AUDI A6 1999 C5 / 2.G 01E Transmission Final Drive Pinion Assembly Workshop Manual

A6 1999 C5 / 2.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/1302/w960_1302-0.png

AUDI A6 1999 C5 / 2.G 01E Transmission Final Drive Pinion Assembly Workshop Manual

Page 3 of 13

39-135

Thrust pad 3062

Drift 3138

Fitting appliance 3253 with 3253/3 and

3253/4

Retainer 3304

Engine/transmission jack V.A.G 1383 A

Universal support V.A.G 1359/2

Separating tool Kukko 17/2

Two-arm puller Kukko 21/7

Counter-support Kukko 22/2

Torque gauge 0-600 Ncm

Socket attachment (long), 32 mm A/F

Pa

ge 3 of 13 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.18

Page 4 of 13

39-136

Note:

General repair instructions Page 00

-11

.

Removing drive flange housing from rear final

drive with final drive installed Page 39

-82

.

Removing drive flange housing from rear final

drive with final drive removed Page 39

-111

.

Replace both tapered roller bearings together.

Use same make if possible.

Do not additionally oil new tapered roller

bearings for friction torque measurement. The

bearings have already been treated with a

special oil by the manufacturer.

Removing differential Page 39

-112

.

Adjustments are required when replacing

components marked with a 1) Page 39

-150

,

Adjustment overview

Pa

ge 4 of 13 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.18

Page 5 of 13

39-137

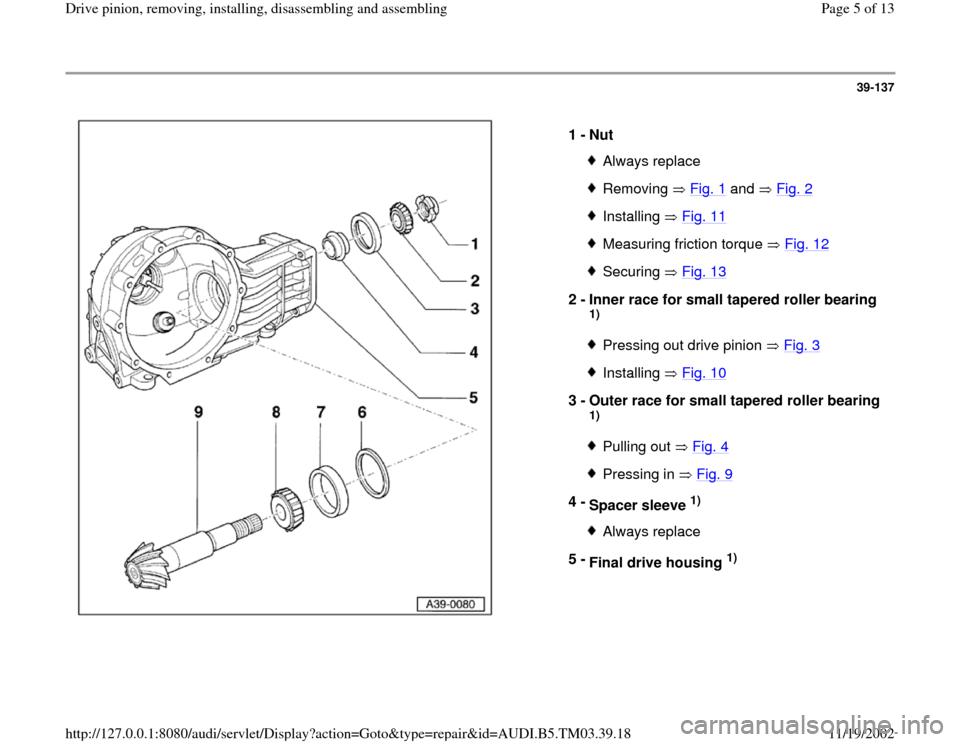

1 -

Nut

Always replaceRemoving Fig. 1

and Fig. 2

Installing Fig. 11Measuring friction torque Fig. 12Securing Fig. 13

2 -

Inner race for small tapered roller bearing

1) Pressing out drive pinion Fig. 3Installing Fig. 10

3 -

Outer race for small tapered roller bearing

1) Pulling out Fig. 4Pressing in Fig. 9

4 -

Spacer sleeve

1)

Always replace

5 -

Final drive housing

1)

Pa

ge 5 of 13 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.18

Page 12 of 13

39-144

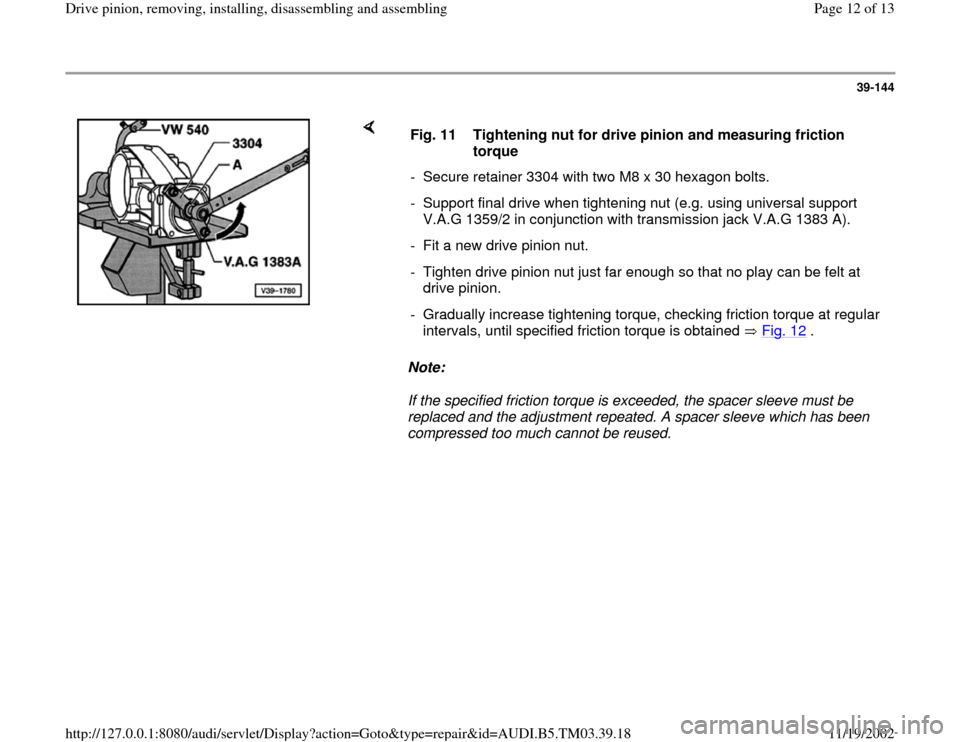

Note:

If the specified friction torque is exceeded, the spacer sleeve must be

replaced and the adjustment repeated. A spacer sleeve which has been

compressed too much cannot be reused. Fig. 11 Tightening nut for drive pinion and measuring friction

torque

- Secure retainer 3304 with two M8 x 30 hexagon bolts.

- Support final drive when tightening nut (e.g. using universal support

V.A.G 1359/2 in conjunction with transmission jack V.A.G 1383 A).

- Fit a new drive pinion nut.

- Tighten drive pinion nut just far enough so that no play can be felt at

drive pinion.

- Gradually increase tightening torque, checking friction torque at regular

intervals, until specified friction torque is obtained Fig. 12

. Pa

ge 12 of 13 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.18

Page 13 of 13

39-145

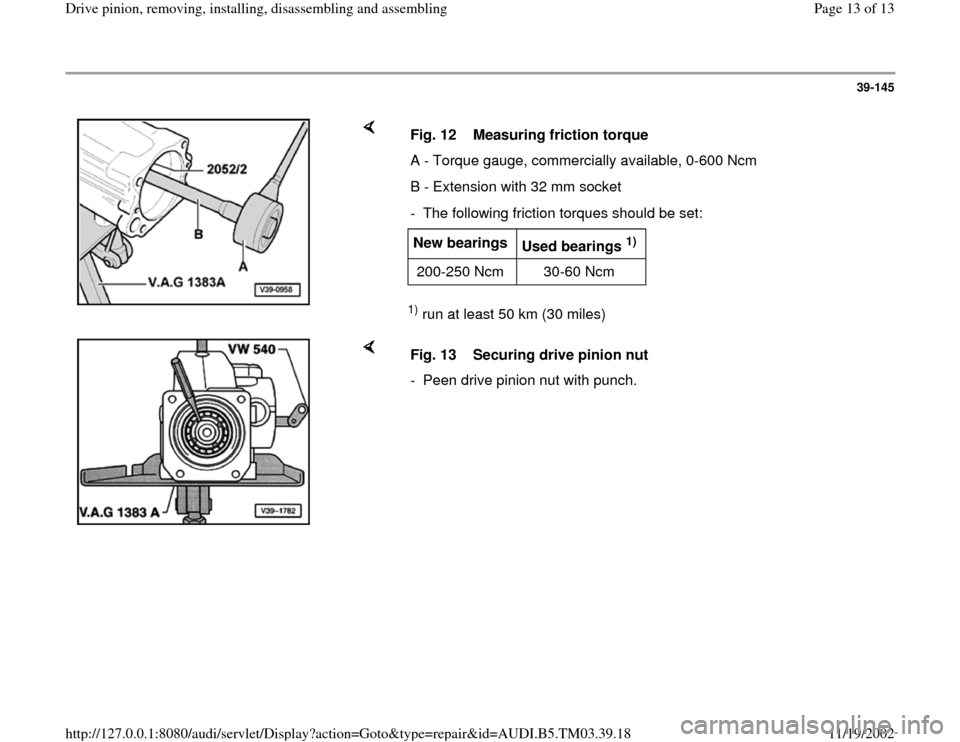

1) run at least 50 km (30 miles) Fig. 12 Measuring friction torque

A - Torque gauge, commercially available, 0-600 Ncm

B - Extension with 32 mm socket

- The following friction torques should be set:New bearings

Used bearings

1)

200-250 Ncm 30-60 Ncm

Fig. 13 Securing drive pinion nut

- Peen drive pinion nut with punch.

Pa

ge 13 of 13 Drive

pinion, removin

g, installin

g, disassemblin

g and assemblin

g

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.39.18