jack points AUDI A3 CABRIOLET 2015 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2015, Model line: A3 CABRIOLET, Model: AUDI A3 CABRIOLET 2015Pages: 302, PDF Size: 73.83 MB

Page 268 of 302

266 What do I do n ow ?

Raising the vehicle

The vehicle must be lifted with the jack first

before the wheel can be removed .

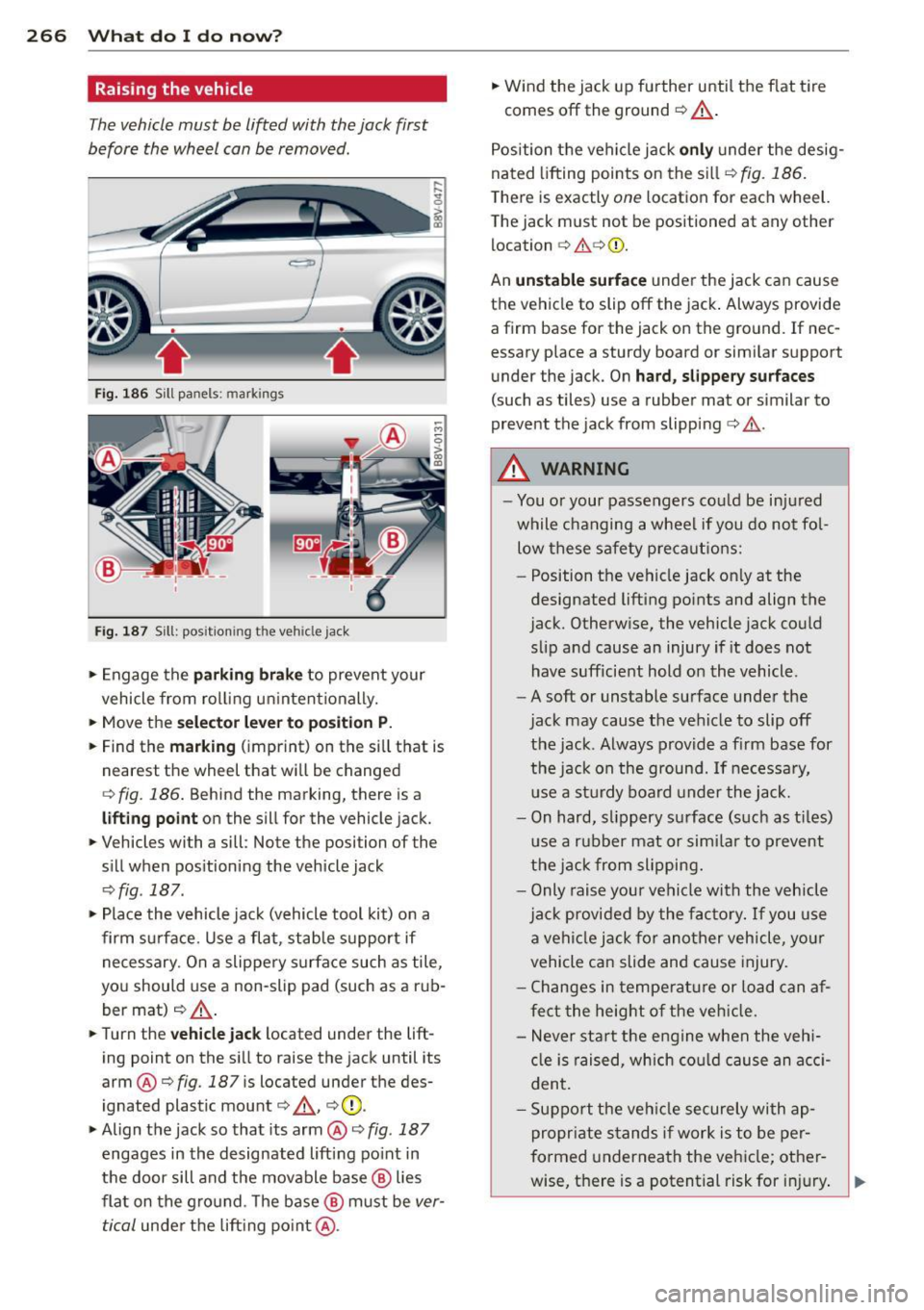

Fig. 186 Sill panels: mark ings

Fig. 187 Sill : posit ion ing the veh icle jack

., Engage the pa rkin g brak e to prevent your

vehicle from rolling un intentionally.

., Move the

se lect or l ever to po siti on P .

., Find the marking (imprint) on the sill that is

nearest the wheel that wi ll be changed

r::> fig. 186. Behind the marking, there is a

lifting po int on the sill for the vehicle jack.

., Vehicles with a sill : Note the position of the

s ill when pos itioning the vehicle jack

¢ fig . 187 .

., Place the vehicle jack (vehicle tool kit) on a

firm su rface. Use a flat, stab le support if

necessary. On a slippe ry surface such as tile,

you should use a non-slip pad (such as a rub

ber mat)

c::> A .

., Turn the vehicle jack located under the lift

ing point on the sill to raise the jack until its

arm @r=>

fig. 187 is located under the des

ignated plastic mount

c> A, r=>@ .

., Align the jack so that its arm@r=> fig. 187

engages in the designated lifting point in

the door sill and the movable base @ lies

flat on the gro und . T he base @ must be

ver

tical

under the lift ing po int @ . .,

Wind the jack up fu rther until the f lat tire

comes off the ground

r=> A.

Position t he vehicle jack only under the desig

nated lifting points on the si ll

¢fig. 186.

There is exactly one location for each wheel.

The jack must not be positioned at any other

location

r=> ,&. r=>Q).

An un sta ble surf ace under the jack can cause

the vehicle to slip off the jack . Always provide

a firm base for the jack on the ground . If nec

essary place a sturdy board or similar support

under the jack. On

hard, sl ipp ery su rfaces

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping

c> ,&. .

A WARNING ~

-You or your passengers could be injured

while changing a wheel if you do not fo l

low these safety preca utio ns:

- Position the vehicle jack on ly at the

designated lifting points and align the

jack. Otherwise, the vehicle jack could

slip and cause an injury if it does not

have sufficient hold on the vehicle .

- A soft or unstable surface under the

jack may cause the vehicle to slip off

the jack . Always provide a firm base for

the jack on the ground. If necessa ry,

use a stu rdy board under the jack.

- On hard, slippery surface (such as t iles)

use a rubber mat or simi lar to prevent

the jack from slipping.

- Only raise your vehicle with the vehicle

jack provided by the fac to ry.

If you use

a vehi cle jack for another vehicle, your

vehicle can slide and cause injury.

- Changes in temperat ure or load can af

fect the height o f the veh icle .

- Never start the engine when the vehi cle is raised, which co uld cause an acc i

dent.

- Suppo rt the ve hicle securely with ap

propr iate s tands if work is to be per

formed underneath the vehicle; other

wise, there is a potential risk for in jury . .,.

Page 269 of 302

....,

N

r--. > co

rl I.O

"' rl

"' rl

-To help prevent injury to yourself and

your passengers:

- Do not raise the vehicle until you are

sure the jack is secu rely engaged.

- Passengers must not remain in the ve

h icle when it is jacked up.

- Make sure that passengers wait in a

safe place away from the vehicle and

well away from the road and t raffic.

- M ake sure jack position is correct, ad

just as necessary and then conti nue to

ra ise the jack .

- Changes i n temperature or load can af

fect the height of the ve hicl e.

CD Note

Do not lift the vehicle by the sill. Pos ition

the vehicle jack only at the des ignated lift

ing points o n the sill. Othe rwise, your vehi

cle will be damaged.

Taking the wheel off/installing the spare

Follow these instructions step-by-step for

changing the wheel.

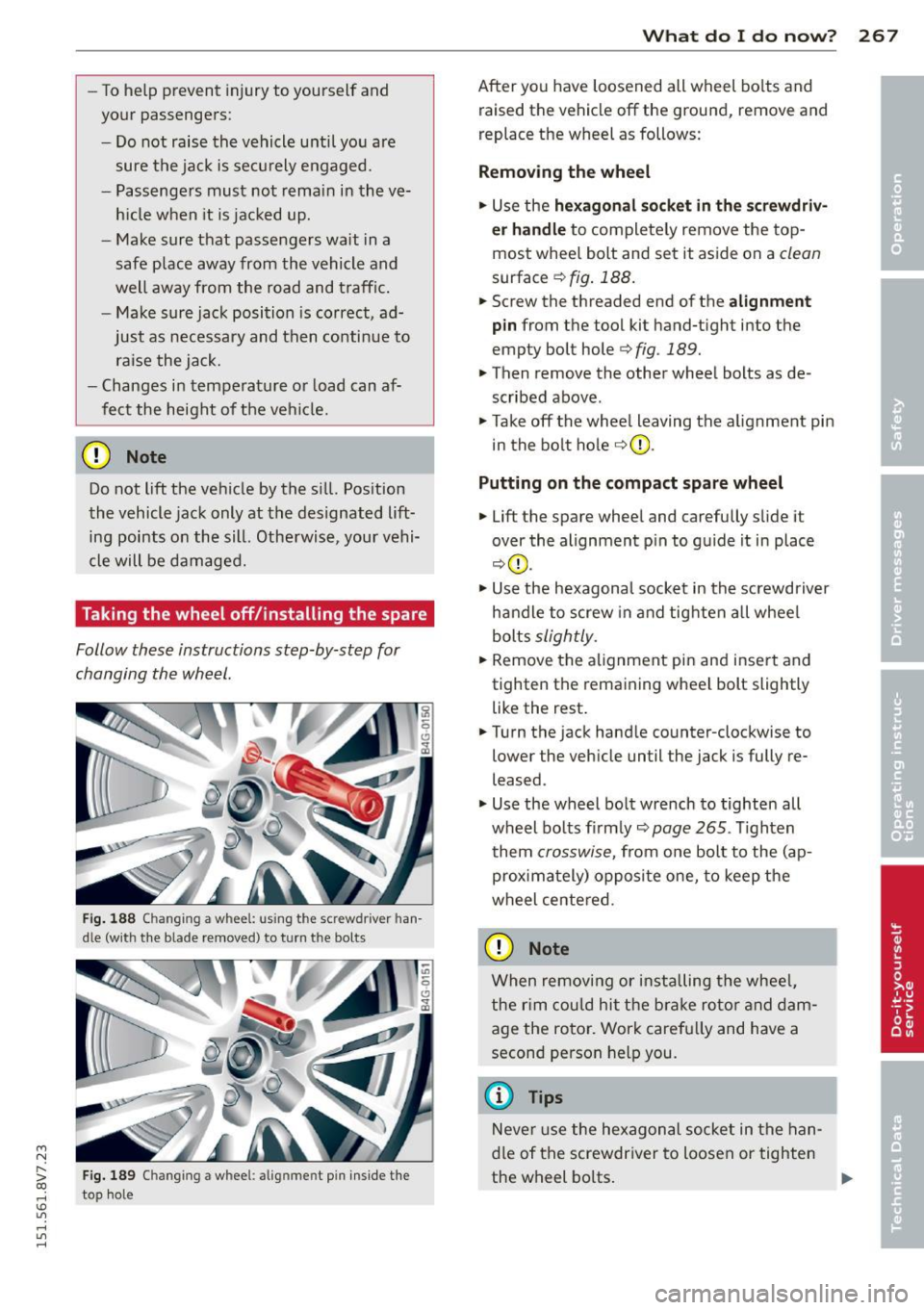

Fi g. 188 Changing a wheel: using the screwdriver han

dle (with th e blade re moved} to turn the bolts

F ig . 189 Changing a wheel: alignment pin inside th e

top hole

What do I d o now ? 267

After you have loosened all wheel bo lts and

raised the vehicle off the grou nd, remove and

replace the wheel as follows:

Removing the wheel

.,. Use the hexag onal socket in the scr ewdriv

er handle

to completely remove the top

most wheel bolt and set it aside on a

clean

surface c:> fig. 188.

.,. Screw the threaded end of the alignment

pin

from the tool kit hand-tight into the

empty bolt hole

c:> fig. 189.

.,. Then remove the other wheel bolts as de

scribed above.

.,. Tak e off the whee l leaving the a lignment pin

in the bo lt ho le

c:> (D .

Putting on the compact spare wheel

.,. Lift the spare wheel and carefully s lide it

over the alignment pin to guide it in place

c:>(D .

.,. Use the hexagona l socket in the screwdriver

handle to screw in and tig hten all whee l

bolts

slightly.

.,. Remove the a lignment pin and inse rt and

tighten the rema ining whee l bolt slightly

Like the rest .

.,. Turn the jack hand le counter-clockwise to

lower the vehicle until the jack is fully re

leased .

.,. Use the wheel bo lt wrench to tighten all

wheel bo lts f irmly

c:> page 265 . Tighten

them

crosswise, from o ne bolt to the (ap

proxima tely) oppo site one, to keep the

wheel cente red.

CD Note

When remov ing or i nsta lling the whee l,

the r im cou ld hit the b rake roto r and dam

age the ro tor. Wor k carefu lly and have a

second pe rson help you.

(D Tips

Neve r use the hexagonal socket in the han

d le of the screwdriver to loosen or tighten

the wheel bo lts .

llll-

Page 279 of 302

....,

N

r--. > co

rl I.O

"' rl

"' rl

Loading the vehicle onto a flat bed truck

Fig. 200 Veh icle on flat bed truck

Front hook up

.. Align the vehicle with the centerline of the

car carr ier ramp.

.. Attach the winch hook to the front towline

eye previously installed .

Rear hook up

.. Align the vehicle with the centerline of the

car carrier ramp.

.. Attach the winch hook to the rear towline

eye previously installed.

(D} Tips

Check carefully to make sure the hook-up

is secure before moving the car up the flat

bed truck ramp.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

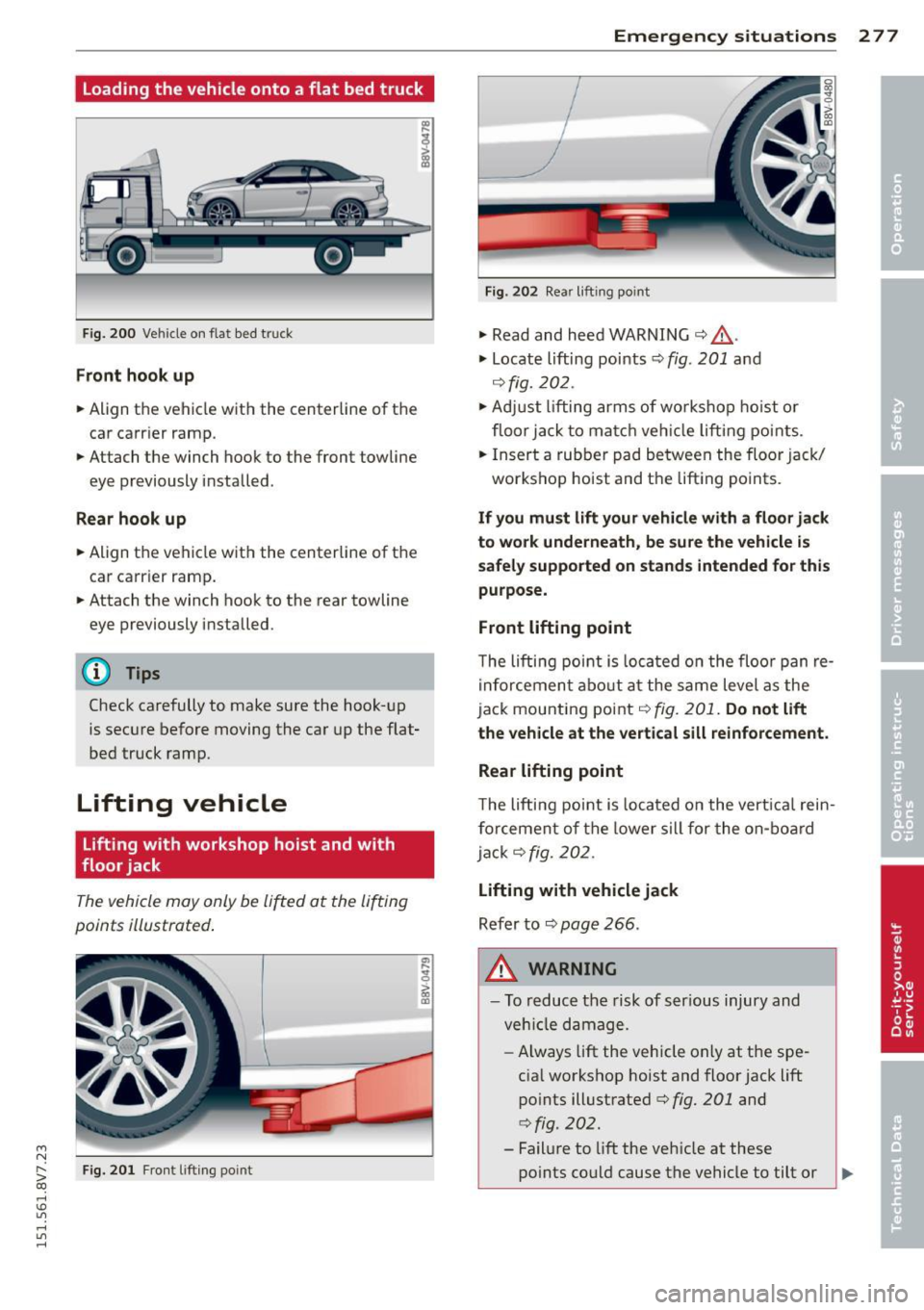

The vehicle may only be lifted at the lifting

points illustrated .

Fig. 201 Front l ifting point

Emergency situations 2 77

Fig. 202 Rea r liftin g po int

.,. Read and heed WARNING c::> .&, .

.,. Locate lifting points c::> fig. 201 and

¢ fig. 202 .

.,. Adju st lifting arms of workshop hoist or

floor jack to match veh icle lifting points.

.. Insert a rubber pad between the floor jack/

workshop hoist and the lift ing points.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stands intended for this

purpose .

Front lifting point

T he lifti ng point is loca ted on the floo r pan re

info rcemen t about at the same level as the

jack mounting point

c::>fig. 201. Do not lift

the vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located o n the vert ica l rein

forcement of the lower sill for the on-board

jack

c::> fig. 202 .

Lifting with vehicle jack

Refer to c:;, page 266.

A WARNING

-To reduce the risk of ser ious injury and

vehicle damage .

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jack lift

points illustrated

c:;, fig. 201 and

c:;, fig. 202.

- Failure to lift the veh icle at these

-

points could cause the vehicle to tilt or ..,.

Page 280 of 302

2 78 Emergency situations

fa ll from a lift if the re is a change in ve

h icle we ight d istribution and balance.

This might happen, for example, when h eavy components such as the engine

b lock or transmiss io n are removed .

- When removing heavy components like

these, ancho r vehicle to ho ist or add cor

r e spond ing weig hts to ma inta in the cen

te r of g ravity . Othe rwise, the vehicle

m ight tilt o r slip off th e hois t, c aus ing

s er ious pers on al injury.

(D Note

-Be awa re of th e f ollowing poin ts b efo re

li fting th e vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission housing, the

front or rear axle or the body side members. This could lead to serious

damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be

inserted between the floor jack and

the lift points.

- Before driving over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity

of the hoist .

- Before driving over a workshop hoist,

ensure that there is sufficient clear

ance between the hoist and low parts

of the vehicle.