AUDI A5 COUPE 2012 Owners Manual

Manufacturer: AUDI, Model Year: 2012, Model line: A5 COUPE, Model: AUDI A5 COUPE 2012Pages: 316, PDF Size: 78.59 MB

Page 281 of 316

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in

the right direction.

Using a spare tire with a tread pattern

intended for use in a specific direction

When using a spare tire w ith a tread pattern

in tended for use in a specific direction, please

note the following:

- The direction of rotation is marked by an

ar

row on the side of the tire .

-If the spare t ire has to be installed in the in

correct direction, use the spare tire only

temporarily since the tire will not be able to

achieve its optimum performance character

istic s with rega rd to aquaplaning, noise and

wear.

- We recommend that you pay particular at

tention to this fact during wet weather and

that you adjust your speed to match road

conditions.

- Replace the flat tire with a new one and

have it installed on your veh icle as soon as

possib le to restore the handling advantages

of a unid irectiona l tire .

Notes on wheel changing

Please read the information c:> page 263, New

tires and replacing tires and wheels

i f you are

going to use a spare t ire which is different

from the tires on your veh icle.

After you change a tire :

-Check the tire pressure on the spare imme

diately after installation .

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as

possible by your authorized Audi dealer or

a qualified workshop.

- With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of

90 ft lbs . (120 Nm).

- If you notice that the wheel bolts are cor

roded and difficult to turn while changing

a tire, they should be replaced before you

check the tightening torque. What do I do now? 2 79

- Replace the flat tire with a new one and

have it installed on your vehicle as soon as

possible. Remount the wheel cover.

Until then , drive with extra care and at re

duced speeds.

A WARNING

-

- If you are going to equ ip your vehicle

with tires or rims which differ from those

which were factory installed, then be

sure to read the information

c:> page 263,

New tires and replacing tires and

wheels.

- Always make sure the damaged wheel or

even a flat tire and the jack and tool kit

are properly secured in the luggage com

pa rtment and are not loose in the pas

senger compartment.

- In an accident or sudden maneuver they

could fly forward, injuring anyone in the

veh icle.

- Always store damaged wheel, jack and

tools securely in the luggage compa rt

ment. Otherwise, in an accident or su d

den maneuver they could fly forward,

causing injury to passengers in the vehi

cle.

([) Note

Do not use commercially available tire

sea lants. Otherwise, the electrica l compo

nents of the tire pressure monitoring sys

tem* wi ll no longer work properly and the

sensor for the tire pressure monitoring

system* will have to be replaced by a

qualified workshop . •

•

Page 282 of 316

280 Fuses and bulbs

Fuses and bulbs

Fuses

Replacing a fuse

Fuses that have blown will have metal strips

that have burned through.

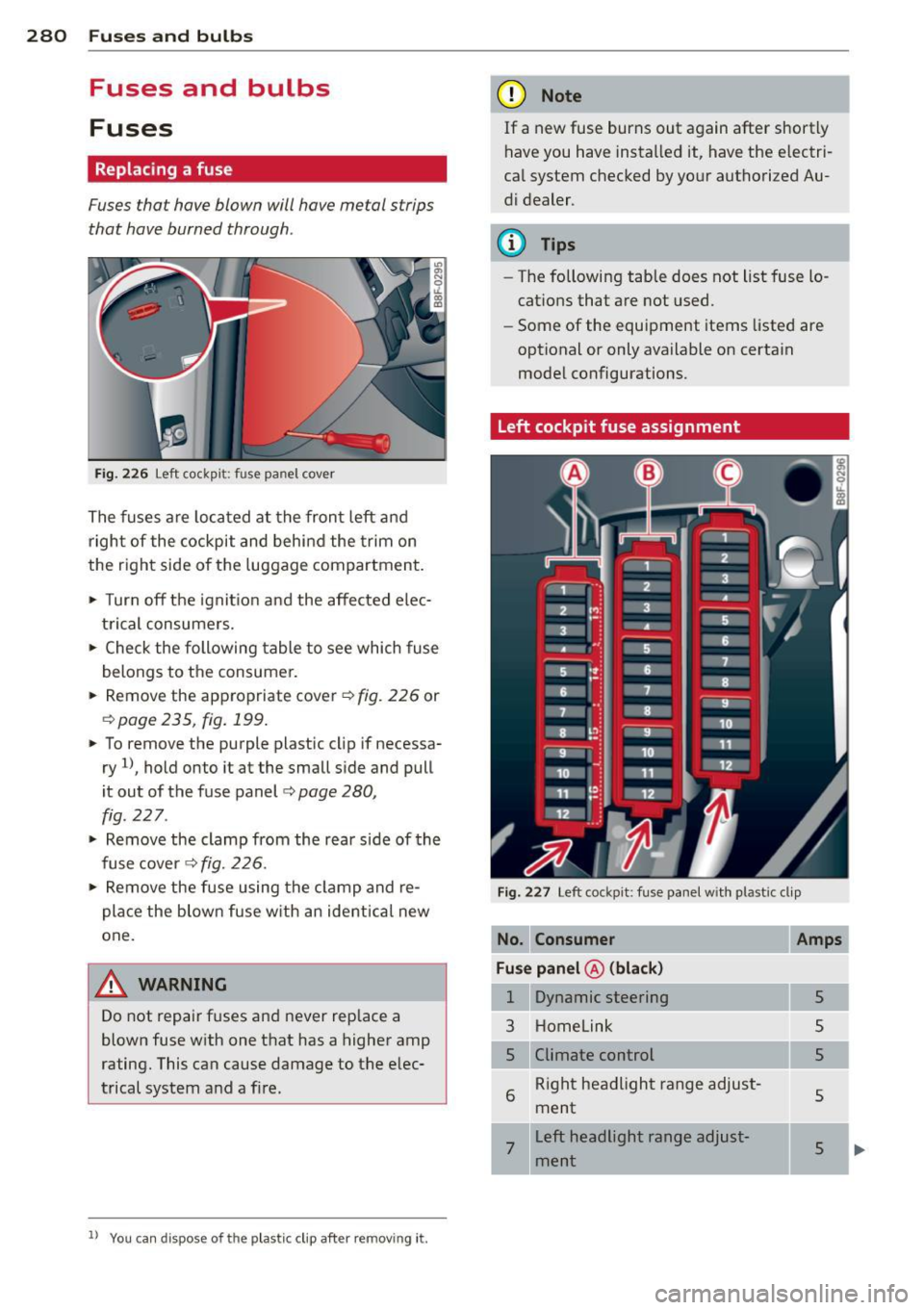

Fig. 226 Left cockpit: fuse panel cover

The fuses are located at the front left and

right of the cockpit and behind the trim on

the right side of the luggage compartment.

• Turn off the ignit ion and the affected elec

trical consumers.

• Check the following table to see which fuse

belongs to the consumer.

• Remov e the appropriate cover¢

fig. 226 or

¢ page 235, fig. 199.

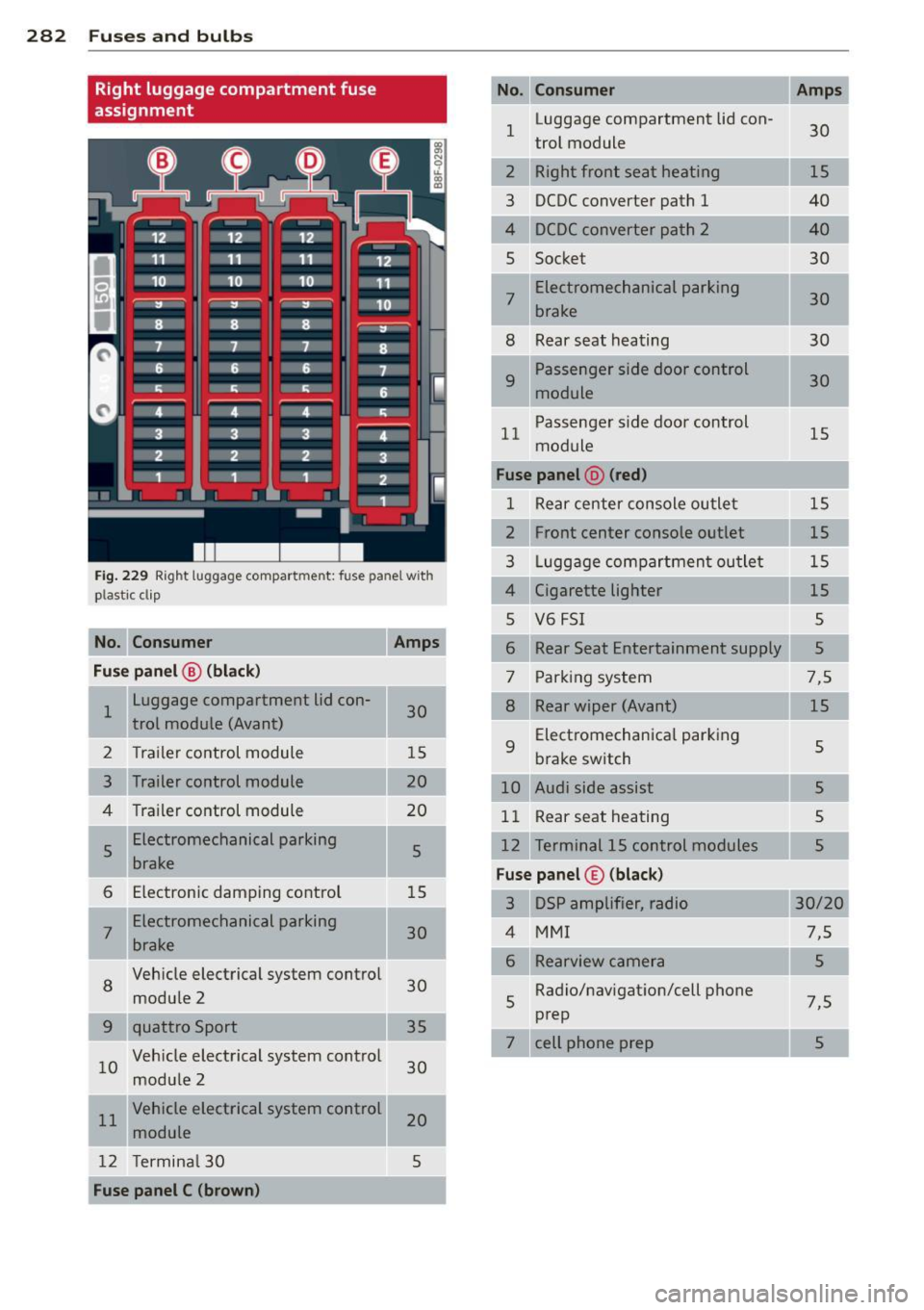

• To remove the purple plastic cl ip if necessa

ry

1l, hold onto it at the small side and pull

it out of the fuse panel

c:> page 280,

fig. 227.

• Remove the clamp from the rear side of the

fuse cover ¢

fig. 226.

• Remove the fuse using the clamp and re

place the blown fuse w ith an ident ical new

one.

A WARNING

Do not repair fuses and never replace a

blown fuse with one that has a higher amp

rating. This can cause damage to the elec

trical system and a fire.

ll You ca n dispose of the p lastic clip afte r remov ing it.

(D Note

If a new fuse burns out again after shortly

have you have installed it, have the electri

cal system checked by your authorized Au

d i dealer .

(D Tips

-The following table does not list fuse lo

cations that are not used.

- Some of the equipment items listed are

optional or only available on certain

model configurations.

Left cockpit fuse assignment

Fig . 227 Left cockpi t: fu se pane l with plastic clip

No. Consumer

Fuse panel @(black)

1 Dynamic steering

3 Homelink

5

6

Climate control Right headlight range adjust

ment

Amps

5

5

5

5

7

Left headlight range adjust

ment

5 ...

•

Page 283 of 316

Fuses and bulbs 281

No. Fuse Location, Instrument Panel right

8

Vehicle electrical system control

5

module 1

9 Adaptive Cruise Control

10 Shift gate

11 Heater washer flu id nozzles

12 Climate control

13 Cell phone prep 5

14 Airbag

s

15 Terminal 15 25

16 Terminal 15 engine

40

Fuse panel@ (brown)

1 Automatic dimming

interior s rearview mirror

2 Clutch sensor 5

3 Gasoline fuel pump 25

5 Left seat heating with/without

15/30

seat heating

Fig. 228 Righ t cockpi t: fuse panel wi th pla stic clip

6 Electronic Stabilization Program 10 No. Consumer

7 Horn 25 Fuse panel@ (black)

8

Left door window regulator mo-

30

tor 5

Steering column switch module

5

6 Electronic Stabilization Program 5

9 Wiper motor 30

10 Electronic Stabilization Program

25

7

Terminal 15 diagnostic connec-

5

tor

11 Left doors 15

12 Rain and light sensor 5

8

Gateway (Databus diagnostic in-

5

terface)

Fuse panel © (red)

Fuse panel@ (brown)

3 lumbar support

10

1 C0-/DVD player

5

4 Dynamic steering 35

2 Audi drive select switch module 5

5 Antenna (Avant)

5

3 MMI/Radio

5/20

6

Vehicle electrical system control

35

module

1

7

Vehicle electrical system control

20

module 1 Instrument cluster

5

5 Gateway (instrument cluster

5

control module)

6 Ignition lock 5

8

Vehicle electrical system control

30

module 1

9 sunroof 20

10 Vehicle electrical system control

30

module 1

7 Rotary light switch 5

8 Climate control system blower

40

9 Steering column lock 5

10 Climate control 10

11 sunroof shade (Avant) 20 11 Terminal 30

diagnostic connec-

tor 10

12 Convenience electronics

5

12 Steering column switch module

5

Page 284 of 316

282 Fuses and bulbs

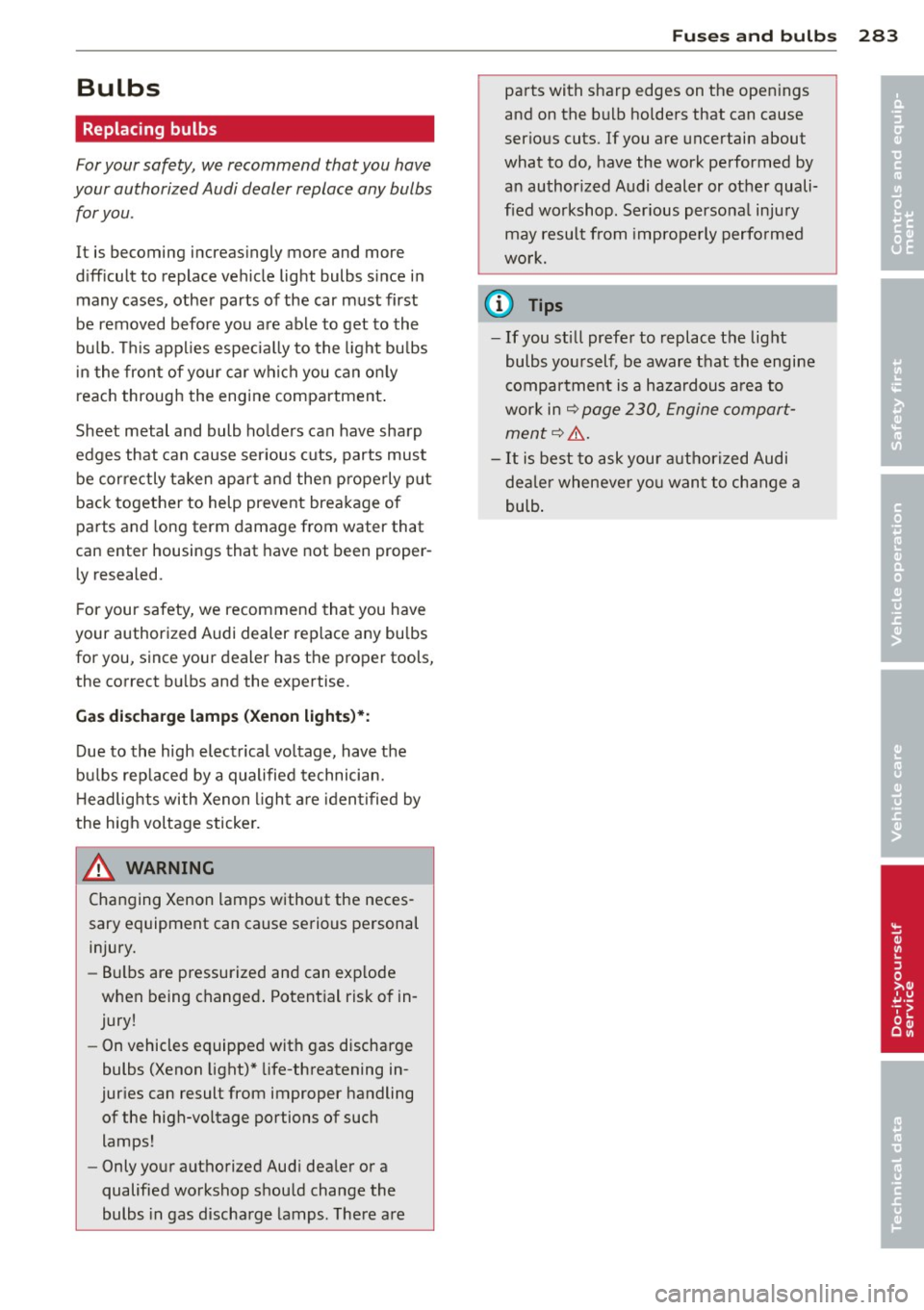

Right luggage compartment fuse

assignment

Fig. 229 Rig ht luggag e compar tmen t: fus e pan el w ith

pla stic cl ip

No. Consumer

Amps

Fuse panel @ (black)

1 Luggage compartment lid con-

30

trol module (Avant)

2 Trailer control module 15

3 Trailer control module

20

4 Trailer control module 20

I 5 Electromechanical parking

5

brake

6 Electronic damping control

15

7 Electromechanical

parking

30

brake

8

Vehicle electrical system control

30

module 2

35

10 Vehicle electrical system control

30

module 2

11 Vehicle electrical system control

20

module

12 Terminal 30 5

Fuse panel C (brown) No. Consumer

1

Luggage compartment lid con-

30

trol module

2 Right front seat heating

3 DCDC converter path 1

4 DCDC converter path 2

5 Socke t

7 Electromechanical parking

30

brake

8 Rear seat heating 30

9

Passenger side door control

30

module

11 Passenger

side door control

15

module

Fuse panel @ (red)

1 Rear center console outlet 15

2 Front center console outlet 15

3 Luggage compartment outlet 15

4 Cigarette lighter

15

5 V6 FSI 5

6 Rear Seat Entertainment supply

5

7 Parking

system 7,5

8 Rear wiper (Avant) 15

9

Electromechanical parking

5

brake switch

10 Audi side assist 5

11 Rear seat heating

5

Terminal 15 control modules

Fuse panel© (black)

3 DSP amplifier, radio

MMI

Rearview camera

5 Radio/navigation/cell

phone

prep 7,5

7 cell phone prep

5

Page 285 of 316

Bulbs

Replacing bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you .

It is becoming increasingly more and more

difficult to replace vehicle light bulbs since in

many cases, other parts of the car must first

be removed before you are able to get to the

bu lb . T his appl ies especially to the light bu lbs

in the front of your car which you can on ly

reach through the engine compartment .

Sheet metal and bulb ho lders can have sharp

edges that can cause ser ious cuts, parts must

be correctly taken apart and then p roperly put

back together to help prevent breakage of

parts and long term damage from water that

can enter housings that have not been proper

l y resealed.

F or your safety, we recommend that you have

your authorized Audi dealer replace any bulbs

for you, since your dealer has the proper tools,

the correct bu lbs and the expertise.

G as disch arge la mp s (Xe no n li ght s)*:

Due to the high electrical vo ltage, have the

bu lbs rep laced by a qualified technician.

H eadlights with Xenon l ight a re identified by

the high voltage sticker.

& WARNING

Changing Xenon lamps without the neces

sary equipment can cause serious personal

injury.

- Bul bs are pressurized and can exp lode

when being changed . Potential risk of in

jury!

- On vehicles equipped with gas discharge

bulbs (Xenon light) * life-threatening in

jur ies can result from improper handling

of the high-voltage portions of such

lamps!

- Only your authorized Aud i dea ler or a

qualified workshop should change the

bulbs in gas discharge lamps. There a re

Fu ses and bulb s 28 3

parts with sharp edges on the open ings

and on the bulb holders that can cause

serious cuts. If you are uncertain about

what to do, have the work performed by

an author ized Audi dealer or other quali

fied workshop . Ser ious personal injury

may result from improperly perfo rmed

wo rk.

(j) Tips

- If you still prefer to replace the light

bulbs yourself , be aware that the engine

compartment is a hazardous area to

work in

c::> page 230, Engine compart

ment

o=:> ,& .

-It is best to ask your authorized Audi

dealer whenever yo u want to change a

bulb .

•

•

Page 286 of 316

284 Emergency situations

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to perform these operations.

Starting by pushing or

towing

Q;) Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary , the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another vehicle,

using a

pair of jumper cables to start the en

gine .

Jumper cables

Use only jumper cables of sufficiently

large cross section to carry the starter current

safely. Refer to the manufacturer's specifica

ti ons.

Use only jumper cables with

insulated termi

nal clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus (-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal

injury. Follow the instructions below for

safe handling of your vehicle's battery.

- Always shield your eyes and avoid lean

ing over the battery whenever possible. -

A discharged battery can freeze at tem

peratures just below

32 °F (0 °(). Before

connecting a jumper cable, you must

thaw the frozen battery completely, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to

start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es . Keep sparks, flame and lighted ciga

rettes away from batteries .

- Do not try to jump start any vehicle with

a low acid level in the battery .

- The voltage of the booster battery must

also have a 12-Volt rating. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of different voltage

or substantially different "Ah" rating

may cause an explosion and personal in

jury.

- Never charge a frozen battery. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batteries of different voltage or

substantially different capacity (Ah) rat

ing may cause an explosion and injury.

The capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS¢

page 230, Engine com

partment.

@ Note

- Applying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

control units, relays, radio, etc.

- There must be no electrical contact be

tween the vehicles as otherwise current

could already start to flow as soon as the

positive(+) terminals are connected. ..,.

Page 287 of 316

@ Tips

-The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump start ing or charging the

battery, never connect the negative

ground cable to the battery negative

post because the battery manager sys

tem must be able to detect the battery's

state of cha rge . A lways connect the neg

ative g round cab le to the negative

gro und post o f the battery manage r con

trol uni t.

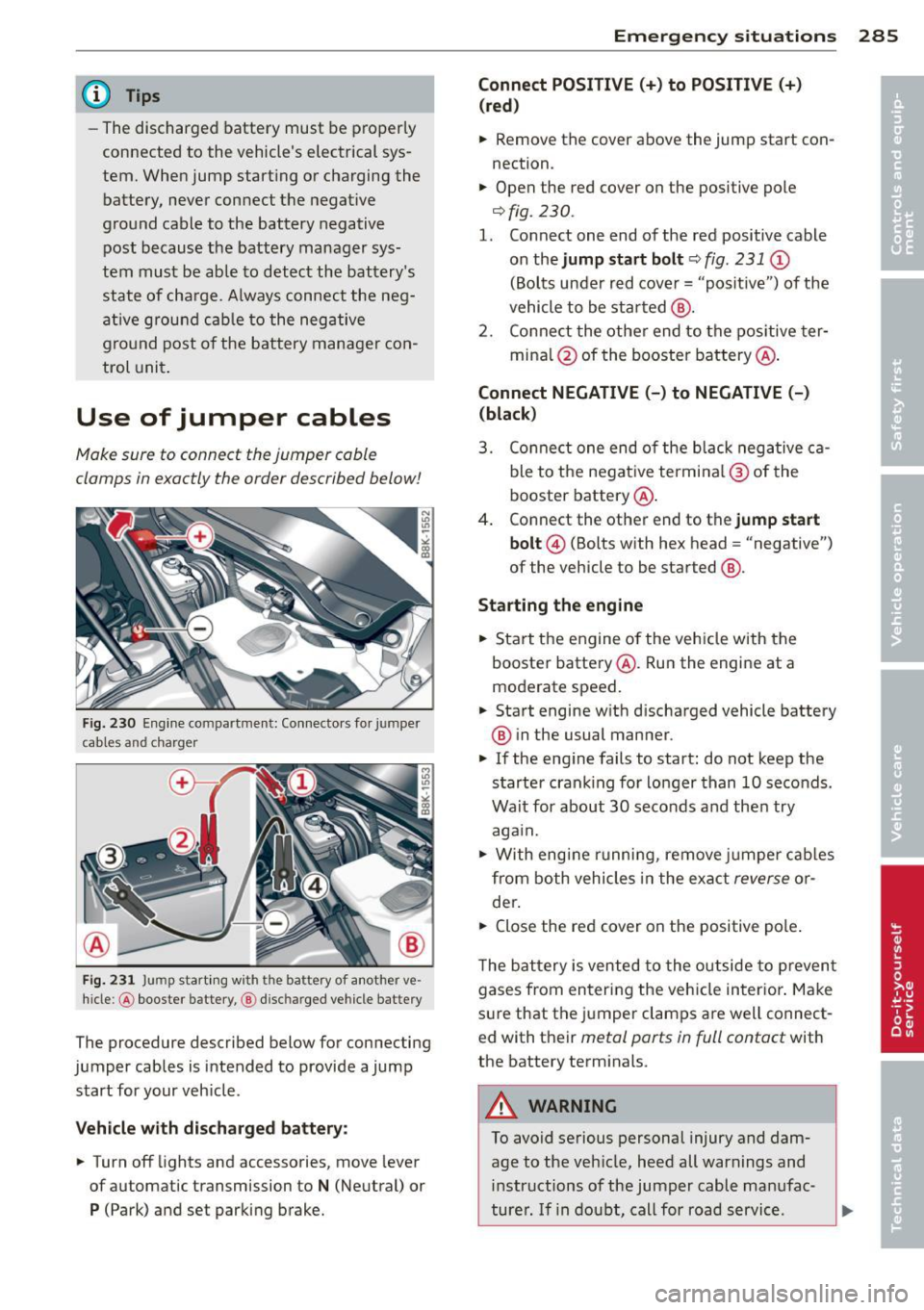

Use of jumper cables

Make sure to connect the jumper cobl e

clomps in exactly the order describ ed b elow!

Fig. 230 Engine co mpartmen t: Con ne ctors fo r jum per

c ables a nd char ger

Fi g. 231 Jump s tart in g w ith t he ba ttery of a not her ve

hi cle :@ booster battery, @ disc harged vehicle bat tery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle .

Vehicle with discharged batter y:

.. Turn off lights and accessories , move lever

of automatic transmission to

N (Neutral) or

P (Park) and set parking brake.

Emergenc y situ ation s 285

Connect POSI TIVE(+ ) to POSITIVE (+ )

(red )

.. Remove the cover above the jump start con

nection .

.. Open the red cover on the positive pole

¢fig. 230 .

1. Connect one end of the red positive cable

on the

jump sta rt bolt ¢ fig. 231 (D

(Bolts under red cover= "positive ") of the

vehicle to be star ted @.

2. Connect the othe r end to the pos itive ter -

mina l@ of the booster battery @.

Connect NEGATIVE (-) to NEGATIVE (-)

(black )

3. Connect one end of the b lack negative ca

ble to the nega tive te rmi na l@ of the

booster battery @.

4 . Connect the other end to the

jump start

bolt @

(Bolts with hex head = "negative")

of the vehicle to be started @.

Sta rting the engine

.. Start t he engine of the veh icle w ith the

booster battery @. Run the engine at a

moderate speed .

.. Start engine w ith d ischarged vehicle battery

® in the usual manner .

.. If the eng ine fails to start: do not keep the

starter crank ing for lo nger than 10 seconds .

Wait for about 30 seconds and the n try

aga in .

.,. With engi ne runni ng , remove j umper cab les

from both vehicles in the exact

reverse o r

der .

.. Close the red cover on the positive pole .

T he battery is vented to the o utside to p revent

gases from entering the veh icle in ter ior . Make

s ur e that the j umper clamps a re well connect

e d with their

metal ports in full contact with

the batte ry terminals.

A WARNING

To avoid serious personal injury and dam

age to the vehicle, heed all warnings and

instructions of the jumper cable manufac-

turer . If i n doubt, call for road service .

Ill>

Page 288 of 316

28 6 Em ergency sit uat ions

-Jumper cables must be long enough so

that the vehicles do not touch.

- When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the engine compart

ment.

- Do not bend over the batteries -danger

of chemical burns!

- The battery ce ll locking screws must be

tightened securely .

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS 9

page 230, Engine com

partment.

(D Note

Improper hook-up of jumper cables can ru

in the generator.

- Always connect POSITIVE( +) to POSI

TIVE(+), and N EGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery cells are sc rewed in firmly . If not, tighten

plugs prior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

nect ing a jumper cable as described

above applies spec ifically to the case of

your vehicle being jump started . When

you are giving a jump start to another ve hicle, do

not connect the negat ive (-) ca

ble to the negative( -) terminal on the

discharged battery@9fig.

231. In

stead, securely connect the negative(-)

cab le to either a solid metal component

that is firmly bolted to the engine block

or to the engine block itse lf. If the bat

tery that is being charged does not vent

to the outside, escaping batte ry gas

could ignite and explode!

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing.

T he following information is to be used by

commercial tow truck operators who know

how to operate their equipment safely.

- Nev er tow y our Audi , tow in g will cau se

damage t o the engi ne and tr an smi ssion .

- Ne ver wrap th e safety chain s or winch ca

bl es around the b rak e lin es.

- To pre vent unne ce ss ary dam age, your Audi

mus t be tr an sp o rt ed with a flat bed t ruck.

- To load th e vehicle on to th e flat b ed, use

th e t owing l oop found in th e vehicle too ls

a nd a ttac h to th e front or rea r a nchor age

c;,poge 287 and c;,page 287 .

& WARNING

= -

A vehicle being towed is not safe for pas

sengers. Never allow anyone to ride in a

vehicle being towed, for any reason.

Page 289 of 316

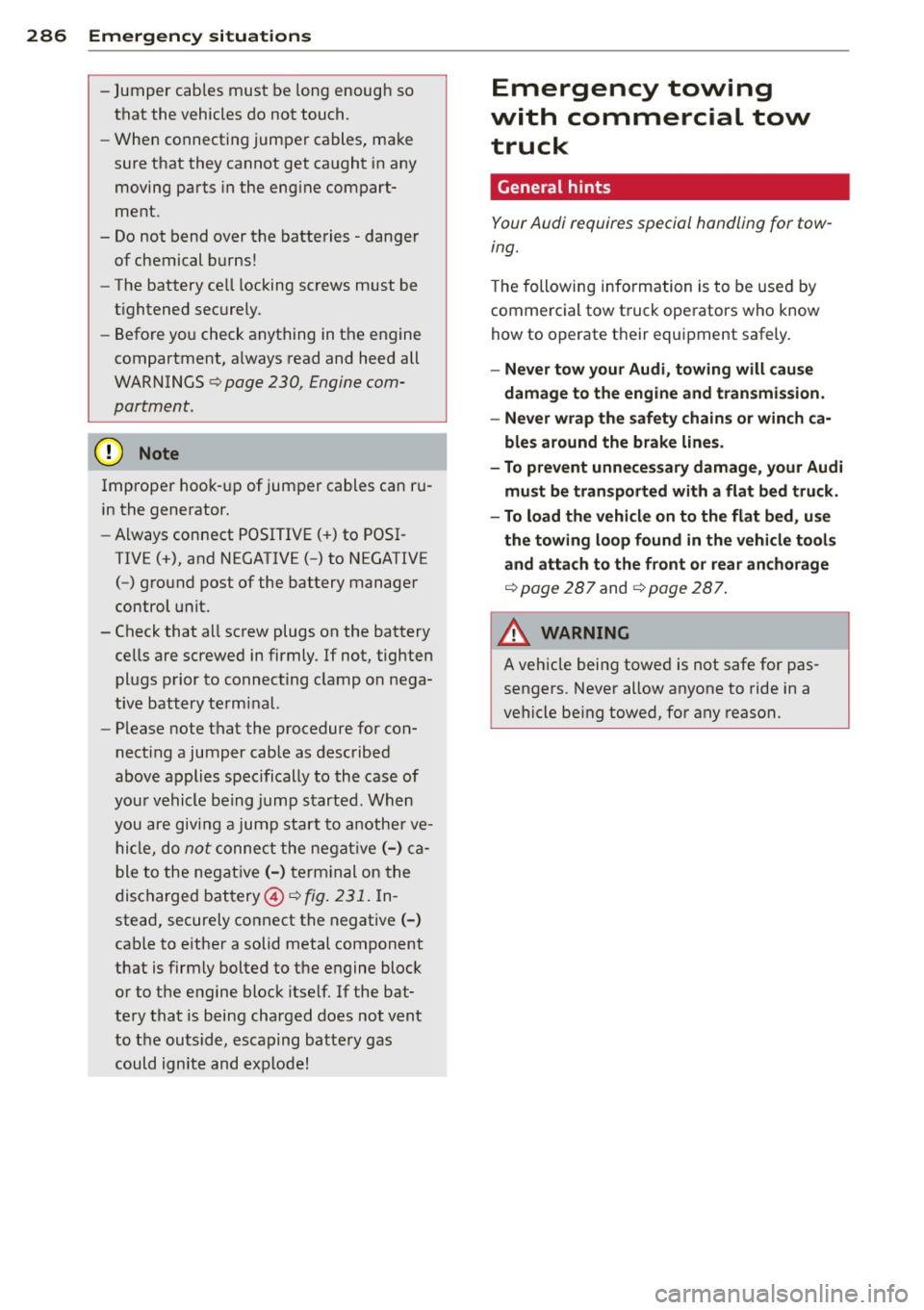

Front towing loop

Do not install the front towing loop until it is

needed.

Fig. 232 Fro nt bumper : removing t he cover cap

Fi g. 233 Front bumper: screw ing in t he tow ing loop

The tow ing loop fits into the th readed hole lo

cated on the r igh t side of the fron t bumper

and covered by a small cover when not in use .

"' Remove the towing loop from the veh icle

toolkit

c:::> page 2 73 .

"' Press the cover in by applying short st rong

pressure to the bottom part to re lease it

from the bumper

c:::> fig. 232 .

"' Screw the towing loop tight ly into the

threaded hole as far as it will go

c:::> fig. 233 .

When it is no longer needed, unscrew the

towing loop and put it back into the vehicle

too lkit. Be sure to have the tow ing loop stored

in the vehicle at all times.

A WARNING

If the towing loop is not screwed in as far

as it w ill go, the thread can pull out when

the vehicle is towed - potential risk of an

acc ident.

Emergenc y situ ation s 287

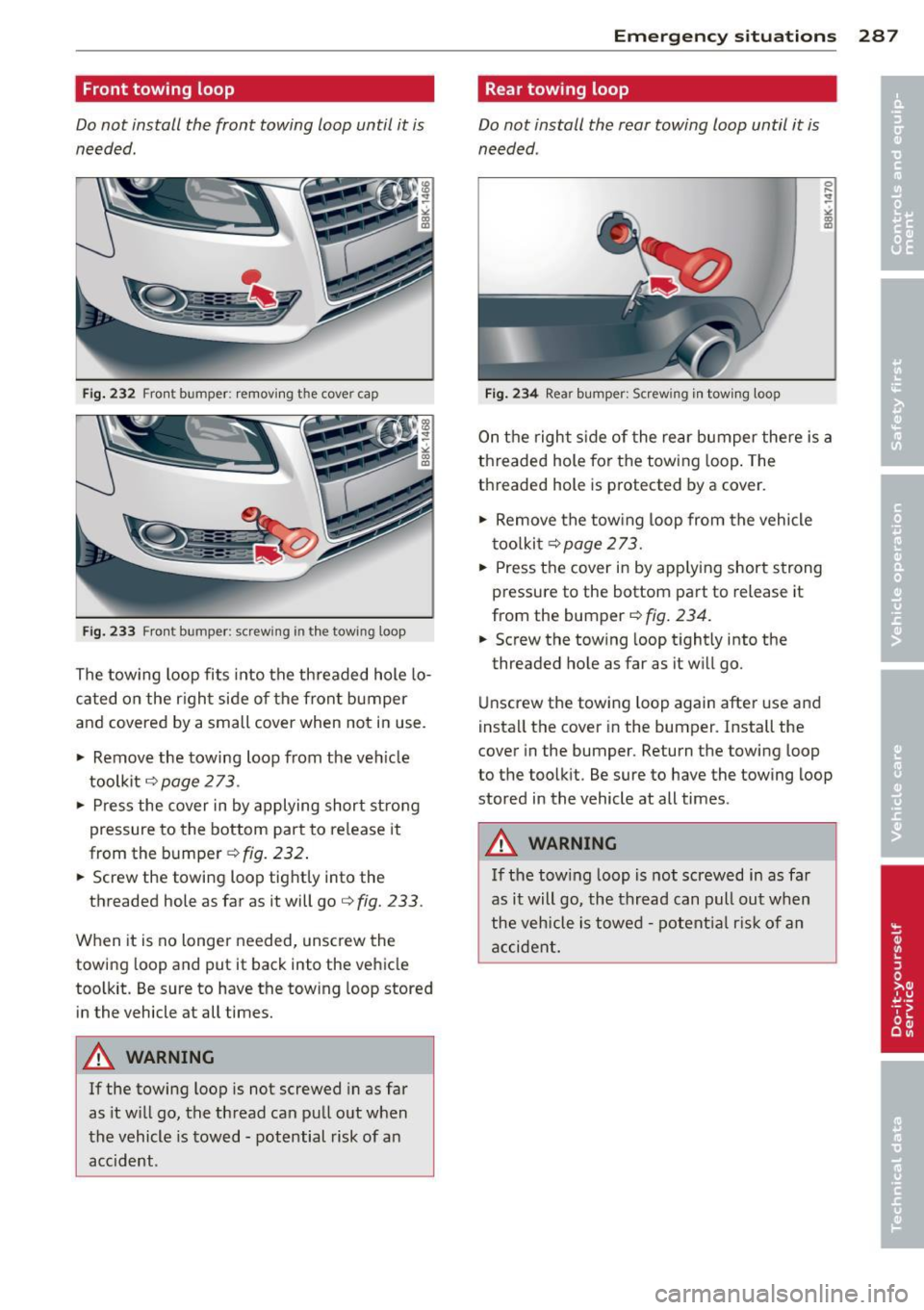

Rear towing loop

Do not install the rear towing loop until it is

needed .

Fig . 23 4 Rea r bumper: Screw ing in tow ing loop

On the right s ide of the rear bumper there is a

th readed hole for the towing loop . The

threaded hole is protected by a cover .

"' Remove the tow ing loop from the vehicle

t oo lkit

c:::> page 2 73.

"' Press the cover in by app lying short strong

pressure to the bottom part to release it

from the bumper

c:::> fig. 234.

"' Screw the tow ing loop tightly into the

threaded hole as far as it w ill go.

Unscrew the towing loop again after use and

insta ll the cover in the bumper. Install the

cover in the bumper. Return the towing loop

to the toolkit. Be sure to have the towing loop

stored in the vehicle at all times .

A WARNING

If the towing loop is not screwed in as far

as it will go, the thread can pull out when

the veh icle is towed -potent ia l risk o f an

accident.

Page 290 of 316

288 Emergency situations

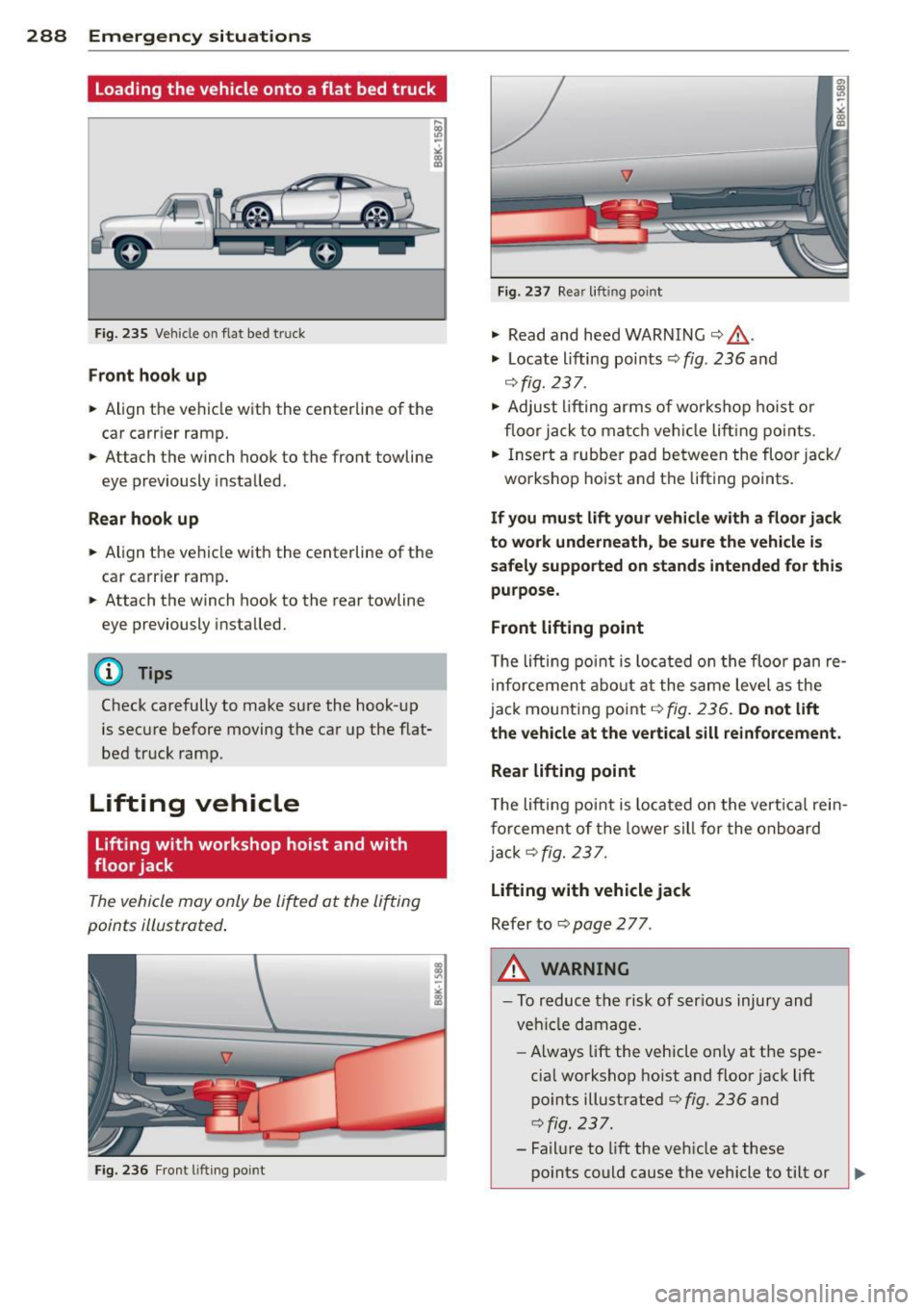

loading the vehicle onto a flat bed truck

Fig . 235 Vehi cle on flat bed t ruck

Front hook up

,,. Align the ve hicle with the centerline of the

car carr ier ramp.

,,. Attach the winch hook to the front towline

eye previously insta lled .

Rear hook up

,,. Align the vehicle with the centerline of the

car ca rrier ramp .

,,. Attach the winch hook to the rear towline

eye previously installed.

{!) Tips

Check carefully to make sure the hook- up

is secure be fore moving the car up the flat

bed truck ramp.

Lifting vehicle

lifting with workshop hoist and with

floor jack

The vehicle may only be li~ed at the lifting

points illustrated .

Fig . 2 36 Front lift ing po int

Fig. 237 Rea r liftin g po int

,,. Read and heed WARNING r=;, .&, .

,,. Locate lifting poi nts r=;, fig . 236 a nd

r=;, fig. 237 .

,,. Adjust lifting arms of wo rks hop ho ist o r

floor ja ck to ma tc h veh icle lift ing poi nts .

,,. Insert a rubber pad be tween the floo r jac k/

workshop hoist and t he lift ing points.

If you mu st lift your vehi cle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stand s intended for this

purpose.

Front lifting point

T he lift ing po in t is loca ted o n the floo r pan re

i nforcemen t abo ut a t the same leve l as the

jack mounting point

r=;, fig. 236. Do not lift

the vehicle at the vertical sill reinforcement .

Rear lifting point

T he lifti ng poi nt is located o n the vert ic al rei n

f o rcemen t of the lower s il l for the onboard

jac k

r=;, fig. 23 7.

lifting with vehicle jack

Refer to c:> page 2 77 .

A WARNING

---To r educe the risk of ser ious injury and

veh icle damage.

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jac k lift

po ints illustrated

r=;, fig. 236 and

r=;, fig. 237 .

- Failure t o lift the vehicle at these

po ints could cause the vehicle to tilt or ,...