tire ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 460 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)4-4-10 Workshop Manual May 2007

Display Unit

The display unit provides additional features when correctly

connected to a previously installed ‘Smartire’ system. The

display unit connects directly to the front of the basic

‘Smartire’ receiver and is powered from the vehicle circuits.

The display will be fully illu minated during use but will go

into ‘Energy Saver’ mode when no activity is detected.

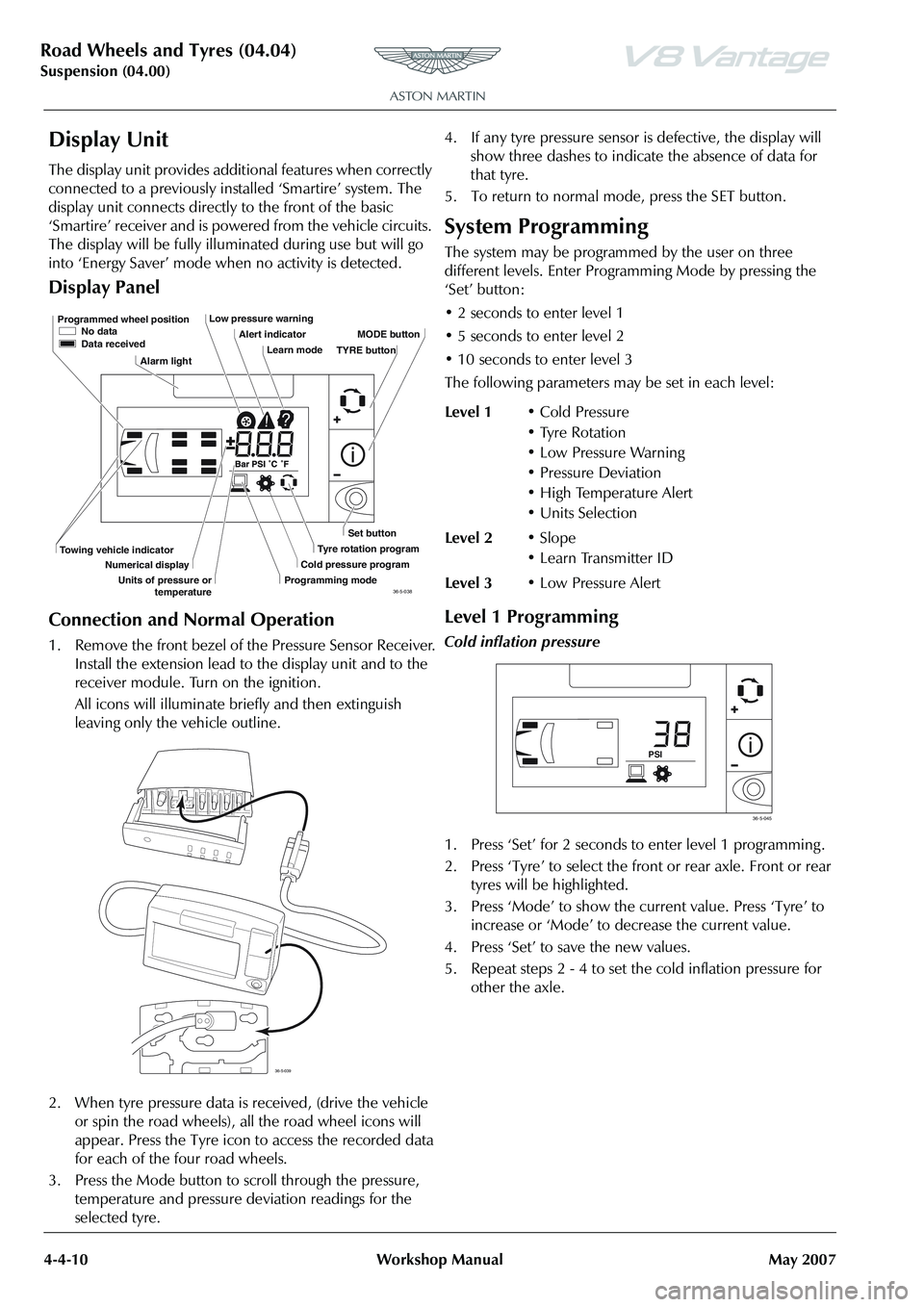

Display Panel

Connection and Normal Operation

1. Remove the front bezel of the Pressure Sensor Receiver. Install the extension lead to the display unit and to the

receiver module. Turn on the ignition.

All icons will illuminate briefly and then extinguish

leaving only the vehicle outline.

2. When tyre pressure data is received, (drive the vehicle

or spin the road wheels), all the road wheel icons will

appear. Press the Tyre icon to access the recorded data

for each of the four road wheels.

3. Press the Mode button to scroll through the pressure, temperature and pressure deviation readings for the

selected tyre. 4. If any tyre pressure sensor is defective, the display will

show three dashes to indicate the absence of data for

that tyre.

5. To return to normal mode, press the SET button.

System Programming

The system may be programmed by the user on three

different levels. Enter Progra mming Mode by pressing the

‘Set’ button:

• 2 seconds to enter level 1

• 5 seconds to enter level 2

• 10 seconds to enter level 3

The following parameters ma y be set in each level:

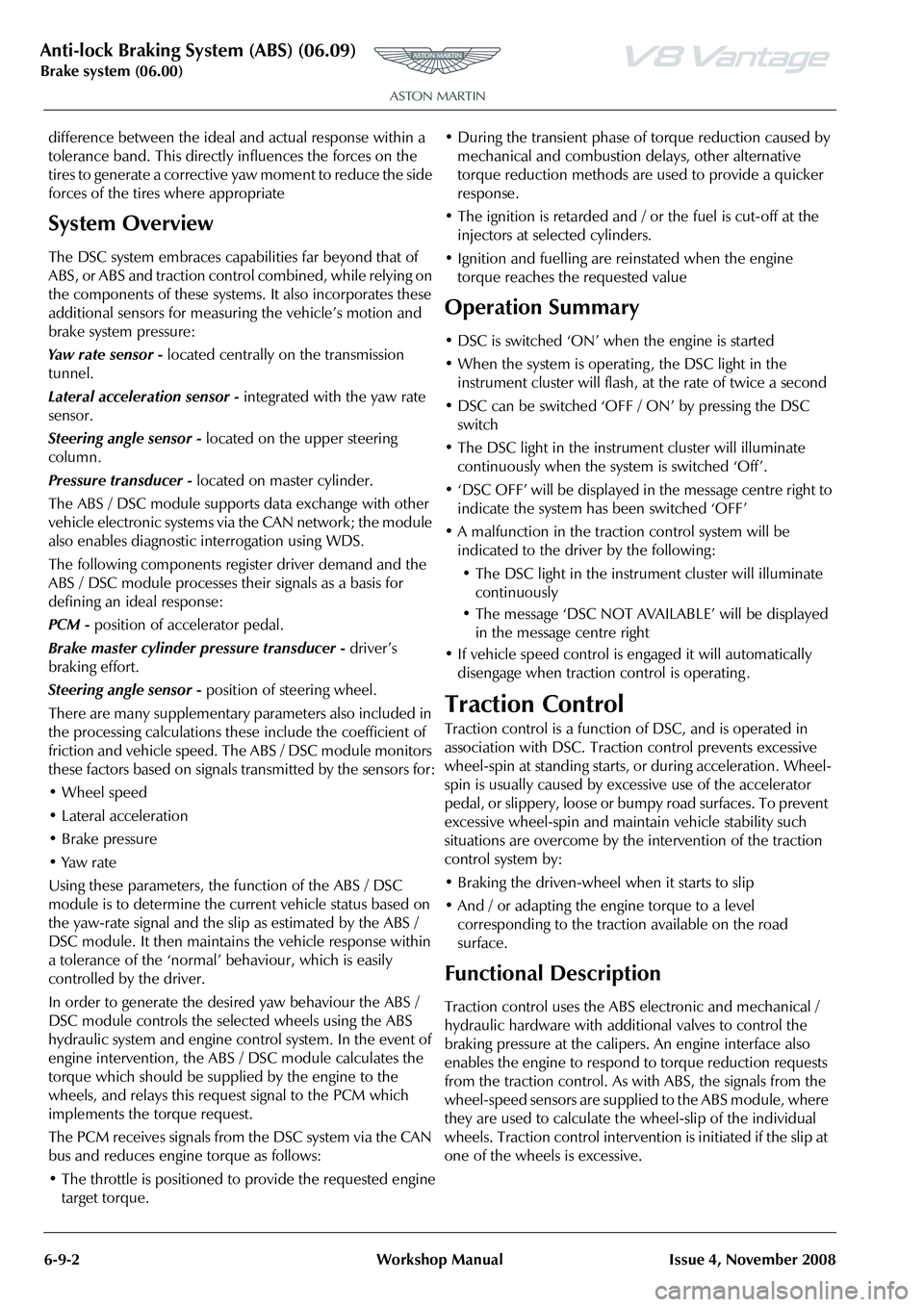

Level 1 Programming

Cold inflation pressure

1. Press ‘Set’ for 2 seconds to enter level 1 programming .

2. Press ‘Tyre’ to select the front or rear axle. Front or rear

tyres will be highlighted.

3. Press ‘Mode’ to show the current value. Press ‘Tyre’ to increase or ‘Mode’ to decrease the current value.

4. Press ‘Set’ to save the new values.

5. Repeat steps 2 - 4 to set the cold inflation pressure for other the axle.

Programmed wheel position No data

Data received

Alarm light Low pressure warning

Alert indicatorLearn mode MODE button

Set button

Tyre rotation program

Cold pressure program

Programming mode

Towing vehicle indicator

Numerical display

Units of pressure or temperature TYRE button

36-5-038

36-5-039

Level 1

• Cold Pressure

• Tyre Rotation

• Low Pressure Warning

• Pressure Deviation

• High Temperature Alert

•Units Selection

Level 2 •Slope

• Learn Transmitter ID

Level 3 • Low Pressure Alert

PSI

36-5-045

Page 508 of 947

Anti-lock Braking System (ABS) (06.09)

Brake system (06.00)

6-9-2 Workshop Manual Issue 4, November 2008

difference between the ideal and actual response within a

tolerance band. This directly influences the forces on the

tires to generate a corrective yaw moment to reduce the side

forces of the tires where appropriate

System Overview

The DSC system embraces capabilities far beyond that of

ABS, or ABS and traction control combined, while relying on

the components of these systems. It also incorporates these

additional sensors for measur ing the vehicle’s motion and

brake system pressure:

Ya w r a t e s e n s o r - located centrally on the transmission

tunnel.

Lateral acceleration sensor - integrated with the yaw rate

sensor.

Steering angle sensor - located on the upper steering

column.

Pressure transducer - located on master cylinder.

The ABS / DSC module supports data exchange with other

vehicle electronic systems via the CAN network; the module

also enables diagnostic interrogation using WDS.

The following components register driver demand and the

ABS / DSC module processes their signals as a basis for

defining an ideal response:

PCM - position of accelerator pedal.

Brake master cylinder pressure transducer - driver’s

braking effort.

Steering angle sensor - position of steering wheel.

There are many supplementary parameters also included in

the processing calculations these include the coefficient of

friction and vehicle speed. The ABS / DSC module monitors

these factors based on signals transmitted by the sensors for:

• Wheel speed

• Lateral acceleration

• Brake pressure

• Yaw rate

Using these parameters, the function of the ABS / DSC

module is to determine the current vehicle status based on

the yaw-rate signal and the slip as estimated by the ABS /

DSC module. It then maintains the vehicle response within

a tolerance of the ‘normal’ behaviour, which is easily

controlled by the driver.

In order to generate the desired yaw behaviour the ABS /

DSC module controls the selected wheels using the ABS

hydraulic system and engine control system. In the event of

engine intervention, the ABS / DSC module calculates the

torque which should be supplied by the engine to the

wheels, and relays this request signal to the PCM which

implements the torque request.

The PCM receives signals from the DSC system via the CAN

bus and reduces engine torque as follows:

• The throttle is positioned to provide the requested engine target torque. • During the transient phase of torque reduction caused by

mechanical and combustion delays, other alternative

torque reduction methods are used to provide a quicker

response.

• The ignition is retarded and / or the fuel is cut-off at the injectors at selected cylinders.

• Ignition and fuelling are reinstated when the engine torque reaches the requested value

Operation Summary

• DSC is switched ‘ON’ when the engine is started

• When the system is operating , the DSC light in the instrument cluster will flash, at the rate of twice a second

• DSC can be switched ‘OFF / ON’ by pressing the DSC switch

• The DSC light in the instru ment cluster will illuminate

continuously when the system is switched ‘Off’.

• ‘DSC OFF’ will be displayed in the message centre right to indicate the system has been switched ‘OFF’

• A malfunction in the traction control system will be indicated to the driver by the following:

• The DSC light in the instru ment cluster will illuminate

continuously

• The message ‘DSC NOT AVAILABLE’ will be displayed in the message centre right

• If vehicle speed control is engaged it will automatically disengage when traction control is operating .

Traction Control

Traction control is a function of DSC, and is operated in

association with DSC. Traction control prevents excessive

wheel-spin at standing starts, or during acceleration. Wheel-

spin is usually caused by ex cessive use of the accelerator

pedal, or slippery, loose or bumpy road surfaces. To prevent

excessive wheel-spin and mainta in vehicle stability such

situations are overcome by the intervention of the traction

control system by:

• Braking the driven-wheel when it starts to slip

• And / or adapting the engine torque to a level corresponding to the traction available on the road

surface.

Functional Description

Traction control uses the ABS electronic and mechanical /

hydraulic hardware with additional valves to control the

braking pressure at the calipe rs. An engine interface also

enables the engine to respond to torque reduction requests

from the traction control. As with ABS, the signals from the

wheel-speed sensors are supplied to the ABS module, where

they are used to calculate the wheel-slip of the individual

wheels. Traction control intervention is initiated if the slip at

one of the wheels is excessive.

Page 742 of 947

Fluids/Capacities

Appendix & Glossary

May 2007 Workshop Manual 20-1-3

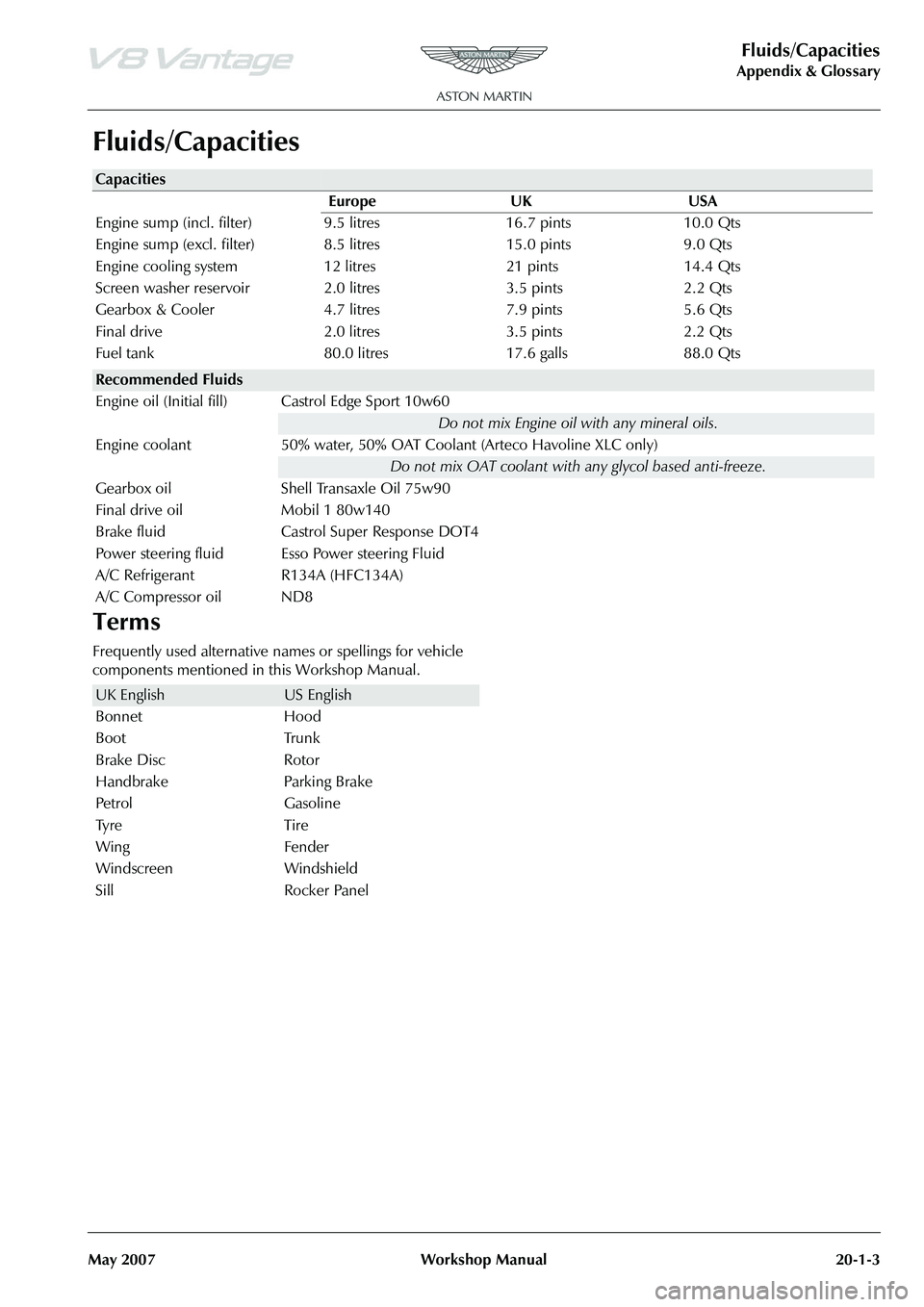

Fluids/Capacities

Terms

Frequently used alternative names or spellings for vehicle

components mentioned in this Workshop Manual.

Capacities

Europe UK USA

Engine sump (incl. filter) 9 .5 litres 16.7 pints 10.0 Qts

Engine sump (excl. filter) 8 .5 litres 15.0 pints 9.0 Qts

Engine cooling system 12 litres 21 pints 14.4 Qts

Screen washer reservoir 2.0 litres 3.5 pints 2.2 Qts

Gearbox & Cooler 4.7 litres 7.9 pints 5.6 Qts

Final drive 2.0 litres 3.5 pints 2.2 Qts

Fuel tank 80.0 litres 17.6 galls 88.0 Qts

Recommended Fluids

Engine oil (Initial fill) Castrol Edge Sport 10w60

Do not mix Engine oil with any mineral oils.

Engine coolant 50% water, 50% OAT Coolant (Arteco Havoline XLC only)

Do not mix OAT coolant with any glycol based anti-freeze.

Gearbox oil Shell Transaxle Oil 75w90

Final drive oil Mobil 1 80w140

Brake fluid Castrol Super Response DOT4

Power steering fluid Esso Power steering Fluid

A/C Refrigerant R134A (HFC134A)

A/C Compressor oil ND8

UK EnglishUS English

Bonnet Hood

Boot Trunk

Brake Disc Rotor

Handbrake Parking Brake

Petrol Gasoline

Tyre Tire

Wing Fender

Windscreen Windshield

Sill Rocker Panel

Page 828 of 947

Electronics Training Programme

Making Calls

When connected, all calls are handsfree. Termin ate a VR session at any time by pressing the

button.

A phone number can be entered as a whole number or by two or more segments. A segment can

include up to 15 digits. An entire number can inclu de no more than 32 digits. If required a number

can also begin by saying either ‘Star’ (*), ‘Hash’ (#) or ‘Plus’ (+).

Note: Speak numbers as continuous digits. For exampl e, dictate 555-2211 as ‘5-5-5-2-2-1-1’, not ‘5-

5-5-twenty-two-eleven’.

To make a call using a whole number:

1. Press the button. When prompted, say ‘Dial Nu mber’. The system responds with

‘Number please?’.

2. Dictate the phone number as a single set of digits (without pauses between digits). The system

recites the digits heard.

3. If the number recited by the system is correct, say ‘Dial’. The system re sponds with ‘Dialling’.

To make a call using a number segment:

1. Press the button. When prompted, say ‘Dial Number’. The system responds with

‘Number please?’.

2. Dictate the first segment of the whole number (For example, say the 1st three numbers.) The system recites the numbers heard.

3. Dictate the next segment of the whole number. The system recites the numbers heard. Repeat

until you have entered the complete phone number.

4. When the complete number is recited by t he system, say ‘Dial’. The system responds:

‘Dialling’.

Note: To delete a phone number segment, say ‘Clear ’ when prompted for the next segment. The

system responds with ‘Last String Entry Cleared’, ec hoes any remaining segments, and waits for you to

dictate a new segment.

Note: To clear all phone number segments dictated so far, say ‘Clear All’ when prompted for the next

segment. The system clears all segments and returns to the ‘Number please?’ prompt.

23

Page 832 of 947

Electronics Training Programme

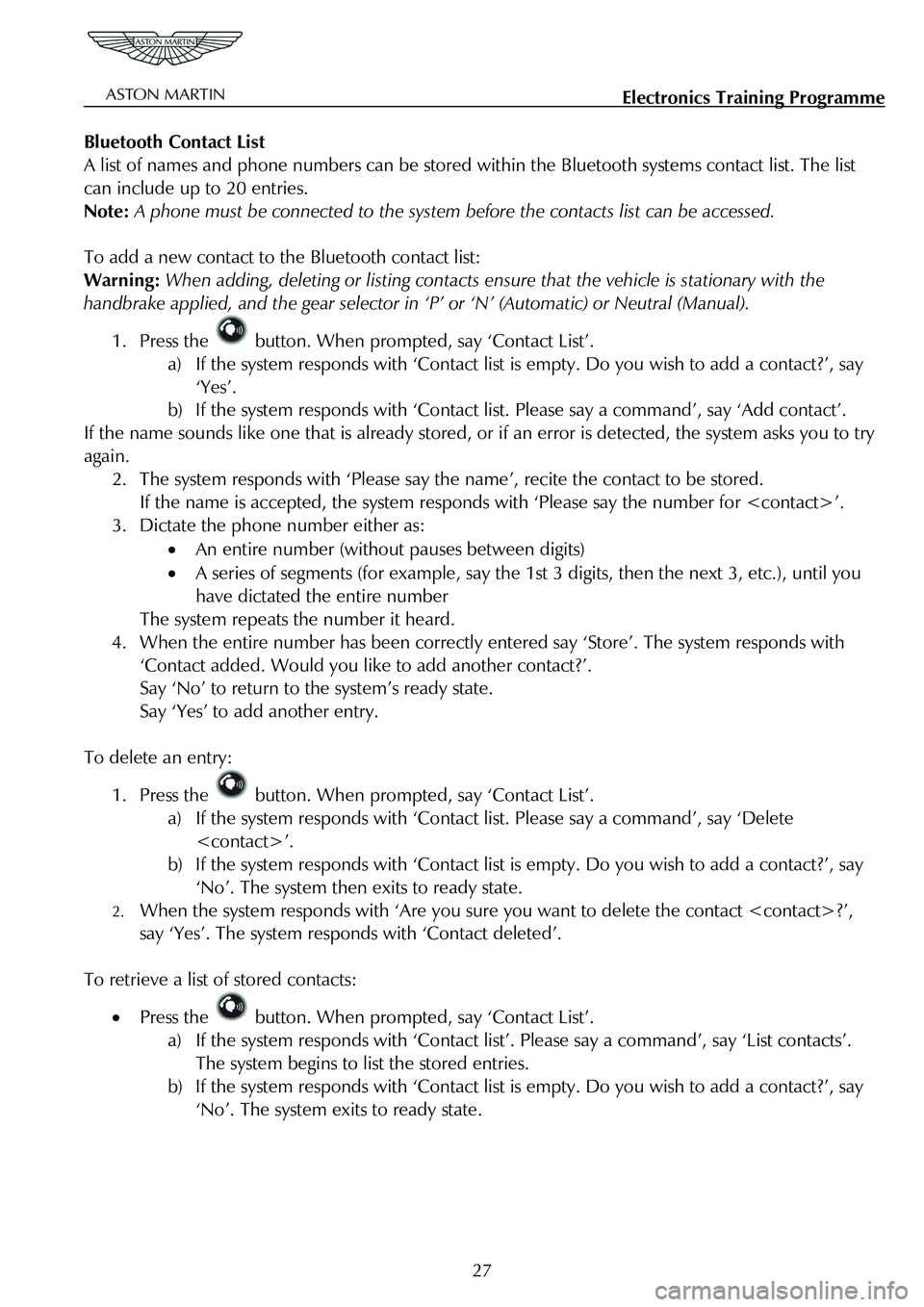

Bluetooth Contact List

A list of names and phone numbers can be stored wi thin the Bluetooth systems contact list. The list

can include up to 20 entries.

Note: A phone must be connected to the system be fore the contacts list can be accessed.

To add a new contact to the Bluetooth contact list:

Warning: When adding, deleting or listing contacts en sure that the vehicle is stationary with the

handbrake applied, and the gear selector in ‘P’ or ‘N’ (Automatic) or Neutral (Manual).

1. Press the button. When prompted, say ‘Contact List’.

a) If the system responds with ‘Contact list is empty. Do you wish to add a contact?’, say

‘Yes’.

b) If the system responds with ‘Contact li st. Please say a command’, say ‘Add contact’.

If the name sounds like one that is already stored, or if an error is detected, the system asks you to try

again.

2. The system responds with ‘Please say t he name’, recite the contact to be stored.

If the name is accepted, the system responds with ‘Please say the number for

3. Dictate the phone number either as:

• An entire number (without pauses between digits)

• A series of segments (for example, say the 1st 3 digits, then the next 3, etc.), until you

have dictated the entire number

The system repeats the number it heard.

4. When the entire number has been correctly entered say ‘Store’. The system responds with

‘Contact added. Would you like to add another contact?’.

Say ‘No’ to return to the system’s ready state.

Say ‘Yes’ to add another entry.

To delete an entry:

1. Press the button. When prompted, say ‘Contact List’.

a) If the system responds with ‘Contact list. Please say a command’, say ‘Delete

b) If the system responds with ‘Contact list is empty. Do you wish to add a contact?’, say

‘No’. The system then exits to ready state.

2. When the system responds with ‘Are you sure you want to delete the contact

say ‘Yes’. The system respon ds with ‘Contact deleted’.

To retrieve a list of stored contacts:

• Press the button. When prompted, say ‘Contact List’.

a) If the system responds with ‘Contact list ’. Please say a command’, say ‘List contacts’.

The system begins to list the stored entries.

b) If the system responds with ‘Contact list is empty. Do you wish to add a contact?’, say

‘No’. The system exits to ready state.

27

Page 854 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 8 of 43

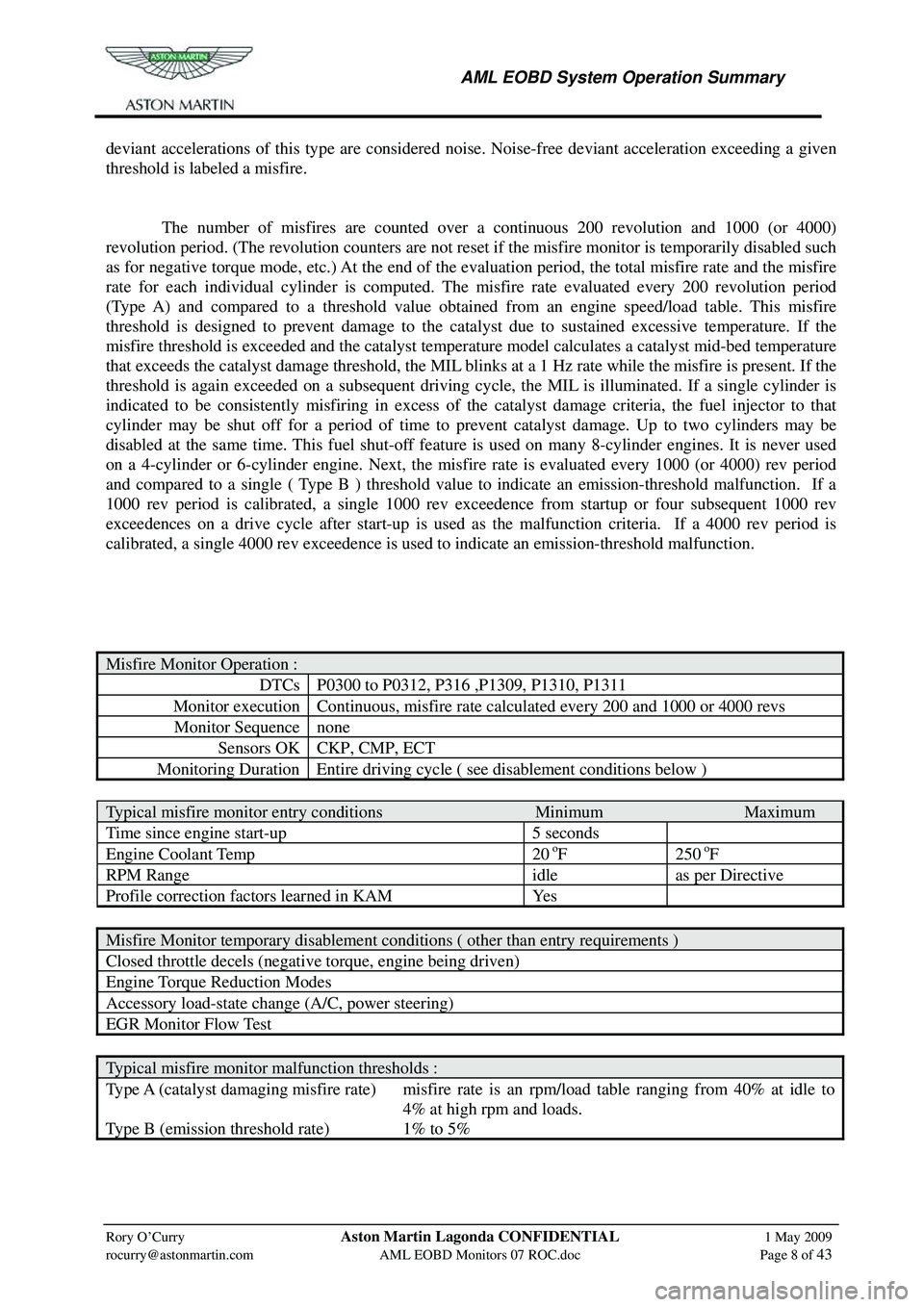

deviant accelerations of this type are considered noise. Noise-free deviant acceleration exceeding a given

threshold is labeled a misfire.

The number of misfires are counted over a continuous 200 revolution and 1000 (or 4000)

revolution period. (The revolution counters are not reset if the misfire monitor is temporarily disabled such

as for negative torque mode, etc.) At the end of the evaluation period, the total misfire rate and the misfire

rate for each individual cylinder is computed. The misfire rate evaluated every 200 revolution period

(Type A) and compared to a threshold value obtaine d from an engine speed/load table. This misfire

threshold is designed to prevent damage to the cat alyst due to sustained excessive temperature. If the

misfire threshold is exceeded and the catalyst temperature model calculates a catalyst mid-bed temperature

that exceeds the catalyst damage threshold, the MIL blinks at a 1 Hz rate while the misfire is present. If the

threshold is again exceeded on a subsequent driving cy cle, the MIL is illuminated. If a single cylinder is

indicated to be consistently misfiring in excess of the catalyst damage criteria, the fuel injector to that

cylinder may be shut off for a period of time to pr event catalyst damage. Up to two cylinders may be

disabled at the same time. This fuel shut-off feature is used on many 8-cylinder engines. It is never used

on a 4-cylinder or 6-cylinder engine. Next, the misf ire rate is evaluated every 1000 (or 4000) rev period

and compared to a single ( Type B ) threshold value to indicate an emission-threshold malfunction. If a

1000 rev period is calibrated, a single 1000 rev exceedence from startup or four subsequent 1000 rev

exceedences on a drive cycle after start-up is used as the malfunction criteria. If a 4000 rev period is

calibrated, a single 4000 rev exceedence is used to indicate an emission-threshold malfunction.

Misfire Monitor Operation :

DTCs P0300 to P0312, P316 ,P1309, P1310, P1311

Monitor execution Continuous, misfire rate calculated every 200 and 1000 or 4000 revs

Monitor Sequence none

Sensors OK CKP, CMP, ECT

Monitoring Duration Entire driving cycle ( see disablement conditions below )

Typical misfire monitor entry conditions Minimum Maximum

Time since engine start-up 5 seconds

Engine Coolant Temp 20 oF 250 oF

RPM Range idle as per Directive

Profile correction factors learned in KAM Yes

Misfire Monitor temporary disablement conditions ( other than entry requirements )

Closed throttle decels (negative torque, engine being driven)

Engine Torque Reduction Modes

Accessory load-state change (A/C, power steering)

EGR Monitor Flow Test

Typical misfire monitor malfunction thresholds :

Type A (catalyst damaging misfire rate) misfire rate is an rpm/load table ranging from 40% at idle to

4% at high rpm and loads.

Type B (emission threshold rate) 1% to 5%

Page 900 of 947

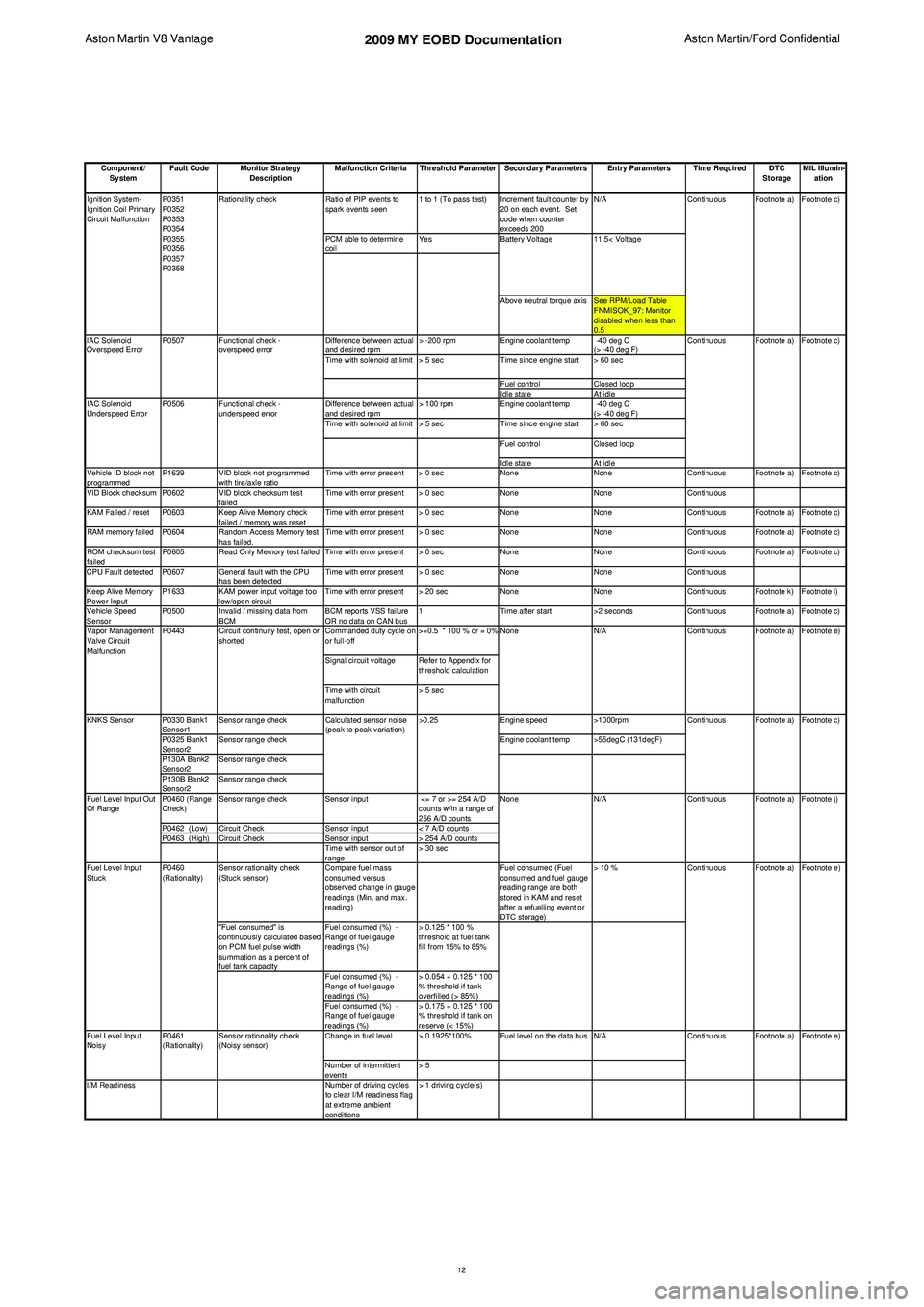

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Increment fault counter by

20 on each event. Set

code when counter

exceeds 200 N/A

PCM able to determine

coil Yes

Above neutral torque axis See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Difference between actual

and desired rpm > -200 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Vehicle Speed

Sensor P0500 Invalid / missing data from

BCM BCM reports VSS failure

OR no data on CAN bus1

Time after start >2 secondsContinuous Footnote a) Footnote c)

Commanded duty cycle on

or full-off >=0.5 * 100 % or = 0%

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0330 Bank1

Sensor1 Sensor range check

Engine speed>1000rpm

P0325 Bank1

Sensor2 Sensor range check

Engine coolant temp >55degC (131degF)

P130A Bank2

Sensor2 Sensor range check

P130B Bank2

Sensor2 Sensor range check

P0460 (Range

Check) Sensor range check

Sensor input <= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) Circuit Check Sensor input< 7 A/D counts

P0463 (High) Circuit Check Sensor input> 254 A/D counts

Time with sensor out of

range > 30 sec

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gauge

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refuelling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulse width

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.125 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.054 + 0.125 * 100

% threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.175 + 0.125 * 100

% threshold if tank on

reserve (< 15%)

Change in fuel level > 0.1925*100% Fuel level on the data bus N/A

Number of intermittent

events > 5

I/M Readiness Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Footnote e)

Footnote a)

Footnote c)

Footnote a) Footnote j) Footnote e)

Fuel Level Input

Noisy Continuous Footnote a)

Continuous Footnote a)

P0461

(Rationality) Sensor rationality check

(Noisy sensor)

Fuel Level Input

Stuck

P0460

(Rationality) Continuous

N/A Continuous

Calculated sensor noise

(peak to peak variation)

>0.25

KNKS Sensor

Fuel Level Input Out

Of Range NoneFootnote a) Footnote e)

Vapor Management

Valve Circuit

Malfunction P0443 Circuit continuity test, open or

shorted None

N/A Continuous

11.5< Voltage

Ignition System-

Ignition Coil Primary

Circuit Malfunction

IAC Solenoid

Underspeed Error P0507

P0506

Functional check -

overspeed error

Functional check -

underspeed error

IAC Solenoid

Overspeed Error

Footnote a) Footnote c)

Continuous

P0351

P0352

P0353

P0354

P0355

P0356

P0357

P0358

Rationality check

Continuous Footnote a) Footnote c)

Battery Voltage

12

Page 922 of 947

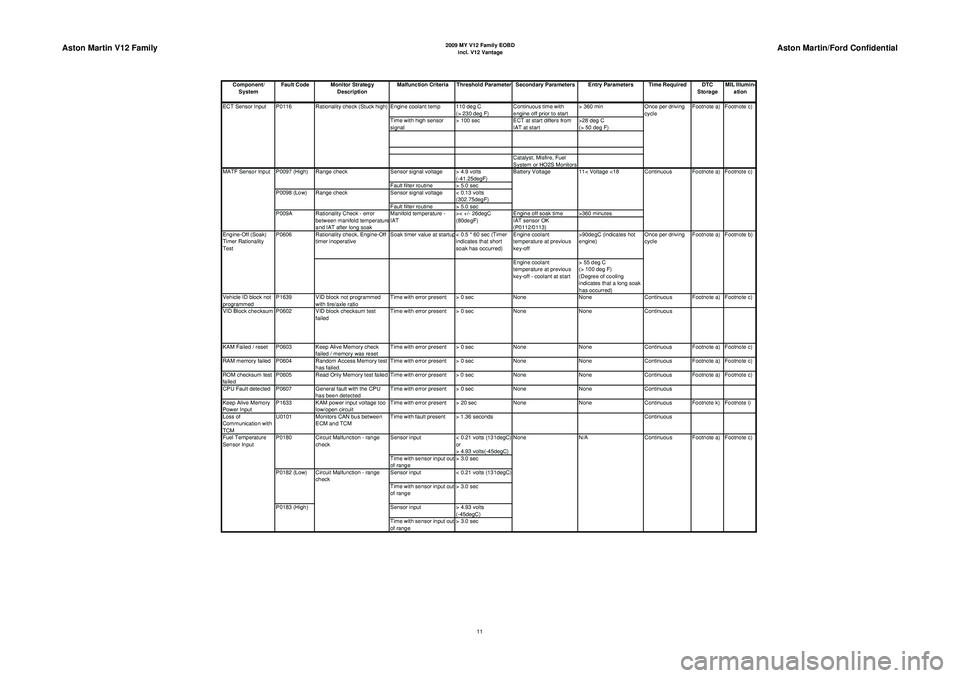

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Engine coolant temp 110 deg C (> 230 deg F)Continuous time with

engine off prior to start > 360 min

Time with high sensor

signal > 100 sec

ECT at start differs from

IAT at start >28 deg C

(> 50 deg F)

Catalyst, Misfire, Fuel

System or HO2S Monitors

Sensor signal voltage > 4.9 volts (-41.25degF)

Fault filter routine > 5.0 sec

Sensor signal voltage < 0.13 volts (302.75degF)

Fault filter routine > 5.0 sec Engine off soak time >360 minutes

IAT sensor OK

(P0112/0113)

Rationality check, Engine-Off

timer inoperative Soak timer value at startup < 0.5 * 60 sec (Timer

indicates that short

soak has occurred)Engine coolant

temperature at previous

key-off >90degC (indicates hot

engine)

Engine coolant

temperature at previous

key-off - coolant at start > 55 deg C

(> 100 deg F)

(Degree of cooling

indicates that a long soak

has occurred)

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Loss of

Communication with

TCM U0101 Monitors CAN bus between

ECM and TCM Time with fault present > 1.36 seconds

Continuous

Sensor input < 0.21 volts (131degC)

or

> 4.93 volts(-45degC)

Time with sensor input out

of range > 3.0 sec

Sensor input < 0.21 volts (131degC)

Time with sensor input out

of range > 3.0 sec

Sensor input > 4.93 volts

(-45degC)

Time with sensor input out

of range > 3.0 sec 11< Voltage <18 Continuous Footnote a) Footnote c)

MATF Sensor Input P0097 (High) Range check Battery Voltage

P0098 (Low) Range check

P009A Rationality Check - error between manifold temperature

and IAT after long soak Manifold temperature -

IAT

>< +/- 26degC

(80degF)

ECT Sensor Input P0116 Rationality check (Stuck high)

Once per driving

cycleFootnote a) Footnote c)

Engine-Off (Soak)

Timer Rationality

Test P0606

Once per driving

cycleFootnote a) Footnote b)

Fuel Temperature

Sensor Input P0180

P0182 (Low)

P0183 (High)Circuit Malfunction - range

check

Circuit Malfunction - range

check

None

N/A Continuous Footnote a) Footnote c)

11