transmission oil AUDI A6 1999 C5 / 2.G 01E Transmission Repair Instruction Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A6, Model: AUDI A6 1999 C5 / 2.GPages: 12, PDF Size: 0.05 MB

Page 1 of 12

00-11

Repair instructions

The maximum possible care and cleanliness and

proper tools are essential to ensure satisfactory

and successful transmission repairs. The usual

basic safety precautions also, naturally apply

when carrying out vehicle repairs.

A number of generally applicable instructions for

individual repair operations, which are otherwise

mentioned at various points in the Repair

Manual, are summarized here. They apply to this

Repair Manual.

Special tools

For a complete list of special tools used in this

Repair Manual

Special Tools Catalog

Transmission

When installing a replacement transmission or

rear final drive, check oil level and top-up if

necessary Page 34

-39

and Page 39

-80

.

Vehicles with 2.7 ltr 195 kW engine:

replacement transmissions contain an

additional 0.3 ltr of oil for the lines of the

Pa

ge 1 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5

Page 2 of 12

transmission oil cooling circuit. For this reason

the transmission oil lines and oil cooler must be

drained when fitting a replacement

transmission.

Capacities and specifications from Page 00

-

3 and Page 00

-6 .

Pa

ge 2 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5

Page 3 of 12

00-12

Thoroughly clean all connections and the

surrounding area before disconnecting.

When installing transmission, ensure dowel

sleeves are correctly seated.

O-rings, seals, gaskets

Always replace O-rings, seals and gaskets.

After removing gaskets and seals, always

inspect the contact surface on the housing or

shaft for burrs resulting from removal or for

other signs of damage.

Thoroughly clean housing joint surfaces before

assembling.

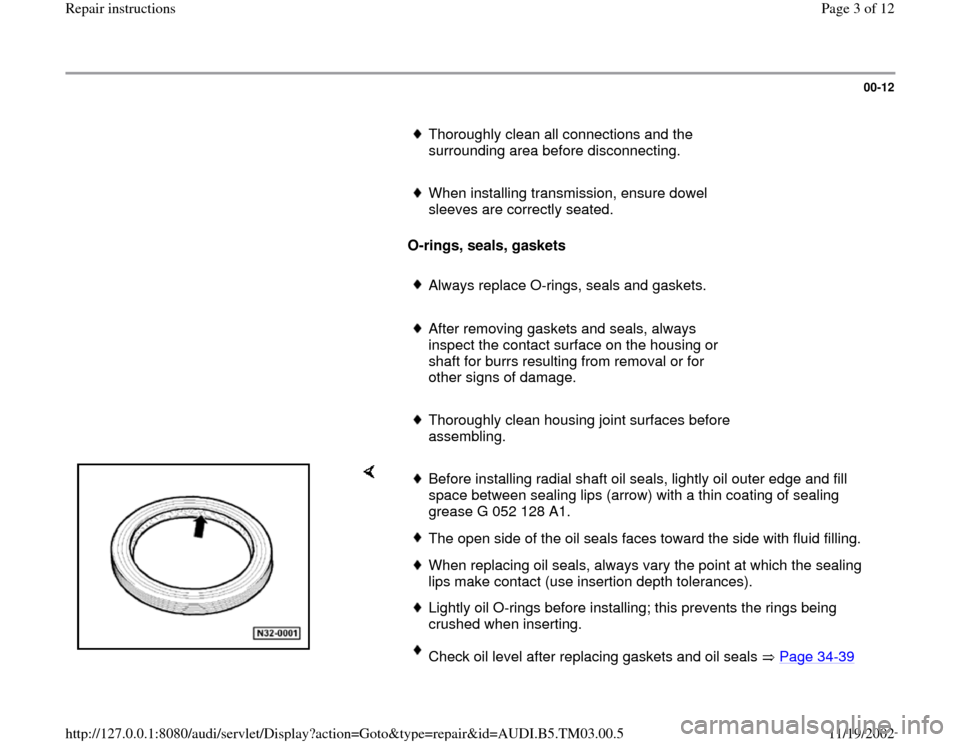

Before installing radial shaft oil seals, lightly oil outer edge and fill

space between sealing lips (arrow) with a thin coating of sealing

grease G 052 128 A1. The open side of the oil seals faces toward the side with fluid filling.When replacing oil seals, always vary the point at which the sealing

lips make contact (use insertion depth tolerances). Lightly oil O-rings before installing; this prevents the rings being

crushed when inserting. Check oil level after replacing gaskets and oil seals Page 34

-39

Pa

ge 3 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5

Page 7 of 12

00-15

Bearings

Install needle bearings with the lettering on the

bearing (the side with thicker metal) facing

towards the drift or other tool used for installing.

Mark needle bearings of 1st to 6th speed sliding

gears when removing, this ensures that when

installing, the same installation position can be

guaranteed.

Grease needle bearing for transmission input

shaft in rear of flywheel.

Lubricate all bearings in transmission housing

with gear oil before installing.

Heat inner races of tapered roller bearings to

approx. 100 C before installing. Press in onto

stop when installing so there is no axial

clearance.

Do not interchange the outer or inner races of

bearings of the same size.

Always replace the tapered roller bearings on

one shaft together and use new bearings from a

single manufacturer.

Pa

ge 7 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5

Page 8 of 12

The tapered roller bearings for the output shaft

and the differential in the transmission are low-

friction bearings. Do not additionally oil new

tapered roller bearings when measuring friction

torque. The bearings are pre-treated at the

factory with a special type of oil for this

purpose.

Pa

ge 8 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5

Page 11 of 12

00-17

Synchronizer rings

Do not interchange synchronizer rings. When

reusing always fit to the same gear.

Check for wear, replace if necessary.

Lubricate with gear oil before installing.

Clutch mechanism

When removing transmission, remove clutch

slave cylinder without disconnecting lines.

If the slave cylinder is removed with the

hydraulic line attached, do not depress clutch

pedal. Otherwise the piston will be pressed out

of the slave cylinder.

Ensure that the pressure plate is kept straight:

loosen and tighten bolts in a diagonal sequence

and in several gradual stages.

To reduce odor caused by a burnt clutch,

thoroughly clean the clutch bellhousing, the

flywheel and the parts of the engine facing the

transmission.

Pa

ge 11 of 12 Re

pair instructions

11/19/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.TM03.00.5