warning AUDI A5 CABRIOLET 2014 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2014, Model line: A5 CABRIOLET, Model: AUDI A5 CABRIOLET 2014Pages: 286, PDF Size: 70.4 MB

Page 247 of 286

jack, always fully set the parking brake

and block the wheel diagonally opposite

the wheel being changed with the fold

ing chocks o r other objects. When one

front wheel is lifted off the ground, plac

ing the Automat ic Transm iss ion in "P"

(Park) wi ll

not prevent the vehicle from

moving.

- Before you change a wheel, be sure the

ground is level and firm. If necessary,

use a st urdy board under the jack.

- Always store the vehicle tool kit, the

jack* and the repla ced ti re in the l uggage

compartment

¢ page 12 7.

(D Note

If you are chang ing the wheel on a steep

incline, use a rock or similar object to

block the opposite wheel to prevent the

ve hicl e from mov ing.

(l) Tips

Obey a ll laws.

Changing a wheel

When you change a wheel, follow these

quence described below step-by-step and in

exactly tha t order .

1. Remove the dec orative whe el co ver* or

the

wh eel b olt cap s* . Fo r mor e details see

a lso

¢ page 245, Decorative wheel cov

ers

or¢ page 246, Wheels with wheel

bolt caps.

2 . Loosen the wheel bo lts ¢ page 246.

3. Locate the proper mounting po int for the

jack and align the jack below that point

c::> page247.

4. Lift the car with the jack c::> page 247 .

5. Remove the wheel with th e flat tire and

then install the

s pare tir e c::> page 248 .

6. Tighten all wh eel bo lts light ly .

7.

Low er the ve hicle wit h the ja ck.

8. Use the wheel bolt wrenc h and

firmly

tighten a ll whee l bolts in a cr isscross pa t

tern ¢

page 246.

What do I do now ? 245

9. Replace the decorative wheel co ver* or

the

wheel bolt caps*.

A WARNING

Always read and fo llow all WARNINGS and

i n format ion

c::> .&. in Raising the vehicle on

page 247

and c::> page 249.

After changing a wheel

A wheel change is not complete without the

doing the following.

.,. Always store the vehicle tool kit, the jack*,

and the replaced tire in the luggage com

partment

c::> page 12 7 .

.,. Check the tire pressu re of the spare tire as

soon as possible .

.,. As soon as poss ib le, have the

t ightening

torqu es

on all wheel bolts checked with a

t orque wrench. The co rrect tighte ning tor

que is

90 ft lbs. (120 Nm).

.,. Have the fla t tire

repl ace d as soon as possi

b le.

(D Tips

- If you not ice tha t the wheel bo lts a re

c orroded and difficult to turn while

chang ing a tire, they shou ld be replaced

before you c heck the tightening torque.

- Drive at reduced speed until you have the tightening torques checked .

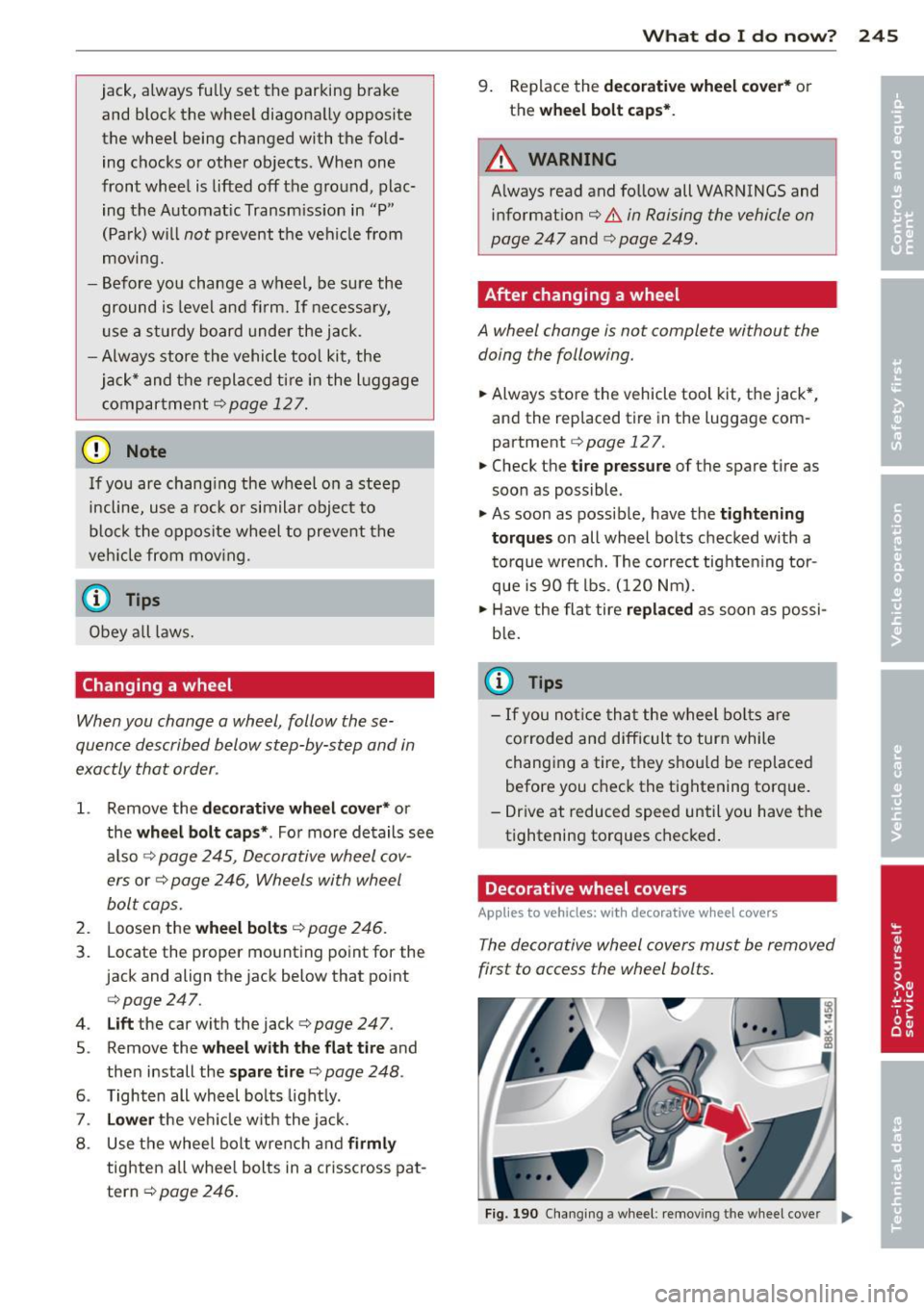

Decorative wheel covers

Applies to vehicles: wit h deco rat ive w hee l covers

The decorative wheel covers must be removed

first to access the wheel bolts .

Fig. 19 0 C ha ngi ng a w heel : re moving the w hee l cove r ...

Page 248 of 286

246 What do I do now?

Removing

.,. Inse rt the hook provi ded wi th the ve hicle

tool kit in t he hole in the hub.

.,. Pull

off the decorat ive wheel cover

¢ fig. 190 .

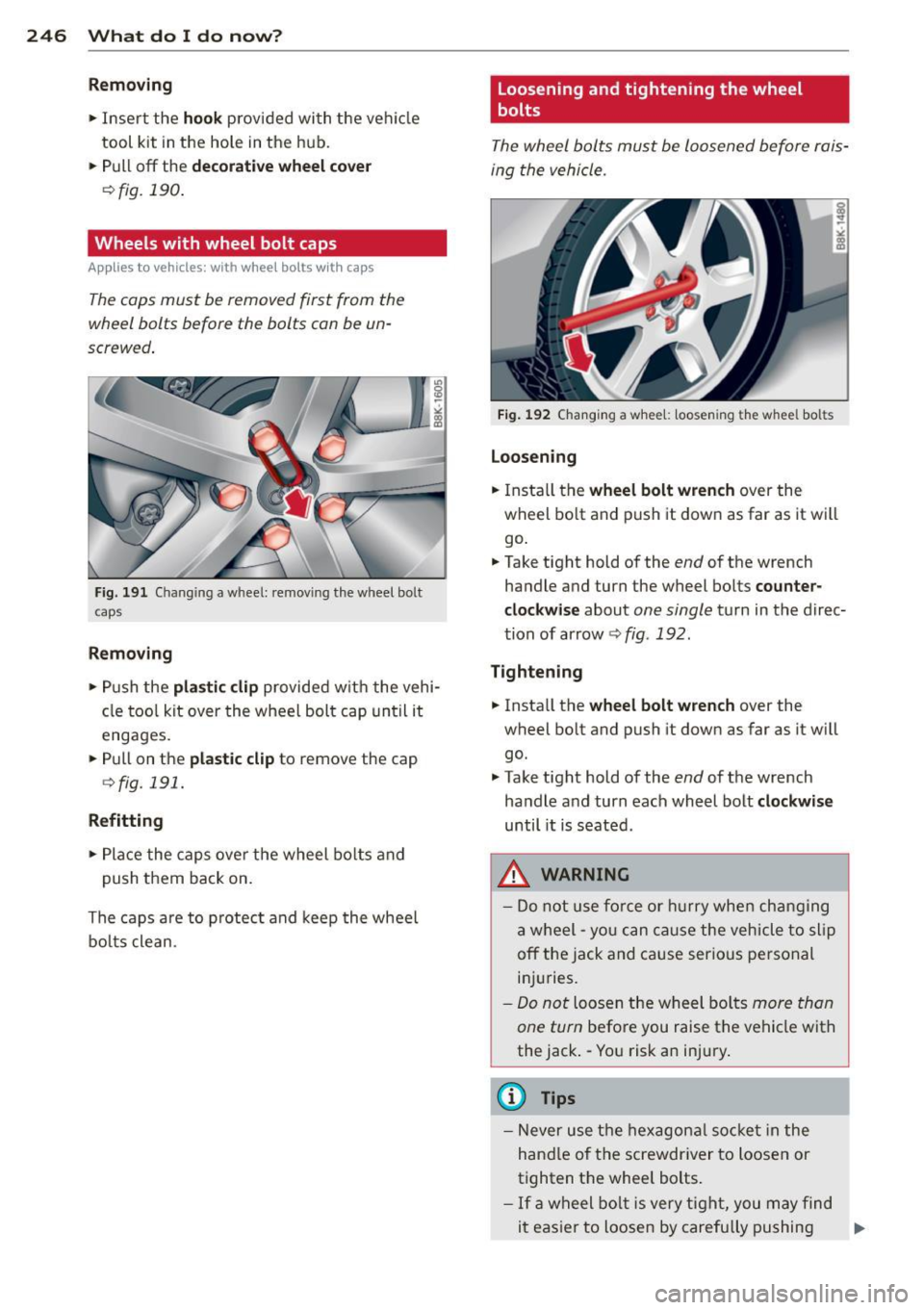

Wheels with wheel bolt caps

App lies to vehicles: with whee l bolts w it h cap s

The caps must be removed first from the

wheel bolts b efore the bolts can be un

screwed .

Fig. 191 Chang ing a w hee l: remov ing t he w hee l bo lt

c ap s

Removing

.,. Push the pla stic dip provide d wit h the vehi

cl e too l kit over the whee l bol t cap until it

engages.

.,. Pull on the

plastic clip to remove the cap

~ fig . 191.

Refitting

.,. Pla ce the caps ove r th e wheel bo lts and

p ush them back on.

The caps are to p rotect and keep the wheel

b ol ts cle an .

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle.

Fi g. 1 92 Chang ing a w hee l: loosening t he w hee l bol ts

Loosening

.,. Insta ll the wheel bolt wrench over the

wheel bo lt and push it dow n as far as it w ill

go .

.,. Take tight hold of the

end of the wrench

handle and turn the wheel bo lts

counter

clockwise

about one single t u rn in the direc

tion of arrow~

fig. 192.

Tightening

.,. Insta ll the wheel bolt wrench over the

wheel bo lt and push it down as far as it w ill

go .

.,. Take tight hold of the

end of t he wrench

ha ndle and turn each wheel bolt

clockwise

until it is seated .

_& WARNING

- Do not u se f orc e or hur ry whe n ch an ging

a w heel -yo u ca n cau se the vehicle to slip

off the jack and ca use serio us pe rsonal

i njur ies.

-Do not loosen the w heel bo lts more th an

one tu rn

befo re you raise the ve hicle with

the jack . - Yo u risk a n inj ury.

(D Tips

- N ever u se th e hexagon al socket i n the

h andl e of t he screwdr iver to lo ose n or

tighten t he wheel bolts .

-If a w heel bolt i s very ti ght, yo u m ay fin d

i t easier to loosen by carefu lly pushing ..,.

Page 249 of 286

down on the end of the wheel bolt

wrench with

one foot only. As you do so,

ho ld on to the car to keep your ba lance

and take care not to slip.

Raising the vehicle

The vehicle must be li~ed with the jock first

before the wheel can be removed.

*

Fi g. 193 Sill panels: markings

Fig. 194 S ill: posit ion ing the vehicle jack

The location of the jack point is indicated by

an indentat io n on the unders ide of the vehicle

¢fig . 193 .

.,. Activate the park in g brake to prevent the

vehicle from rolling u nintentionally.

.,. Move the selecto r lever to position P.

.,. Find the

mark ing ( impr int) on the si ll that is

nearest the wheel that w ill be changed

¢fig. 193. Behind the ma rking, there is a

li ft ing p oint on the s ill for the vehicle jac k.

.,. Turn the

vehicle jack located unde r the lift

ing point on the si ll to raise the jack until

the jaw

¢ fig . 194 @ covers the notch on

the vehicle¢

,&.¢CI) .

.,. Align the vehicle jack so the jaw @covers

the notch and the base p late @ is flat on

t h e f loor. The base plate @ must be

vertical

under the lifting point @.

What do I do now ? 24 7

.,. Insta ll the rod on the vehicle jack: Insert the

rod into the opening on the handwheel. T urn

the rod left or r ight to secure it.

.,. Continue raising the jack w ith the rod unt il

the wheel lifts off the ground slightly.

Position the vehicle jack

only under the desig

nated lifting points on the si ll

¢fig. 193.

There is exactly one locat ion for each wheel.

The jack must not be positioned at any other

location

r::;, & r::;,(D.

Soft g round u nder the jack can cause the ve

hicle to slip off the jack. Always place the jack

o n firm ground. Use a flat, stab le support if

necessary . Use a non-slip surface such as a

rubber mat on a

slippery surface such as tile .

.&_ WARNING

- You or your passengers co uld be inju red

while changing a wheel if you do no t fo l

low these sa fety p reca utions:

- Position the vehicle jack only at the designated lifting points and align the

jack. Otherwise, the vehicle jack could sli p and cause an injury if it does not

have sufficient hold on the vehicle.

-A soft or unstable surface under the jack may cause the veh icle to slip off

the jack. Always p rov ide a fi rm base for

t h e jack on the ground. If ne cessary,

u se a st urdy board under the j ack.

- On hard, slippery su rface (such as t iles)

u se a rubber mat or simi lar to p revent

the jack from sl ipping .

- To help prevent injury to yo urself and

your p assengers:

- Do not ra ise the vehicle until you are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up .

- Make sure that passengers wait in a

safe p lace away from the veh icle and

well away from the road and traffic.

- Make sure jack position is correct, ad

just as necessary and then cont inue to

raise the jack.

Page 251 of 286

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the right direction.

Using a sp are t ire w ith a tread p attern

int ended fo r use in a specific dir ection

When us ing a spare tire w ith a tread pattern

in tended for use in a specific direction, please

note the following:

- The direction of rotation is marked by an

a r

ro w o n th e side o f th e tire .

-If the spare t ire has to be installed in the in

correct direction, use the spare tire only

temporarily since the ti re will not be able to

achieve its optimum performance character

i st ics with rega rd to aquaplaning, noise and

wear.

- We recommend that you pay particular at

tent ion to this fact du ring wet weathe r and

that you adjust your speed to match road conditions.

- Replace the fla t tire w ith a new one and

have it installed on your veh icle as soon as

possib le to restore the handling advantages

of a unid irectiona l tire .

Notes on wheel changing

Please read the information c:> page 233, New

tires and replacing tires and wheels

i f you are

going to use a spare t ire which is different

from the tires on your veh icle.

After you change a tire :

-Check the tir e p re ss ure on the spare imme

di ately after in st a ll at ion.

- Have th e wheel b olt ti ghtenin g torqu e

ch ecked with a t orque wrench as soon as

possible by your autho riz ed Audi dealer o r

qu alified work shop .

- With ste el a nd all oy wh eel rims , the wheel

bolts are correc tly tighten ed at a torque of

90 ft lb s. (120 Nm ).

- If yo u n otice that the wheel bolt s are cor

r oded a nd d ifficult to tu rn whil e changi ng

a t ire, the y should be replaced be fore you

chec k the t igh tening to rque. What do I do now? 249

- Repla ce the flat ti re w ith a new one and

h av e it i nsta lled on you r veh icle as s oon as

po ssible. Remount the whe el cov er.

Un til th en, d riv e with extr a care and at re

duc ed sp eeds.

A WARNING

-

- If you are going to equ ip your vehicle

with tires or rims which differ from those

which were factory installed, then be

sure to read the information

c:> page 233,

New tires and replacing tires and

wheels.

- Always make sure the damaged wheel or

even a flat tire and the jack and tool kit

are properly secured in the luggage com

pa rtment and are not loose in the pas

senger compartment.

- In an accident or sudden maneuver they

could fly forward, injuring anyone in the

veh icle.

- Always sto re damaged wheel, jack and

too ls se curely in the luggage compa rt

ment. Otherwise, in an accident or su d

den maneuver they could f ly forward,

causing injury to passengers in the vehi

cle.

([) Note

Do not use comme rcially ava ilab le tire

sea lants. Otherwise, the e lectrica l compo

nents of the tire pressure monitoring sys

tem* wi ll no longer work properly and the

sensor for the tire pressure monitoring

system* will have to be replaced by quali

fied workshop. •

•

Page 252 of 286

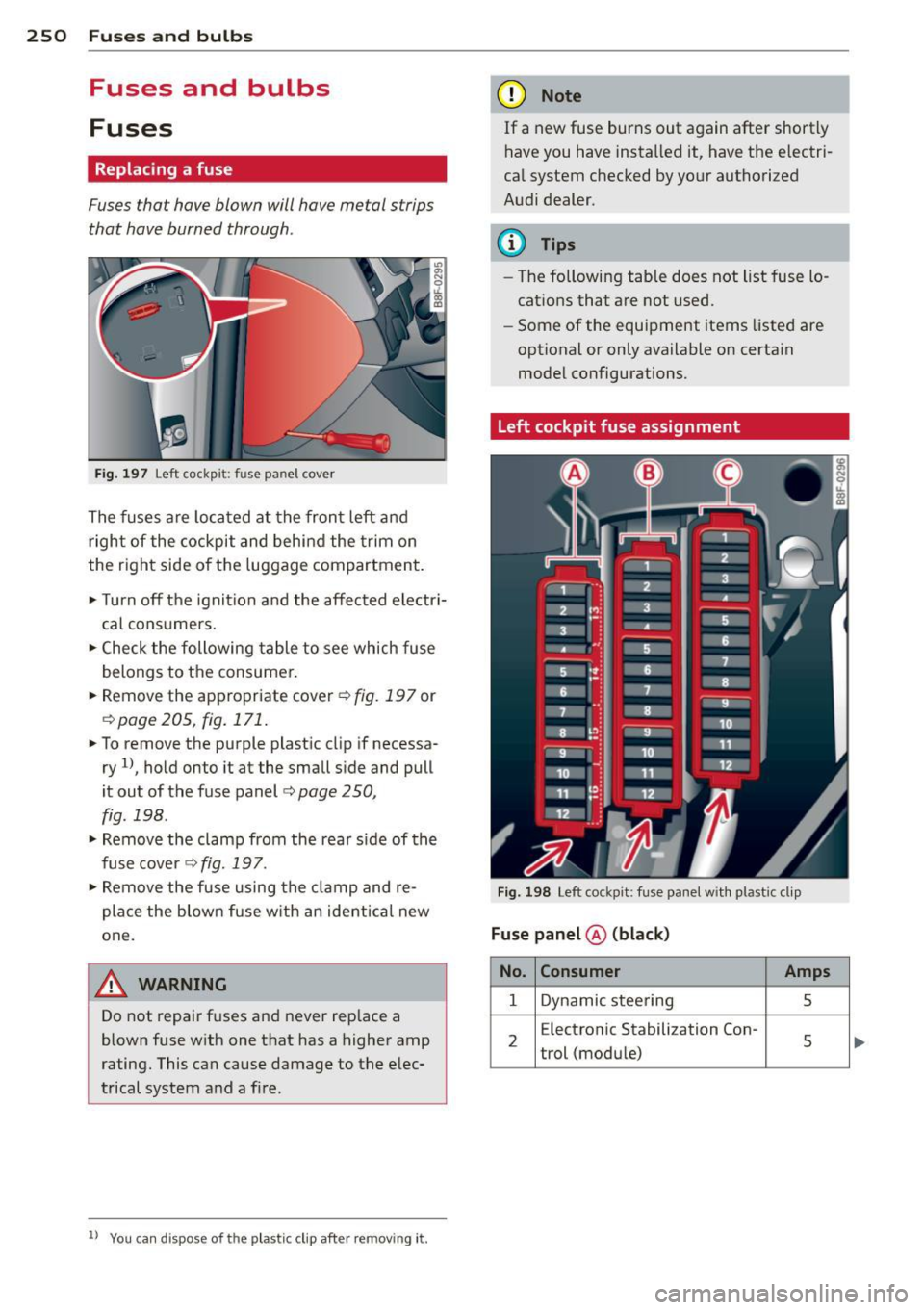

250 Fuses and bulbs

Fuses and bulbs

Fuses

Replacing a fuse

Fuses that have blown will have metal strips

that have burned through.

Fig. 197 Left cockpit: fuse panel cover

The fuses are located at the front left and

right of the cockpit and behind the trim on

the right side of the luggage compartment.

•Turnoff the ignit ion and the affected electri-

cal consumers.

• Check the following table to see which fuse

belongs to the consumer.

• Remov e the appropriate cover ¢

fig. 197 or

¢ page 205, fig. 171.

• To remove the purple plastic clip if necessa

ry

1l, hold onto it at the small side and pull

it out of the fuse panel

c:> page 250,

fig . 198 .

• Remove the clamp from the rear side of the

fuse cover <>

fig. 197 .

• Remove the fuse using the clamp and re

place the blown fuse w ith an ident ical new

one.

A WARNING

Do not repair fuses and never replace a

blown fuse with one that has a higher amp

rating. This can cause damage to the elec

trical system and a fire.

ll You can dis pose of the p last ic clip afte r re moving it.

(D Note

If a new fuse burns out again after shortly

have you have installed it, have the electri

cal system checked by your authorized

Audi dealer .

(D Tips

-The following table does not list fuse lo

cations that are not used.

- Some of the equipment items listed are

optional or only available on certain

model configurations.

Left cockpit fuse assignment

Fig. 198 Left cockpi t: fu se pane l with plastic clip

Fuse panel ® (black)

No. Consumer Amps

1 Dynamic steering s

2

E lectronic Stabilization Con-

s tr ol (module)

Page 253 of 286

Fuses and bulb s 251

No. Con sumer Amps No. Consumer Amps

•

A/C system pressure sensor, Two-door models: rear left

• electromechanical parking window regulator; Four-

brake, Homelink, automatic 11 door models:

rear left door

30

3 dimming interior rear view

5 (window regulator, central

m irror, air quality/outside locking, switch, lighting)

air sensor, Electronic Stab ili-

12 Rain and light sensor

5

zation Control (button)

5 Sound

actuator

5

Fuse panel© (r e d )

6 Headlight

range cont rol/

5/7,5

head light (cornering light)

No. Consumer Amps

3 Lumbar support 10

7 Headlight (corner

ing light) 7,5

4 Dynamic steering 35

Contro l modu les (e lectro-

s Inter ior lighting (Cabriolet)

5

8 mechanical parking brake,

5

shock absorber, quattro

sport), DCDC converter

9 Adaptive cru ise contro l 5 6

W

indshield washer system,

35

h eadlight washe r system

7 Vehicle electrical

system

20

control module 1

10 Shift gate/clutch

sensor

5

1 1 Side ass ist 5

8

Vehicle electr ica l system

30

control module 1

1 2 Headlight range

control,

5

park ing system 9 Left rear window regulator

7,5/20

motor (Cabriolet)/sunroof

13 Airbag 5

14 Rear wiper (allroad) 15 10 Vehicle e

lectrical system

30

control module 1

1 5 Auxi

liary fuse (instrument

10

pane l) 11 R

ight rea r window regulato r

7,5/20

(Cabriolet)/sun shade motor

16 Aux

iliary fuse terminal 15

40

(engine area) 12 Anti-theft

alarm warning

5

system

Fuse p anel @ (brown )

No. Con sumer Amps

2 Brake light sensor 5

3 Fuel

pump

25

4 Clutc h sensor 5

5 Left

seat heating with/w ith-

15/30

out seat vent ilation

6 Electronic Stab

il iz at ion Con-

5

tro l (e lectric)

7 Horn 15

Front left door (window reg-

8 ulator, centra

l locking, mir-

30

ror, switch, lighting)

9 Winds hield wipe r motor 30

1 0 Electronic

Stabilizat ion Con-

25

trol (valves)

Page 255 of 286

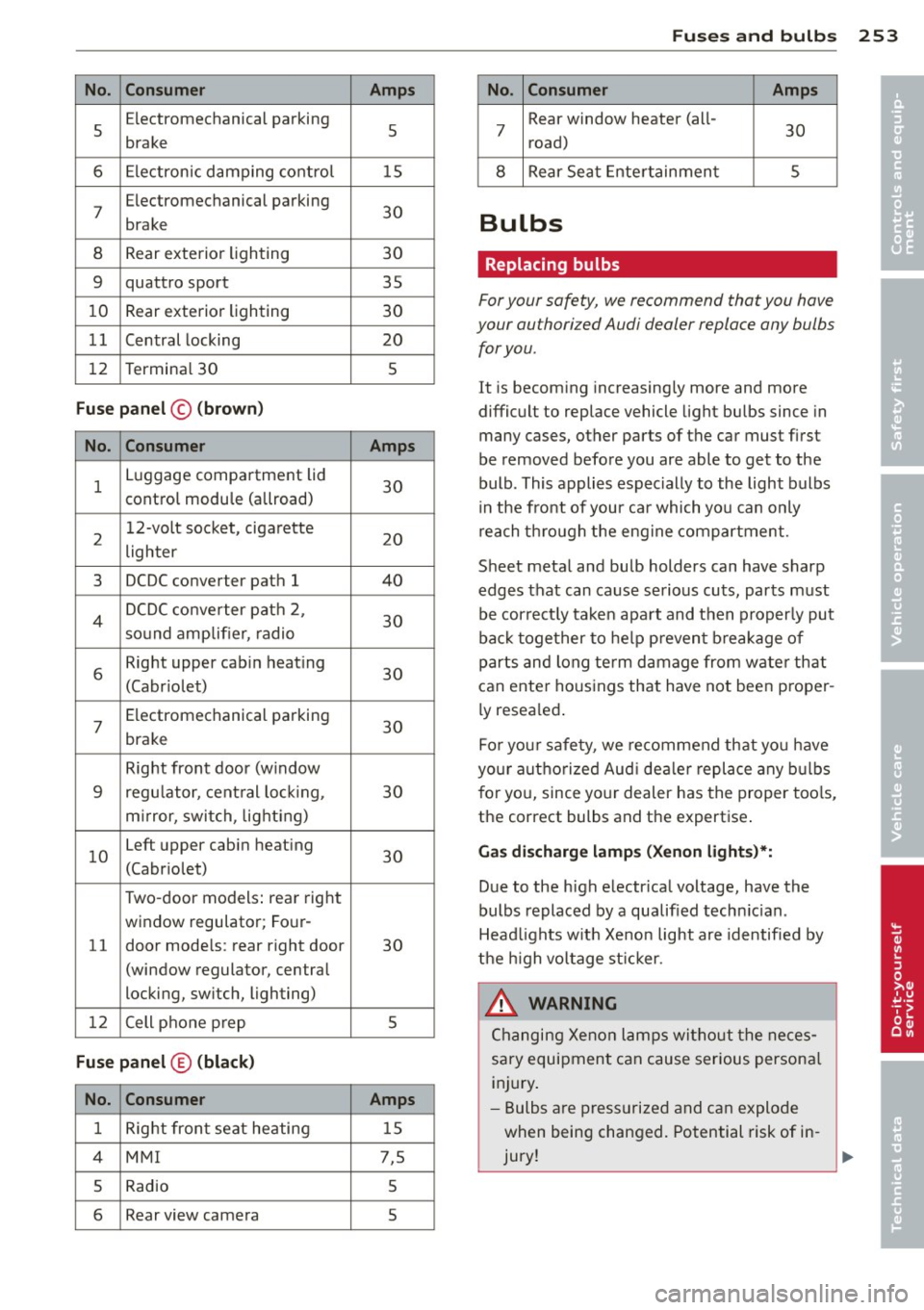

No. Consumer

5 Electromechanical

parking

brake

6 Electronic damping control

7

Electromechanical parking

brake

8 Rear exterior lighting

9 quattro sport

10 Rear

exterior lighting

1 1 Central locking

12 Termina

l 30

Fu se pa nel © (brown )

No. Con sumer

1 Luggage compartment lid

control module (allroad)

2 1

2-volt socket, cigarette

lighter

3 DCDC

converter path 1

4 DCDC converter path 2,

so und amplifier, radio

6

Right upper cabin heat ing

(Cabr iolet)

7

Electromechanical parking

brake

Right front door (w indow

9 regu lator, central lock ing,

m irror, swit ch, lig hting)

10 Left upper

cabin heating

(Cabriolet)

Two -door models: rear right

window regulator; Four-

11 door mode

ls: rear right door

(window regulator, central

locking, sw itch, lighting)

12 Cell phone prep

Fu se panel © (black )

No. Consumer

1 Right front seat heating

4

MMI

5 Radio

6 Rear view camera

Amp s

5

15

30

30

35

30

20 5

Amp s

30

20

40

30

30

30

30

30

30

5

Amps

15

7,5

5

5

Fu ses and bulb s 253

No. Consumer Amps

7

Rear window heater (all-

30

road)

8 Rear Seat Entertainment 5

Bulbs

Replacing bulbs

For your safety, we recommend that you hove

your authorized Audi dealer replace any bulbs

for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bulb. This applies especially to the light bulbs

in the front of your car which you can only

reach through the engine compartment.

Sheet metal and bulb holders can have sharp

edges that can cause serious cuts, parts must

be correct ly take n apa rt and then p roperly put

bac k together to he lp p revent breakage of

parts and long te rm damage from water that

can enter housings that have not been p roper

ly re sea led .

Fo r you r safety, we re commend that you have

your autho rized Audi de aler replace any b ulbs

f or you, since your dealer has the proper too ls,

the correct bulbs and the expertise.

Gas disc har ge la mp s (Xenon l ig hts)*:

Due to the high electr ical voltage, have the

bulbs replaced by a qualified techn ic ian .

Head lights w ith Xenon light are identified by

the h igh vol tage sticker.

_&. WARNING

Changing Xenon lamps without the neces

sary equipment can cause serious persona l

injury .

- Bulbs are pressurized and can explode

when being changed. Potential risk of in

jury!

-

•

•

Page 257 of 286

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumper cables to start the en

gine.

Jumper cables

Use only jumper cables of sufficiently

largecross section to carry the starter current

safely. Refer to the manufacturer's specifica

tions.

Use only jumper cables with

insulated termi

nal clamps which are distinctly marked:

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

injury. Follow the instructions below for

safe handling of your vehicle's battery.

- Always shield your eyes and avoid lean

ing over the battery whenever possible.

Emergency situations 255

-A discharged battery can freeze at tem

peratures just below 32 °F (0 °C). Before

connecting a jumper cable, you must

thaw the frozen battery completely, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to

start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with

a low acid level in the battery.

- The voltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery. Use of batteries of different voltage

or substantially different "Ah" rating

may cause an explosion and personal in

jury.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batteries of different voltage or

substantially different capacity (Ah) rat

ing may cause an explosion and injury.

The ca pa city (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS¢

page 206.

(D Note

- Applying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

control units, relays, radio, etc.

- There must be no electrical contact be tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected. ..,. •

•

Page 258 of 286

256 Emergency situations

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump starting or charging the

battery, never connect the negative

ground cable to the battery negative post

because the batte ry manager system must

be able to detect the battery 's state of

charge. Always connect the negative

ground cab le to the negative ground post

of the battery manager control unit.

Use of jumper cables

Make sure to connect the jumper cable

clamps in exactly the order described below!

Fig. 201 Engine compartment: Connectors fo r jum per

cables and charger

Fig. 202 Jump sta rting wi th the battery of anot her ve ·

h ide :@ booster battery, @ disc harged vehicle battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your vehicle .

Vehicle with discharged battery:

.. Turn off lights and accessories, move lever

of automatic transmission to N (Neutral) or

P (Park) and set parking brake .

Connect POSITIVE(+) to POSITIVE(+)

(red)

.. Remove the cover above the jump start con

nection .

.. Open the cover on the positive pole

¢fig. 201.

1. Connect one end of the red positive cable

on the

jump start bolt c::> fig. 202 @

(Bolts under cover= "positive") of the ve

hicle to be started @.

2. Connect the other end to the positive ter-

minal @of the booster battery@.

Connect NEGATIVE (-) to NEGATIVE (-)

(black)

3. Connect one end of the b lack negative ca

ble to the negative terminal @of the

booster battery @.

4. Connect the other end to the

jump start

bolt @

(Bolts with hex head= "negative")

of the vehicle to be started @.

Starting the engine

.. Start the engine of the vehicle with the

booster battery@. Run the engine at a

moderate speed.

.. Start engine with discharged vehicle battery

@ in the usual manner .

.. If the engine fails to start: do not keep the

starter cranking for longer than 10 seconds .

Wait for about 30 seconds and then try

again .

.. With eng ine running, remove jumper cables

from both vehicles in the exact

reverse or

der .

.. Close the cover on the positive pole .

T he battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connect

ed with their

metal parts in full contact with

the battery terminals.

A WARNING

--

To avoid serious personal injury and dam

age to the veh icle, heed all warnings and

instructions of the jumper cable manufac-

turer . If in doubt, call for road service . ..,.

Page 259 of 286

-Jumper cables must be long enough so

that the vehicles do not t ouch.

- W hen connecting jumper ca bles, make

sure that they cannot get caught in any

moving parts in the eng ine compart

ment.

- Do not bend over the batteries - danger

of chemical burns!

- The battery ce ll locking screws must be

t ightened securely .

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS ¢

page 206.

Improper hook-up of jumper cables can ru

in the generator.

- Always connect POSITIVE( +) to POSI

TIVE(+), and NEGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

ce lls are screwed in firmly . If not, tighten

plugs p rior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

necting a jumper cable as described

above applies spec ifically to the case of

your vehicle be ing jump started. When

you are givi ng a jump start to another ve

hicle, do

not connect the negat ive( -) ca

ble to the negat ive( -) term inal on the

discharged battery @¢

fig. 20 2. In

stead, securely connect the negative(- )

cable to e ither a solid metal component

that is firmly bolted to the engine block

or to the engine block itse lf. If the bat

tery that is being charged does not vent

to the outside, escaping battery gas

could ignite and explode!

Em erg en cy si tuation s 257

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing.

T he following information is to be used by

commercial tow t ruck operators who know

how to operate their equipment safely.

- Never tow your Audi , towing will cause

damage to the engine a nd transmi ssion.

- Never wrap th e safet y chain s or winch c a

ble s around th e brak e lin es.

- To prevent unne ce ss ary dam age, your Aud i

mu st be t ransp orted with a flat bed truck .

- To load th e vehi cle on to the fl at bed , use

the t owing loop found in the vehicle t ool s

and atta ch to the front or rear anch o rage

r=:> page 258 and ¢page 258 .

A WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyone to ride in a

vehicle be ing towed, for any reason.

-

•

•