differential AUDI A4 1998 B5 / 1.G 01A Transmission Final Drive Gear Set Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 31, PDF Size: 0.39 MB

Page 1 of 31

39-148

Final drive gear set,

recommended sequence for

adjusting

If the pinion shaft and ring gear have to be re-

adjusted, the following sequence is

recommended for maximum efficiency:

1.) Determine total shim thickness Stotal for S1 +

S2 for the specified tension of the tapered roller

bearing for differential.

2.) Determine total shim thickness S3, so that

pinion shaft obtains the specified installed

position determined by the test machine in

production.

3.) Split up total shim thickness Stotal for S1 +

S2, so that the specified torsional backlash exists

between ring gear and pinion shaft.

Note:

Overview of components and shims Page 39

-

149

.

Pa

ge 1 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 2 of 31

39-149

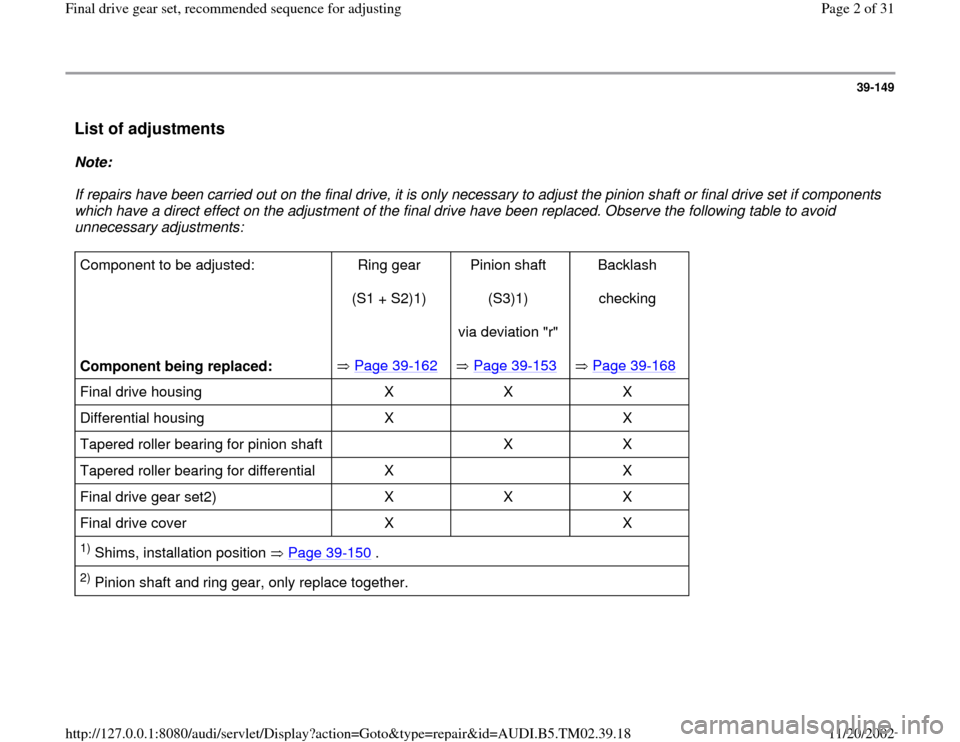

List of adjustments

Note:

If repairs have been carried out on the final drive, it is only necessary to adjust the pinion shaft or final drive set if components

which have a direct effect on the adjustment of the final drive have been replaced. Observe the following table to avoid

unnecessary adjustments:

Component to be adjusted:

Component being replaced: Ring gear

(S1 + S2)1)

Page 39

-162

Pinion shaft

(S3)1)

via deviation "r"

Page 39

-153

Backlash

checking

Page 39

-168

Final drive housing X X X

Differential housing X X

Tapered roller bearing for pinion shaft X X

Tapered roller bearing for differential X X

Final drive gear set2) X X X

Final drive cover X X 1) Shims, installation position Page 39

-150

.

2) Pinion shaft and ring gear, only replace together.

Pa

ge 2 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 11 of 31

39-155

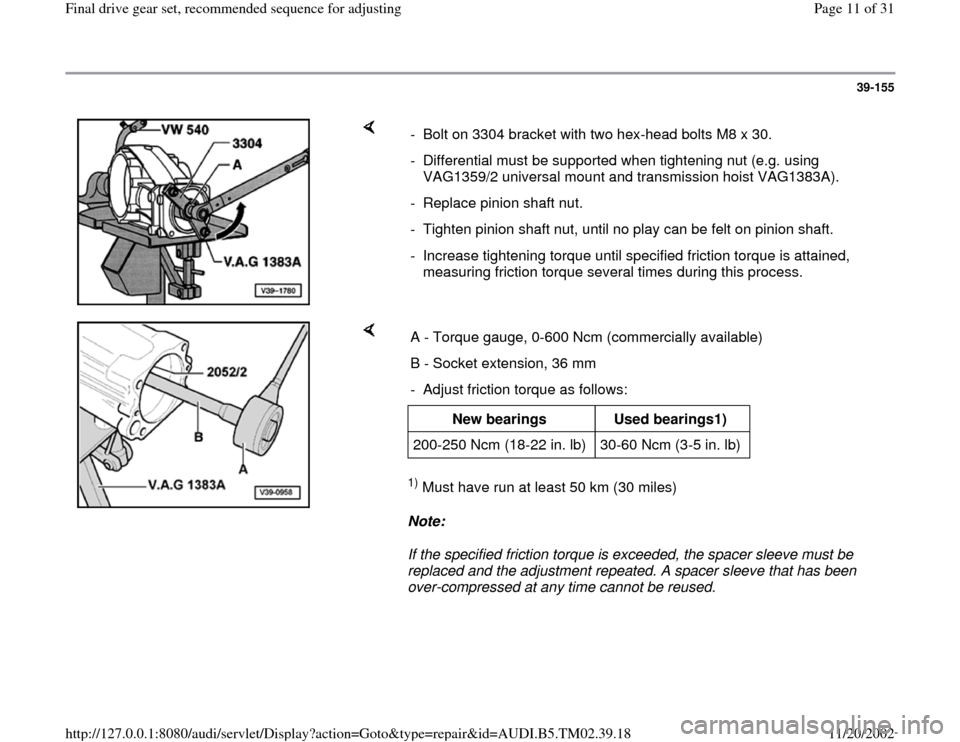

- Bolt on 3304 bracket with two hex-head bolts M8 x 30.

- Differential must be supported when tightening nut (e.g. using

VAG1359/2 universal mount and transmission hoist VAG1383A).

- Replace pinion shaft nut.

- Tighten pinion shaft nut, until no play can be felt on pinion shaft.

- Increase tightening torque until specified friction torque is attained,

measuring friction torque several times during this process.

1) Must have run at least 50 km (30 miles)

Note:

If the specified friction torque is exceeded, the spacer sleeve must be

replaced and the adjustment repeated. A spacer sleeve that has been

over-compressed at any time cannot be reused. A - Torque gauge, 0-600 Ncm (commercially available)

B - Socket extension, 36 mm

- Adjust friction torque as follows:

New bearings

Used bearings1)

200-250 Ncm (18-22 in. lb) 30-60 Ncm (3-5 in. lb)

Pa

ge 11 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 19 of 31

39-162

Ring gear, adjusting

Adjusting differential

The ring gear must be adjusted if any of the

components have been replaced table,

Page 39

-149

.

Notes:

Differential tapered roller bearings are low

friction bearings. Therefore the friction torque

only has a limited use as a check. Correct

adjustment is only possible by determining the

total shim thickness Stotal.

Do not additionally oil new tapered roller

bearings for the friction torque measurement.

The bearings have already been treated with a

special oil by the manufacturer.

Determining total shim thickness "Stotal" for

shims S1 + S2

(Setting preload of tapered roller bearing for

differential)

Pinion shaft removed or ring gear removed

from differential housing.

- Pry out drive flange seal using pry bar.

Pa

ge 19 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 20 of 31

- Remove differential tapered roller bearing outer

races and remove shims Page 39

-121

.

Pa

ge 20 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 21 of 31

39-163

- Press left tapered roller bearing outer race for

differential (housing side) with shim S2 into

housing Page 39

-126, Fig. 2

. To perform the

measurement use shim S2* with thickness of

1.00 mm (one 0.80 mm shim and one 0.20 mm

shim).

Note:

For measurement specification, a shim S2 of 1.0

mm thickness is initially inserted which will be

designated S2* in the following. After determining

the backlash S2* will be replaced by the correct

shim S2.

- Press in right tapered roller bearing outer race

for differential (final drive cover side) without

shims, until stop Fig. 8, Page 39

-130

.

- Insert differential into housing. Ring gear is

positioned on right side (cover side).

- Install final drive cover and tighten bolts to 25

Nm (18 ft lb).

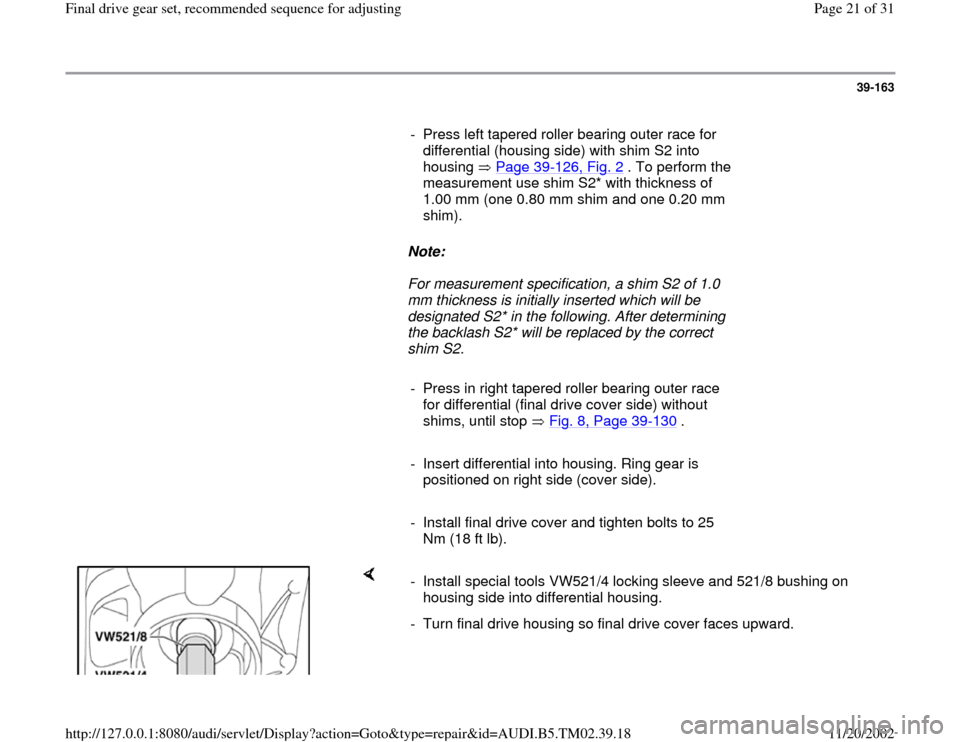

- Install special tools VW521/4 locking sleeve and 521/8 bushing on

housing side into differential housing.

- Turn final drive housing so final drive cover faces upward.

Pa

ge 21 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 22 of 31

39-164

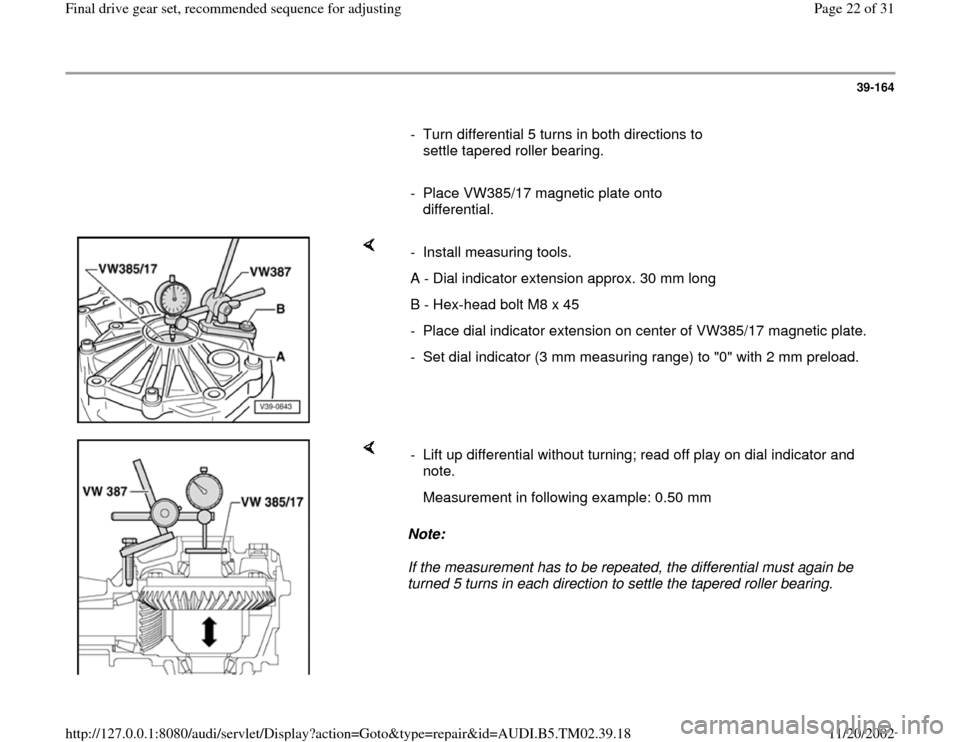

- Turn differential 5 turns in both directions to

settle tapered roller bearing.

- Place VW385/17 magnetic plate onto

differential.

- Install measuring tools.

A - Dial indicator extension approx. 30 mm long

B - Hex-head bolt M8 x 45

- Place dial indicator extension on center of VW385/17 magnetic plate.

- Set dial indicator (3 mm measuring range) to "0" with 2 mm preload.

Note:

If the measurement has to be repeated, the differential must again be

turned 5 turns in each direction to settle the tapered roller bearing. - Lift up differential without turning; read off play on dial indicator and

note.

Measurement in following example: 0.50 mm

Pa

ge 22 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 25 of 31

39-167

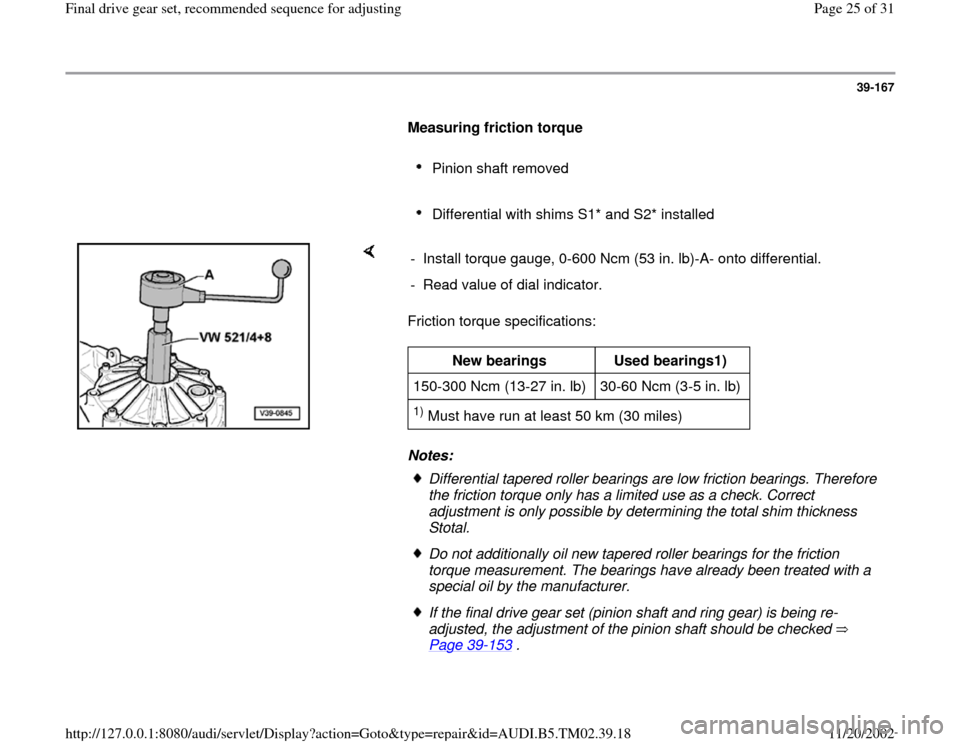

Measuring friction torque

Pinion shaft removed

Differential with shims S1* and S2* installed

Friction torque specifications:

Notes: - Install torque gauge, 0-600 Ncm (53 in. lb)-A- onto differential.

- Read value of dial indicator.

New bearings

Used bearings1)

150-300 Ncm (13-27 in. lb) 30-60 Ncm (3-5 in. lb)

1) Must have run at least 50 km (30 miles) Differential tapered roller bearings are low friction bearings. Therefore

the friction torque only has a limited use as a check. Correct

adjustment is only possible by determining the total shim thickness

Stotal. Do not additionally oil new tapered roller bearings for the friction

torque measurement. The bearings have already been treated with a

special oil by the manufacturer. If the final drive gear set (pinion shaft and ring gear) is being re-

adjusted, the adjustment of the pinion shaft should be checked

Page 39

-153

.

Pa

ge 25 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 26 of 31

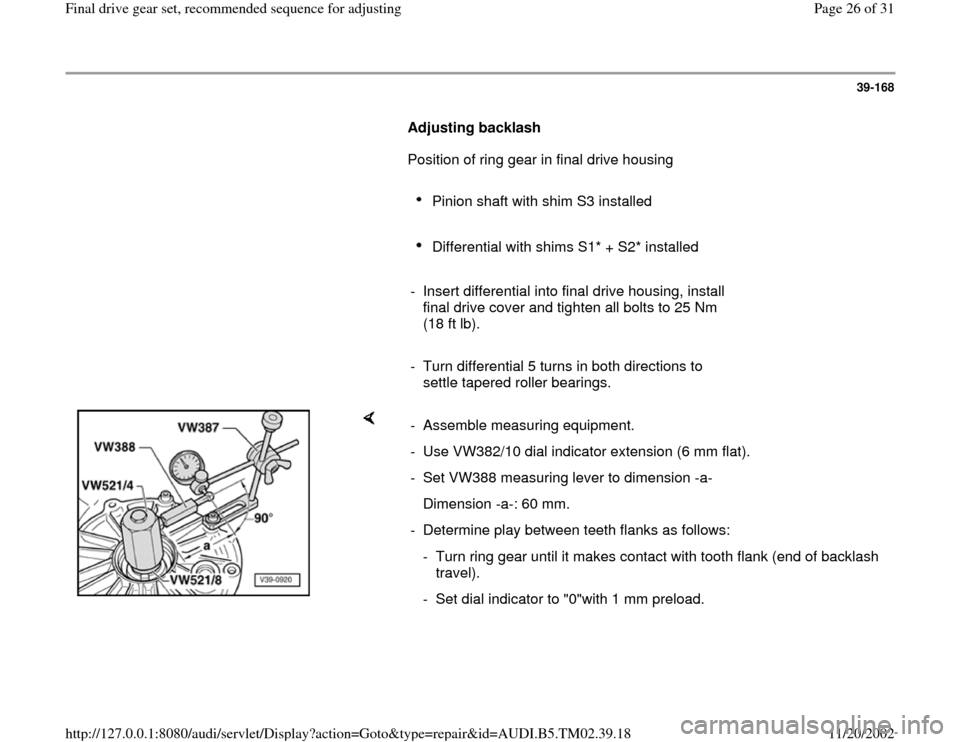

39-168

Adjusting backlash

Position of ring gear in final drive housing

Pinion shaft with shim S3 installed

Differential with shims S1* + S2* installed

- Insert differential into final drive housing, install

final drive cover and tighten all bolts to 25 Nm

(18 ft lb).

- Turn differential 5 turns in both directions to

settle tapered roller bearings.

- Assemble measuring equipment.

- Use VW382/10 dial indicator extension (6 mm flat).

- Set VW388 measuring lever to dimension -a-

Dimension -a-: 60 mm.

- Determine play between teeth flanks as follows:

- Turn ring gear until it makes contact with tooth flank (end of backlash

travel).

- Set dial indicator to "0"with 1 mm preload.

Pa

ge 26 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18

Page 31 of 31

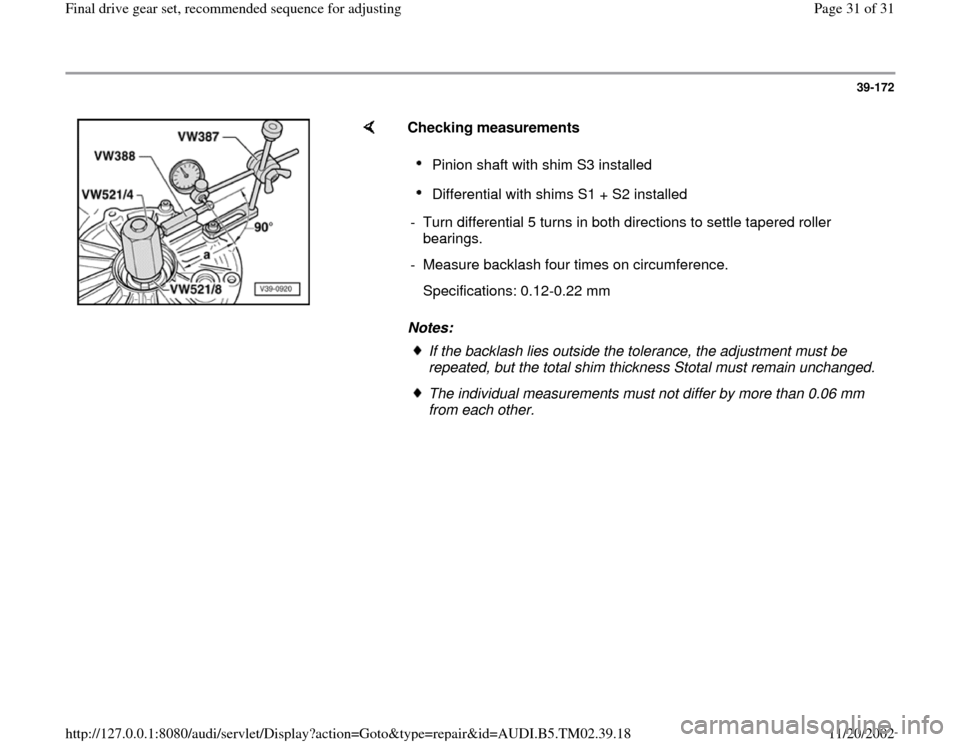

39-172

Checking measurements

Notes:

Pinion shaft with shim S3 installed Differential with shims S1 + S2 installed

- Turn differential 5 turns in both directions to settle tapered roller

bearings.

- Measure backlash four times on circumference.

Specifications: 0.12-0.22 mmIf the backlash lies outside the tolerance, the adjustment must be

repeated, but the total shim thickness Stotal must remain unchanged. The individual measurements must not differ by more than 0.06 mm

from each other.

Pa

ge 31 of 31 Final drive

gear set, recommended se

quence for ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM02.39.18