ECU AUDI A5 COUPE 2014 Owner's Guide

[x] Cancel search | Manufacturer: AUDI, Model Year: 2014, Model line: A5 COUPE, Model: AUDI A5 COUPE 2014Pages: 286, PDF Size: 70.99 MB

Page 208 of 286

206 Checking and filling

Checking and filling

Engine hood

Releasing and opening the engine hood

The engine hood is released from inside the

vehicle .

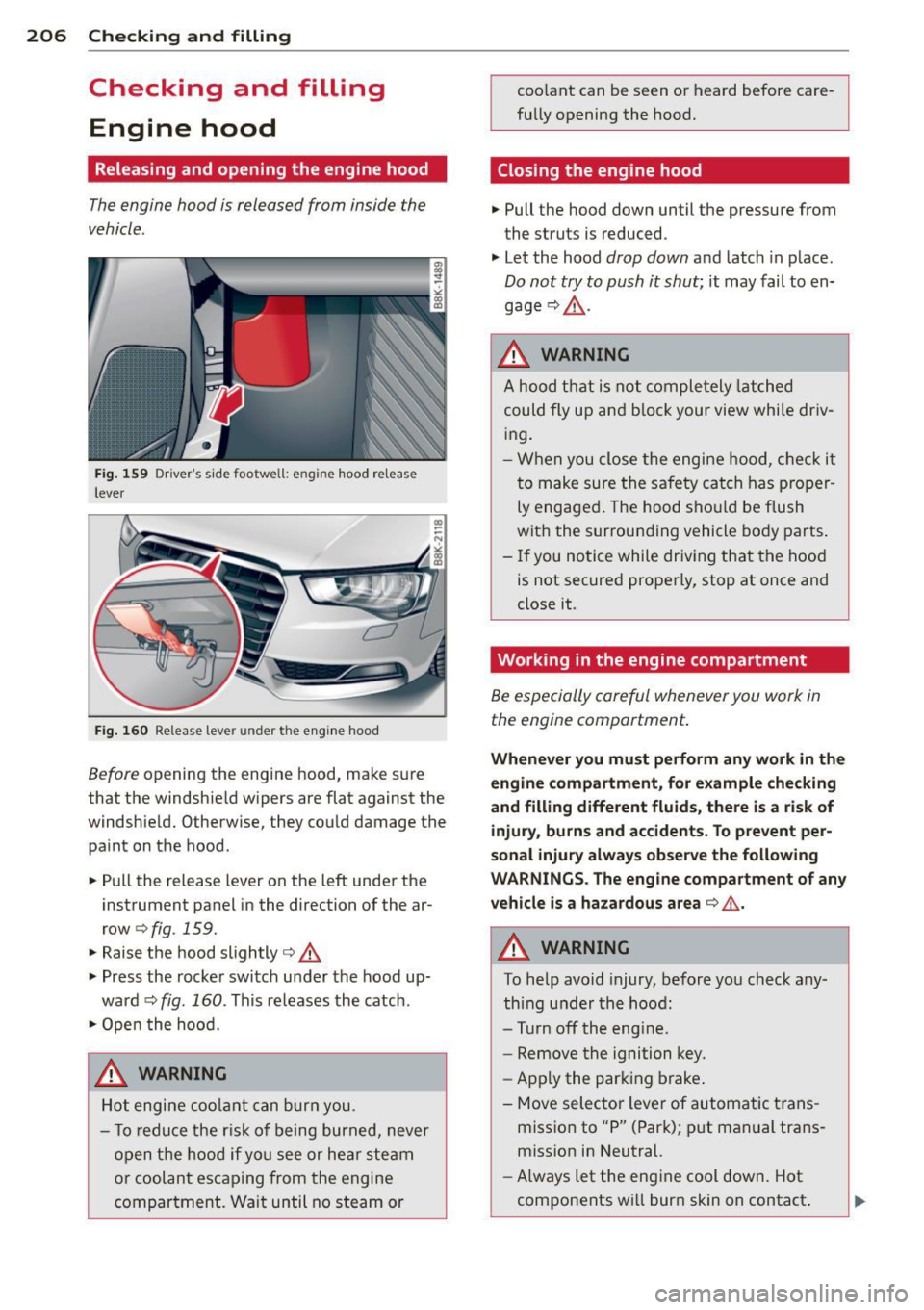

Fig . 159 D river' s side footwe ll: e ngin e hood re lease

lever

F ig. 160 Re lease lever u nde r the eng ine hood

Before openin g the engine hood, ma ke s ure

that the windshie ld w ipers are flat against the

windshield. Otherwise, they co uld damage the

pa int on the hoo d.

... Pull the release lever on the left unde r the

inst rument panel in the direction of the ar

row

c;, fig . 159.

... Raise the hood slightly r::;, .&,

... Press the rocke r swi tch u nder the hood up

ward

c;, fig . 160 . Th is re leases the catch .

... Ope n t he hood.

A WARNING

Hot engi ne co olan t ca n bur n you.

- T o redu ce the r is k o f being burned, never

op en t he ho od if yo u see or hea r steam

or cool an t esc aping from the en gine

c ompartment. Wait unti l no steam or co

olant can be seen or heard before care

fu lly opening the hood.

Closing the engine hood

... Pull the hood down until the pressure from

the struts is reduced .

... Le t the hood

drop down and latch in p lace.

Do not try to push it shut; it may fail to en

gage

r::;, .&, .

A WARNING

-

A ho od th at is not co mpletely latched

could fly u p an d block your view while driv

in g.

- Wh en you close the engi ne ho od, ch ec k it

t o make sure the sa fe ty ca tch has pro pe r

ly engaged . The hood s hould be flush

wit h the surroun ding vehicle body pa rts .

-If you notice while driv in g that t he hood

is not secured prope rly, sto p at once and

close it.

Working in the engine compartment

Be especially ca reful whenever you work in

the engine compartment.

Whenever you must perform any work in the

engine compartment, for example checking

and filling different fluid s, there is a ri sk of

injury , burns and accidents . To prevent per

sonal injury always observe the following

WARNINGS. The engine compartment of any

vehicle is a hazardous area

r::;, ,&. .

A WARNING

-To help avo id injury, before yo u check any-

thing unde r the hoo d:

- Turn off the eng ine.

- Remove the ignition key.

- Ap ply the park ing brake .

- Move selector leve r of automatic t rans -

miss io n to "P" (Par k); pu t man ual trans

miss ion in Neu tral.

- Al ways let the eng ine cool down. Hot

components wi ll burn skin on contact .

Page 232 of 286

230 Tire s and wheel s

the function of the tire pressure monitor

ing system*.

- Always inflate tires to the recommended

and correct tire pressure before driving

off.

- Driv ing with under inflated tires bend

more, letting them get too hot resu lting

in tread separation, sudden t ire fail ure

and loss of control.

- Excess ive speed and/overloading can

cause heat bui ld-up, sudden t ire failure

and loss of control.

- If the t ire pressure is too low or too high,

the tires w ill wear prematurely and the

vehicle will not hand le we ll.

- If the t i re is not flat and you do not have

to change a wheel immed iate ly, dr ive at

reduced speed to the nearest service sta

t ion to check the tire pressure a nd add

air as required.

0 Note

Dr iving without va lve stem caps can cause

damage to the t ire va lves . To prevent this,

always ma ke sure that facto ry installed

valve stem caps on all wheels a re secu re ly

mou nte d on the valve.

@) For the sake of the environment

Unde rinflated tires will a lso inc reas e the

fue l cons umption .

Tires and vehicle load limits

There are limits to the amo unt of load or

weight that any vehicle and any t ire can carry .

A vehicle that is overloaded w ill not handle

well and is more difficult to stop. Overloading

can not only lead to loss of vehicle contro l,

but c an also damage import ant parts of the

vehicle and can lead to sudde n tire failure, in

cluding a blowout and sudden deflation that

can cause t he veh icle to crash .

Your safety and that of your passengers a lso

depends on making sure that load limits are

not exceeded . Vehicle load includes everybody

and everyth ing in and on the vehicle. These load lim

its are technically referred to as the

vehicle's

Gro ss Vehicle Weight R ating

("GVWR").

T he "GVWR" includes t he weight of the basic

vehicle , a ll f actory installed accessories, a f ull

tank of fuel, oi l, coo lant and other f luids plus

maximum load. The max imum load incl udes

the number of passengers that the vehicle is

intended to carry ("seat ing capac ity ") wi th an

assumed we ight of 150 lbs . (68 kg) for each

passenger at a designated seating posit ion

and the total weight of a ny luggage in the ve

hicle. If you tow a trai le r, the we ight of the

t ra ile r hi tc h and the tongue we ight of the

l oaded tra iler mus t be include d as part of the

vehicle load .

T he

Gro ss Ax le Weight Rating ("GAWR ") is

the max imum load that can be applied a t each

of the veh icle's two axles .

T he Gross Vehicle Weight Rat ing and the

G ross Ax le Weig ht Ra ting are listed on the

sa fety comp lian ce s ticke r label loca ted on the

driver's side B-pillar. Yo ur Audi has 4 seat ing

pos itions , 2 in the front and 2 in the rea r fo r

total seati ng capacity of 4. Each seating posi

t ion has a seat belt c:>

page 129, Safety belts.

T he fact that there is an upper limit to yo ur

vehicle's Gross Vehicle Weight Rating means

t h at the total weight of whatever is being car

ried in the vehicle ( includ ing the weight of a

trailer hitch and the tongue weight of the

loaded tra iler) is lim ited. The more passen

gers in the vehicle or passengers who are

heavier tha n the sta ndard we igh ts assumed

mean that less we ight can be carried as lug

gage.

The tire pressure label o n your Aud i also lists

the max imum combi ned weig ht of all of the

occupants and luggage or other cargo that

t h e vehi cle can carry . Fo r th e lo ca tion of the

l a bel c:>page 226,

fig.168.

8_ WARNING

<=

Over loading a vehicle can cause loss o f ve -

hicl e co ntro l, a c rash or other accident, se-

rious personal injury, and even death. .,.

Page 241 of 286

driving a few yards and correct if neces

sary . Follow the instructions from the

snow cha in manufacturer when doing so.

(D Tips

Where snow chains are mandatory oncer

tain roads, this norma lly also applies to

veh icles with all wheel drive .

Wheel bolts

Wheel bolts must always be tightened to the

correct torque.

The design o f whee l bolts is matched to the

factory insta lled r ims . If different rims are fit

ted, the correct wheel bo lts wit h the right

l ength and correctly shaped bolt heads must

be used. This ensures that wheels are f itted

securely and that the brake system functions

correctly .

In certain circumstances, you may not use

wheel bo lts from a different vehicle -even if it

is the same model<=>

page 266.

A WARNING

Improperly tightened or maintained wheel

bolts can become loose caus ing loss of

cont ro l, a co llision and serious persona l in

Jury .

- Always keep the w heel bolts and the

threads in the wheel hubs clea n so the

w hee l bolts can t urn easily and be p rop

erly t igh tened.

- Never grease or oil the wheel bolts and

the threads in the wheel h ubs. They can

become loose wh ile d riving if greased or

oiled, even if tightened to the specified

torq ue.

- Only use whee l bo lts that belong to the

rim being installed .

- Never use different whee ls bolts on your

vehicle.

- Alw ays m ain ta in the co rrec t tig hten ing

torq ue fo r the wheel bo lts to reduce the

risk of a wheel loss . If the tightening tor

que of the wheel bo lts is too low, they

can loosen and come out when the vehi-

Tire s an d wheel s 239

cle is mov ing. If the tightening torq ue is

too high, the wheel bolts and threads

can be damaged and the whee l can be

come loose.

@ Note

The specified torque for the whee l bolts is

90 ft lbs . (120 Nm) w ith a tolerance of

± 7,4 ft lbs. (± 10 Nm). Torque whee l bolts

diagonally . After changi ng a wheel, the

torque m ust be checked as soon as poss i

ble with a to rque wrench -preferably by an

a uthorized Aud i dea le r or qualified wor k

shop .

Low aspect ratio tires

Your A udi is fac tory -eq uipped w ith low aspect

ratio tires . These tires have been tho ro ughly

tested and been se lected specifically for your

model for their superb performance, road fee l

and handling under a variety of driving condi

tions . Ask your authorized Aud i dealer for

more details .

The low aspect ratio of these t ires is ind icated

by a numeral of

55 or less in the tire's size

designation. The numera l represents the ratio

of the tire's sidewa ll height in relation to its

tread width exp ressed in percentage. Conven

tiona l tires have a he ight/w idth ratio of 60 or

more.

The performance of low-a spect-r atio tire s is

particularly sensit ive to improper inflation

pre ssure. It is therefor e important that low

a spect ratio tire s are inflated to the specified

pres sure and that th e inflation pr essure i s

regularly checked and maintained. Tire pre s

sure s should be chec ked at lea st once a

month and always before a long trip

<=> page 228 , Checking tire pressure.

What you can do to avo id tire and rim

damage

Low aspect ratio tires can be damaged mo re

easily by impact w ith potholes, curbs, gull ies

or ridges on the road, particularly if the tire is

under inflated . ..,.

•

•

Page 245 of 286

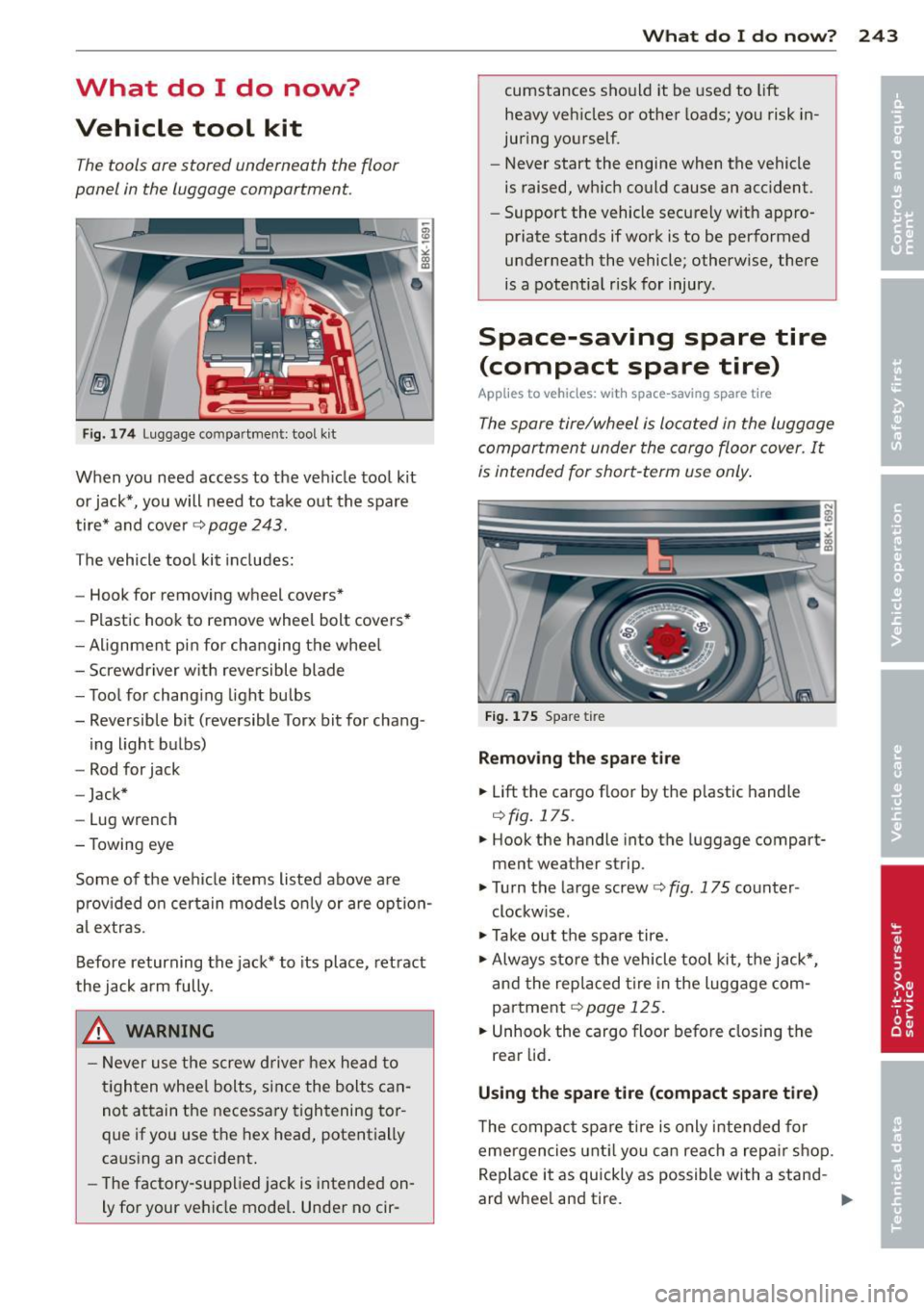

What do I do now?

Vehicle tool kit

The tools ore stored underneath the floor

panel in the luggage comportment.

Fig. 174 Luggage compartment: tool kit

When you need access to the veh icle tool kit

or jack*, you will need to take o ut the spare

tire* and cover¢

page 243.

The vehicle tool kit includes:

- Hook for removing wheel covers*

- Plastic hook to remove wheel bolt covers*

- Alignmen t pin for ch anging the whee l

- Screwdriver w ith reversible blade

- Too l for chang ing light bulbs

- Reversible bit (reversible Torx bit for chang -

ing light bulbs)

- Rod for jack

- Jack*

- Lug wrench

- Towing eye

Some of the vehi cle items listed above are

p rov ided o n certain models o nly or are opt io n

al extras .

Before returning the jack* to its place, retract

the jack arm fully.

.&, WARNING

-

-Never use the screw d river hex head to

tighten whee l bolts, since the bolts can

not attain the necessary tightening tor

que if yo u use the hex head, potentially

caus ing an accident.

- The factory-supplied jac k is intended on

ly for your vehicle model. Unde r no cir-

What do I d o now ? 243

cumstances should it be used to lift

heavy veh icles or other loads; you risk in

juring yourself.

- Never start the engine when the vehicle

is raised, wh ich could cause an acc ident.

- Support the vehicle securely w it h appro

priate stands if work is to be performed

underneath the vehicle; otherwise , there

is a pote ntia l risk for injury .

Space-saving spare tire

(compact spare tire)

App lies to vehicles: wit h space -saving spare t ire

The spore tire/wheel is located in the luggage

comportment under the cargo floor cover. It

is intended for short-term use only .

Fig. 175 Spa re tir e

Remo ving th e spare tire

.. Lift the cargo floor by the p lastic handle

¢ fig. 175 .

.. Hook the handle into the luggage compart

ment wea ther strip .

.,. Turn the large screw <=>

fig. 175 counter

clockw ise.

.,. Take out the spa re tire .

.,. Always s tore the vehicle tool kit, the jack*,

and the rep laced tire in the luggage com

partment

¢ page 125 .

.. Unhook the cargo floor before closing the

rear lid .

Using th e spare tire (compact spar e tire )

The compact spare t ire is only intended fo r

eme rgencies unt il you can reach a repa ir sh op.

Rep lace it as qu ickly as possible with a stand -

ard whee l and tire.

Ill-

Page 249 of 286

@ Tips

-Never use the hexagonal socket in the

handle of the screwdriver to loosen or

tighten the wheel bolts.

- If a whee l bolt is very tight, you may find

it easier to loosen by carefully pushing

down on the end of the wheel bolt

wrench w ith

one foot only. As you do so,

hold on to the car to keep your ba lance

and take ca re not to slip.

Raising the vehicle

The vehicle must be li~ed with the jack first

before the wheel can be removed .

*- '*

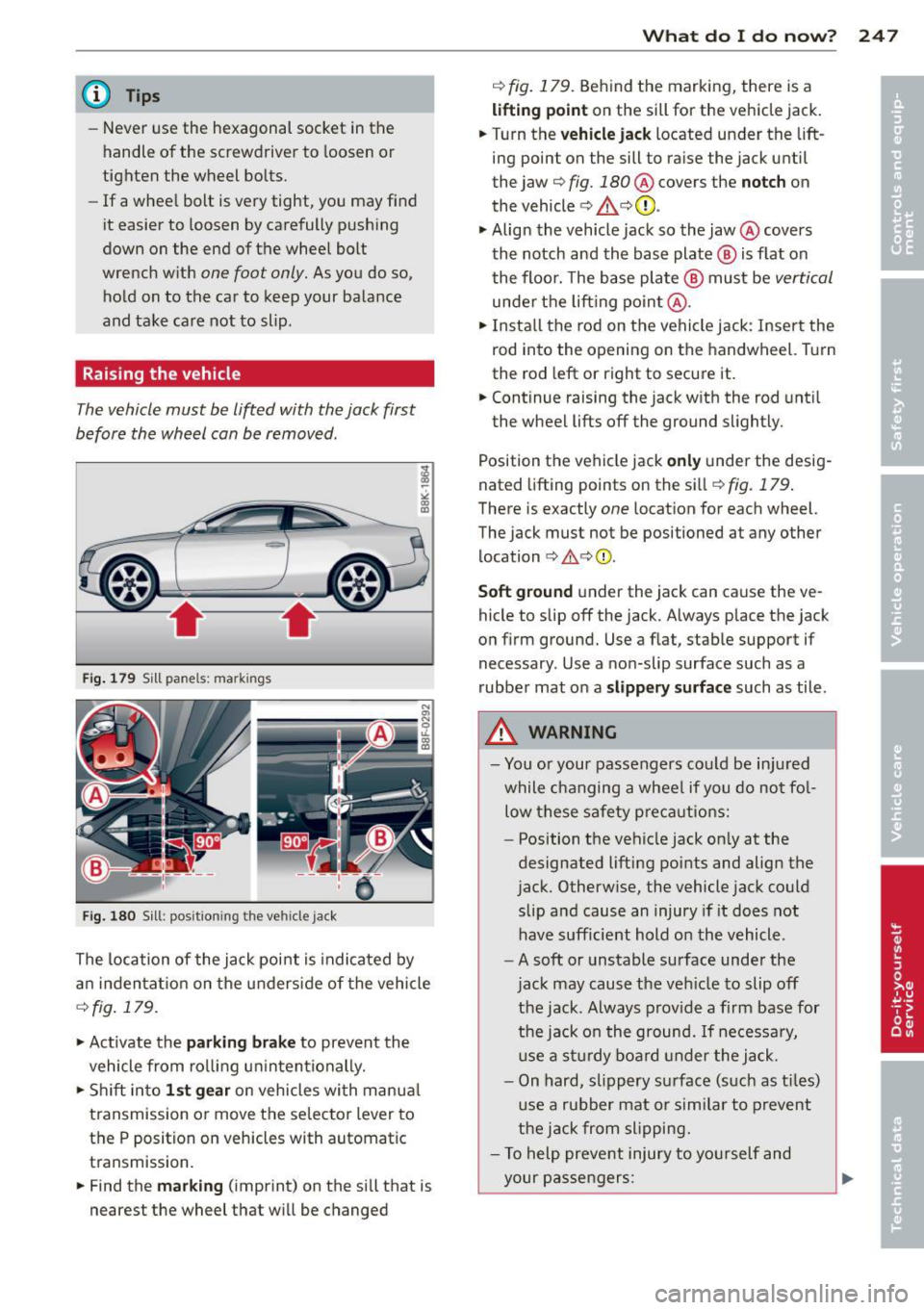

Fig. 1 79 Sill pane ls: ma rk ings

Fi g. 180 Sill: posit ion ing the ve hicle

jack

The location of the jack point is indica ted by

a n in den ta ti on on the underside of the vehicle

¢ fig . 179.

"'Activate the parking b rake to prevent the

vehicle from ro lling u ninten tionally.

"' Shift in to

1st gear on vehicles with manua l

transmission or move the se lector lever to

the P position on vehicles with automatic

transmission.

"' Find the

marking (imprint) on the sill that is

nearest the wheel that w ill be changed

What do I d o now ? 24 7

¢ fig. 179. Behind the marking, there is a

lifting point on the sill for the vehicle jack.

"' Turn the

vehicle ja ck located under the lift

ing point on the sill to ra ise the jack until

the jaw ¢

fig. 180 @ covers the notch on

the vehicle

¢ & ¢ (D .

"'Align the vehicle jack so the jaw@ covers

th e notch and the base plate @ is flat on

the floor. The base plate @ must be

vertical

unde r th e lift ing po in t @ .

"'I nsta ll the rod on the vehicle jack : Inser t the

rod into the opening on the handwheel. T urn

the rod left or right to secure it.

"' Continue raising the jack w ith the rod unt il

the wheel lifts off the ground slightly.

Position the veh icle jack

only under the desig

nated lifting points on the sill ¢

fig. 179 .

There is exactly one locat ion for each wheel.

The jack must not be positioned at any other location c> &, c>(D.

Soft ground under the jack can cause the ve

hicle to slip off the jack. Always place the jack

on f irm ground. Use a f lat, stab le support if

necessary . Use a non-slip surface such as a

rubber mat on a

s lipp ery surface such as tile .

A WARNING

-You or your passengers co uld be in ju red

while changing a wheel if you do no t fo l

low these safety p re ca utions:

- Position t he veh icle jack on ly at the

designated lifting poi nts and align the

jack. Otherw ise, the vehicle jack could

slip a nd cause an injury if it does not

have sufficie nt hold o n the vehicle.

- A soft or unstable surface under the

jac k may cause the ve hicle to slip off

the jack . A lways prov ide a fi rm base for

the jack o n the ground. If necessa ry,

u se a st ur dy boa rd under the jack .

- On hard, sl ippery su rface (such as t iles)

u se a rubber mat or simi lar to prevent

the j ack from slipping.

- T o help preve nt injury to yo urself and

your pas sengers:

Page 250 of 286

248 What do I do now?

-Do not raise the vehicle unti l you are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up.

- Make sure that passengers wait in a

safe p lace away from the vehicle and

well away from the road and traffic.

- Make sure jack position is correct, ad

just as necessary and then continue to ra ise the jack.

CD Note

Do not lift the vehicle by the sill. Position

the vehicle jack only at the designated lift

ing points on the sill. Otherwise, your vehi

cle will be damaged.

Taking the wheel off/installing the spare

tire

Follow these instructions step-by-step for

changing the wheel .

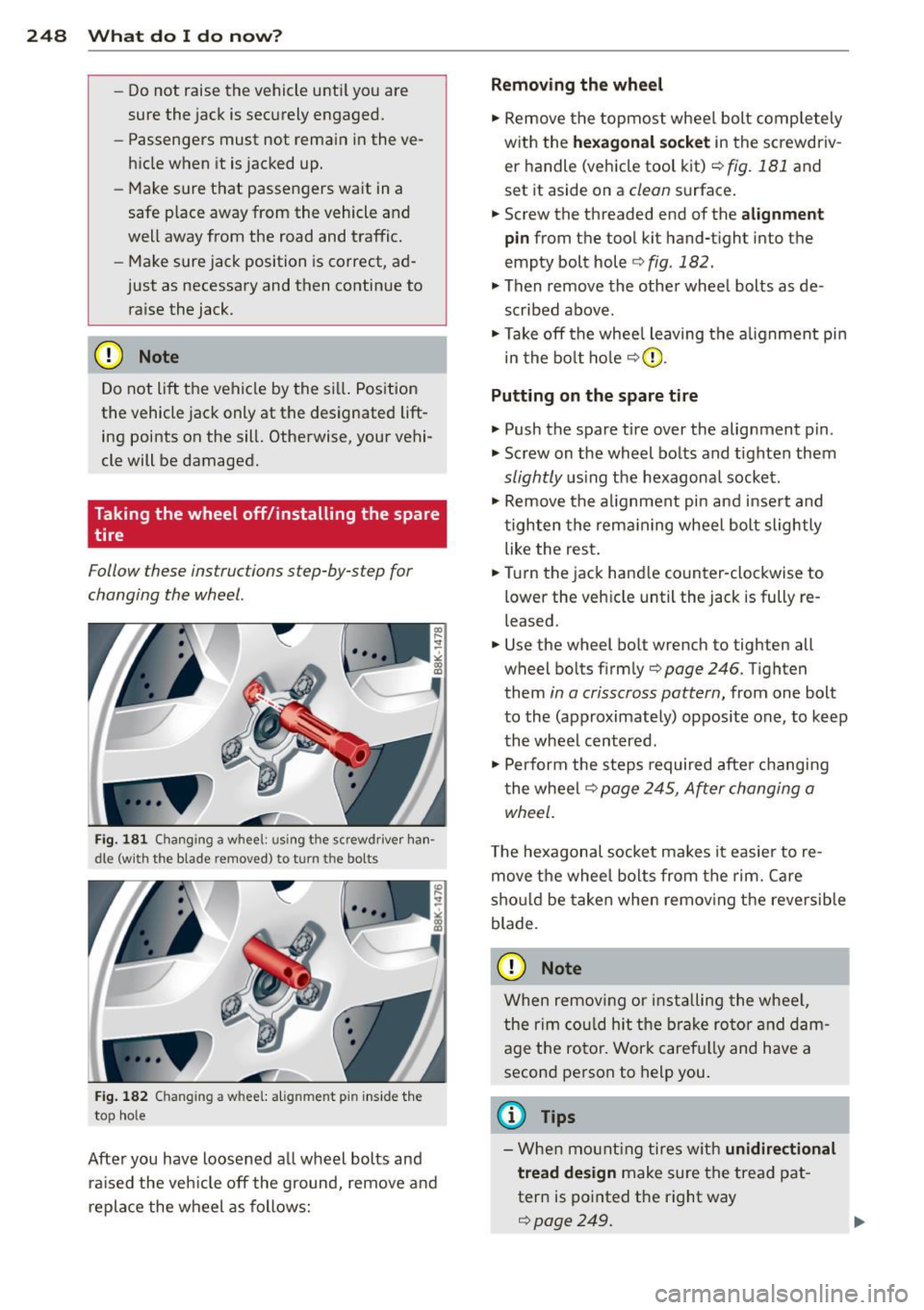

Fig. 181 Changing a w hee l: usi ng the screwdriver han ·

dle (with the blade r~mo ved) to turn th e bo lts

Fig. 182 C hangin g a w hee l: alig nmen t pin inside the

to p hole

After you have loosened a ll wheel bolts and

ra ised the veh icle off the ground, remove and

replace the wheel as follows:

Removing the wheel

"' Remove the topmost wheel bolt comp letely

with the

hexagonal socket in the screwdriv

er handle (vehicle tool kit)¢

fig. 181 and

set it aside on a

clean surface.

"' Screw the threaded end of the

alignment

pin

from the tool kit hand-tight into the

empty bolt hole¢

fig. 182.

"' Then remove the other wheel bolts as de

scribed above.

"' Take off the whee l leaving the alignment pin

in the bolt hole ¢(D .

Putting on the spare tire

"' Push the spare tire over the alignment p in.

"' Screw on the wheel bolts and tighten them

slightly using the hexagonal socket .

"' Remove the alignment pin and insert and

tighten the remain ing wheel bolt slightly

like the rest.

"' Turn the jack handle counter-clockwise to

lower the veh icle until the jack is fully re

leased.

"' Use the wheel bo lt wrench to tighten all

wheel bolts firmly¢

page 246 . Tighten

them

in a crisscross pattern, from one bolt

to the (approximately) opposite one, to keep

the wheel centered.

"' Perform the steps required after changing

the wheel

c::> page 245, After changing a

wheel.

T he hexagonal socket ma kes it easier to re

move the wheel bolts from the rim. Care

sho uld be taken when removing the reversible

blade .

CD Note

When removing or installing the wheel,

the rim could hit the brake rotor and dam

age the rotor. Work carefu lly and have a

second person to help you.

(D Tips

-When mount ing tires with unidirectional

tread design

make sure the tread pat

tern is po inted the right way

c::> page 249. Iii>

Page 251 of 286

-The wheel bol ts should be clean and easy

to tu rn. Check for d irt and corrosion on

t h e mat ing s urfaces of both the whee l

and t he hu b. Remove a ll dirt from these

su rfaces before remo unt ing t he wheel.

- Do n ot use the hexagonal socket in the

screwdriver ha ndle to loosen or tig hten

t h e wheel bo lts .

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern

intended for use in a specific direction

When using a spare tire w ith a t read patte rn

i ntended for use in a specific direction, please

n ot e th e follow ing:

- The direction of rotation is ma rked by an

ar

row on the s ide of the t ire .

-If the spare t i re has to be installed in the in

correct di rection, use the spare tire only

temporar ily since the t ire will not be able to

achieve its optimum perfo rma nce character

ist ics with r ega rd to aquaplani ng, noise and

wea r.

- We recommend that you pay particular at

tent io n t o this fact du ring wet weathe r and

t h at you adjus t your spee d to matc h road

cond itio ns.

- Replace th e flat tire w ith a n ew one and

have it ins talled o n your ve hicle as soon as

poss ible to re st ore the hand ling advant ages

of a uni direct io na l t ire .

Notes on wheel changing

Please rea d the information ¢ page 233, New

tires and replacing tires and wheels

if you are

going to use a spare t ire which is different

from the tires on your ve hicle.

Afte r you change a tire :

-Check the tire pressure on the spare imme

diately after installation . What do I do now? 249

- Have the wheel bolt tightening torque

checked with a torque wrench as soon a s

possible by your authorized Audi dealer or

qualified workshop.

- With steel and alloy wheel rims , the wheel

bolts are cor rectly tightened at a torque of

90 ft lbs. (120 Nm ).

- If you notice that the wheel bolts are cor·

roded and difficult to turn while changing

a tire, they should be replaced before you

check the tightening torque .

- Replace the flat tire with a new one and

have it installed on your veh icle as soon as

possible. Remount the wheel cover.

Until then , drive with extra care and at re·

duced speeds.

A WARNING

-

- If you are going to equ ip your ve hicle

w it h tires o r rims which differ from those

which w ere fac to ry installed, t hen be

s ure to re ad the information ¢

page 233,

N ew tire s and re pla cing tires and

whee ls.

- Always make s ure th e da maged wheel o r

eve n a flat t ire and t he j ack and to ol ki t

a re p roperly secu red in the lugg age com

pa rtment an d are no t loose in the pas

sen ger compartment.

- In an accident or sud den maneuver they

co uld f ly forwa rd, in ju ring a nyo ne in the

ve hicle .

-A lways s to re damage d wheel, jack and

too ls sec urely in the luggage compa rt

ment . Othe rwise, in a n accident o r su d

den maneuver they co uld f ly forwa rd,

causing inju ry to passengers in the ve hi·

cle.

~ Note

Do not use comme rcially ava ilab le tire

sea lants. Ot herwise, t he e lectr ica l comp o

n ents of t he tire pressu re monitoring sys

t em * w ill no longe r work pr operly and the

senso r fo r th e tire pressure moni tor ing

syst em* will have to be replac ed by quali

fied wor ksh op. •

•

Page 259 of 286

-Jumper cables must be long enough so

that the vehicles do not t ouch.

- W hen connecting jumper ca bles, make

sure that they cannot get caught in any

moving parts in the eng ine compart

ment.

- Do not bend over the batteries - danger

of chemical burns!

- The battery ce ll locking screws must be

t ightened securely .

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS ¢

page 206.

Improper hook-up of jumper cables can ru

in the generator.

- Always connect POSITIVE( +) to POSI

TIVE(+), and NEGATIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

ce lls are screwed in firmly . If not, tighten

plugs p rior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

necting a jumper cable as described

above applies spec ifically to the case of

your vehicle be ing jump started. When

you are givi ng a jump start to another ve

hicle, do

not connect the negat ive( -) ca

ble to the negat ive( -) term inal on the

discharged battery @¢

fig. 188. In

stead, securely connect the negative(- )

cable to e ither a solid metal component

that is firmly bolted to the engine block

or to the engine block itse lf. If the bat

tery that is being charged does not vent

to the outside, escaping battery gas

could ignite and explode!

Em erg en cy si tuation s 257

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing.

T he following information is to be used by

commercial tow t ruck operators who know

how to operate their equipment safely.

- Never tow your Audi , towing will cause

damage to the engine a nd transmi ssion.

- Never wrap th e safet y chain s or winch c a

ble s around th e brak e lin es.

- To prevent unne ce ss ary dam age, your Aud i

mu st be t ransp orted with a flat bed truck .

- To load th e vehi cle on to the fl at bed , use

the t owing loop found in the vehicle t ool s

and atta ch to the front or rear anch o rage

r=:> page 258 and ¢page 258 .

A WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyone to ride in a

vehicle being towed, for any reason.

-

•

•

Page 261 of 286

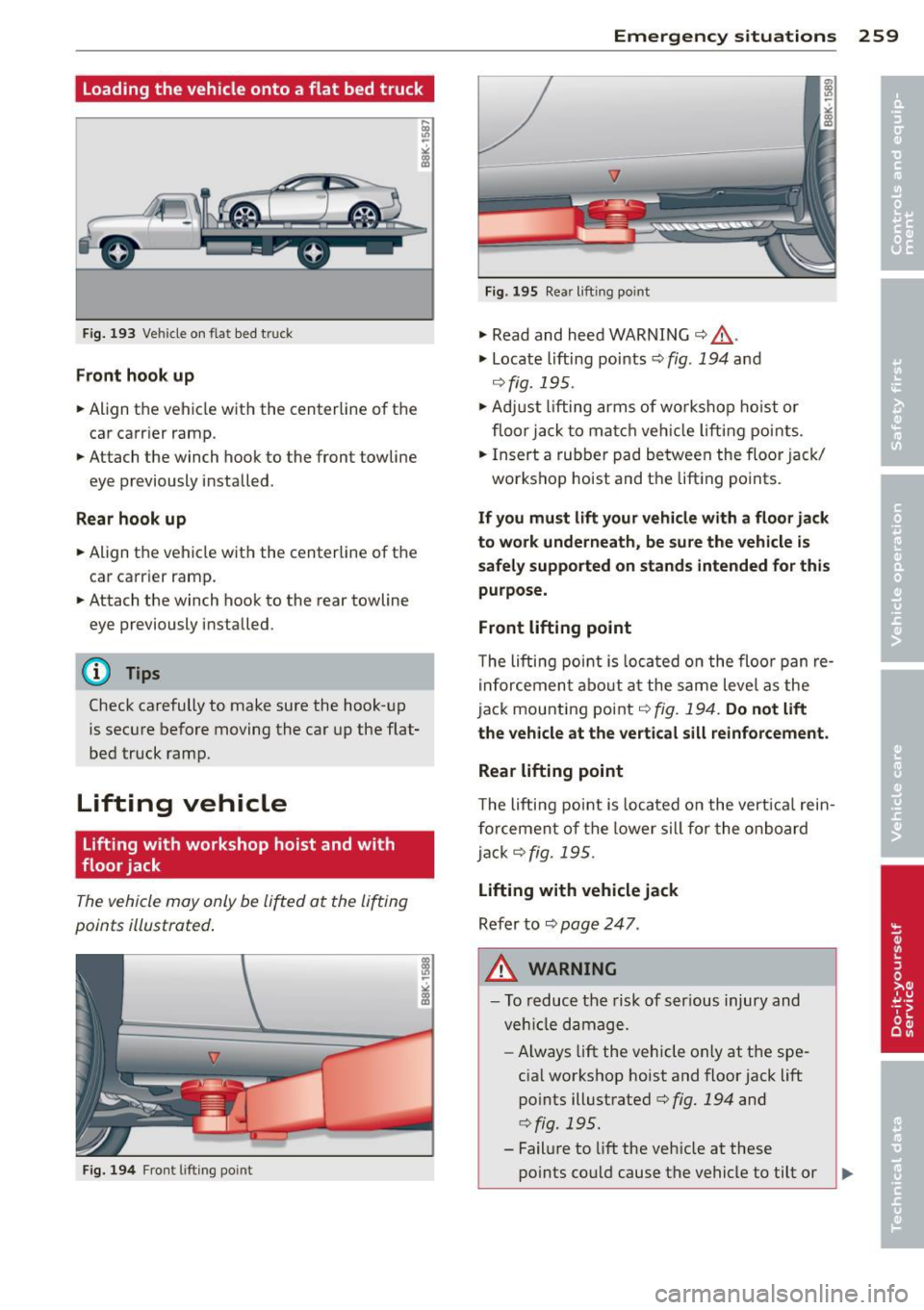

Loading the vehicle onto a flat bed truck

Fig. 193 Ve hicle on fla t bed tr uck

Front hook up

.. Align the vehicle with the centerline of the

car carr ier ramp.

.. Attach the winch hook to the front towline

eye previously installed .

Rear hook up

.. Align the vehicle w ith the centerline of the

car carrier ramp.

.. Attach the winch hook to the rear towline

eye previously installed.

(D} Tips

Check carefully to make sure the hook- up

is secure before moving the car up the flat

bed truck ramp .

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may only be li~ed at the lifting

points illustrated .

Fig. 194 Fro nt l ift ing po int

Emergenc y situ ation s 259

Fig. 1 9 5 Rea r liftin g po int

.,. Read and heed WARNING c::> .&, .

.,. Locate lifting points c::> fig. 194 and

¢ fig. 195 .

.,. Adju st lifting arms of wo rkshop ho ist o r

floor jack to ma tch veh icle lifting points.

.. Insert a rubbe r pad be tween the floor jack/

workshop hoist and the lift ing points.

If y ou mu st lift your veh icl e with a fl oor jack

to w ork und erneath , be sure the vehicle is

safel y supported on stand s intended for thi s

purpo se .

Front lifting point

T he lifti ng point is loca ted o n the floo r pan re

i nforcemen t abo ut a t the same level as the

jack mounting point

c::> fig. 194. Do not lift

the vehicle at the vertic al sill reinforcement.

Rear lifting point

T he lifting point is located o n the vert ica l rein

f o rcement of the lower s ill for the on board

jack

c::> fig. 195 .

Lifting with vehicle jack

Refer to c:;, page 247 .

A WARNING

-To reduce the risk of ser ious injury and

veh icle damage.

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jack lift

points illustrated

c:;, fig. 194 and

c:;, fig. 195.

- Fail ure to lift the veh icle at these

-

po ints could cause the vehicle to tilt or ..,.

Page 267 of 286

complexity of today's automobi les, have

steadi ly reduced the scope of maintenance

and repairs which can be carried out by vehicle

owners.

Also, safe ty and e nvir onm en tal con

cerns place very strict limits on the nature of

repairs and adjustments to engine and trans

miss io n pa rts which an owner can perform .

Maintenance, adjustments and repairs usua lly

require special tools, testing devices and oth

er equipment avai lab le to specially trained

workshop personnel in order to assure prope r

performance, reliab ility and safety of the vehi

cle and its many systems .

Improper ma intenance, adjustments and re

pa irs can impair the operation and reliability

of your vehicle and even void your vehicle war ranty. The refo re, p roof of servic ing in accord

ance w ith the maintenance sched ule may be a

condition for upholding a poss ible war ranty

claim made within the warranty period.

Above all, operational safety can be adversely

affected, crea ting unnecessary risks for you

and your passengers.

If in doubt about any servicing, have it done

by your authorized Audi dealer or any properly

equ ipped and qua lified workshop. We st rong

l y urge you to g ive your authorized Audi dea ler

the opportunity to perform all scheduled

maintenance and necessary repairs . Your dea l

er has the facilities, original parts and trained

specialists to keep your veh icle running prop

erly.

Performing limit ed m aintenance you rself

The following pages describe a limited num

ber of procedures which can be performed on

your vehicle with ordinary too ls, should the

need arise and trained personnel be unavaila

ble. Before performing any of these proce

dures, always thoroughly read all of the appli

cable text and carefully follow the instruc

tions given. Always rigorously obse rve the

WARNINGS provided.

B efore you check anything in th e engine

compartment, a lways re ad and heed all

Con sumer In formation 265

WARNINGS ¢ & and ¢ & in Working in the

engine comportment on page 206 .

A WARNING

-Ser ious personal injury may occur as a re

sult of improperly performed mainte

nance, adjustments or repa irs.

-Always be extremely careful when work

ing on the vehicle. Always follow com

mon ly accepted safety practices and gen

eral common sense. Never r isk personal

lnJUry.

- Do not attempt any of the ma intenance,

checks or repairs descr ibed on the fol

lowing pages if you are not fully fam iliar

wit h these or othe r pro cedures with re

spect to t he veh icle, or are uncerta in how

to p roceed .

- Do not do any work without the proper

too ls and equipment. Have the necessary

work done by your authorized A udi deal

er or any properly equipped and qualified

wo rkshop.

- The engine compartment o f any motor

veh icle is a potentially hazardous area.

Never reach into the area around or

touch the radiator fan. It is temperature

contro lled and can switch on suddenly -

even when the engine is off and the igni

tion key has been removed. The rad iator

fan switches on automat ica lly when the

coo lant reaches a certai n temperatu re

and will cont inue to run until the coo lan t

tempera ture drops .

- Always remove the ign itio n key befo re

anyone gets under the vehicle.

- Always support your veh icle with safety

s tands i f it is necessary to work under

neath the vehicle. The jack s upplied with

the vehicle is not adequate for this pur

pose and cou ld collapse causing serio us

personal injury.

- If you must work underneath the vehicle

with the wheels on the ground, a lways

make sure the vehicle is on leve l ground,

that the wheels are a lways securely

blocked a nd that the engine cannot be

started.

•

•