AUDI A4 1999 B5 / 1.G AHA ATQ Engines Lubrication System Components User Guide

Manufacturer: AUDI, Model Year: 1999,

Model line: A4,

Model: AUDI A4 1999 B5 / 1.G

Pages: 34, PDF Size: 0.68 MB

AUDI A4 1999 B5 / 1.G AHA ATQ Engines Lubrication System Components User Guide

A4 1999 B5 / 1.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/992/w960_992-0.png

AUDI A4 1999 B5 / 1.G AHA ATQ Engines Lubrication System Components User Guide

Trending: washer fluid, air filter, steering, drain bolt, clock, engine coolant, ignition

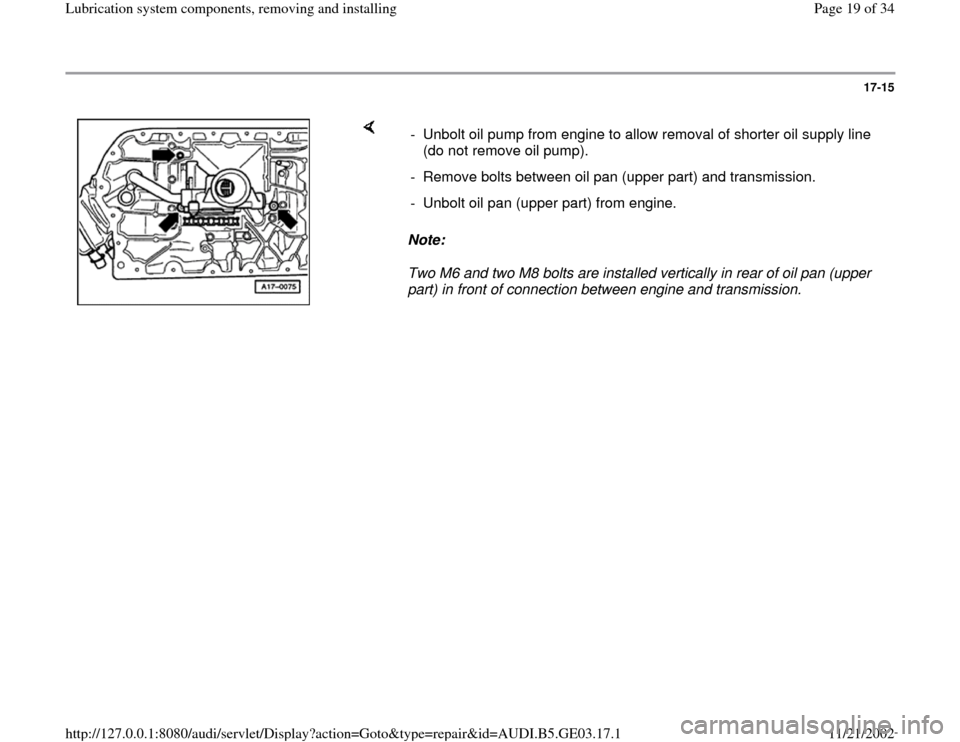

Page 11 of 34

17-7

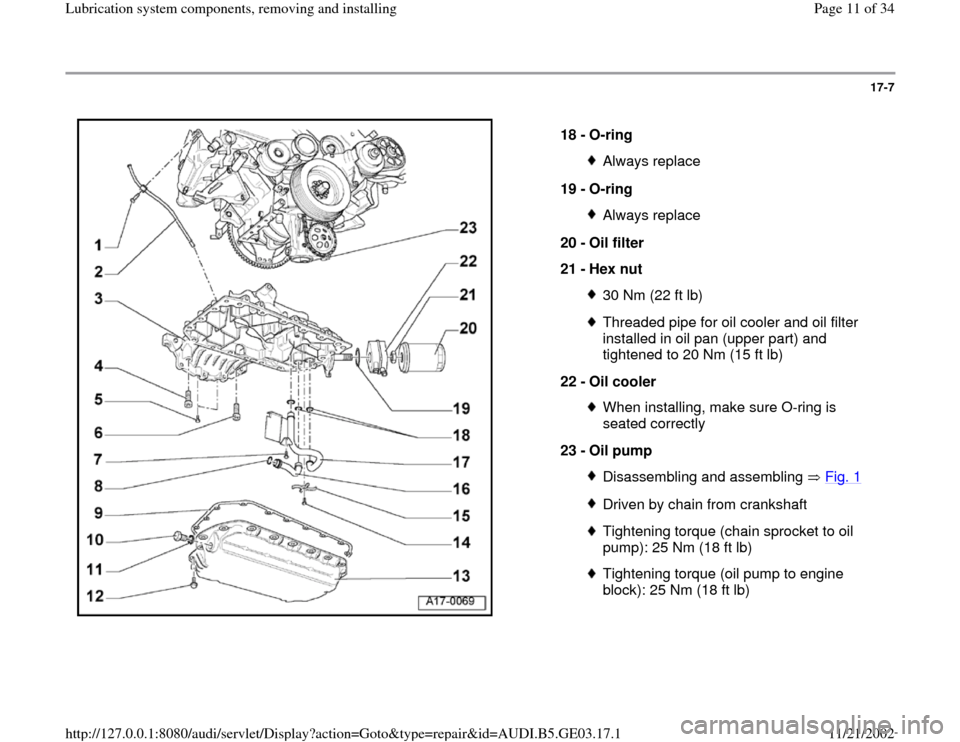

18 -

O-ring

Always replace

19 -

O-ring Always replace

20 -

Oil filter

21 -

Hex nut 30 Nm (22 ft lb)Threaded pipe for oil cooler and oil filter

installed in oil pan (upper part) and

tightened to 20 Nm (15 ft lb)

22 -

Oil cooler When installing, make sure O-ring is

seated correctly

23 -

Oil pump Disassembling and assembling Fig. 1Driven by chain from crankshaftTightening torque (chain sprocket to oil

pump): 25 Nm (18 ft lb) Tightening torque (oil pump to engine

block): 25 Nm (18 ft lb)

Pa

ge 11 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

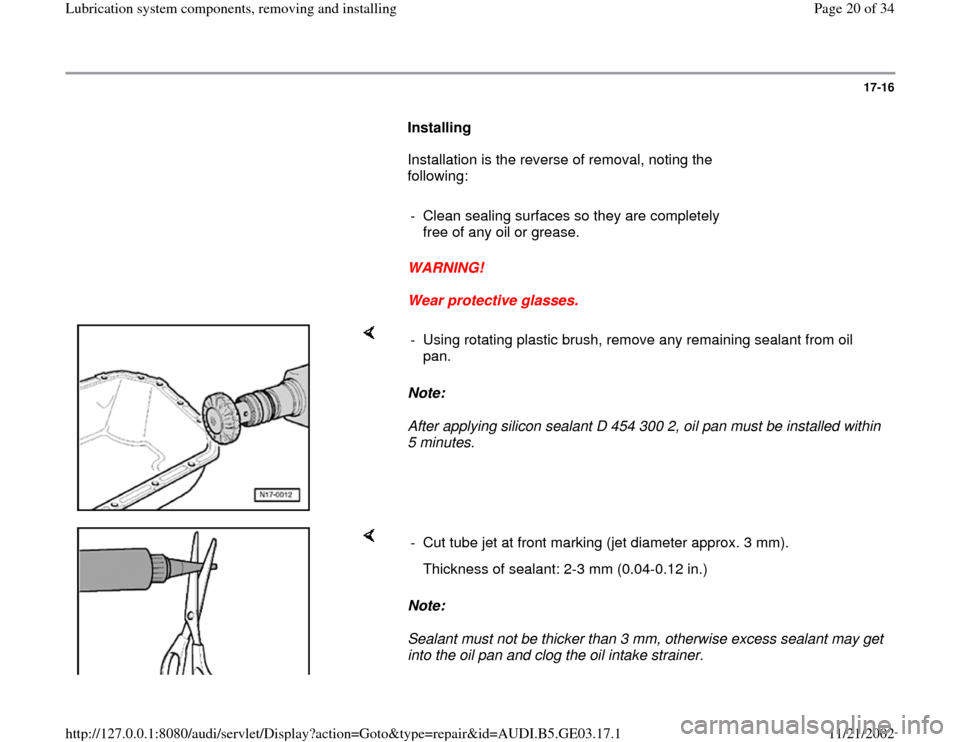

Page 12 of 34

17-8

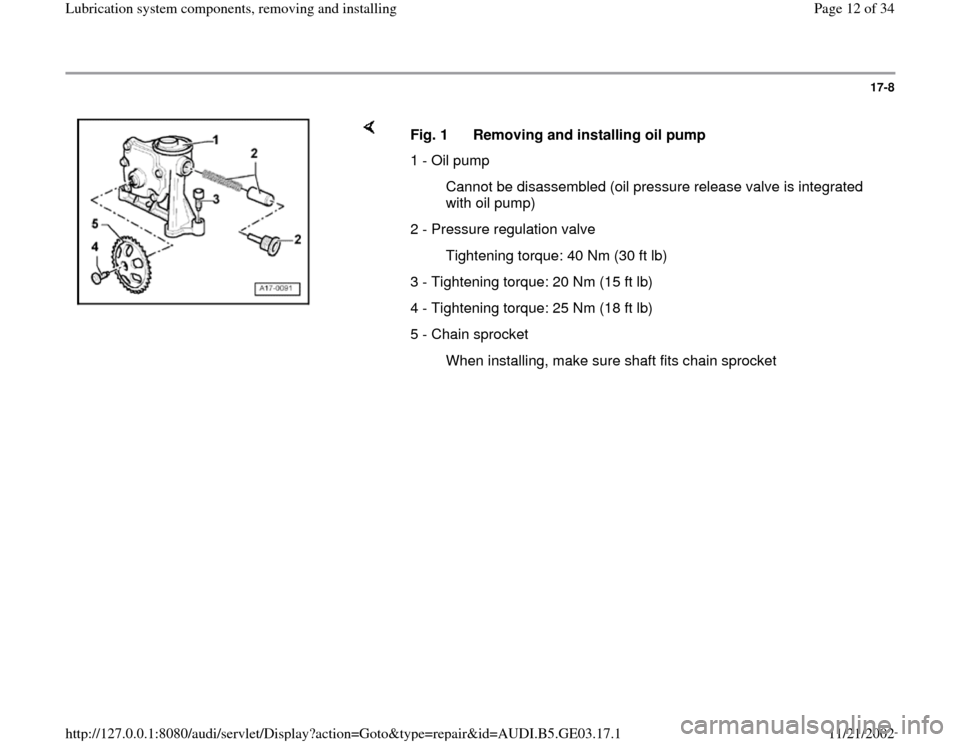

Fig. 1 Removing and installing oil pump

1 - Oil pump

Cannot be disassembled (oil pressure release valve is integrated

with oil pump)

2 - Pressure regulation valve

Tightening torque: 40 Nm (30 ft lb)

3 - Tightening torque: 20 Nm (15 ft lb)

4 - Tightening torque: 25 Nm (18 ft lb)

5 - Chain sprocket

When installing, make sure shaft fits chain sprocket

Pa

ge 12 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 13 of 34

17-9

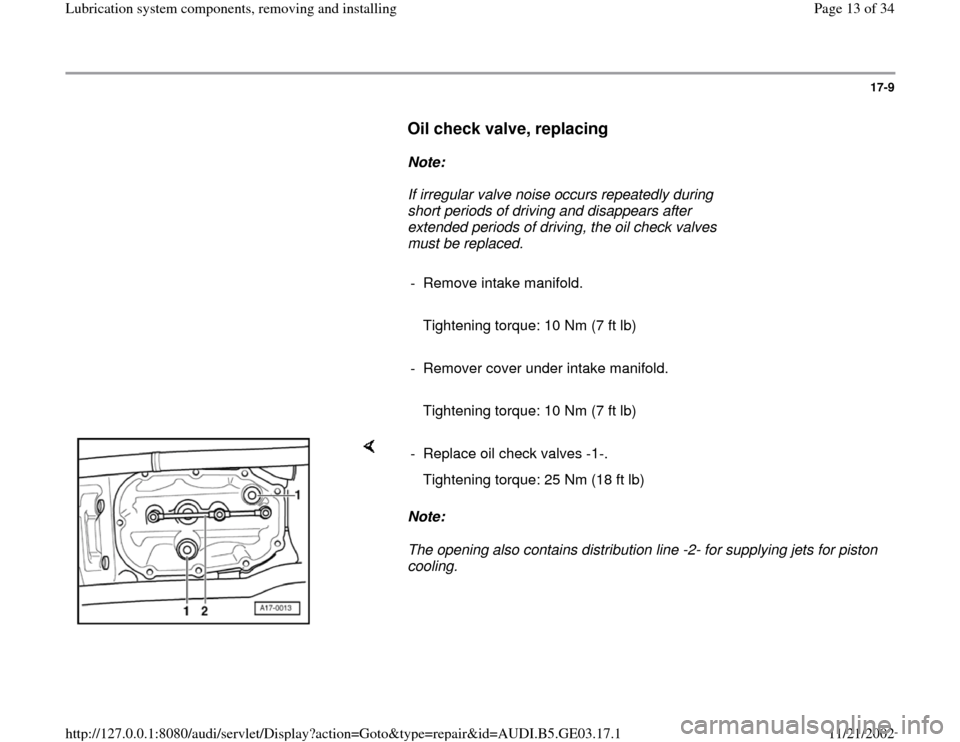

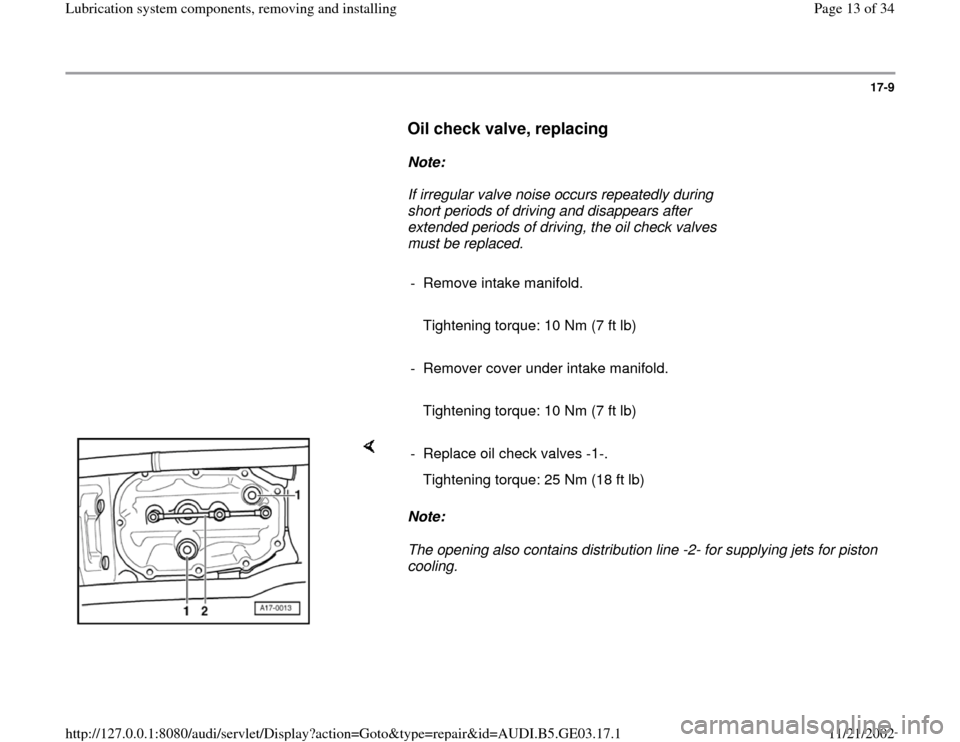

Oil check valve, replacing

Note:

If irregular valve noise occurs repeatedly during

short periods of driving and disappears after

extended periods of driving, the oil check valves

must be replaced.

- Remove intake manifold.

Tightening torque: 10 Nm (7 ft lb)

- Remover cover under intake manifold.

Tightening torque: 10 Nm (7 ft lb)

Note:

The opening also contains distribution line -2- for supplying jets for piston

cooling. - Replace oil check valves -1-.

Tightening torque: 25 Nm (18 ft lb)

Pa

ge 13 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 14 of 34

17-10

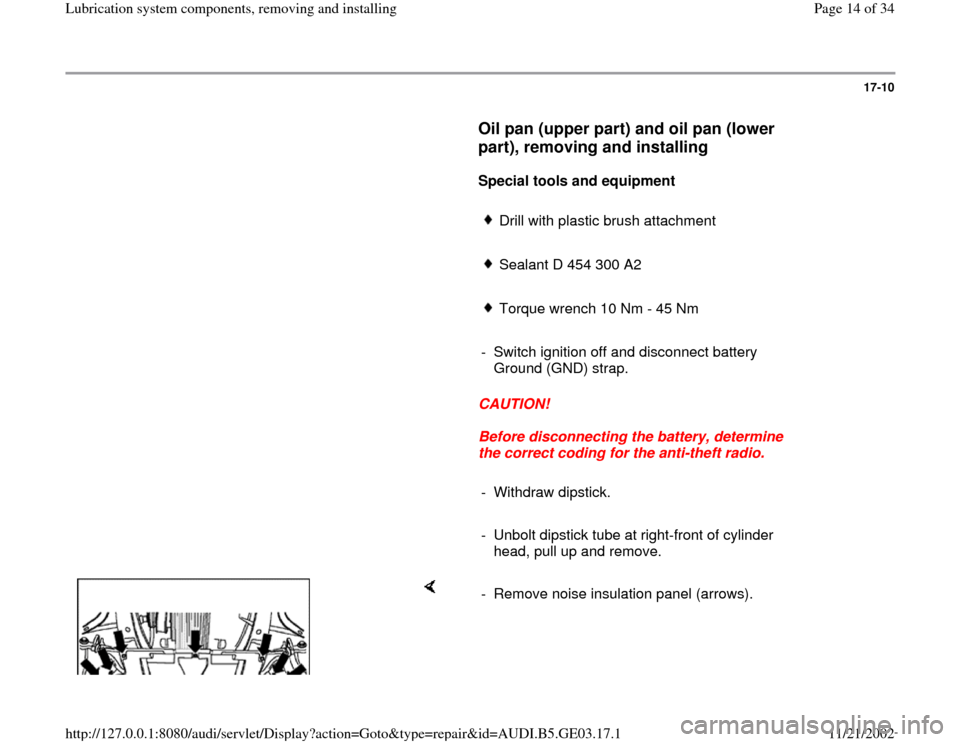

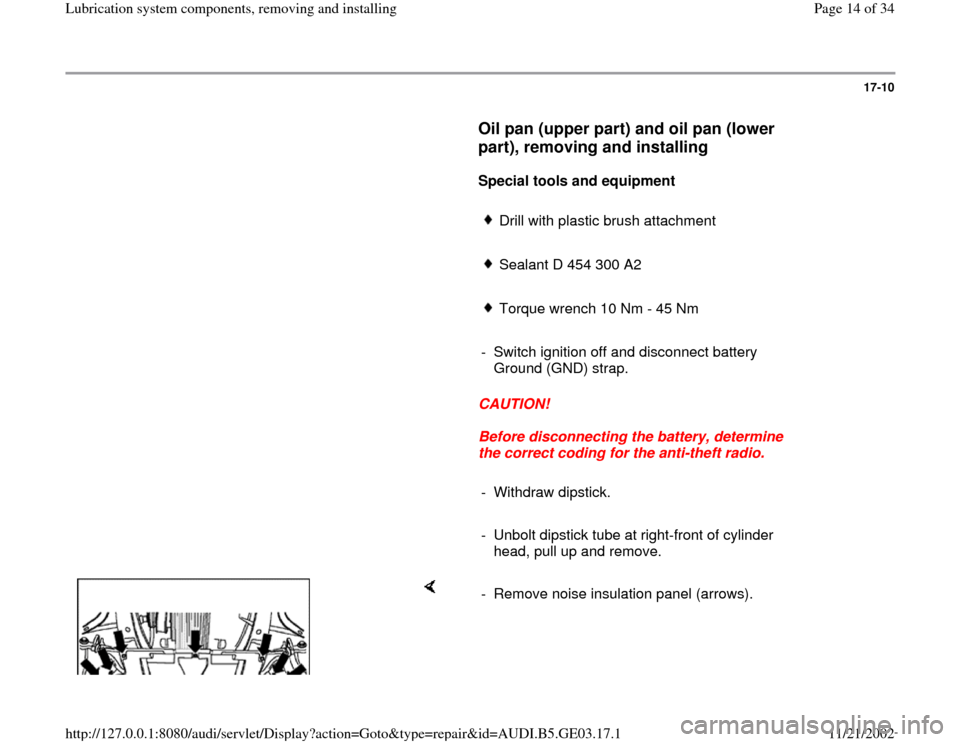

Oil pan (upper part) and oil pan (lower

part), removing and installing

Special tools and equipment

Drill with plastic brush attachment

Sealant D 454 300 A2

Torque wrench 10 Nm - 45 Nm

- Switch ignition off and disconnect battery

Ground (GND) strap.

CAUTION!

Before disconnecting the battery, determine

the correct coding for the anti-theft radio.

- Withdraw dipstick.

- Unbolt dipstick tube at right-front of cylinder

head, pull up and remove.

- Remove noise insulation panel (arrows).

Pa

ge 14 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 15 of 34

17-11

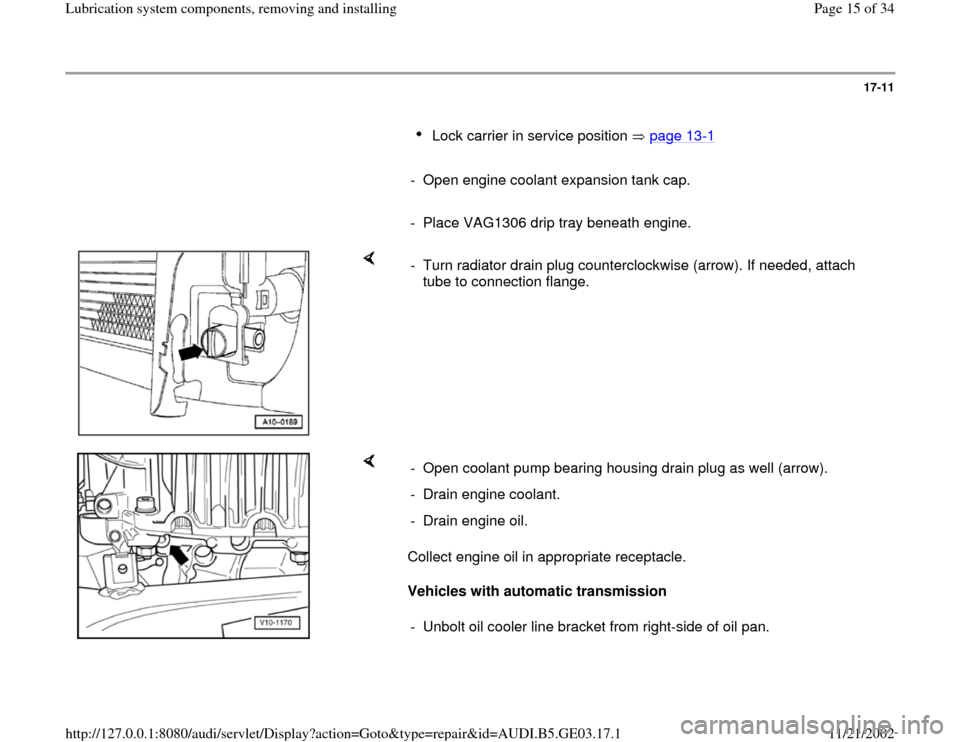

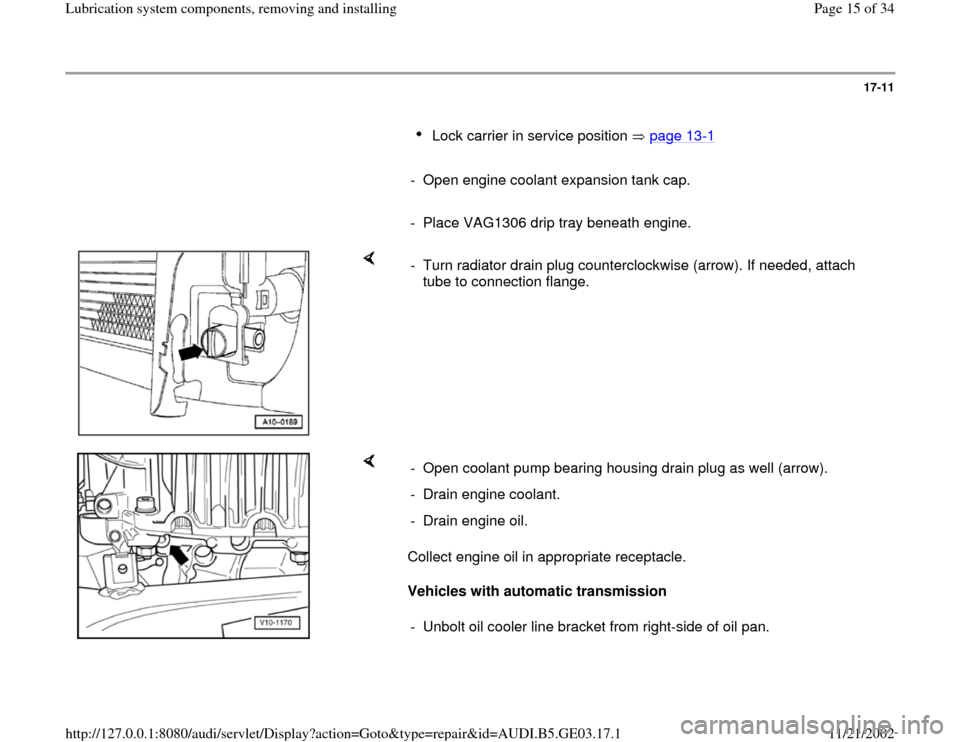

Lock carrier in service position page 13

-1

- Open engine coolant expansion tank cap.

- Place VAG1306 drip tray beneath engine.

- Turn radiator drain plug counterclockwise (arrow). If needed, attach

tube to connection flange.

Collect engine oil in appropriate receptacle.

Vehicles with automatic transmission - Open coolant pump bearing housing drain plug as well (arrow).

- Drain engine coolant.

- Drain engine oil.

- Unbolt oil cooler line bracket from right-side of oil pan.

Pa

ge 15 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 16 of 34

17-12

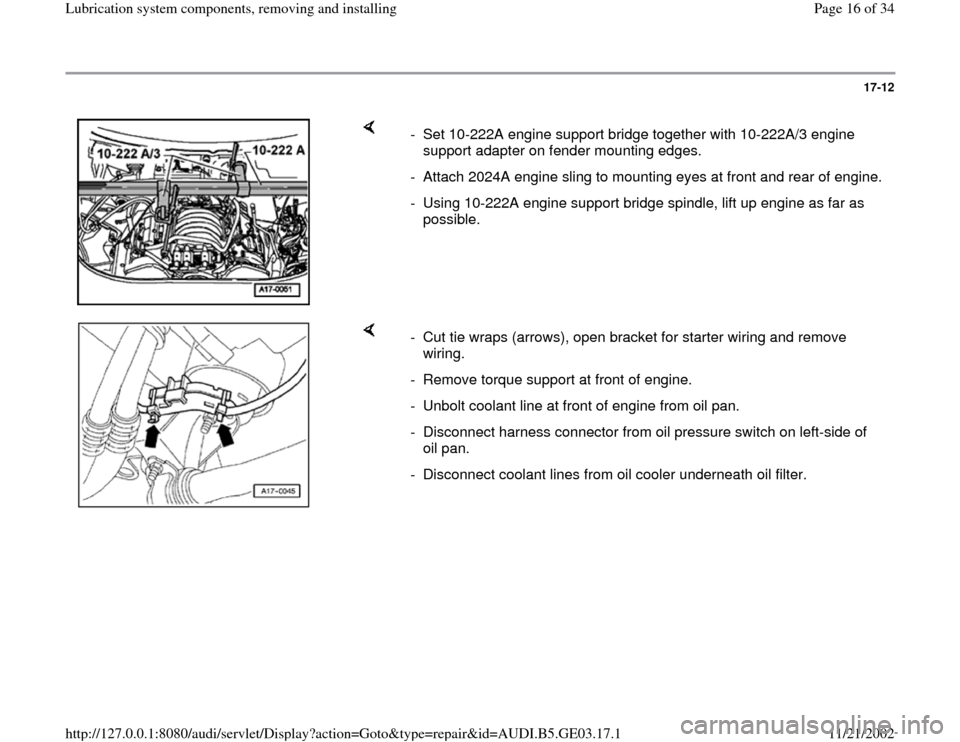

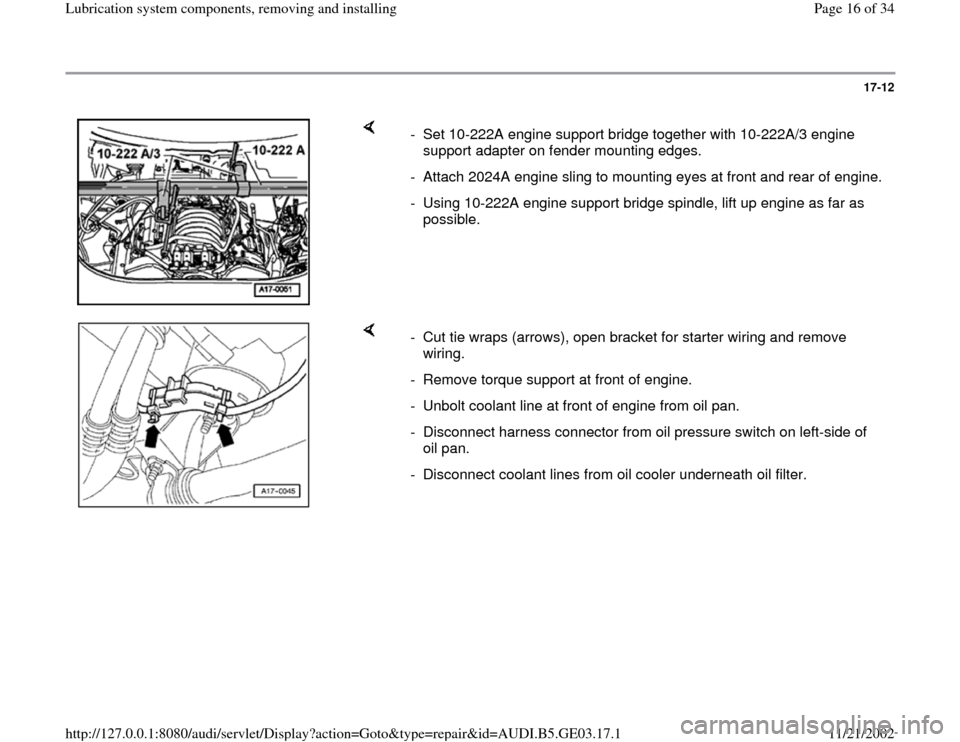

- Set 10-222A engine support bridge together with 10-222A/3 engine

support adapter on fender mounting edges.

- Attach 2024A engine sling to mounting eyes at front and rear of engine.

- Using 10-222A engine support bridge spindle, lift up engine as far as

possible.

- Cut tie wraps (arrows), open bracket for starter wiring and remove

wiring.

- Remove torque support at front of engine.

- Unbolt coolant line at front of engine from oil pan.

- Disconnect harness connector from oil pressure switch on left-side of

oil pan.

- Disconnect coolant lines from oil cooler underneath oil filter.

Pa

ge 16 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 17 of 34

17-13

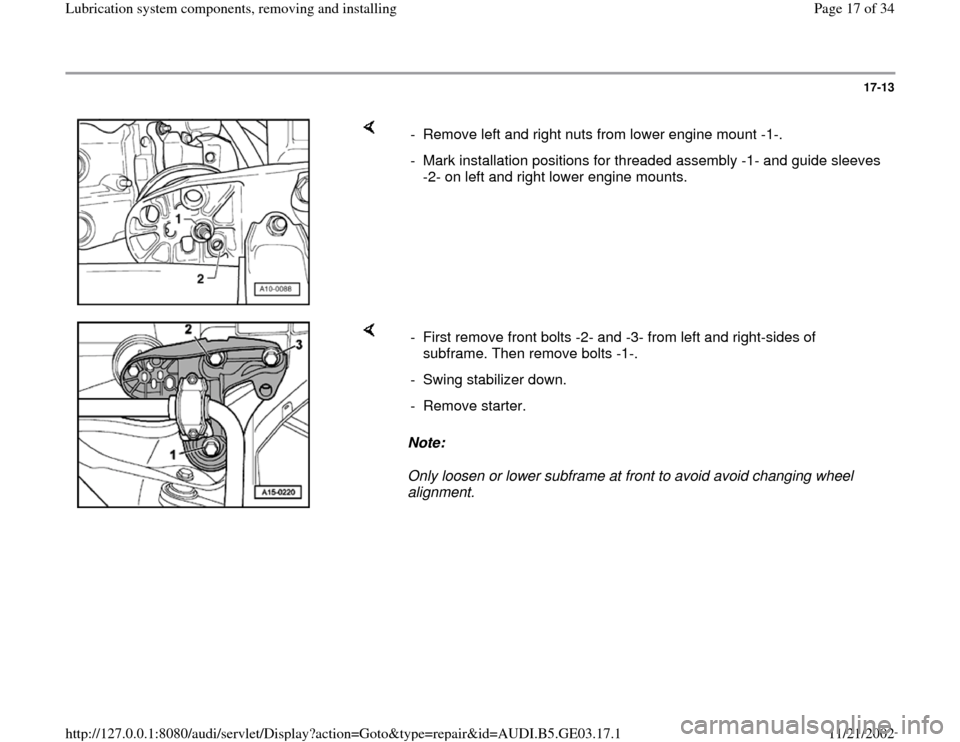

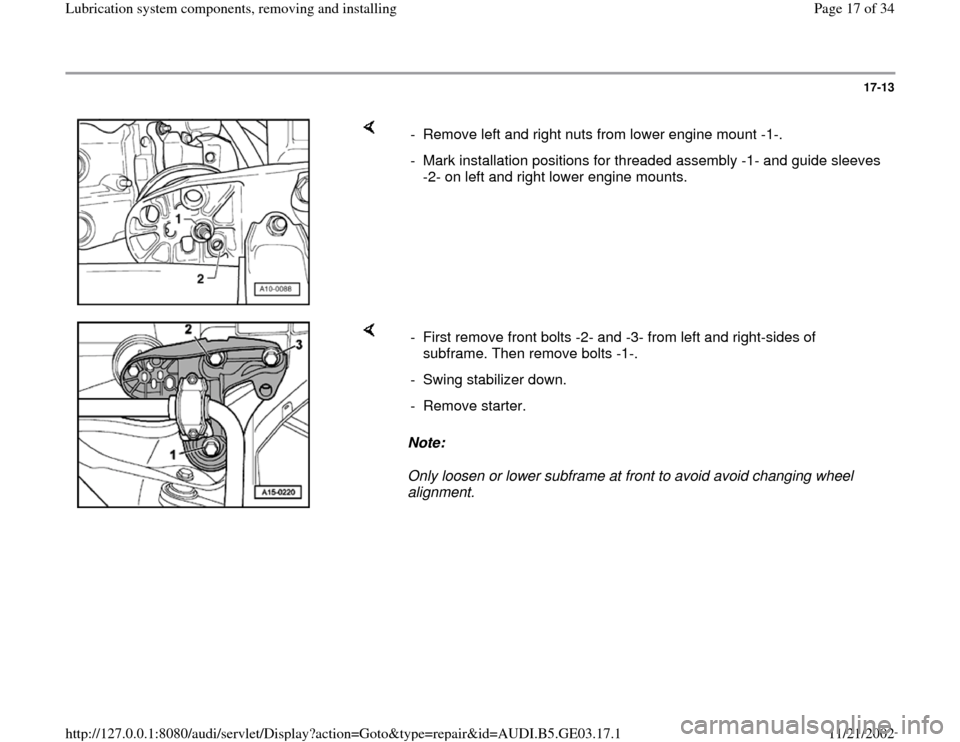

- Remove left and right nuts from lower engine mount -1-.

- Mark installation positions for threaded assembly -1- and guide sleeves

-2- on left and right lower engine mounts.

Note:

Only loosen or lower subframe at front to avoid avoid changing wheel

alignment. - First remove front bolts -2- and -3- from left and right-sides of

subframe. Then remove bolts -1-.

- Swing stabilizer down.

- Remove starter.

Pa

ge 17 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Page 18 of 34

17-14

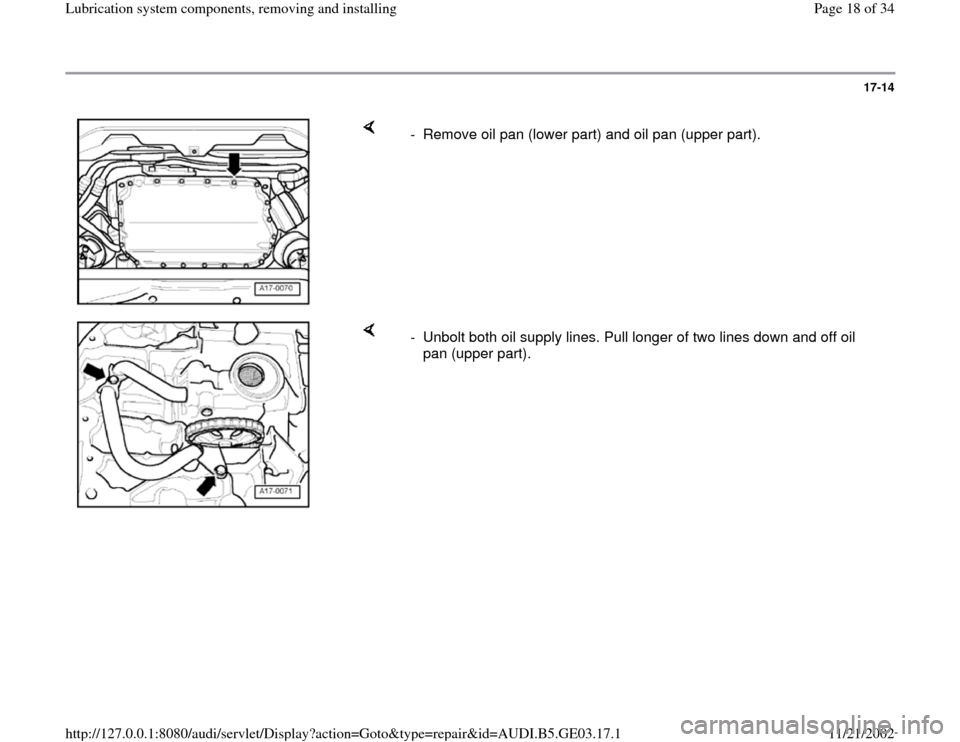

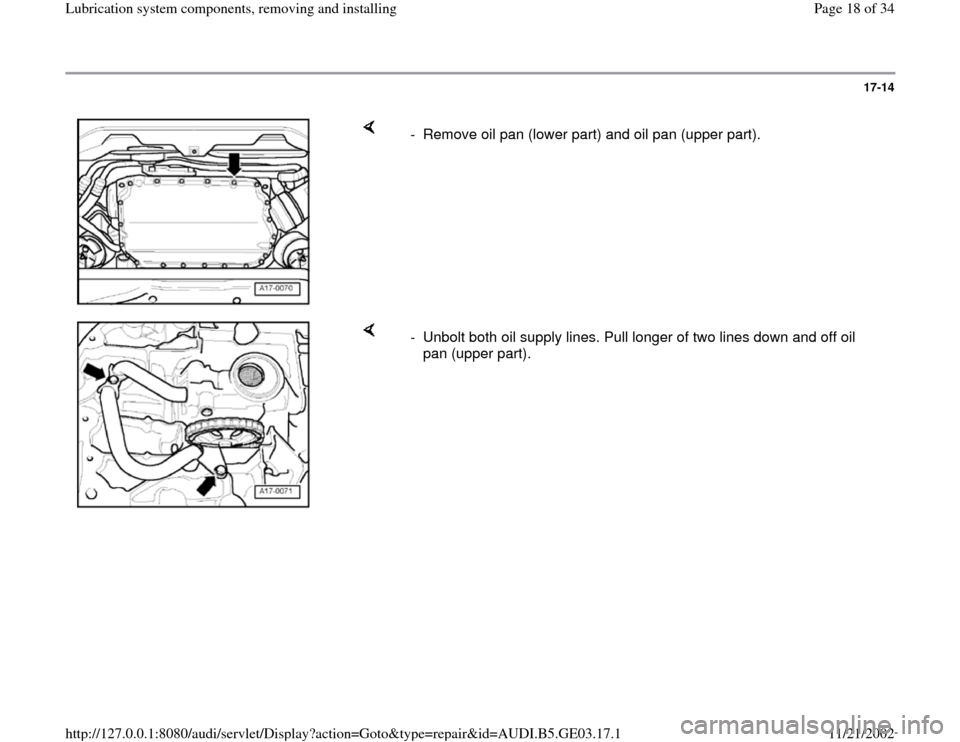

- Remove oil pan (lower part) and oil pan (upper part).

- Unbolt both oil supply lines. Pull longer of two lines down and off oil

pan (upper part).

Pa

ge 18 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

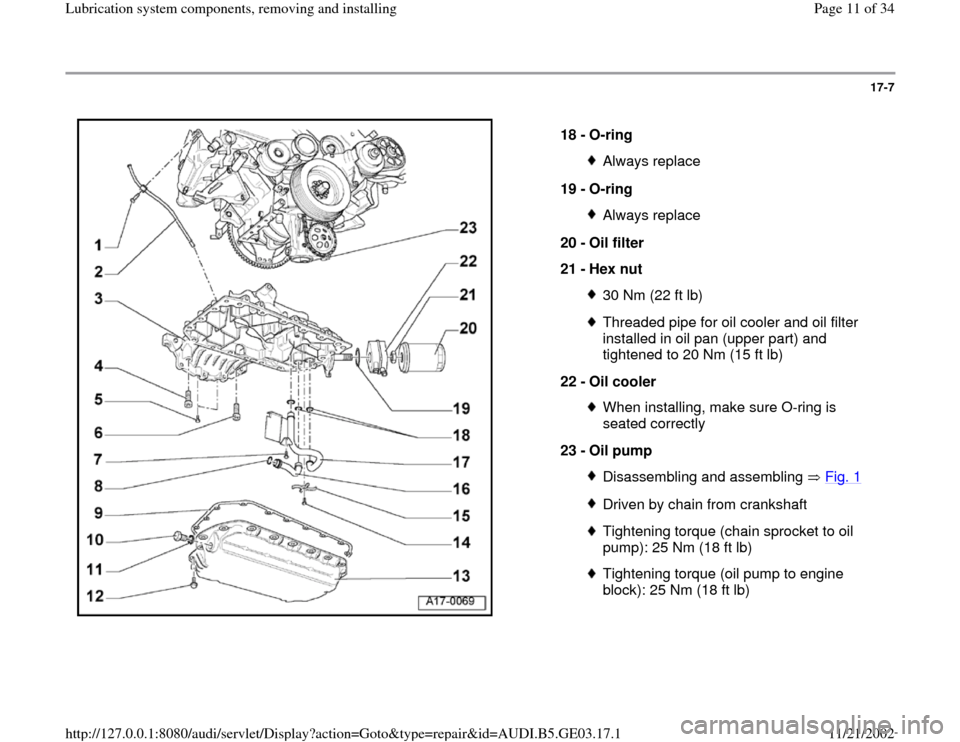

Page 19 of 34

17-15

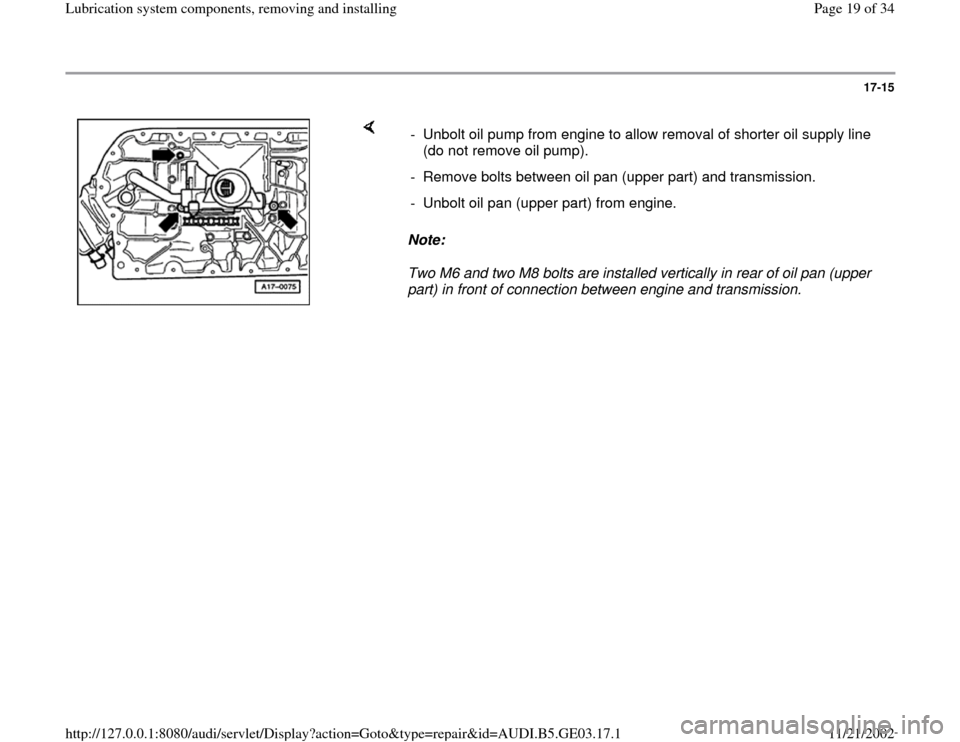

Note:

Two M6 and two M8 bolts are installed vertically in rear of oil pan (upper

part) in front of connection between engine and transmission. - Unbolt oil pump from engine to allow removal of shorter oil supply line

(do not remove oil pump).

- Remove bolts between oil pan (upper part) and transmission.

- Unbolt oil pan (upper part) from engine.

Pa

ge 19 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

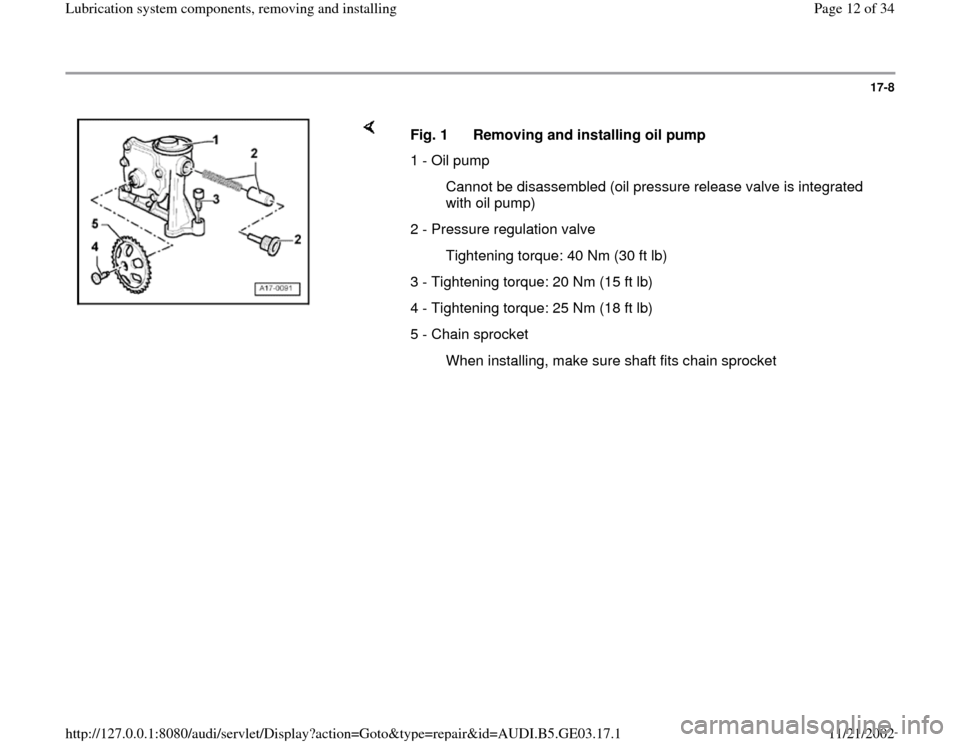

Page 20 of 34

17-16

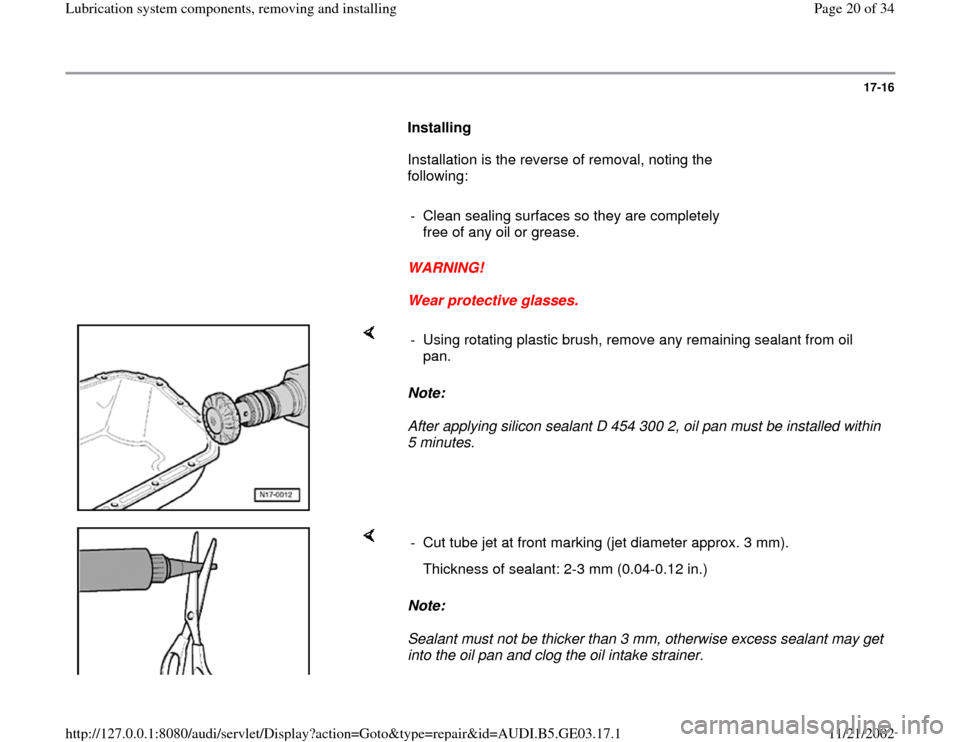

Installing

Installation is the reverse of removal, noting the

following:

- Clean sealing surfaces so they are completely

free of any oil or grease.

WARNING!

Wear protective glasses.

Note:

After applying silicon sealant D 454 300 2, oil pan must be installed within

5 minutes. - Using rotating plastic brush, remove any remaining sealant from oil

pan.

Note:

Sealant must not be thicker than 3 mm, otherwise excess sealant may get

into the oil pan and clog the oil intake strainer. - Cut tube jet at front marking (jet diameter approx. 3 mm).

Thickness of sealant: 2-3 mm (0.04-0.12 in.)

Pa

ge 20 of 34 Lubrication s

ystem com

ponents, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.17.1

Trending: belt, washer fluid, drain bolt, oil filter, engine coolant, oil temperature, suspension