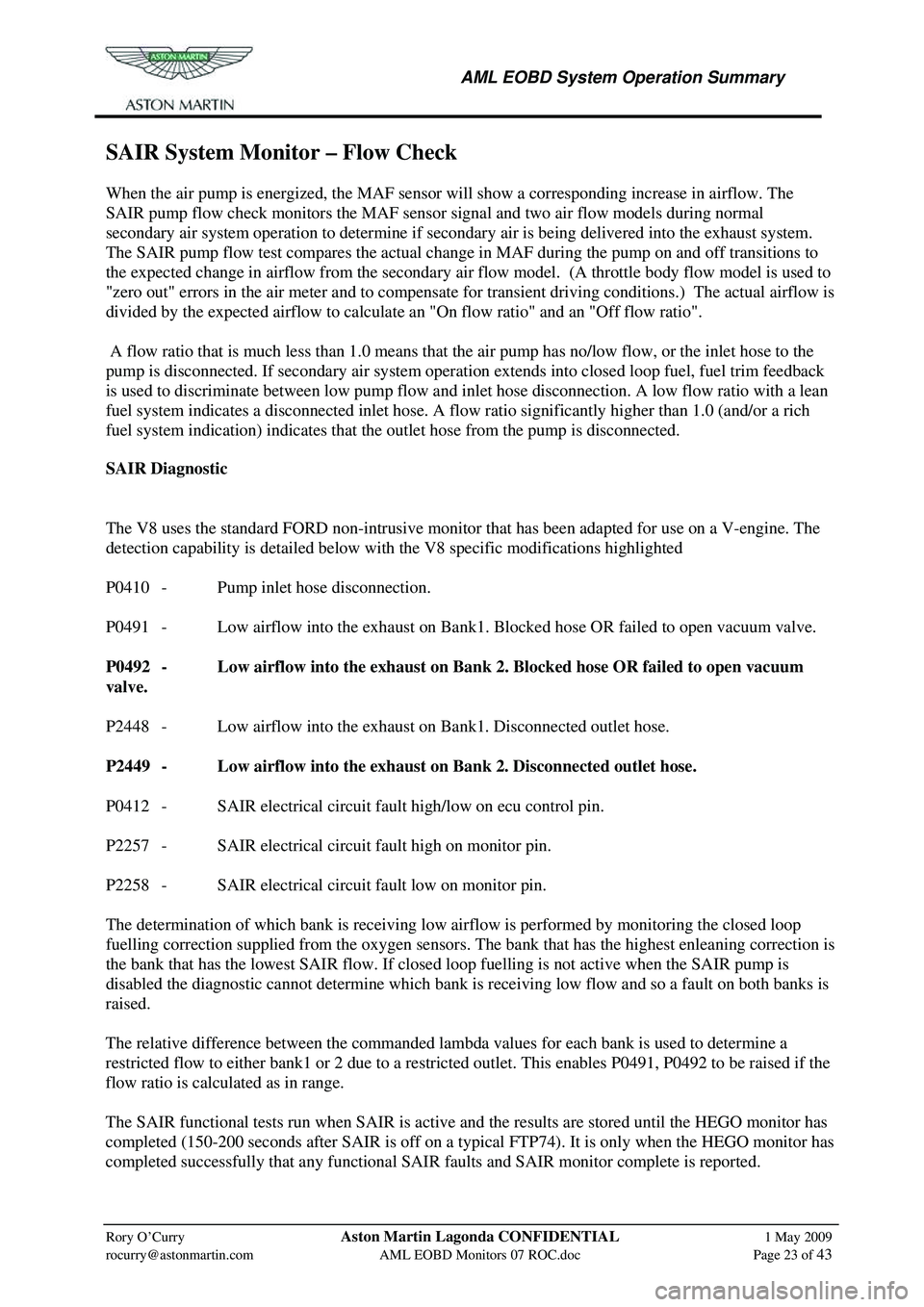

SAIR System Monitor – Flow Check

When the air pump is energized, the MAF sensor will show a corresponding increase in airflow. The

SAIR pump flow check monitors the MAF sensor signal and two air flow models during normal

secondary air system operation to determine if secondary air is being delivered into the exhaust system.

The SAIR pump flow test compares the actual change in MAF during the pump on and off transitions to

the expected change in airflow from the secondary air fl ow model. (A throttle body flow model is used to

"zero out" errors in the air meter and to compensate fo r transient driving conditions.) The actual airflow is

divided by the expected airflow to calculate an "On flow ratio" and an "Off flow ratio".

A flow ratio that is much less than 1.0 means that the air pump has no/low flow, or the inlet hose to the

pump is disconnected. If secondary air system operation ex tends into closed loop fuel, fuel trim feedback

is used to discriminate between low pump flow and in let hose disconnection. A low flow ratio with a lean

fuel system indicates a disconnected inlet hose. A flow ratio significantly higher than 1.0 (and/or a rich

fuel system indication) indicates that th e outlet hose from the pump is disconnected.

SAIR Diagnostic

The V8 uses the standard FORD non-intrusive monitor that has been adapted for use on a V-engine. The

detection capability is detailed below with the V8 specific modifications highlighted

P0410 - Pump inlet hose disconnection.

P0491 - Low airflow into the exhaust on Bank1. Blocked hose OR failed to open vacuum valve.

P0492 - Low airflow into the exhaust on Bank 2. Blocked hose OR failed to open vacuum

valve.

P2448 - Low airflow into the exhaust on Bank1. Disconnected outlet hose.

P2449 - Low airflow into the exhaust on Bank 2. Disconnected outlet hose.

P0412 - SAIR electrical circuit fault high/low on ecu control pin.

P2257 - SAIR electrical circuit fault high on monitor pin.

P2258 - SAIR electrical circuit fault low on monitor pin.

The determination of which bank is receiving low ai rflow is performed by monitoring the closed loop

fuelling correction supplied from the oxygen sensors. The bank that has the highest enleaning correction is

the bank that has the lowest SAIR flow. If closed loop fuelling is not active when the SAIR pump is

disabled the diagnostic cannot determ ine which bank is receiving low flow and so a fault on both banks is

raised.

The relative difference between the commanded lambda values for each bank is used to determine a

restricted flow to either bank1 or 2 due to a restricted outlet. This enables P0491, P0492 to be raised if the

flow ratio is calculated as in range.

The SAIR functional tests run when SAIR is active and the results are stored until the HEGO monitor has

completed (150-200 seconds after SAIR is off on a typical FTP74). It is only when the HEGO monitor has

completed successfully that any functional SAIR fa ults and SAIR monitor complete is reported.

Page 870 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 24 of 43

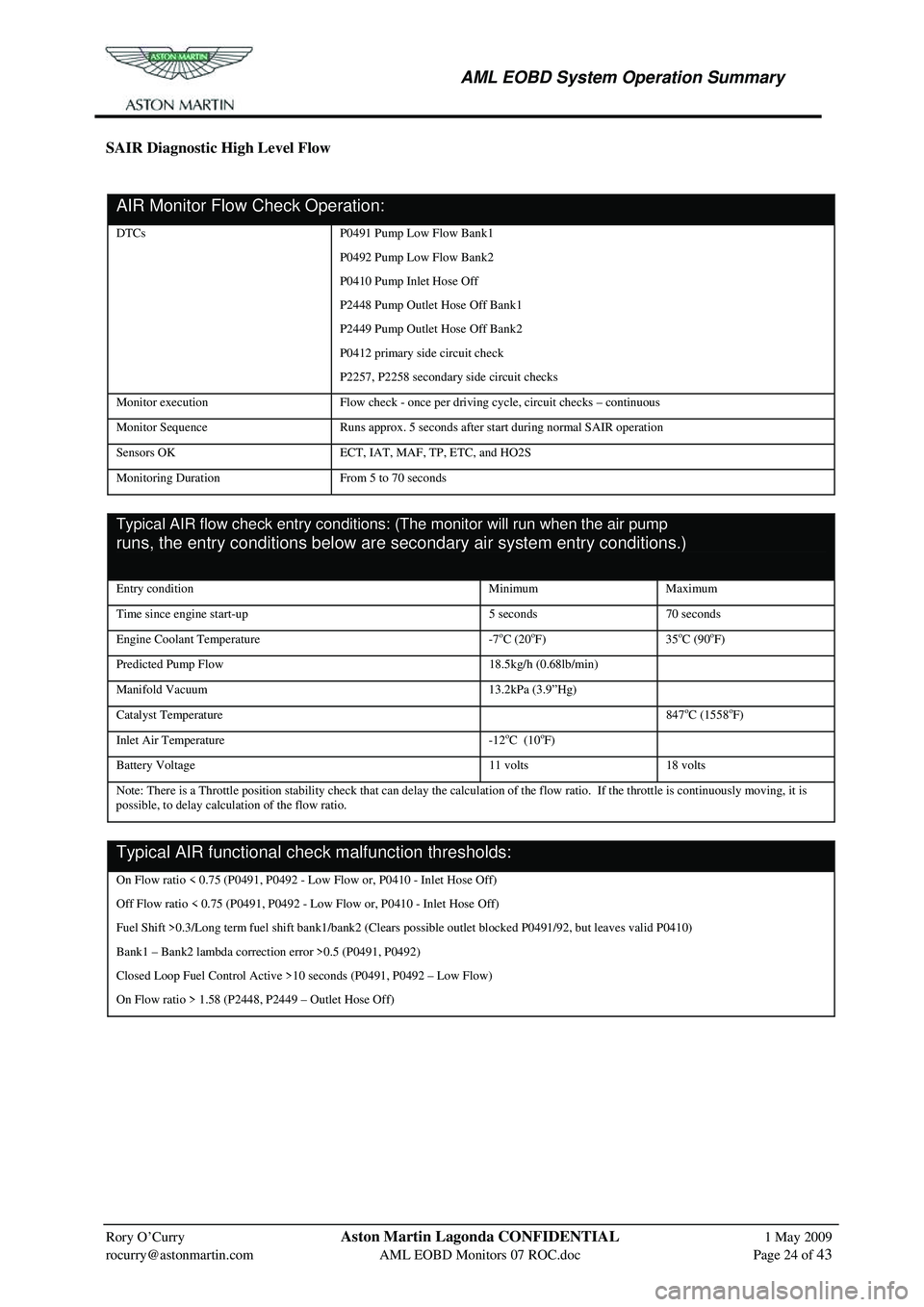

SAIR Diagnostic High Level Flow

AIR Monitor Flow Check Operation: onitor Flow Check Operation:

DTCs P0491 Pump Low Flow Bank1

P0492 Pump Low Flow Bank2

P0410 Pump Inlet Hose Off

P2448 Pump Outlet Hose Off Bank1

P2449 Pump Outlet Hose Off Bank2

P0412 primary side circuit check

P2257, P2258 secondary side circuit checks

Monitor execution Flow check - once per driving cycle, circuit checks – continuous

Monitor Sequence Runs approx. 5 seconds after start during normal SAIR operation

Sensors OK ECT, IAT, MAF, TP, ETC, and HO2S

Monitoring Duration From 5 to 70 seconds

Typical AIR flow check entry conditions: (The monitor will run when the air pump

runs, the entry conditions below are secondary air system entry conditions.) re secondary air

system entry conditions.)

Entry condition Minimum Maximum

Time since engine start-up 5 seconds 70 seconds

Engine Coolant Temperature -7oC (20oF) 35oC (90oF)

Predicted Pump Flow 18.5kg/h (0.68lb/min)

Manifold Vacuum 13.2kPa (3.9”Hg)

Catalyst Temperature 847oC (1558oF)

Inlet Air Temperature -12oC (10oF)

Battery Voltage 11 volts 18 volts

Note: There is a Throttle position stability ch eck that can delay the calculation of the flow ratio. If the throttle is continuously moving, it is

possible, to delay calculation of the flow ratio.

Typical AIR functional check malfunction thresholds:heck malfunction thresholds:

On Flow ratio < 0.75 (P0491, P0492 - Low Flow or, P0410 - Inlet Hose Off)

Off Flow ratio < 0.75 (P0491, P0492 - Lo w Flow or, P0410 - Inlet Hose Off)

Fuel Shift >0.3/Long term fuel shift bank1/bank2 (Clears possible outlet blocked P0491/92, but leaves valid P0410)

Bank1 – Bank2 lambda correcti on error >0.5 (P0491, P0492)

Closed Loop Fuel Control Active >10 seconds (P0491, P0492 – Low Flow)

On Flow ratio > 1.58 (P2448, P2449 – Outlet Hose Off)

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

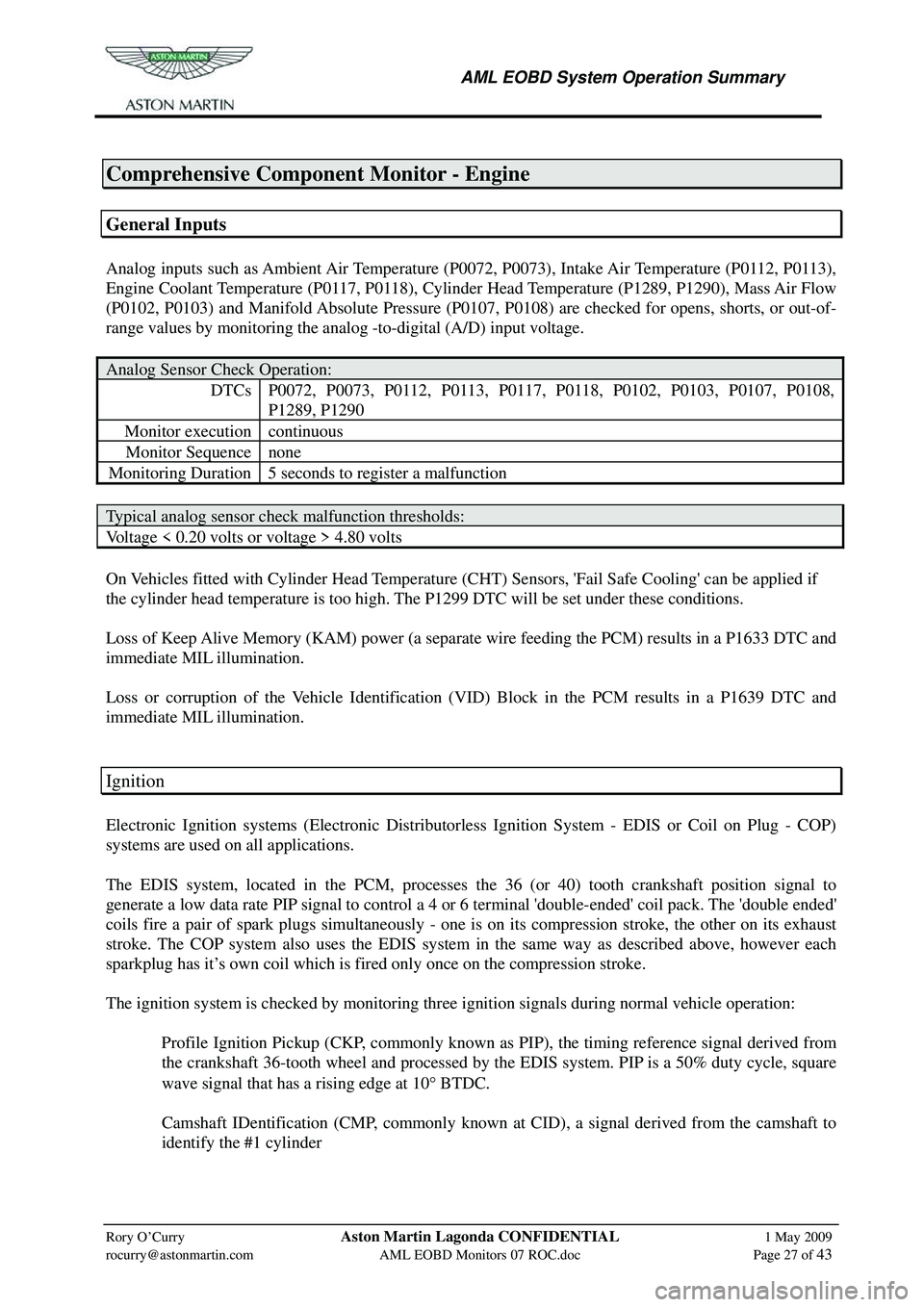

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder