AUDI A4 1998 B5 / 1.G AWM Engine Pistons And Connecting Rods Workshop Manual

Manufacturer: AUDI, Model Year: 1998,

Model line: A4,

Model: AUDI A4 1998 B5 / 1.G

Pages: 8, PDF Size: 0.13 MB

AUDI A4 1998 B5 / 1.G AWM Engine Pistons And Connecting Rods Workshop Manual

A4 1998 B5 / 1.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/940/w960_940-0.png

AUDI A4 1998 B5 / 1.G AWM Engine Pistons And Connecting Rods Workshop Manual

Trending: checking oil, oil change, tow, oil pressure, cooling, check oil, oil

Page 1 of 8

13-79

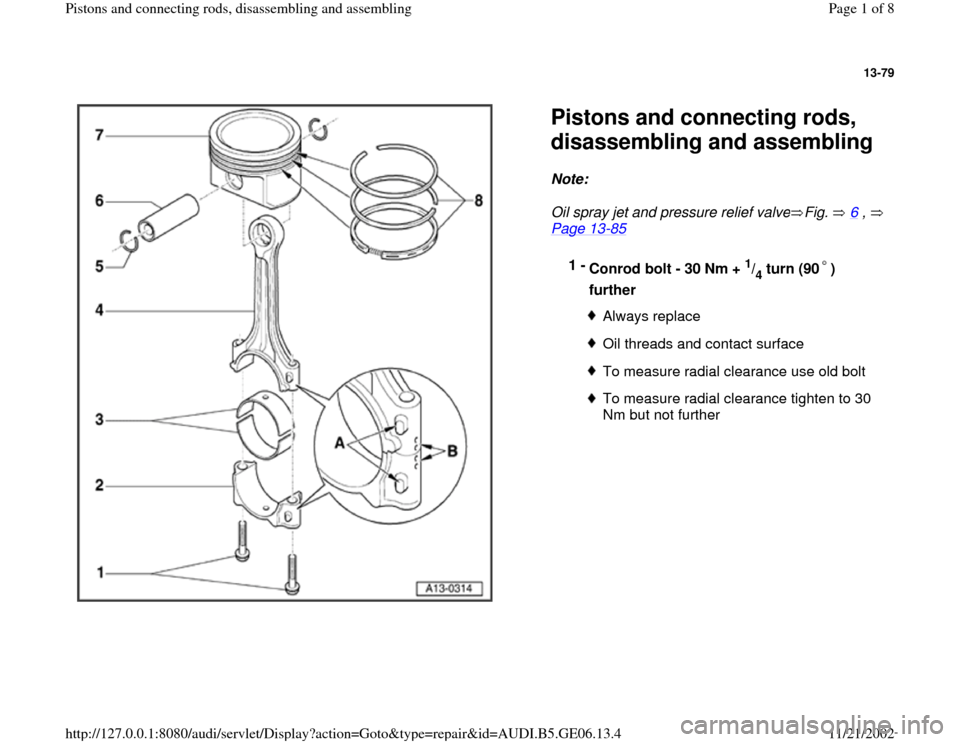

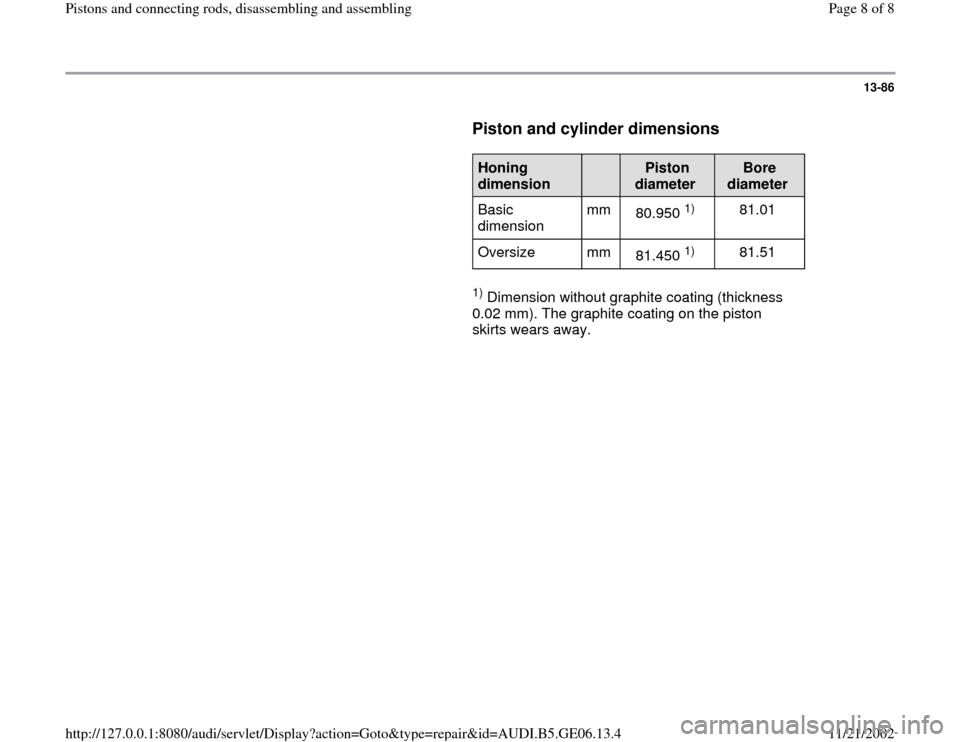

Pistons and connecting rods,

disassembling and assembling Note:

Oil spray jet and pressure relief valve Fig. 6

,

Page 13

-85

1 -

Conrod bolt - 30 Nm +

1/4 turn (90 )

further

Always replaceOil threads and contact surfaceTo measure radial clearance use old boltTo measure radial clearance tighten to 30

Nm but not further

Pa

ge 1 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 2 of 8

13-80

2 -

Connecting rod bearing cap

Mark cylinder number -B-Installation position: Markings -A- face

towards pulley side

3 -

Bearing shells Upper bearing shell with oil bore for piston

bolt lubrication Installation position Fig. 5

, Page

13

-85

Do not interchange used bearing shells

(mark). Axial clearance New: 0.10 to 0.35 mm,

Wear limit: 0.40 mm Check radial clearance with Plastigage :

New: 0.01 to 0.05 mm, Wear limit: 0.12

mm. Do not rotate crankshaft when

checking radial clearance

Pa

ge 2 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 3 of 8

13-81

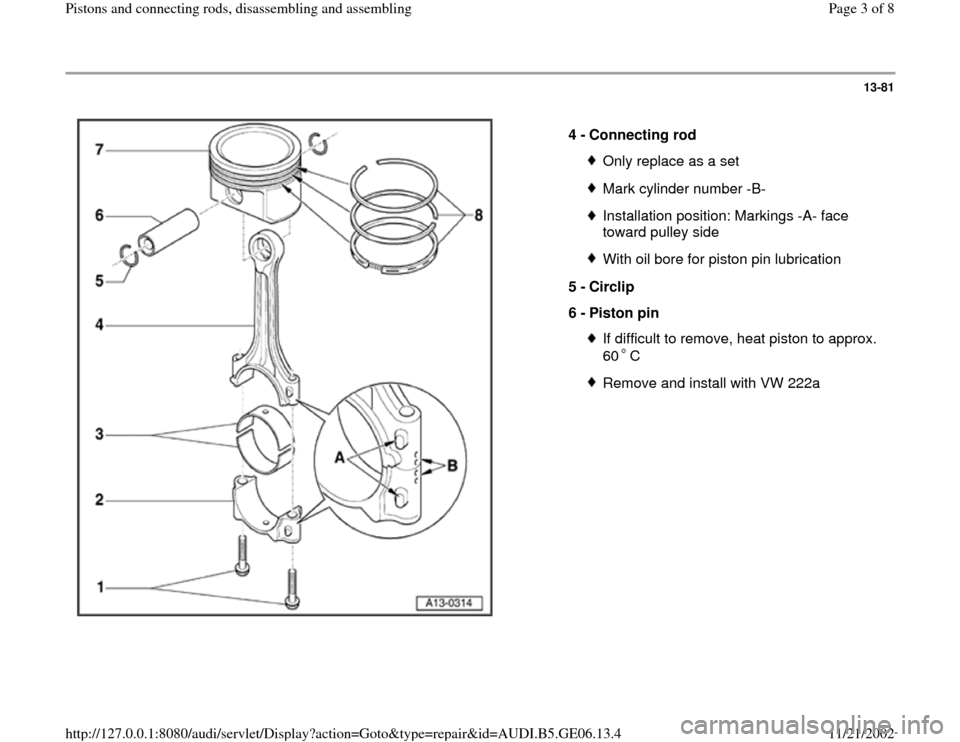

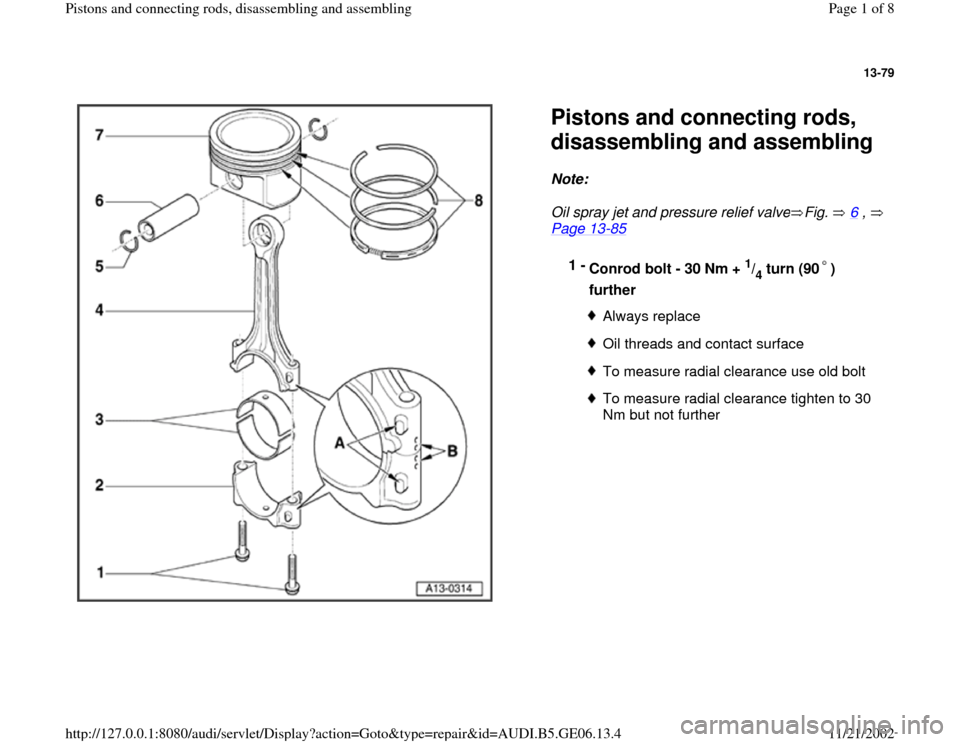

4 -

Connecting rod

Only replace as a setMark cylinder number -B-Installation position: Markings -A- face

toward pulley side With oil bore for piston pin lubrication

5 -

Circlip

6 -

Piston pin If difficult to remove, heat piston to approx.

60 C Remove and install with VW 222a

Pa

ge 3 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 4 of 8

13-82

7 -

Piston

Checking Fig. 3

, Page 13

-84

Mark installation position and cylinder

number. Arrow on piston crown points to pulley endInstall using piston ring clamp.Piston and cylinder dimensions Page 13

-86

8 -

Piston rings

Offset gaps by 120Remove and install with piston ring pliers."TOP" must face piston crownCheck ring gap Fig. 1

, Page 13

-83

Check ring to groove clearance Fig. 2

,

Page 13

-83

Pa

ge 4 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 5 of 8

13-83

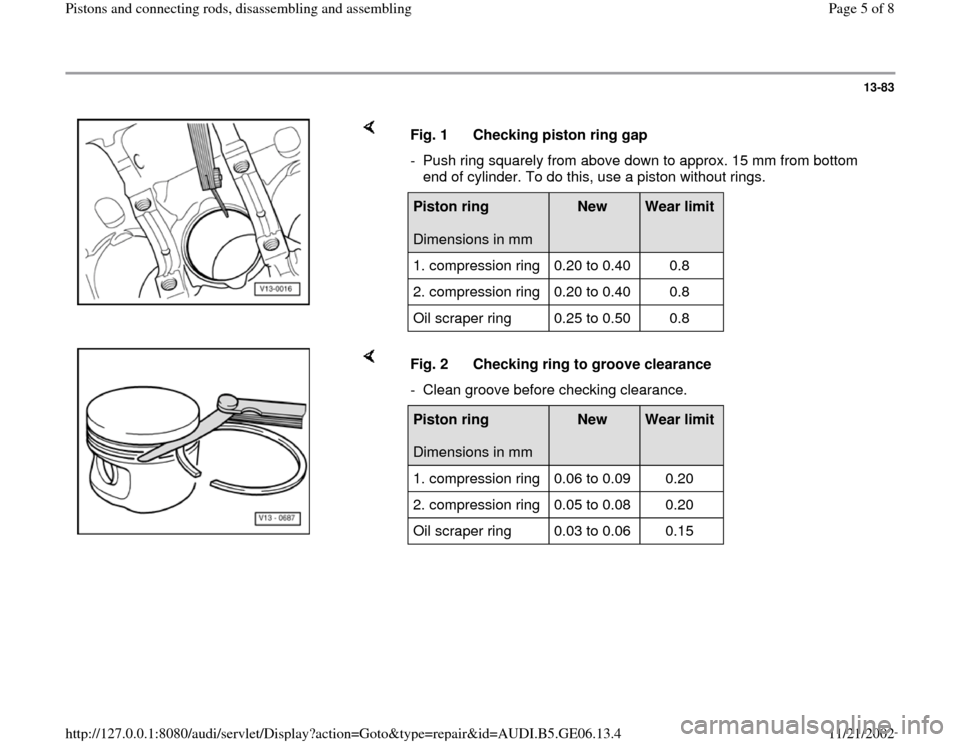

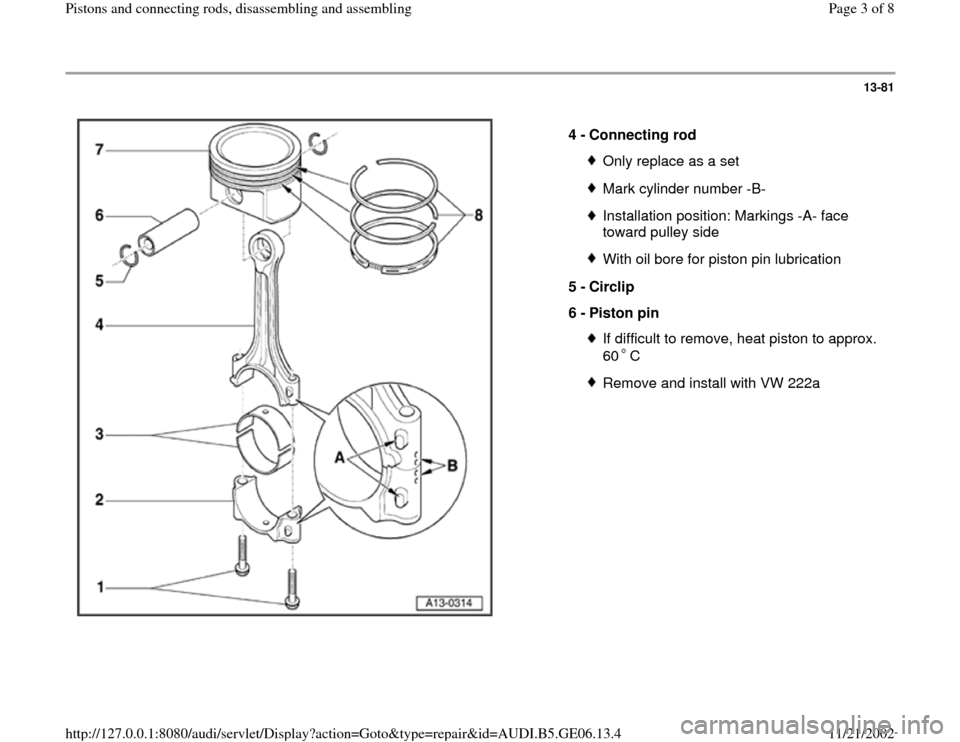

Fig. 1 Checking piston ring gap

- Push ring squarely from above down to approx. 15 mm from bottom

end of cylinder. To do this, use a piston without rings. Piston ring

Dimensions in mm

New

Wear limit

1. compression ring 0.20 to 0.40 0.8

2. compression ring 0.20 to 0.40 0.8

Oil scraper ring 0.25 to 0.50 0.8

Fig. 2 Checking ring to groove clearance

- Clean groove before checking clearance.Piston ring

Dimensions in mm

New

Wear limit

1. compression ring 0.06 to 0.09 0.20

2. compression ring 0.05 to 0.08 0.20

Oil scraper ring 0.03 to 0.06 0.15

Pa

ge 5 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 6 of 8

13-84

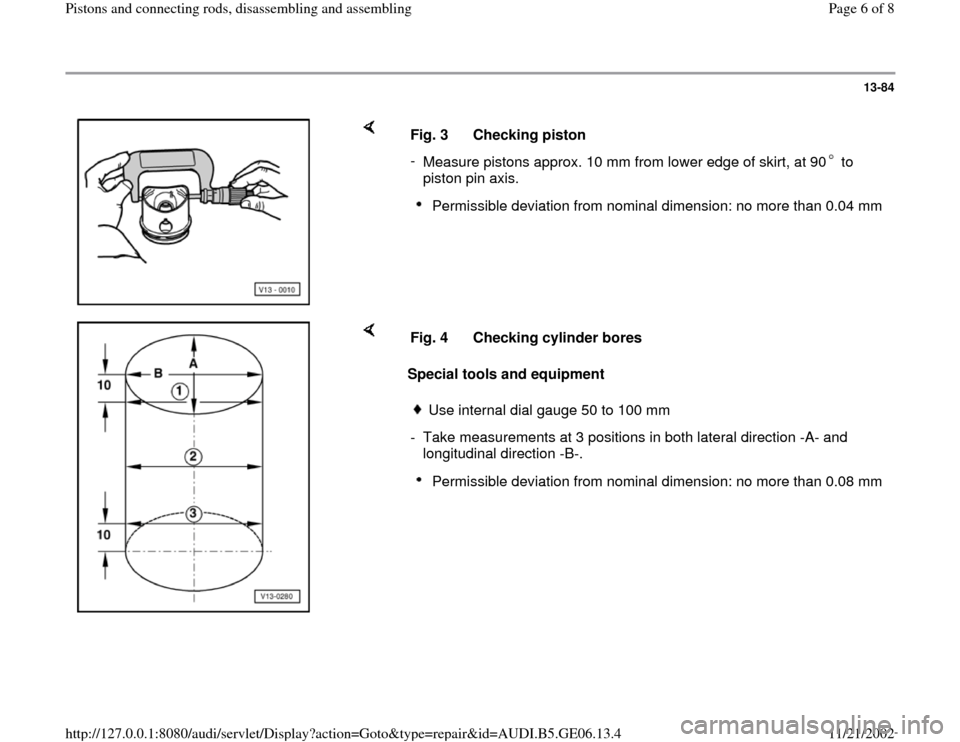

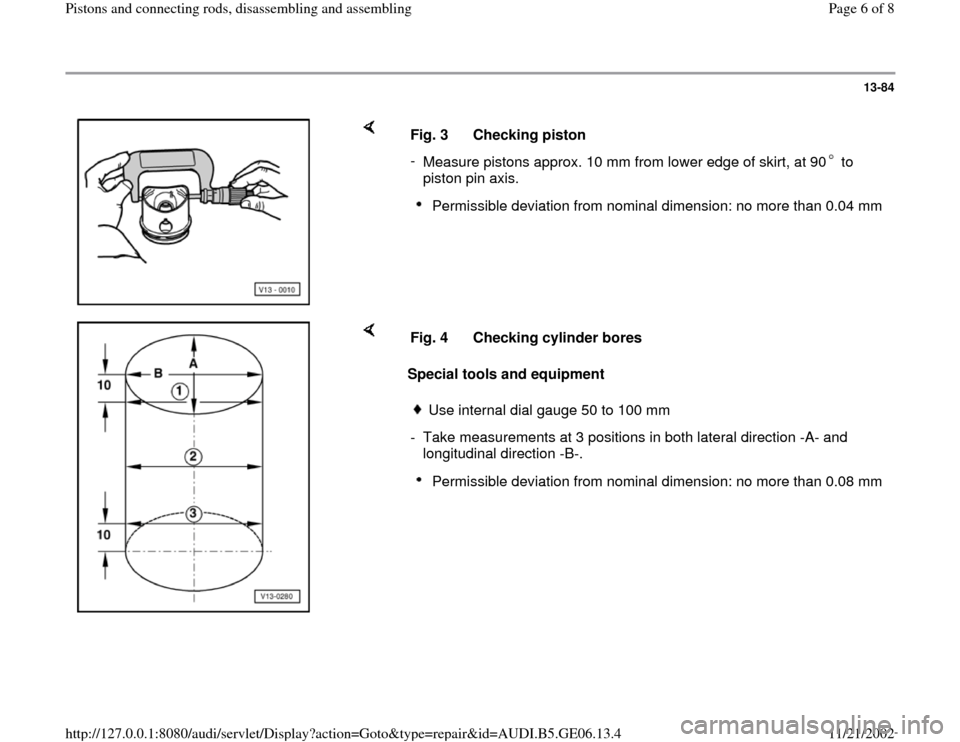

Fig. 3 Checking piston

-

Measure pistons approx. 10 mm from lower edge of skirt, at 90 to

piston pin axis.

Permissible deviation from nominal dimension: no more than 0.04 mm

Special tools and equipment Fig. 4 Checking cylinder bores

Use internal dial gauge 50 to 100 mm

- Take measurements at 3 positions in both lateral direction -A- and

longitudinal direction -B-. Permissible deviation from nominal dimension: no more than 0.08 mm

Pa

ge 6 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 7 of 8

13-85

Fig. 5 Location of bearing shell

- Install bearing shells centrally into connecting rod or into connecting

rod bearing cap.

Distance a = 3.0 mm

Fig. 6 Oil spray jet and pressure relief valve

1 - Oil spray jet (for piston cooling)

2 - Bolt with pressure relief valve - 27 Nm

Opening pressure 1.3 to 1.6 bar

Pa

ge 7 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Page 8 of 8

13-86

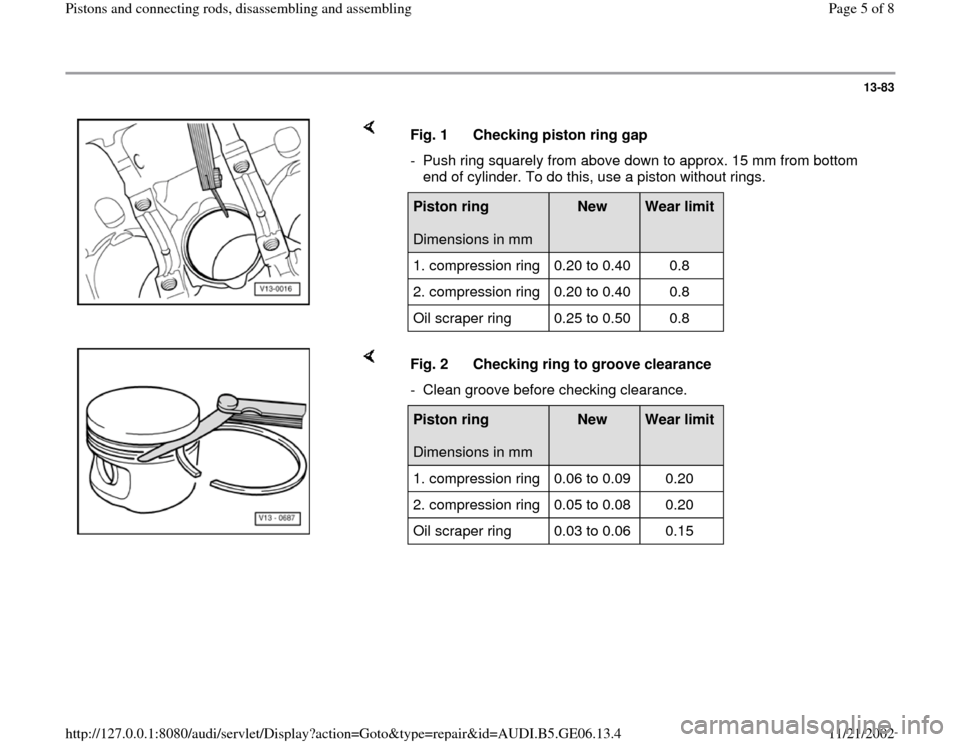

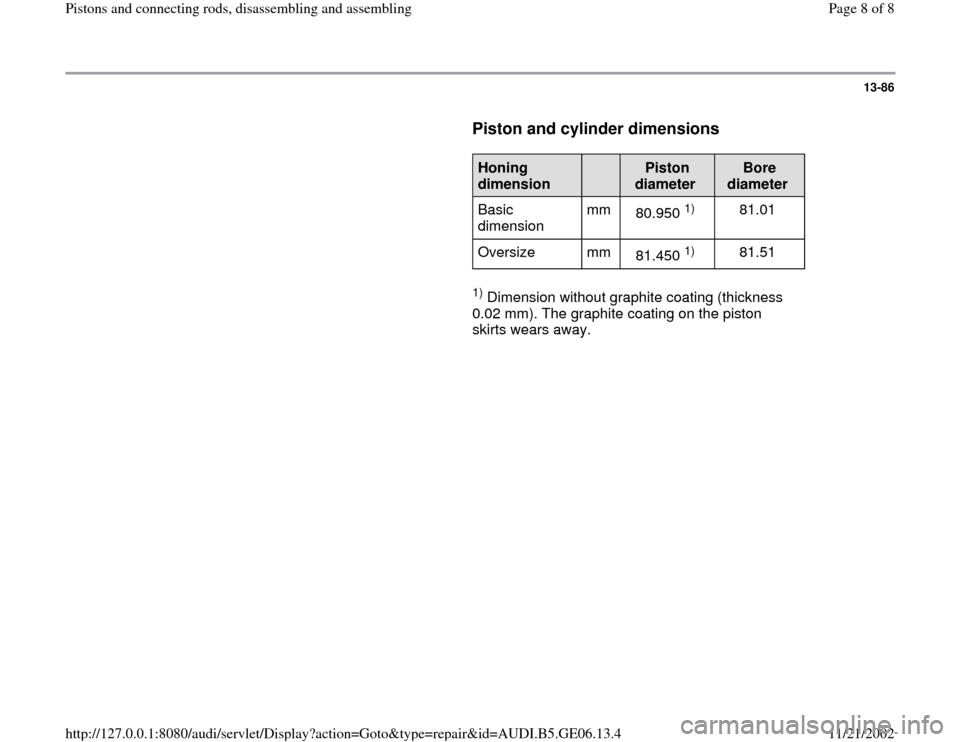

Piston and cylinder dimensions

Honing

dimension

Piston

diameter

Bore

diameter

Basic

dimension mm

80.950

1)

81.01

Oversize mm

81.450 1)

81.51

1) Dimension without graphite coating (thickness

0.02 mm). The graphite coating on the piston

skirts wears away.

Pa

ge 8 of 8 Pistons and connectin

g rods, disassemblin

g and assemblin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE06.13.4

Trending: oil, oil pressure, dimensions, checking oil, oil change, check oil, tow