air condition AUDI A4 2000 B5 / 1.G AFC Engine Assembly Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A4, Model: AUDI A4 2000 B5 / 1.GPages: 20, PDF Size: 0.21 MB

Page 11 of 20

10-8

- Unbolt hydraulic pump from mounting bracket.

CAUTION!

Hydraulic lines should remain connected.

- Unscrew bolts and secure A/C compressor to

one side with wire.

CAUTION!

Disconnect at mounting points only.

DO NOT open the air conditioning refrigerant

circuit.

Set the A/C compressor aside carefully.

Refrigerant lines kink easily.

The A/C refrigerant circuit must only be

opened by specially trained technicians

using the proper tools and equipment.

- Remove bolts securing exhaust manifold and

front exhaust pipe at top.

- Disconnect battery positive (B+) cable from

starter at right of engine below exhaust manifold.

Pa

ge 11 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 14 of 20

10-10

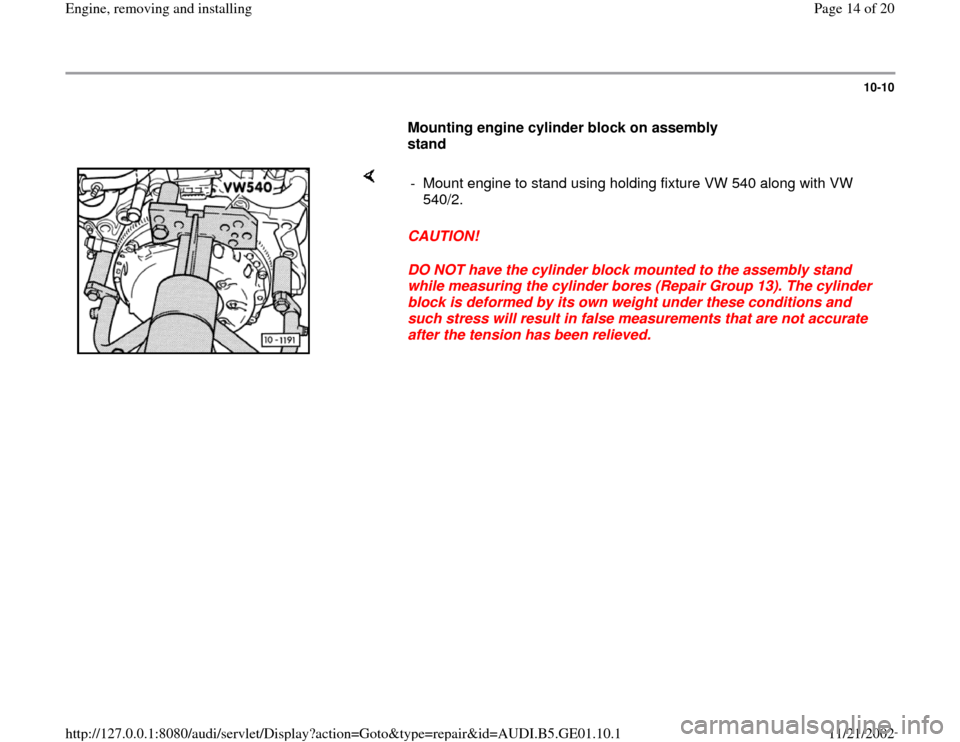

Mounting engine cylinder block on assembly

stand

CAUTION!

DO NOT have the cylinder block mounted to the assembly stand

while measuring the cylinder bores (Repair Group 13). The cylinder

block is deformed by its own weight under these conditions and

such stress will result in false measurements that are not accurate

after the tension has been relieved. - Mount engine to stand using holding fixture VW 540 along with VW

540/2.

Pa

ge 14 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 15 of 20

10-11

Installing

The engine is installed in the reverse order of

removal, with the addition of the following special

conditions and steps:

WARNING!

Do not re-use any fasteners that are worn or

deformed in normal use. Many fasteners are

designed to be used only once and become

unreliable and may fail when used a second

time. This includes, but is not limited to, nuts,

bolts, washers, self-locking nuts or bolts,

circlips and cotter pins. Always follow

recommendations given in this publication.

Always replace these fasteners with new

parts.

- Check that alignment sleeves for centering

engine and transmission are properly installed in

cylinder block. Install sleeves if necessary.

- Always install new seals and gaskets.

- Check centering of clutch disc, if necessary.

- Check clutch release bearing for wear and

replace if necessary.

Pa

ge 15 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1

Page 17 of 20

10-12

- Allow stop of torque support to move down onto

rubber block under its own weight; tighten bolts

to 45 Nm (33 ft lb).

- Align exhaust system free of stress Repair

Group 26.

- Adjust accelerator pedal cable Repair Group

20.

- Re-fill engine cooling system Repair Group

19.

- Drained coolant may only be re-used provided

the cylinder block or the cylinder head was not

replaced.

- Check oil level before starting engine.

- Short blocks are supplied without bushing in

crankshaft. For vehicles with automatic

transmission, tap bushing into place before

installing drive plate.

- Check reconditioned engines with manual

gearbox to determine whether needle bearing is

installed in crankshaft; install if necessary.

Pa

ge 17 of 20 En

gine, removin

g and installin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE01.10.1