air condition AUDI A4 1998 B5 / 1.G Engine Oil Level Checking Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A4, Model: AUDI A4 1998 B5 / 1.GPages: 111, PDF Size: 1.26 MB

Page 1 of 111

10

Description of work

Engine oil level, checking

After turning engine OFF, wait approximately 3

minutes to allow oil to flow back into oil pan.

- Remove dipstick, wipe with a lint free cloth, and

re-insert fully.

Note:

Please observe waste disposal requirements!

- Remove dipstick and read oil level:

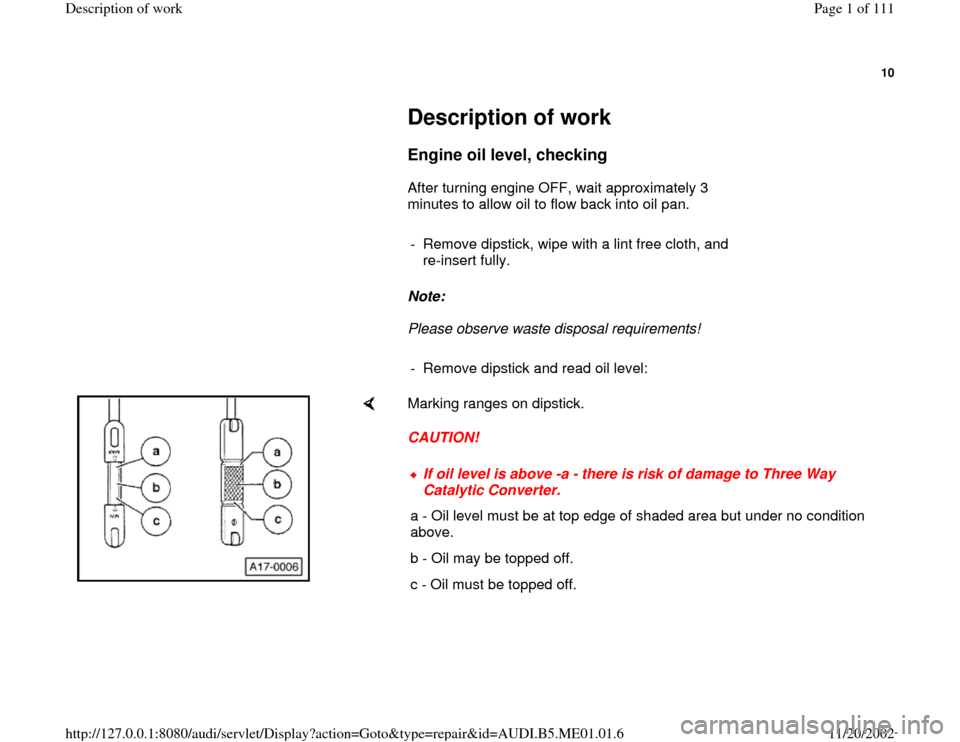

Marking ranges on dipstick.

CAUTION!

If oil level is above -a - there is risk of damage to Three Way

Catalytic Converter.

a - Oil level must be at top edge of shaded area but under no condition

above.

b - Oil may be topped off.

c - Oil must be topped off.

Pa

ge 1 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 21 of 111

27

V-belt and ribbed belts, replacing (4-

cylinder engine AEB)

Lock carrier must be in service position Page 24

Removing

Vehicles with air conditioner

- Remove noise insulation Page 18

.

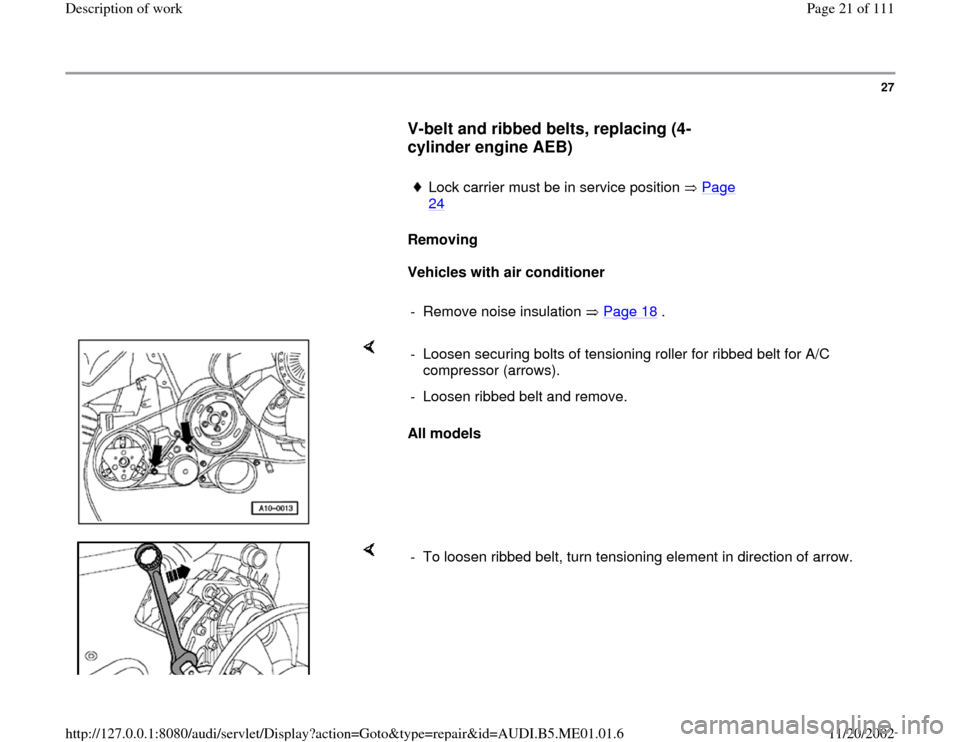

All models - Loosen securing bolts of tensioning roller for ribbed belt for A/C

compressor (arrows).

- Loosen ribbed belt and remove.

- To loosen ribbed belt, turn tensioning element in direction of arrow.

Pa

ge 21 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 24 of 111

30

Note:

It is not possible to adjust the tension of the V-

belt for the coolant pump.

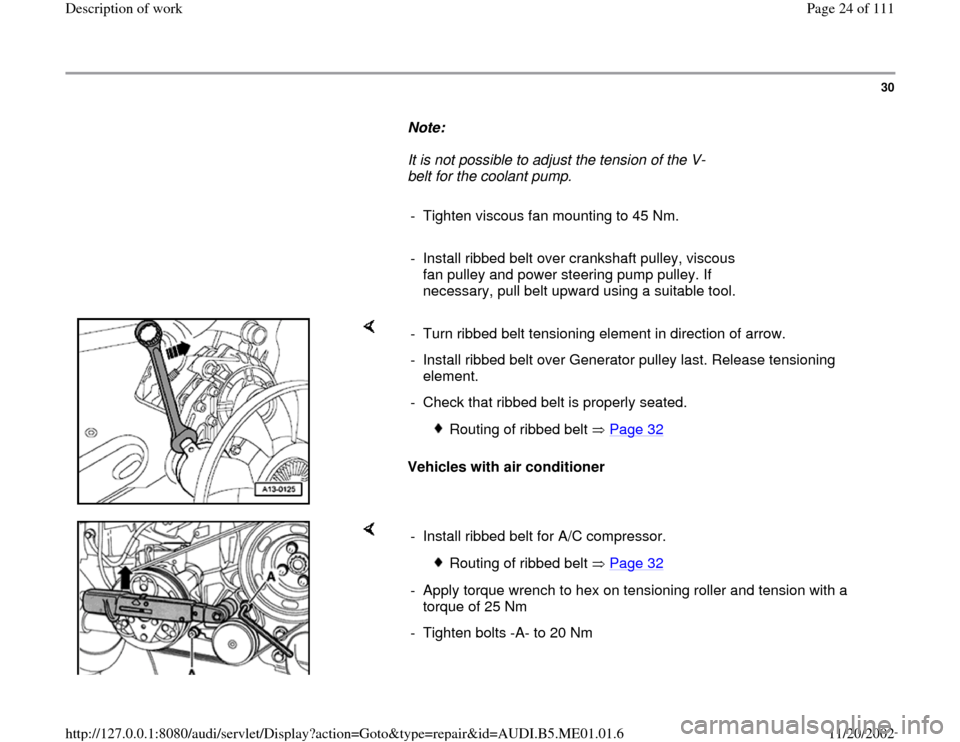

- Tighten viscous fan mounting to 45 Nm.

- Install ribbed belt over crankshaft pulley, viscous

fan pulley and power steering pump pulley. If

necessary, pull belt upward using a suitable tool.

Vehicles with air conditioner - Turn ribbed belt tensioning element in direction of arrow.

- Install ribbed belt over Generator pulley last. Release tensioning

element.

- Check that ribbed belt is properly seated.

Routing of ribbed belt Page 32

- Install ribbed belt for A/C compressor.

Routing of ribbed belt Page 32

- Apply torque wrench to hex on tensioning roller and tension with a

torque of 25 Nm

- Tighten bolts -A- to 20 Nm

Pa

ge 24 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 28 of 111

34

Poly-ribbed belt, checking, removing,

and replacing

Check condition of Poly-ribbed belt for:

Splits in base material (cracks, core

fractures, cross section fractures).

Separation of layers (top layer, tensile

cords).

Bursting on base material.

Fraying of cords.

Flank wear (material flaking, frayed flanks,

hardening of flanks (glassy surface), and

surface cracks).

Traces of oil and grease.

Note:

If defects exist, replace Poly-ribbed belt.

Poly-ribbed belt replacement interval

- Every 144,000 km (90,000 mi.)

Pa

ge 28 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 35 of 111

39

Automatic Transmission Fluid (ATF),

checking (01V transmission)

Requirements for check:

Vehicle standing on level surface.

Transmission must not be in fail-safe mode.

Shift lever in "P" position, parking brake

applied.

Engine idling.

Air Conditioner and heater OFF.

ATF temperature must not exceed 40 C

(104 F) at start of test.

CAUTION!

Part numbers are for reference only. Always

check with your Parts Dept. for the latest

parts information.

Notes:

Only ATF with designation ESSO LT 71 141

Pa

ge 35 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 67 of 111

67

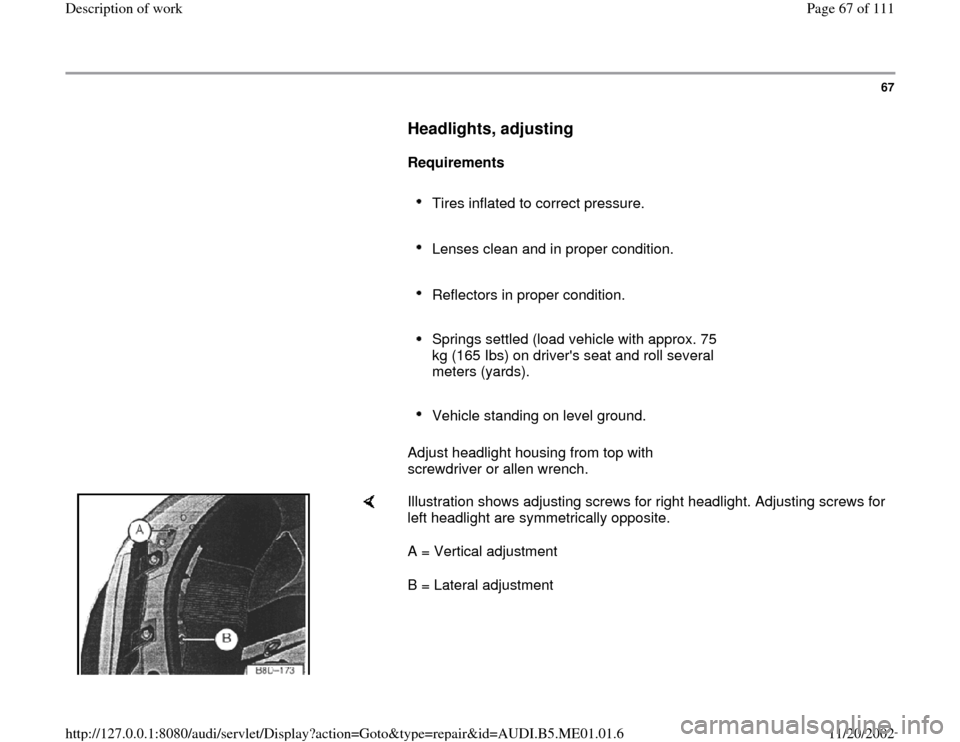

Headlights, adjusting

Requirements

Tires inflated to correct pressure.

Lenses clean and in proper condition.

Reflectors in proper condition.

Springs settled (load vehicle with approx. 75

kg (165 Ibs) on driver's seat and roll several

meters (yards).

Vehicle standing on level ground.

Adjust headlight housing from top with

screwdriver or allen wrench.

Illustration shows adjusting screws for right headlight. Adjusting screws for

left headlight are symmetrically opposite.

A = Vertical adjustment

B = Lateral adjustment

Pa

ge 67 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 100 of 111

97

RAPGARD , paint inspection after removal

- Inspect painted surfaces under one of the

following lighting conditions:

Indoors under fluorescent lighting.

Outdoors under bright sunlight.

Important!:

If any defects on the exterior have been identified

(scratches, dings, dents and other types of body

damage):

- Contact your Service Manager and arrange to

repair defects immediately.

Note:

After removal of RAPGARD , some vehicles

may exhibit temporary paint discoloration or paint

swelling (caused by trapped moisture under the

RAPGARD ).

This temporary swelling is caused by the paint

finish absorbing moisture trapped under the

RAPGARD film.

Pa

ge 100 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 101 of 111

This swelling will disappear with exposure to

the sun or heat lamps within 2 - 3 hours. Severe

Paint swelling may require 2 - 3 days to

recover.

DO NOT buff or refinish paint for this condition!

Pa

ge 101 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6

Page 109 of 111

103

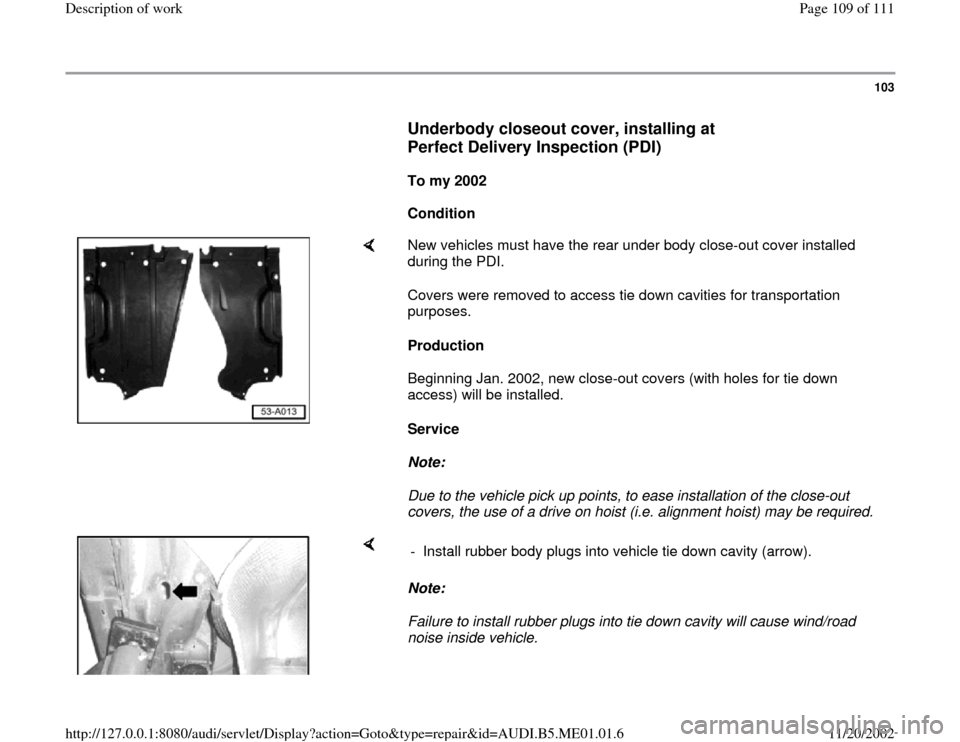

Underbody closeout cover, installing at

Perfect Delivery Inspection (PDI)

To my 2002

Condition

New vehicles must have the rear under body close-out cover installed

during the PDI.

Covers were removed to access tie down cavities for transportation

purposes.

Production

Beginning Jan. 2002, new close-out covers (with holes for tie down

access) will be installed.

Service

Note:

Due to the vehicle pick up points, to ease installation of the close-out

covers, the use of a drive on hoist (i.e. alignment hoist) may be required.

Note:

Failure to install rubber plugs into tie down cavity will cause wind/road

noise inside vehicle. - Install rubber body plugs into vehicle tie down cavity (arrow).

Pa

ge 109 of 111 Descri

ption of wor

k

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.ME01.01.6