differential AUDI A4 1995 B5 / 1.G 01W Transmission Pinion Shaft Ring Gear Adjustment Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1995, Model line: A4, Model: AUDI A4 1995 B5 / 1.GPages: 43, PDF Size: 0.59 MB

Page 6 of 43

39-33

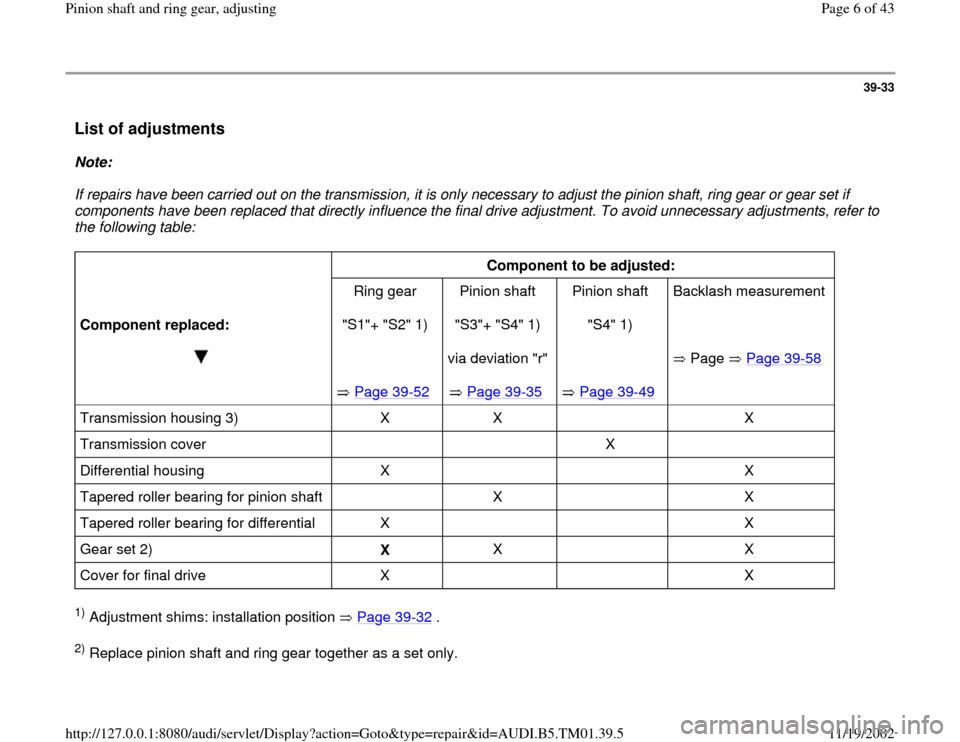

List of adjustments

Note:

If repairs have been carried out on the transmission, it is only necessary to adjust the pinion shaft, ring gear or gear set if

components have been replaced that directly influence the final drive adjustment. To avoid unnecessary adjustments, refer to

the following table:

Component to be adjusted:

Component replaced:

Ring gear

"S1"+ "S2" 1)

Page 39

-52

Pinion shaft

"S3"+ "S4" 1)

via deviation "r"

Page 39

-35

Pinion shaft

"S4" 1)

Page 39

-49

Backlash measurement

Page Page 39

-58

Transmission housing 3) X X X

Transmission cover X

Differential housing X X

Tapered roller bearing for pinion shaft X X

Tapered roller bearing for differential X X

Gear set 2)

X X X

Cover for final drive X X 1) Adjustment shims: installation position Page 39

-32

.

2) Replace pinion shaft and ring gear together as a set only.

Pa

ge 6 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 8 of 43

39-34

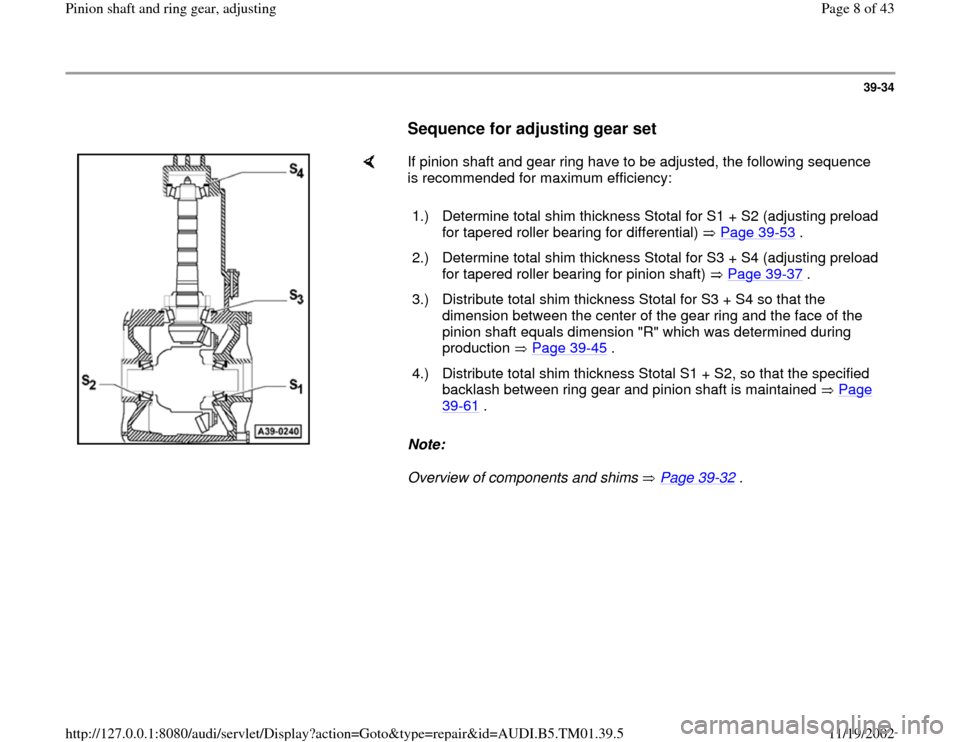

Sequence for adjusting gear set

If pinion shaft and gear ring have to be adjusted, the following sequence

is recommended for maximum efficiency:

Note:

Overview of components and shims Page 39

-32

. 1.) Determine total shim thickness Stotal for S1 + S2 (adjusting preload

for tapered roller bearing for differential) Page 39

-53

.

2.) Determine total shim thickness Stotal for S3 + S4 (adjusting preload

for tapered roller bearing for pinion shaft) Page 39

-37

.

3.) Distribute total shim thickness Stotal for S3 + S4 so that the

dimension between the center of the gear ring and the face of the

pinion shaft equals dimension "R" which was determined during

production Page 39

-45

.

4.) Distribute total shim thickness Stotal S1 + S2, so that the specified

backlash between ring gear and pinion shaft is maintained Page

39

-61

.

Pa

ge 8 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 12 of 43

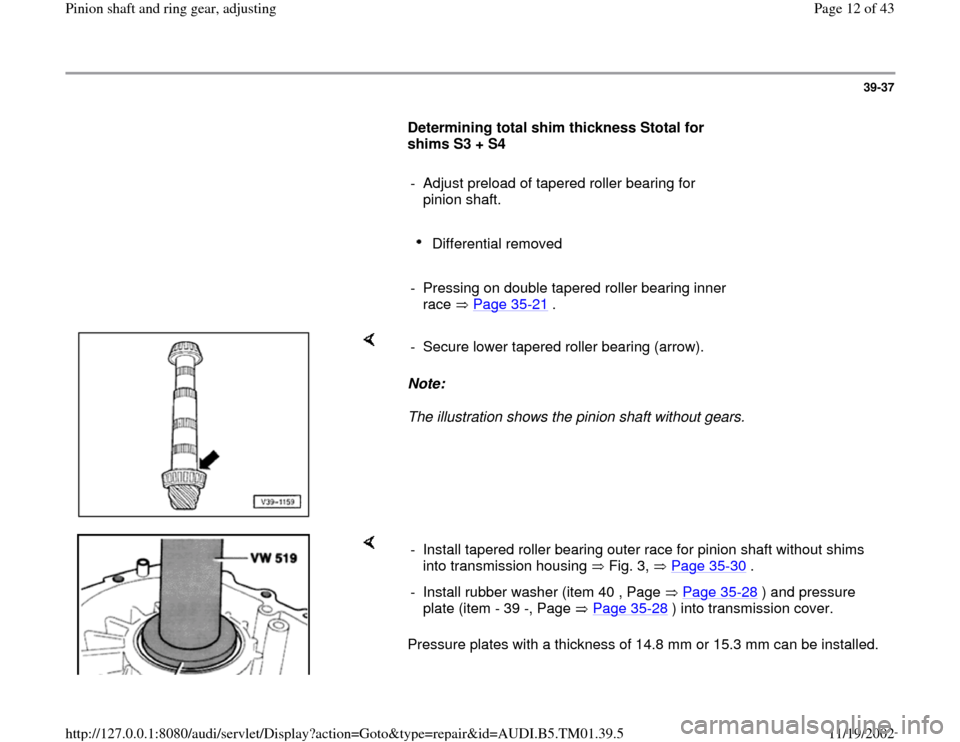

39-37

Determining total shim thickness Stotal for

shims S3 + S4

- Adjust preload of tapered roller bearing for

pinion shaft.

Differential removed

- Pressing on double tapered roller bearing inner

race Page 35

-21

.

Note:

The illustration shows the pinion shaft without gears. - Secure lower tapered roller bearing (arrow).

Pressure plates with a thickness of 14.8 mm or 15.3 mm can be installed. - Install tapered roller bearing outer race for pinion shaft without shims

into transmission housing Fig. 3, Page 35

-30

.

- Install rubber washer (item 40 , Page Page 35

-28

) and pressure

plate (item - 39 -, Page Page 35

-28

) into transmission cover.

Pa

ge 12 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 20 of 43

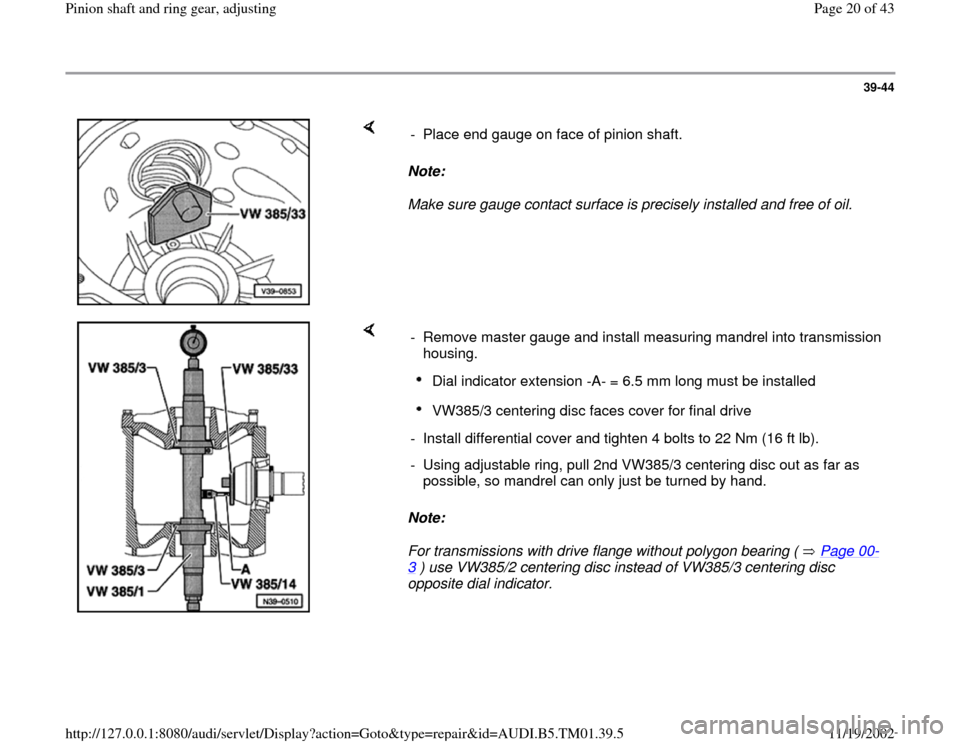

39-44

Note:

Make sure gauge contact surface is precisely installed and free of oil. - Place end gauge on face of pinion shaft.

Note:

For transmissions with drive flange without polygon bearing ( Page 00

-

3 ) use VW385/2 centering disc instead of VW385/3 centering disc

opposite dial indicator. - Remove master gauge and install measuring mandrel into transmission

housing.

Dial indicator extension -A- = 6.5 mm long must be installed VW385/3 centering disc faces cover for final drive

- Install differential cover and tighten 4 bolts to 22 Nm (16 ft lb).

- Using adjustable ring, pull 2nd VW385/3 centering disc out as far as

possible, so mandrel can only just be turned by hand.

Pa

ge 20 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 29 of 43

39-52

Ring gear, adjusting

Adjusting differential

For a list of the repairs which will require the ring

gear to be adjusted Page 39

-33

, List of

adjustments

Special tools and equipment

VW382/10 dial indicator extension

VW385/17 magnetic plate

VW387 dial gauge holder

VW388 measuring lever

VW402 thrust plate

VW408A punch

VW472/1 pressure piece

VW521 adjustment tool

3177 clamp

Pa

ge 29 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 31 of 43

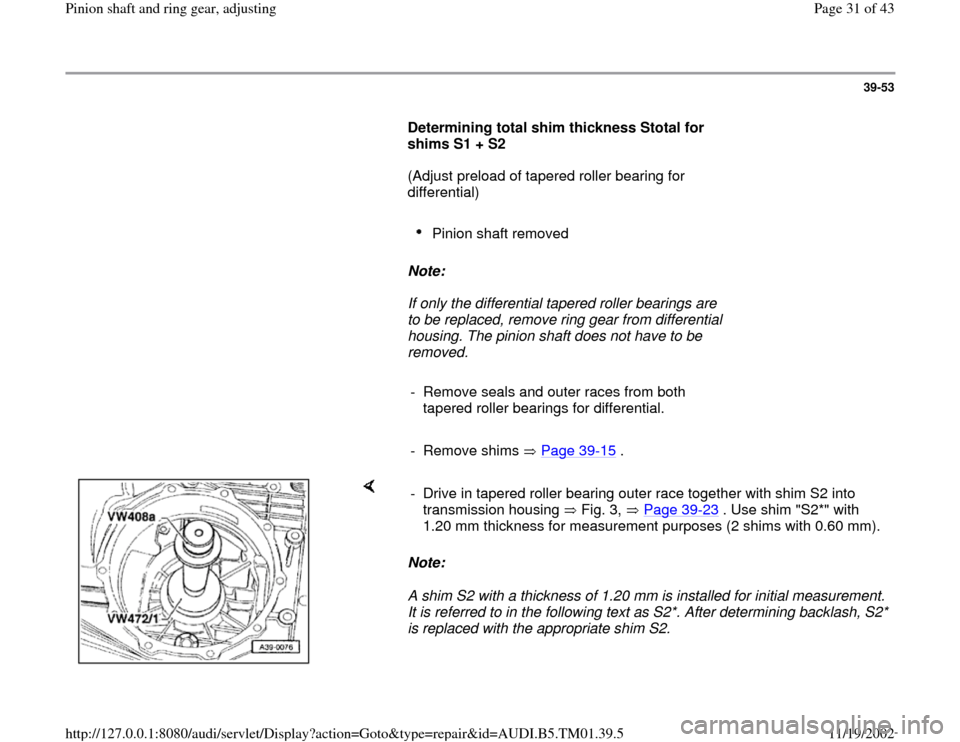

39-53

Determining total shim thickness Stotal for

shims S1 + S2

(Adjust preload of tapered roller bearing for

differential)

Pinion shaft removed

Note:

If only the differential tapered roller bearings are

to be replaced, remove ring gear from differential

housing. The pinion shaft does not have to be

removed.

- Remove seals and outer races from both

tapered roller bearings for differential.

- Remove shims Page 39

-15

.

Note:

A shim S2 with a thickness of 1.20 mm is installed for initial measurement.

It is referred to in the following text as S2*. After determining backlash, S2*

is replaced with the appropriate shim S2. - Drive in tapered roller bearing outer race together with shim S2 into

transmission housing Fig. 3, Page 39

-23

. Use shim "S2*" with

1.20 mm thickness for measurement purposes (2 shims with 0.60 mm).

Pa

ge 31 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 32 of 43

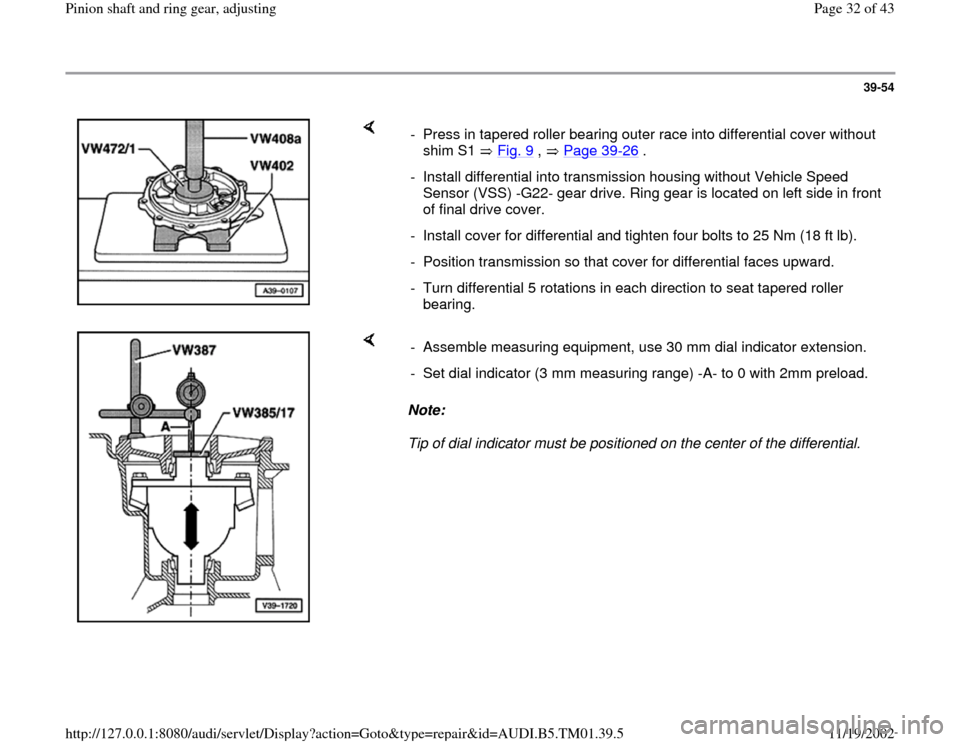

39-54

- Press in tapered roller bearing outer race into differential cover without

shim S1 Fig. 9

, Page 39

-26

.

- Install differential into transmission housing without Vehicle Speed

Sensor (VSS) -G22- gear drive. Ring gear is located on left side in front

of final drive cover.

- Install cover for differential and tighten four bolts to 25 Nm (18 ft lb).

- Position transmission so that cover for differential faces upward.

- Turn differential 5 rotations in each direction to seat tapered roller

bearing.

Note:

Tip of dial indicator must be positioned on the center of the differential. - Assemble measuring equipment, use 30 mm dial indicator extension.

- Set dial indicator (3 mm measuring range) -A- to 0 with 2mm preload.

Pa

ge 32 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

Page 33 of 43

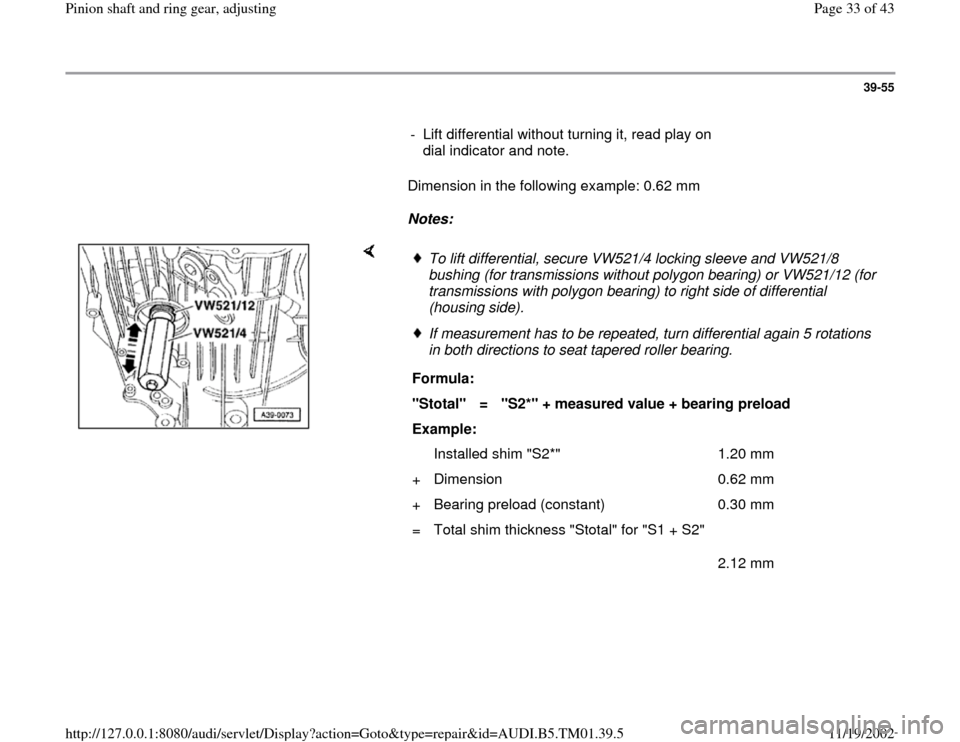

39-55

- Lift differential without turning it, read play on

dial indicator and note.

Dimension in the following example: 0.62 mm

Notes:

To lift differential, secure VW521/4 locking sleeve and VW521/8

bushing (for transmissions without polygon bearing) or VW521/12 (for

transmissions with polygon bearing) to right side of differential

(housing side). If measurement has to be repeated, turn differential again 5 rotations

in both directions to seat tapered roller bearing.

Formula:

"Stotal"

=

"S2*" + measured value + bearing preload

Example:

Installed shim "S2*" 1.20 mm

+ Dimension 0.62 mm

+ Bearing preload (constant) 0.30 mm

=

Total shim thickness "Stotal" for "S1 + S2"

2.12 mm

Pa

ge 33 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

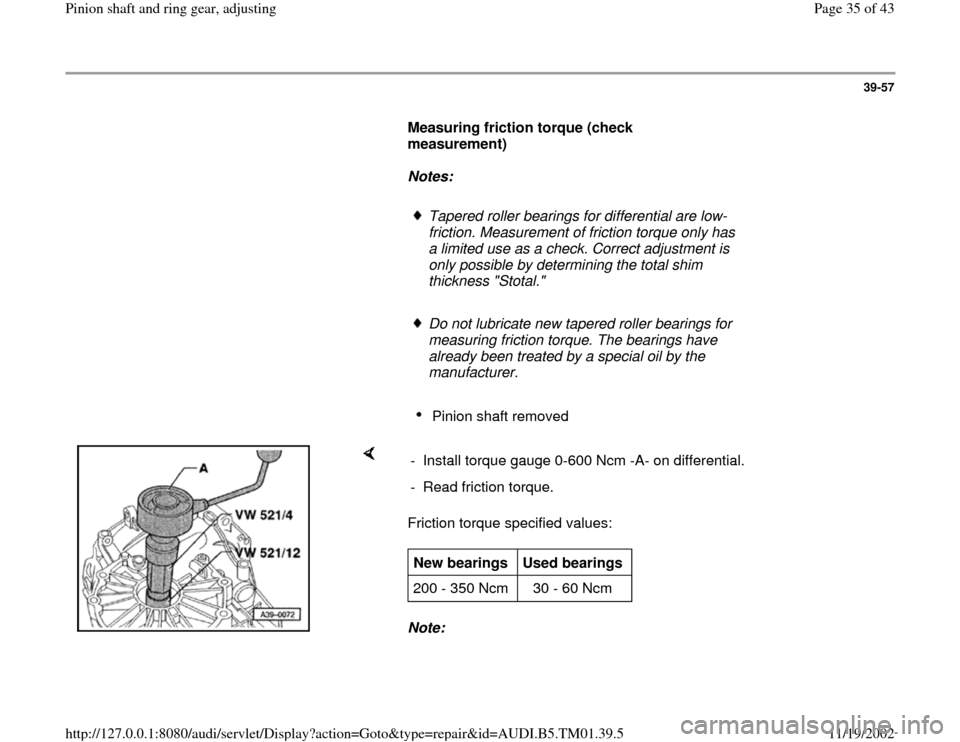

Page 35 of 43

39-57

Measuring friction torque (check

measurement)

Notes:

Tapered roller bearings for differential are low-

friction. Measurement of friction torque only has

a limited use as a check. Correct adjustment is

only possible by determining the total shim

thickness "Stotal."

Do not lubricate new tapered roller bearings for

measuring friction torque. The bearings have

already been treated by a special oil by the

manufacturer.

Pinion shaft removed

Friction torque specified values:

Note: - Install torque gauge 0-600 Ncm -A- on differential.

- Read friction torque.New bearings

Used bearings

200 - 350 Ncm 30 - 60 Ncm

Pa

ge 35 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5

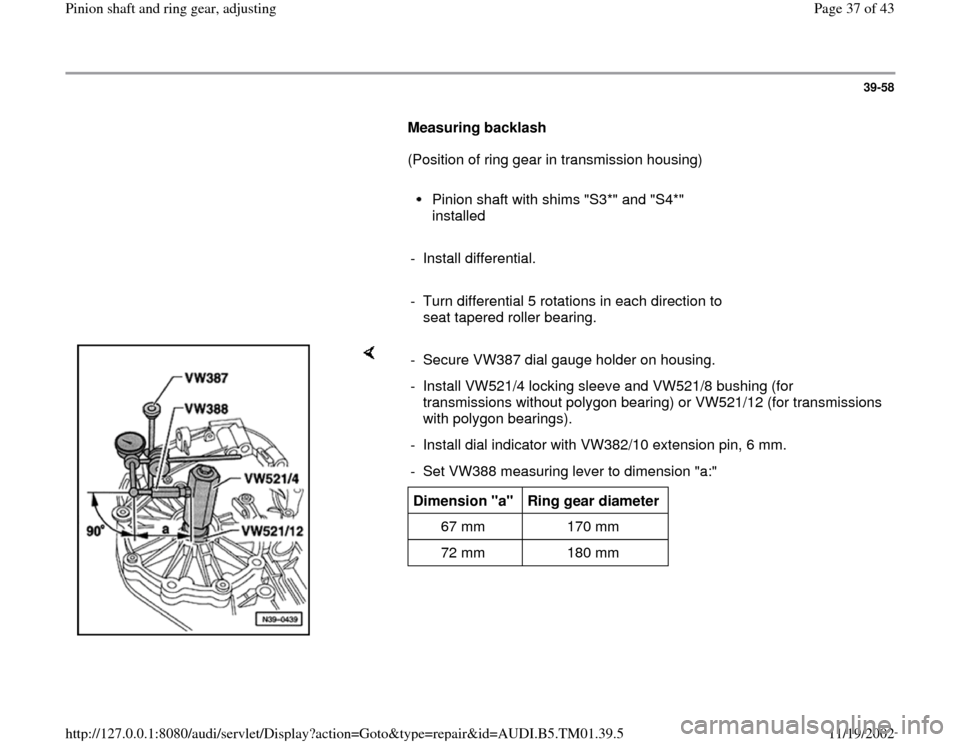

Page 37 of 43

39-58

Measuring backlash

(Position of ring gear in transmission housing)

Pinion shaft with shims "S3*" and "S4*"

installed

- Install differential.

- Turn differential 5 rotations in each direction to

seat tapered roller bearing.

- Secure VW387 dial gauge holder on housing.

- Install VW521/4 locking sleeve and VW521/8 bushing (for

transmissions without polygon bearing) or VW521/12 (for transmissions

with polygon bearings).

- Install dial indicator with VW382/10 extension pin, 6 mm.

- Set VW388 measuring lever to dimension "a:"Dimension "a"

Ring gear diameter

67 mm 170 mm

72 mm 180 mm

Pa

ge 37 of 43 Pinion shaft and rin

g gear, ad

justin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.39.5