coolant capacity ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 7 of 947

Safety Precautions

Issue 5, January 2010 Workshop Manual 0-0-7

Safety Precautions

All service workshops are a source of potential danger and

repair work should only be performed by technically trained

staff following procedures detailed in this manual. A safety

conscious approach to the performance of all service

procedures must be observed at all times. Statutory

requirements governing all aspects of health and safety at

work including directives for the proper use of materials and

equipment must be implemented.

The following contains a list of particular safety precautions

which should be observed; it is not intended to be

exhaustive.

Battery Disconnection

When a service manual procedure requires the vehicle

battery to be disconnected - always physically disconnect

the vehicle battery earth (Negative) lead.

Do not use the ‘Battery Disconnect Switch’.

After reconnecting the vehicle battery the following items

will have to be reset or re-learnt:

•Radio pre-sets

•Windows

• DTCs will be lost

Air Conditioning (A/C) System

Do not break into the A/C refrigeration system until the

refrigerant has been evacuated using the procedure detailed

in this manual. Do not disconne ct any A/C refrigerant system

pipes unless trained and instructed to do so. The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicals used in the servicing of motor vehicles include

acids, adhesives, antifreeze, brake fluids, coolants, grease,

oil, paint, resin and solvents. Exposure to certain chemicals

through direct contact or inhalation can be fatal.

Potential hazards may also be present through the incorrect

use, storage and handling of chemicals causing a fire risk.

The following precaution s should be observed.

• Strictly adhere to handling and safety information found on containers and labels.

• Do not store chemicals in unlabelled or incorrectly labelled containers.

• Containers used for storing chemicals should not be left open; there is a risk of spilling , or evaporation of fumes

which may be inflammable or toxic.

• Do not mix chemicals unless instructed to do so following manufacturers guidelines.

• Do not inhale chemical materials to determine identity, they may be toxic.

• Do not use petrol, kerosene, diesel fuel, gas oil, thinners or solvents for washing skin.

• Containers whose capacity is over 25 litres (5 gallons) require a bund wall in order to contain spillages. • Chemicals based on solvents such as paint should not be

sprayed in a confined space; work areas used for such

operations should be well ve ntilated and fume extraction

equipment should be utilised.

• Ensure that adequate ventilation is provided when volatile de-greasing agents are being used.

• Avoid splashing the skin, eyes and clothing .

• Clean chemicals from the skin and clothing as soon as

possible after soiling .

• Wear protective clothing such as goggles, non porous gloves and apron when handling battery acid and other

corrosive and toxic substances.

Electrical Equipment

• Ensure that electrical equipment is in safe working order before use.

• Inspect power leads of all mains electrical equipment for damage and security, and check that it is properly earthed.

• Ensure that electrical equipment is protected by a fuse of the correct current rating .

• Disconnect the battery before commencing repair operations to the electrical sy stem, fuel system and engine

or when working beneath the vehicle.

Exhaust Fumes

Engines should not be run in confined spaces as exhaust

fumes contain harmful and to xic substances including

carbon monoxide which can prove fatal if inhaled. Engines

must only be run where there is fume extraction equipment

in operation or where there is adequate ventilation.

Fire Precautions

• Ensure that a suitable form of fire extinguisher is conveniently located near the work area.

• Keep oils, solvents and combustible materials away from naked flames and other sources of ignition.

• Ensure that NO SMOKING signs are posted around areas where combustible materials and vapour may be present

and ensure that the warnings are strictly observed.

• Ensure that dry sand is availabl e to soak up any spillage of

fuel or other flammable solutions.

• Fume extraction equipment must be available and in full working order to remove combustible and toxic vapours.

• All personnel should be aware of the fire drill procedures and precautions. WAR NI NG

DO NOT SMOKE IN THE VICINITY OF VOLATILE DE- GREASING AGENTS.

WAR NI NG

FUME EXTRACTION EQUIPMENT MUST BE IN

OPERATION WHEN SOLVENTS ARE USED E.G. TRICHLOROETHANE, WHITE SPIRIT, SBP3,

METHYLENE CHLORIDE, PERCHLORETHYLENE.

Page 889 of 947

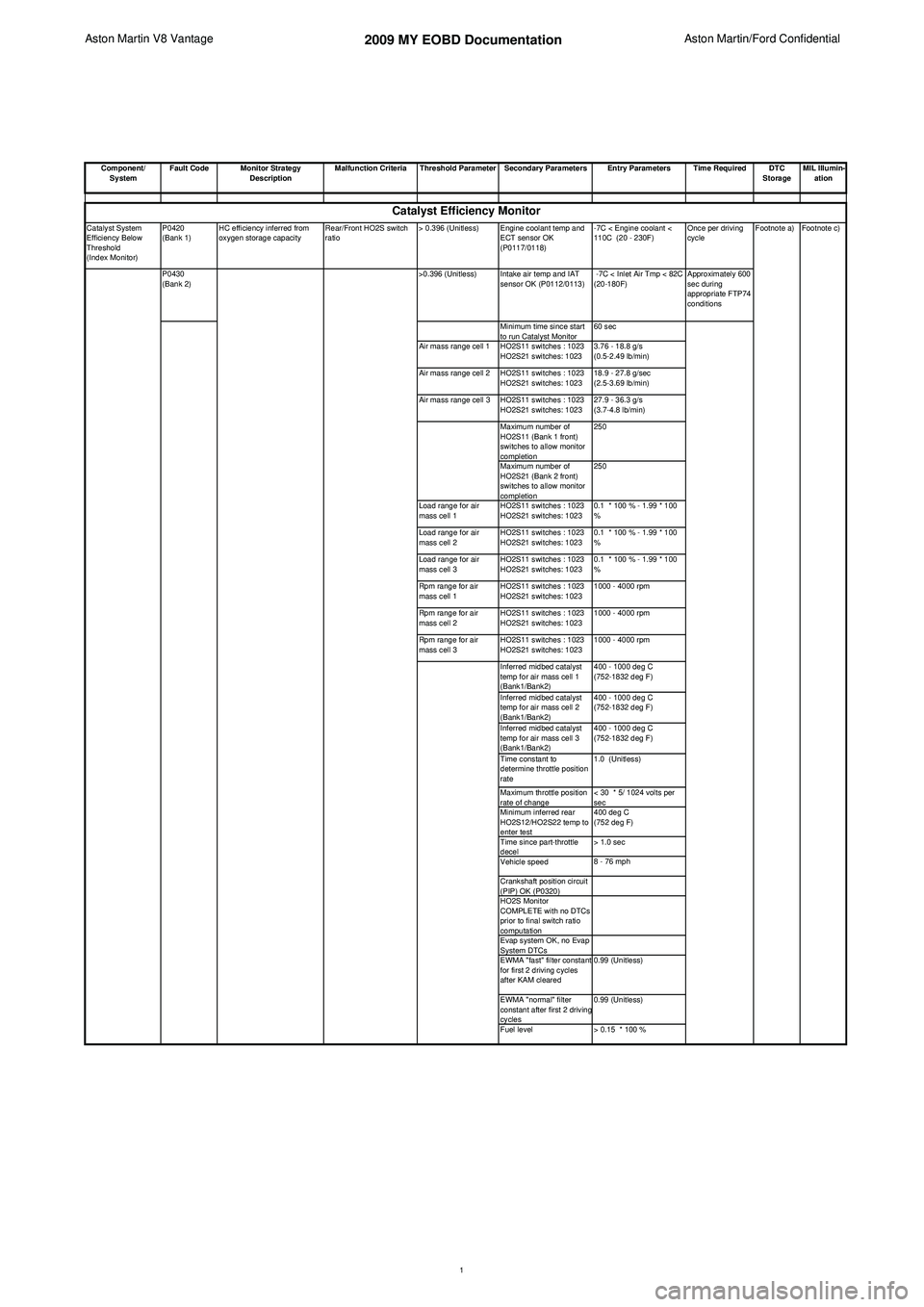

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Catalyst System

Efficiency Below

Threshold

(Index Monitor) P0420

(Bank 1)

HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio> 0.396 (Unitless) Engine coolant temp and

ECT sensor OK

(P0117/0118) -7C < Engine coolant <

110C (20 - 230F)

Once per driving

cycle

P0430

(Bank 2) >0.396 (Unitless) Intake air temp and IAT

sensor OK (P0112/0113) -7C < Inlet Air Tmp < 82C

(20-180F) Approximately 600

sec during

appropriate FTP74

conditions

Minimum time since start

to run Catalyst Monitor 60 sec

Air mass range cell 1 HO2S11 switches : 1023 HO2S21 switches: 1023 3.76 - 18.8 g/s

(0.5-2.49 lb/min)

Air mass range cell 2 HO2S11 switches : 1023 HO2S21 switches: 1023 18.9 - 27.8 g/sec

(2.5-3.69 lb/min)

Air mass range cell 3 HO2S11 switches : 1023 HO2S21 switches: 1023 27.9 - 36.3 g/s

(3.7-4.8 lb/min)

Maximum number of

HO2S11 (Bank 1 front)

switches to allow monitor

completion 250

Maximum number of

HO2S21 (Bank 2 front)

switches to allow monitor

completion 250

Load range for air

mass cell 1 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Load range for air

mass cell 2 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Load range for air

mass cell 3 HO2S11 switches : 1023

HO2S21 switches: 1023 0.1 * 100 % - 1.99 * 100

%

Rpm range for air

mass cell 1 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Rpm range for air

mass cell 2 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Rpm range for air

mass cell 3 HO2S11 switches : 1023

HO2S21 switches: 1023 1000 - 4000 rpm

Inferred midbed catalyst

temp for air mass cell 1

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Inferred midbed catalyst

temp for air mass cell 2

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Inferred midbed catalyst

temp for air mass cell 3

(Bank1/Bank2) 400 - 1000 deg C

(752-1832 deg F)

Time constant to

determine throttle position

rate 1.0 (Unitless)

Maximum throttle position

rate of change < 30 * 5/ 1024 volts per

sec

Minimum inferred rear

HO2S12/HO2S22 temp to

enter test 400 deg C

(752 deg F)

Time since part-throttle

decel > 1.0 sec

Vehicle speed 8 - 76 mph

Crankshaft position circuit

(PIP) OK (P0320)

HO2S Monitor

COMPLETE with no DTCs

prior to final switch ratio

computation

Evap system OK, no Evap

System DTCs

EWMA "fast" filter constant

for first 2 driving cycles

after KAM cleared 0.99 (Unitless)

EWMA "normal" filter

constant after first 2 driving

cycles 0.99 (Unitless)

Fuel level > 0.15 * 100 % Footnote a)

Footnote c)

Catalyst Efficiency Monitor

1

Page 900 of 947

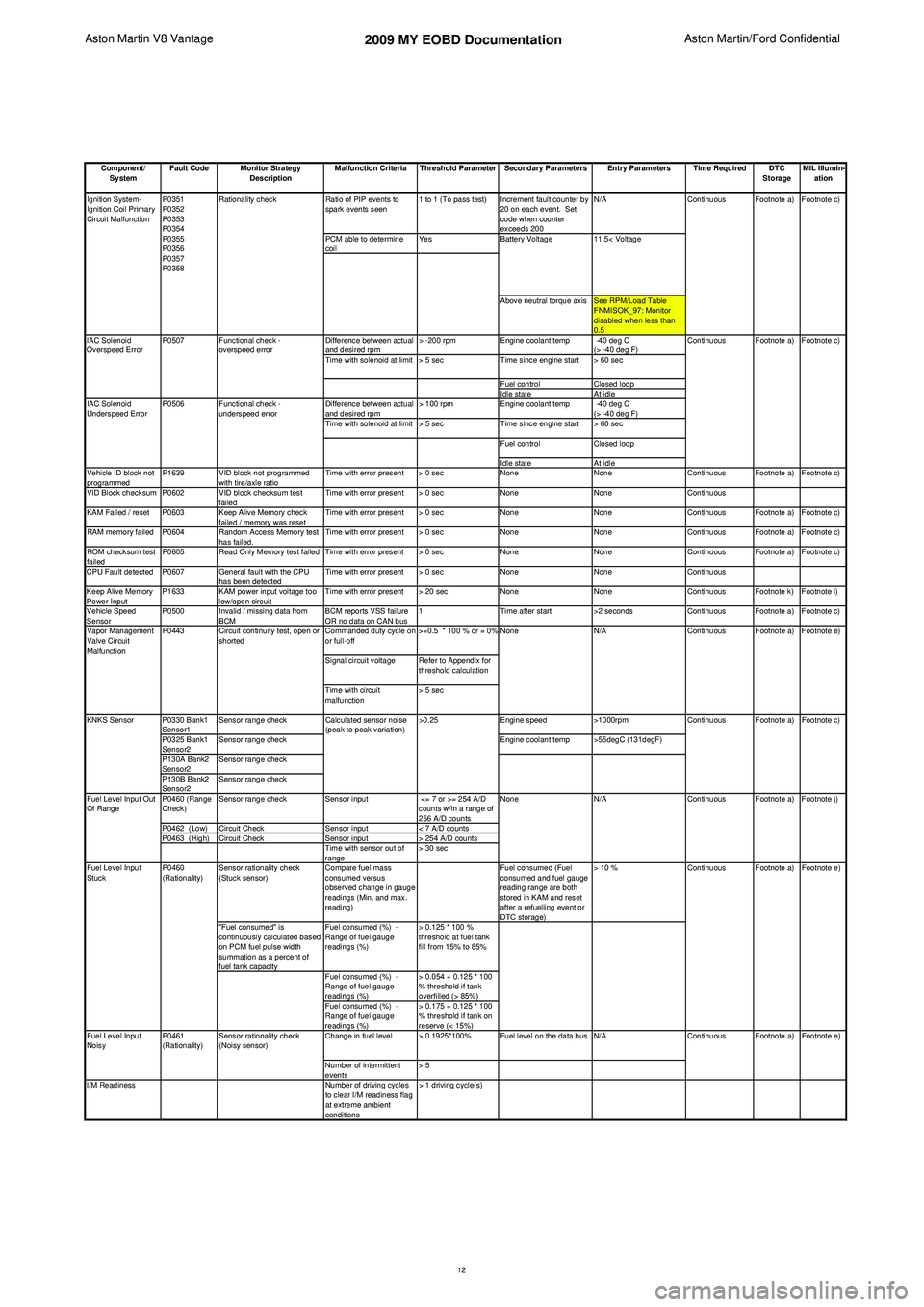

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Increment fault counter by

20 on each event. Set

code when counter

exceeds 200 N/A

PCM able to determine

coil Yes

Above neutral torque axis See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Difference between actual

and desired rpm > -200 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Vehicle Speed

Sensor P0500 Invalid / missing data from

BCM BCM reports VSS failure

OR no data on CAN bus1

Time after start >2 secondsContinuous Footnote a) Footnote c)

Commanded duty cycle on

or full-off >=0.5 * 100 % or = 0%

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0330 Bank1

Sensor1 Sensor range check

Engine speed>1000rpm

P0325 Bank1

Sensor2 Sensor range check

Engine coolant temp >55degC (131degF)

P130A Bank2

Sensor2 Sensor range check

P130B Bank2

Sensor2 Sensor range check

P0460 (Range

Check) Sensor range check

Sensor input <= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) Circuit Check Sensor input< 7 A/D counts

P0463 (High) Circuit Check Sensor input> 254 A/D counts

Time with sensor out of

range > 30 sec

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gauge

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refuelling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulse width

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.125 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.054 + 0.125 * 100

% threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.175 + 0.125 * 100

% threshold if tank on

reserve (< 15%)

Change in fuel level > 0.1925*100% Fuel level on the data bus N/A

Number of intermittent

events > 5

I/M Readiness Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Footnote e)

Footnote a)

Footnote c)

Footnote a) Footnote j) Footnote e)

Fuel Level Input

Noisy Continuous Footnote a)

Continuous Footnote a)

P0461

(Rationality) Sensor rationality check

(Noisy sensor)

Fuel Level Input

Stuck

P0460

(Rationality) Continuous

N/A Continuous

Calculated sensor noise

(peak to peak variation)

>0.25

KNKS Sensor

Fuel Level Input Out

Of Range NoneFootnote a) Footnote e)

Vapor Management

Valve Circuit

Malfunction P0443 Circuit continuity test, open or

shorted None

N/A Continuous

11.5< Voltage

Ignition System-

Ignition Coil Primary

Circuit Malfunction

IAC Solenoid

Underspeed Error P0507

P0506

Functional check -

overspeed error

Functional check -

underspeed error

IAC Solenoid

Overspeed Error

Footnote a) Footnote c)

Continuous

P0351

P0352

P0353

P0354

P0355

P0356

P0357

P0358

Rationality check

Continuous Footnote a) Footnote c)

Battery Voltage

12

Page 912 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0420

(Bank 1) HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio> 0.76 (Unitless) Engine coolant temp and

ECT sensor OK

(P0117/0118) 65C < Engine coolant

< 110C (150 - 230F)

Once per driving

cycleFootnote a) Footnote c)

P0430

(Bank 2) HC efficiency inferred from

oxygen storage capacity Rear/Front HO2S switch

ratio>0.76 (Unitless) Intake air temp and IAT

sensor OK (P0112/0113) -7C < Inlet Air Tmp

< 82C (20-180F) Approximately 900

sec

Minimum time since start

to run Catalyst Monitor 60 sec

Air mass range cell 1 HO2S11 switches : 200 HO2S21 switches: 200 3.78 - 11.3 g/s

(0.5-1.5 lb/min)

Air mass range cell 2 HO2S11 switches : 200 HO2S21 switches: 200 11.3 - 18.9 g/sec

(1.5-2.5 lb/min)

Air mass range cell 3 HO2S11 switches : 200 HO2S21 switches:

FEGO2_MX_CT3 18.9 - 26.5 g/s

(2.5-3.5 lb/min)

Maximum number of

HO2S11 (Bank 1 front)

switches to allow monitor

completion 300

Maximum number of

HO2S21 (Bank 2 front)

switches to allow monitor

completion 300

Load range for air

mass cell 1 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Load range for air

mass cell 2 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Load range for air

mass cell 3 HO2S11 switches : 200

HO2S21 switches: 200 0.1 * 100 % - 1.0 * 100 %

Rpm range for air

mass cell 1 HO2S11 switches : 200

HO2S21 switches: 200 0 - 4000 rpmCatalyst Efficiency MonitorCatalyst System

Efficiency Below

Threshold

(Index Monitor)

1