engine AUDI A4 1998 B5 / 1.G 01W Transmission Clutch Release Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 13, PDF Size: 0.21 MB

Page 6 of 13

30-21

Clutch, servicing

Special tools and equipment

3067 flywheel retainer

3176 centering mandrel

Notes:

Observe general repair instructions Page 00

-

10

.

Replace clutch plates and pressure plates

which have damaged or loose rivets.

Select the correct clutch plate and pressure

plate according to the engine code parts

catalog.

Clean input shaft splines and (in the case of

used clutch plates) the hub splines. Remove

corrosion and apply only a very thin coating of

lubricant G 000 100 to the splines. Then move

clutch plate back and forth on input shaft until

hub moves freely on shaft. Excess grease must

be removed.

Pressure plates have an anti-corrosion coating

Pa

ge 6 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2

Page 7 of 13

and are greased. Only the contact surface may

be cleaned, otherwise the service life of the

clutch will be considerably reduced.

If the clutch has been burned out, thoroughly

clean the bellhousing, flywheel and parts of the

engine facing the transmission to reduce the

smell of burnt clutch.

Pa

ge 7 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2

Page 9 of 13

30-23

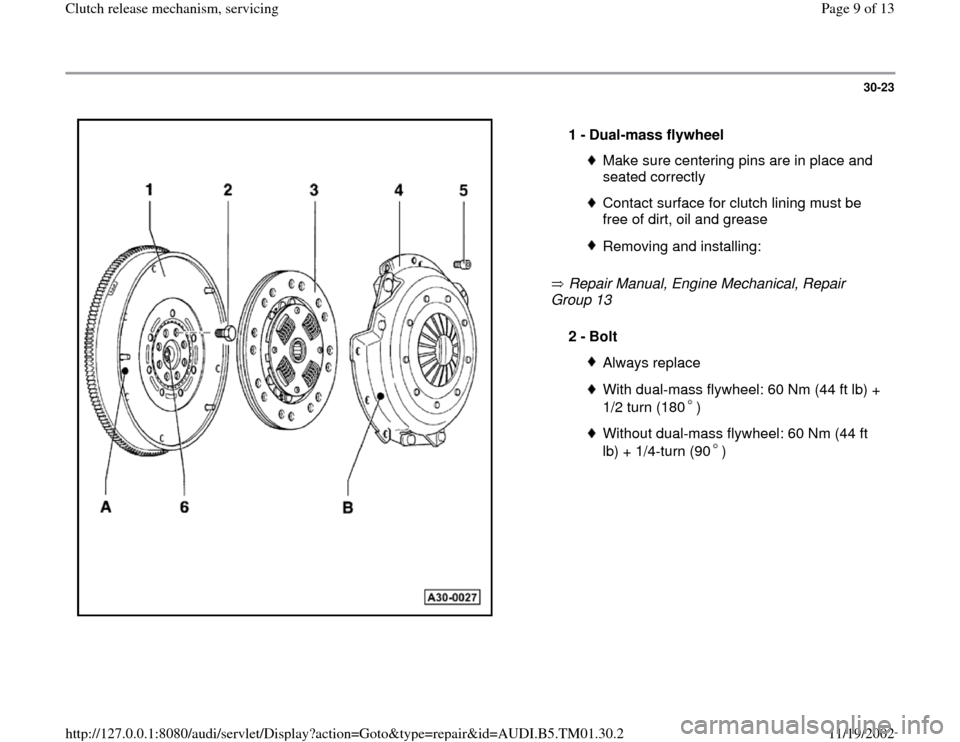

Repair Manual, Engine Mechanical, Repair

Group 13 1 -

Dual-mass flywheel

Make sure centering pins are in place and

seated correctly Contact surface for clutch lining must be

free of dirt, oil and grease Removing and installing:

2 -

Bolt

Always replaceWith dual-mass flywheel: 60 Nm (44 ft lb) +

1/2 turn (180 ) Without dual-mass flywheel: 60 Nm (44 ft

lb) + 1/4-turn (90 )

Pa

ge 9 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2

Page 11 of 13

30-25

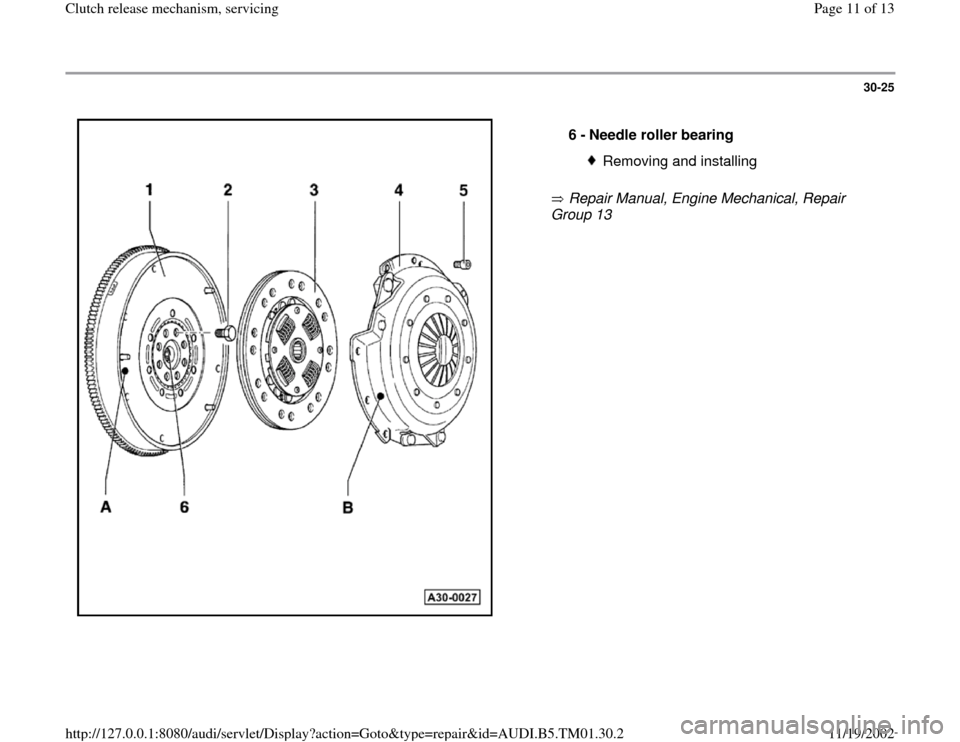

Repair Manual, Engine Mechanical, Repair

Group 13 6 -

Needle roller bearing

Removing and installing

Pa

ge 11 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2

Page 12 of 13

30-26

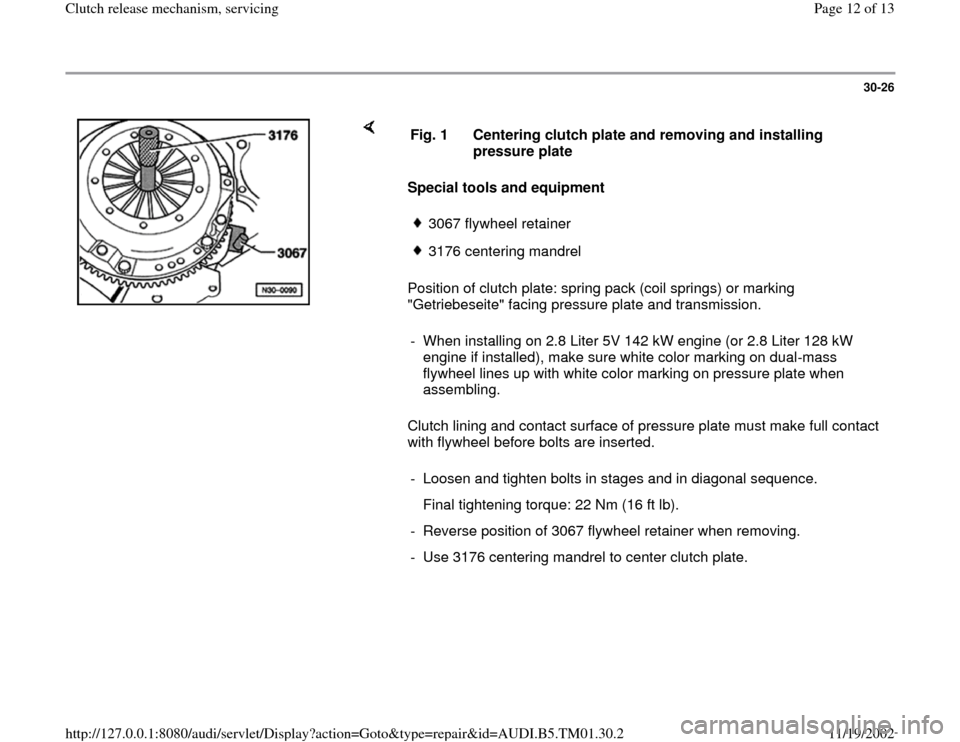

Special tools and equipment

Position of clutch plate: spring pack (coil springs) or marking

"Getriebeseite" facing pressure plate and transmission.

Clutch lining and contact surface of pressure plate must make full contact

with flywheel before bolts are inserted. Fig. 1 Centering clutch plate and removing and installing

pressure plate

3067 flywheel retainer 3176 centering mandrel

- When installing on 2.8 Liter 5V 142 kW engine (or 2.8 Liter 128 kW

engine if installed), make sure white color marking on dual-mass

flywheel lines up with white color marking on pressure plate when

assembling.

- Loosen and tighten bolts in stages and in diagonal sequence.

Final tightening torque: 22 Nm (16 ft lb).

- Reverse position of 3067 flywheel retainer when removing.

- Use 3176 centering mandrel to center clutch plate.

Pa

ge 12 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2

Page 13 of 13

30-27

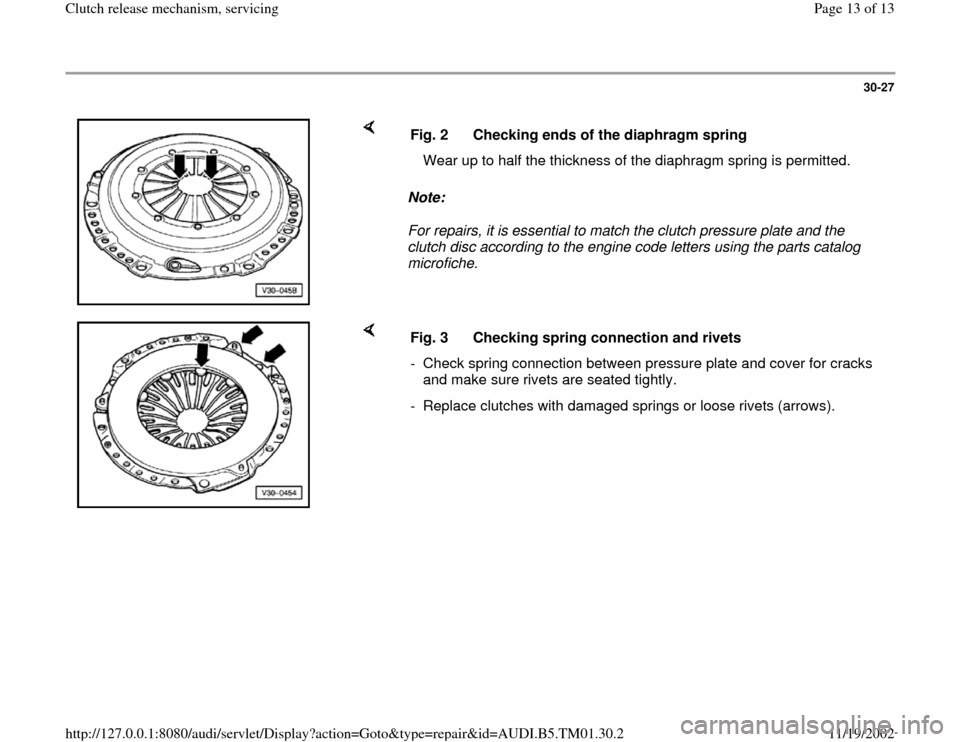

Note:

For repairs, it is essential to match the clutch pressure plate and the

clutch disc according to the engine code letters using the parts catalog

microfiche. Fig. 2 Checking ends of the diaphragm spring

Wear up to half the thickness of the diaphragm spring is permitted.

Fig. 3 Checking spring connection and rivets

- Check spring connection between pressure plate and cover for cracks

and make sure rivets are seated tightly.

- Replace clutches with damaged springs or loose rivets (arrows).

Pa

ge 13 of 13 Clutch release mechanism, servicin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM01.30.2