AUDI A6 1999 C5 / 2.G 01E Transmission Final Drive Pinion And Ring Gear Workshop Manual

Manufacturer: AUDI, Model Year: 1999,

Model line: A6,

Model: AUDI A6 1999 C5 / 2.G

Pages: 8, PDF Size: 0.08 MB

AUDI A6 1999 C5 / 2.G 01E Transmission Final Drive Pinion And Ring Gear Workshop Manual

A6 1999 C5 / 2.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/1300/w960_1300-0.png

AUDI A6 1999 C5 / 2.G 01E Transmission Final Drive Pinion And Ring Gear Workshop Manual

Trending: differential, service, torque, length

Page 1 of 8

39-33

Drive pinion and ring gear,

adjusting

Note:

Careful adjustment of the drive pinion and ring

gear is important for the service life and smooth

running of the final drive. For this reason, the

drive pinion and ring gear are matched together

during manufacture, and checked to ensure a

good mesh pattern and quiet running in both

directions of rotation. The position of quietest

running is found by moving the drive pinion in

an axial direction and at the same time lifting

the ring gear out of the zero-play mesh position

by the amount necessary to maintain the

backlash within the specified tolerance.

The object of the adjustment is to reproduce the

setting for quietest possible running, as

obtained on the test machine in production.

The deviation (tolerance) "r," which is related to

the master gauge "Ro," is measured for the

final drive sets supplied as replacement parts

and marked on the outer circumference of the

ring gear. The final drive set (drive pinion and

ring gear) may only be replaced together as a

matched pair.

Observe the general repair instructions for

Pa

ge 1 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

Page 2 of 8

tapered roller bearings and shims.

The frictional torque measurement is only used

as a final check to make sure that the

adjustment is correct.

Pa

ge 2 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

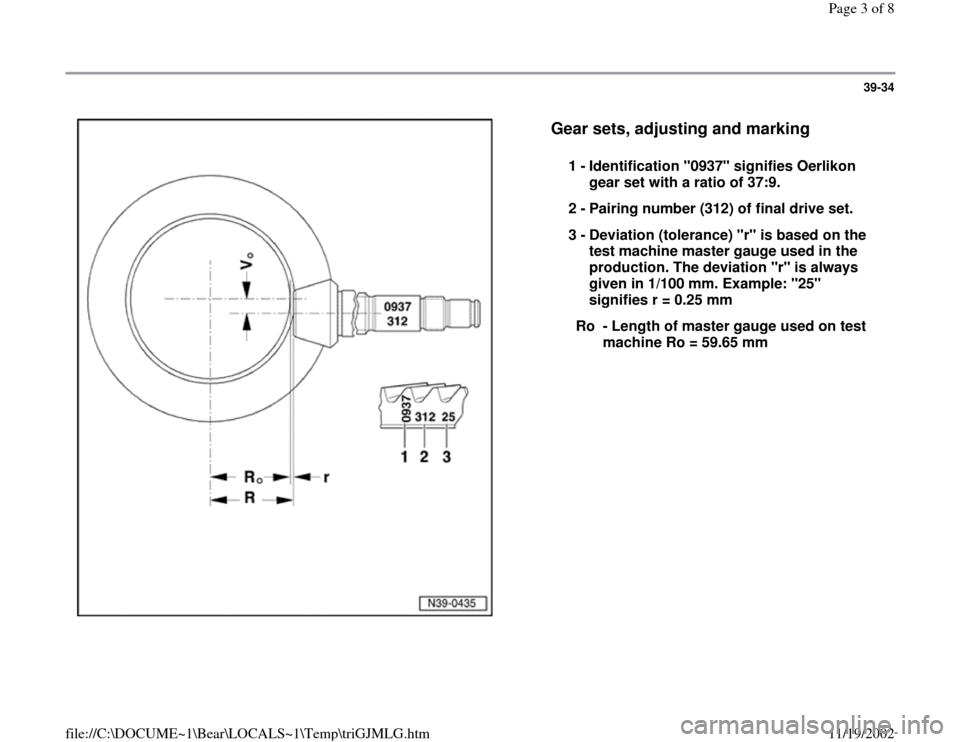

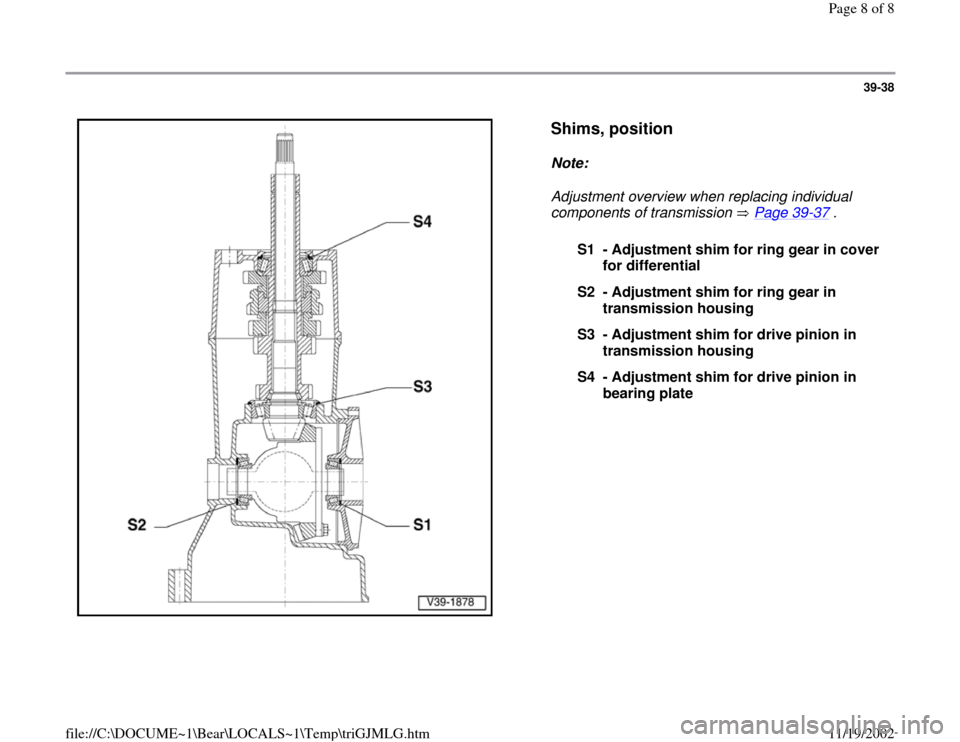

Page 3 of 8

39-34

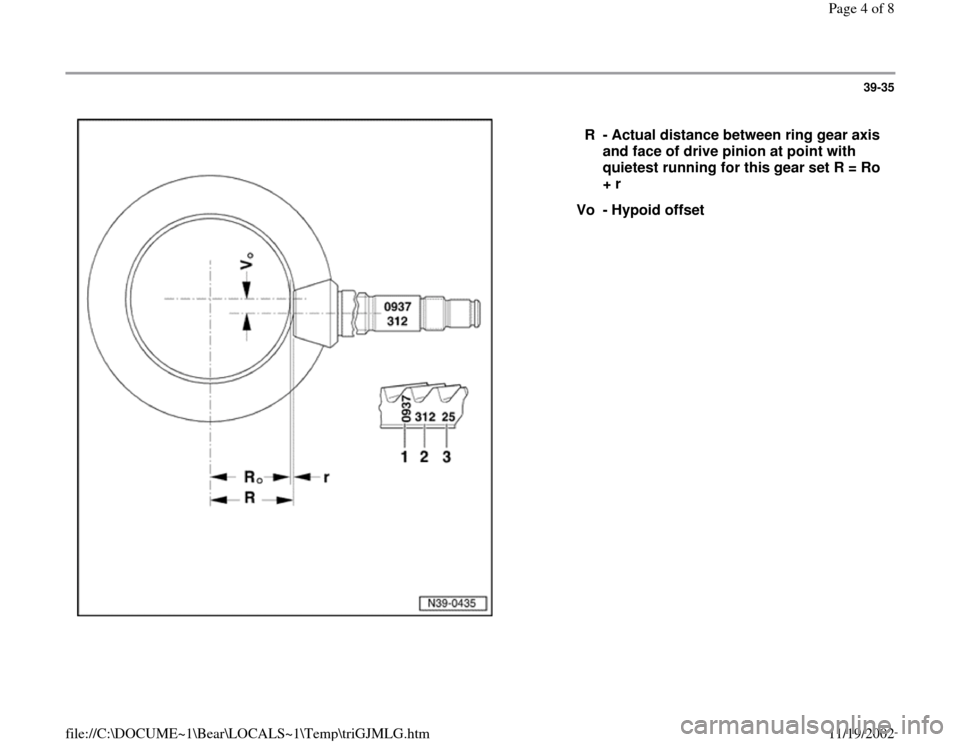

Gear sets, adjusting and marking

1 -

Identification "0937" signifies Oerlikon

gear set with a ratio of 37:9.

2 -

Pairing number (312) of final drive set.

3 -

Deviation (tolerance) "r" is based on the

test machine master gauge used in the

production. The deviation "r" is always

given in 1/100 mm. Example: "25"

signifies r = 0.25 mm

Ro - Length of master gauge used on test

machine Ro = 59.65 mm

Pa

ge 3 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

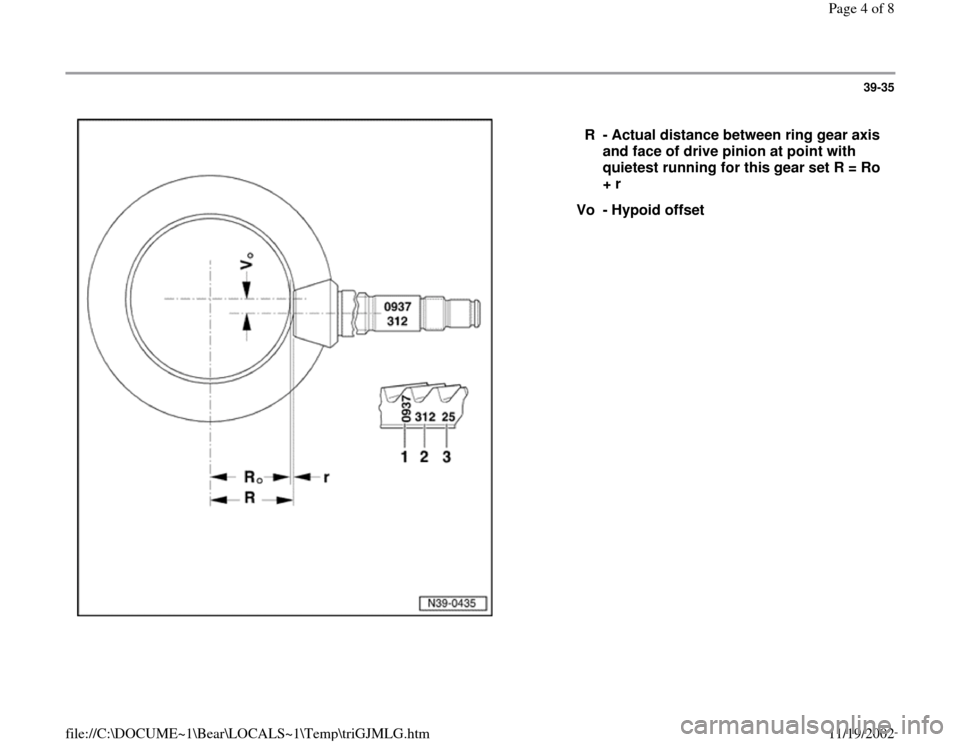

Page 4 of 8

39-35

R - Actual distance between ring gear axis

and face of drive pinion at point with

quietest running for this gear set R = Ro

+ r

Vo - Hypoid offset

Pa

ge 4 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

Page 5 of 8

39-36

Final drive set readjusting,

recommended sequence

The following sequence of work is recommended

to save time when the drive pinion and ring gear

have to be adjusted:

1.) Determine total shim thickness "S

total

" for

"S1" +"S2" (sets preload for tapered roller

bearings for differential) from Page 39

-

54

.

2.) Determine total shim thickness "S

total

" for

"S3" + "S4" (sets preload for tapered roller

bearings for drive pinion) from Page 39

-

41

.

3.) Distribute total shim thickness "S

total

" for "S3"

+ "S4" so that the distance from center of ring

gear to face of drive pinion is the same as

distance "R" which was determined during

production from Page 39

-47

.

4.) Distribute total shim thickness "S

total

" for "S1"

+ "S2" so that the specified backlash

between ring gear and drive pinion is

maintained from Page 39

-61

.

Note:

Overview of components and shims Page 39

-

38

.

Pa

ge 5 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

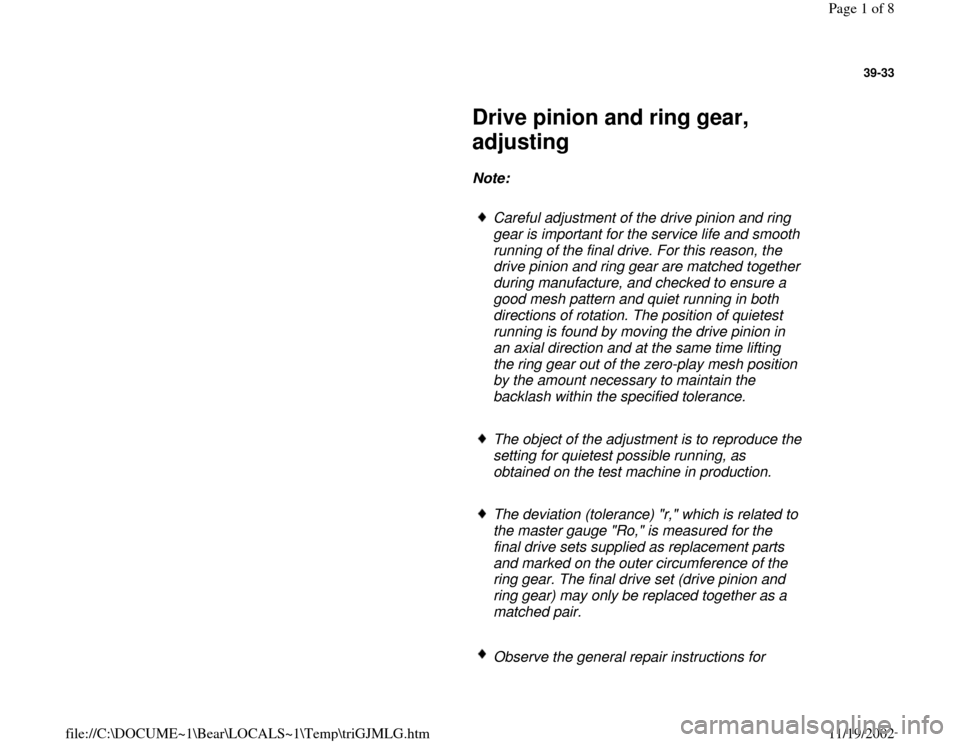

Page 6 of 8

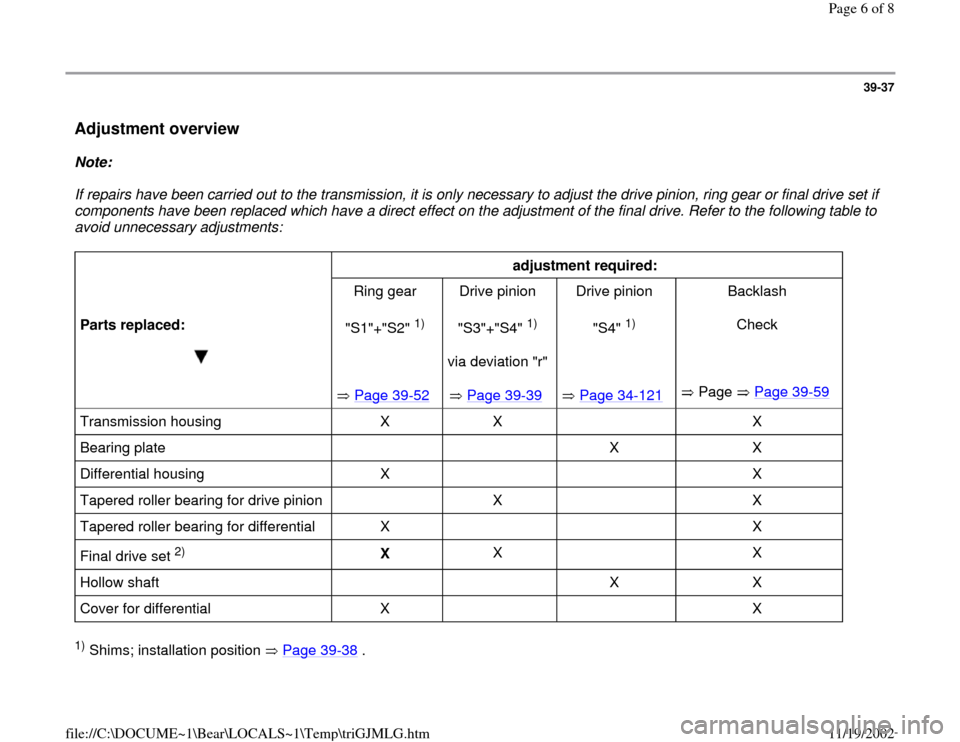

39-37

Adjustment overview

Note:

If repairs have been carried out to the transmission, it is only necessary to adjust the drive pinion, ring gear or final drive set if

components have been replaced which have a direct effect on the adjustment of the final drive. Refer to the following table to

avoid unnecessary adjustments:

adjustment required:

Parts replaced:

Ring gear

"S1"+"S2"

1)

Page 39

-52

Drive pinion

"S3"+"S4"

1)

via deviation "r"

Page 39

-39

Drive pinion

"S4"

1)

Page 34-121

Backlash

Check

Page Page 39

-59

Transmission housing X X X

Bearing plate X X

Differential housing X X

Tapered roller bearing for drive pinion X X

Tapered roller bearing for differential X X

Final drive set

2)

X X X

Hollow shaft X X

Cover for differential X X

1) Shims; installation position Page 39

-38

.

Pa

ge 6 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

Page 7 of 8

2) Drive pinion and ring gear; only replace together.

Pa

ge 7 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

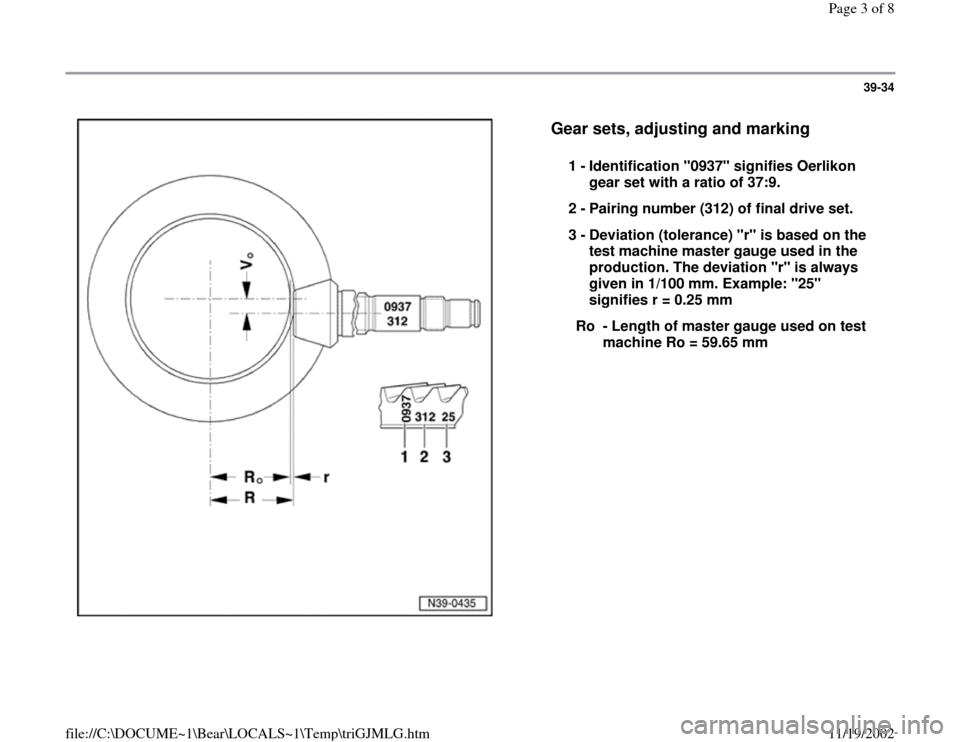

Page 8 of 8

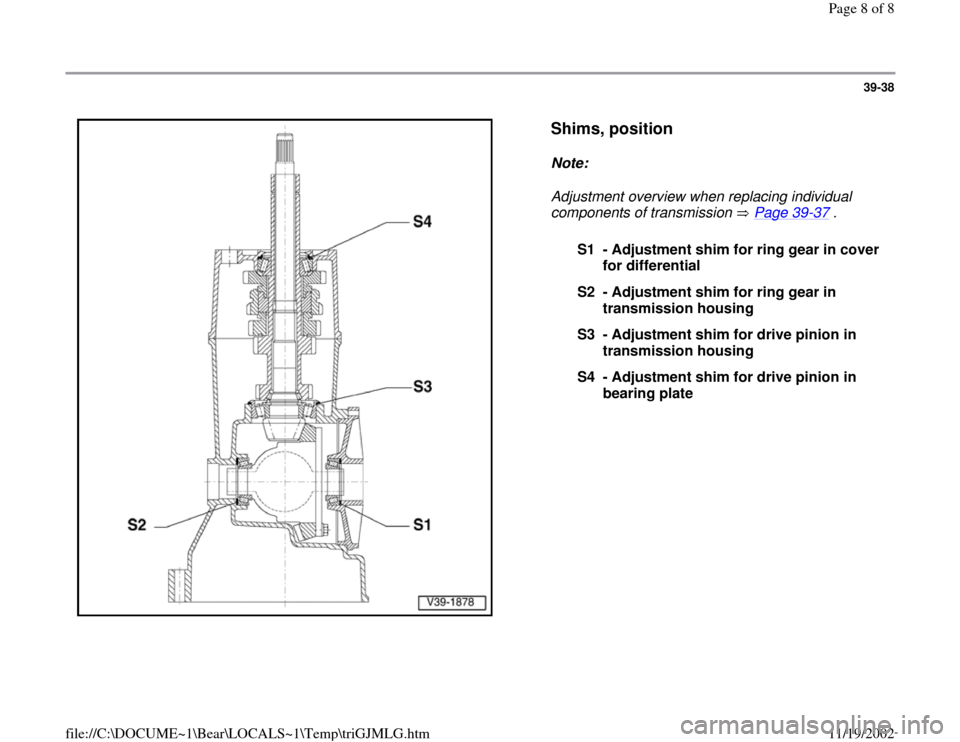

39-38

Shims, position

Note:

Adjustment overview when replacing individual

components of transmission Page 39

-37

.

S1 - Adjustment shim for ring gear in cover

for differential

S2 - Adjustment shim for ring gear in

transmission housing

S3 - Adjustment shim for drive pinion in

transmission housing

S4 - Adjustment shim for drive pinion in

bearing plate

Pa

ge 8 of 8

11/19/2002 file://C:\DOCUME~1\Bear\LOCALS~1\Tem

p\triGJMLG.htm

Trending: differential, length, service, torque