AUDI A6 1999 C5 / 2.G 01V Transmission Drive Pinion And Ring Gear Adjust User Guide

Manufacturer: AUDI, Model Year: 1999,

Model line: A6,

Model: AUDI A6 1999 C5 / 2.G

Pages: 38, PDF Size: 0.52 MB

AUDI A6 1999 C5 / 2.G 01V Transmission Drive Pinion And Ring Gear Adjust User Guide

A6 1999 C5 / 2.G

AUDI

AUDI

https://www.carmanualsonline.info/img/6/1191/w960_1191-0.png

AUDI A6 1999 C5 / 2.G 01V Transmission Drive Pinion And Ring Gear Adjust User Guide

Trending: check oil, engine, transmission oil, seat adjustment, torque, change time, lock

Page 11 of 38

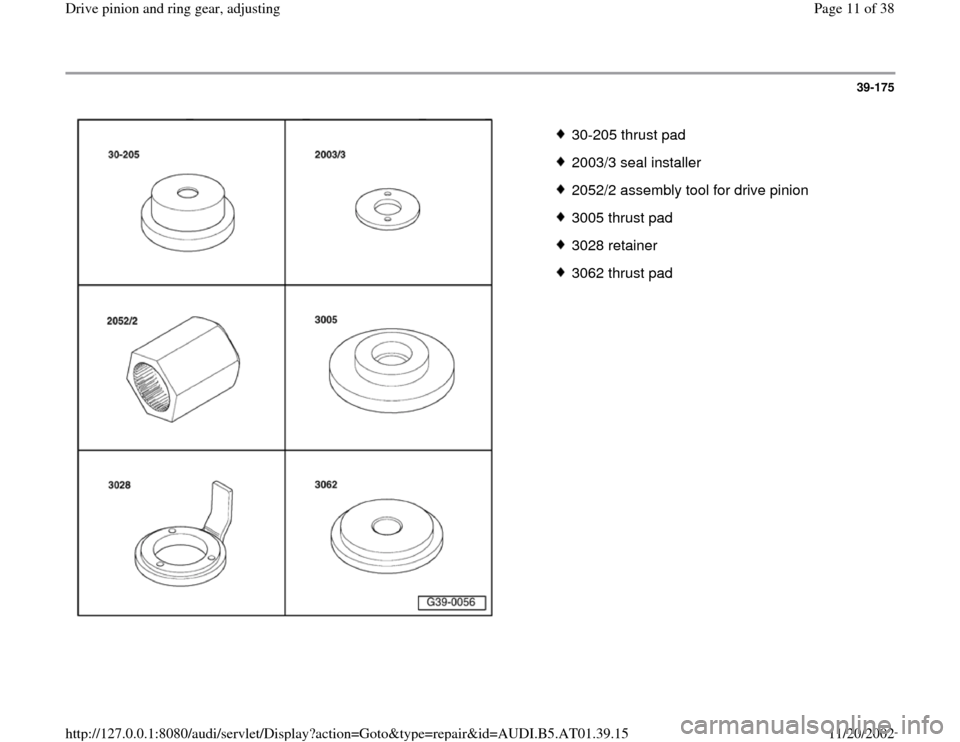

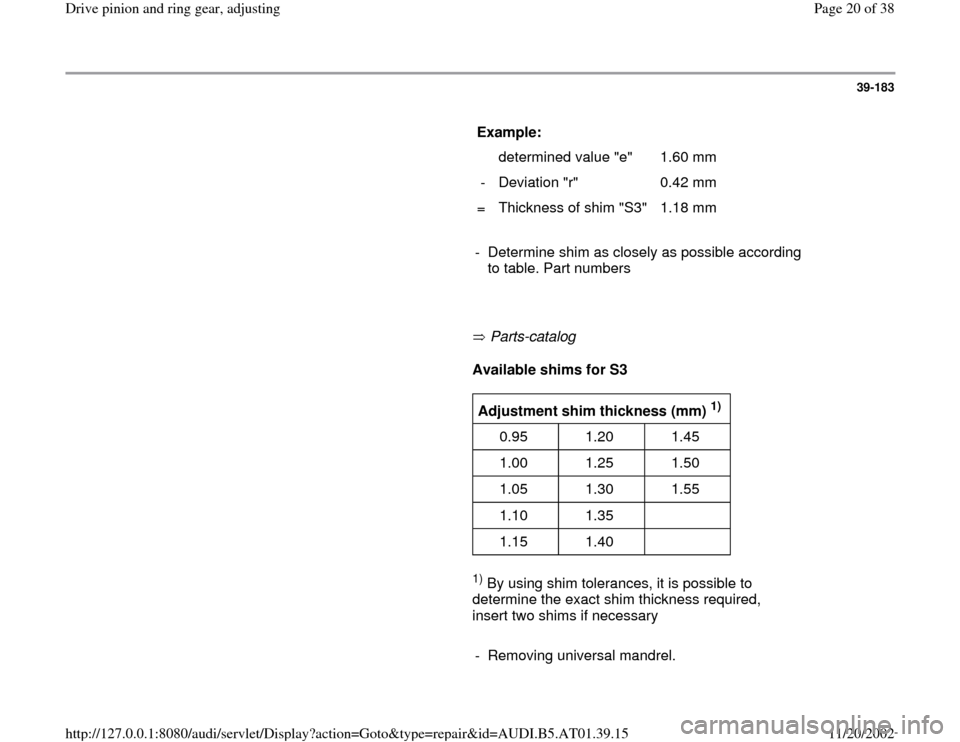

39-175

30-205 thrust pad

2003/3 seal installer

2052/2 assembly tool for drive pinion

3005 thrust pad

3028 retainer

3062 thrust pad

Pa

ge 11 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 12 of 38

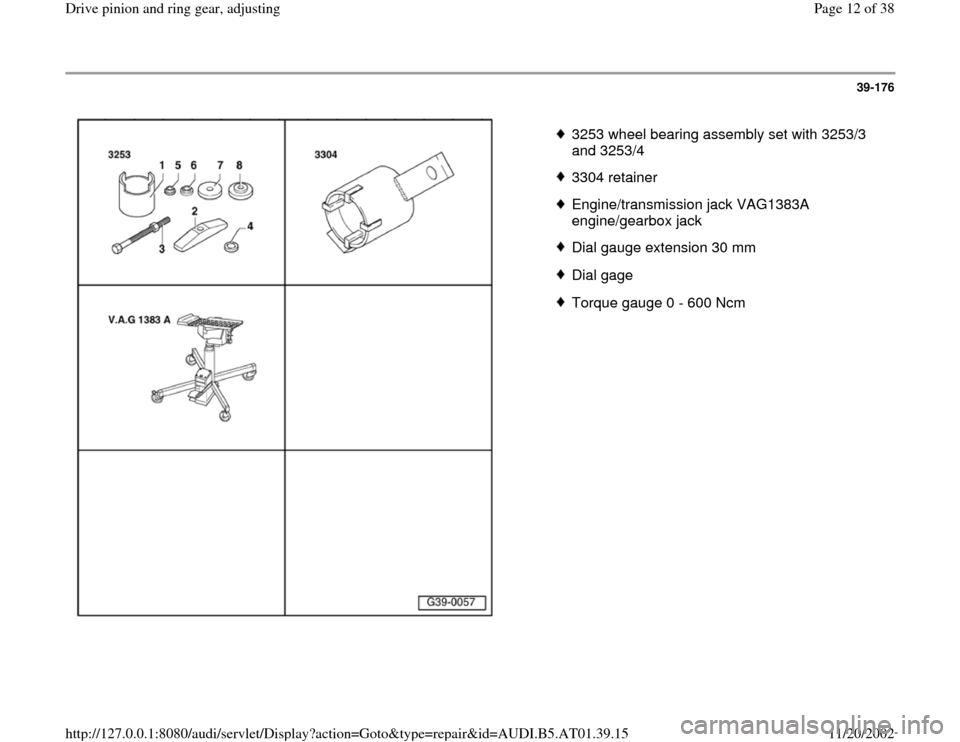

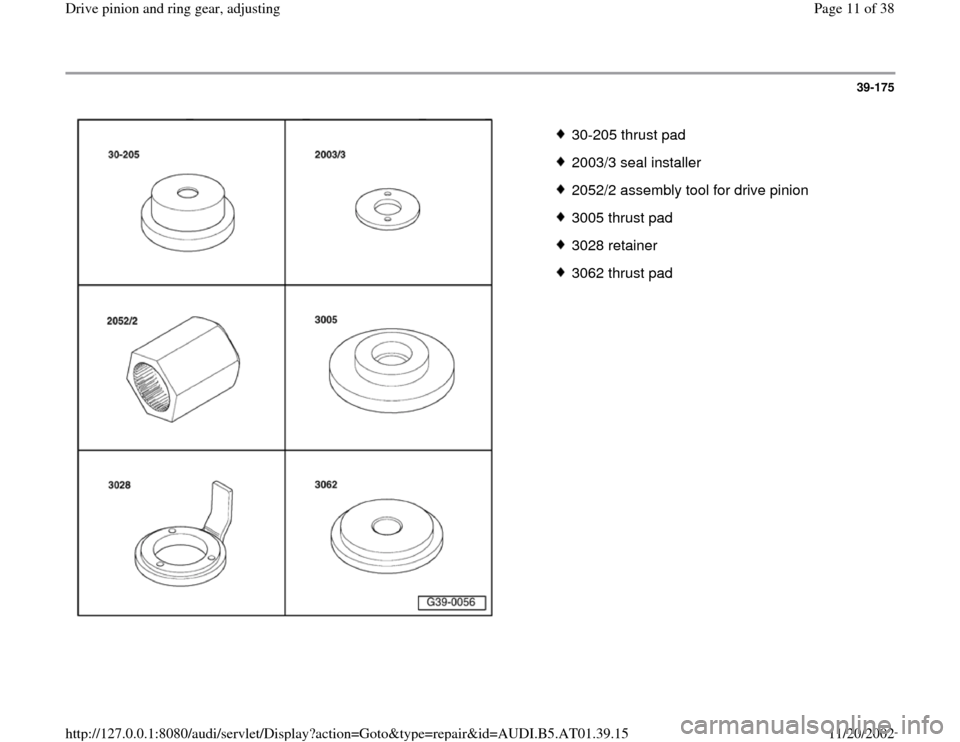

39-176

3253 wheel bearing assembly set with 3253/3

and 3253/4

3304 retainer

Engine/transmission jack VAG1383A

engine/gearbox jack

Dial gauge extension 30 mm

Dial gage

Torque gauge 0 - 600 Ncm

Pa

ge 12 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 13 of 38

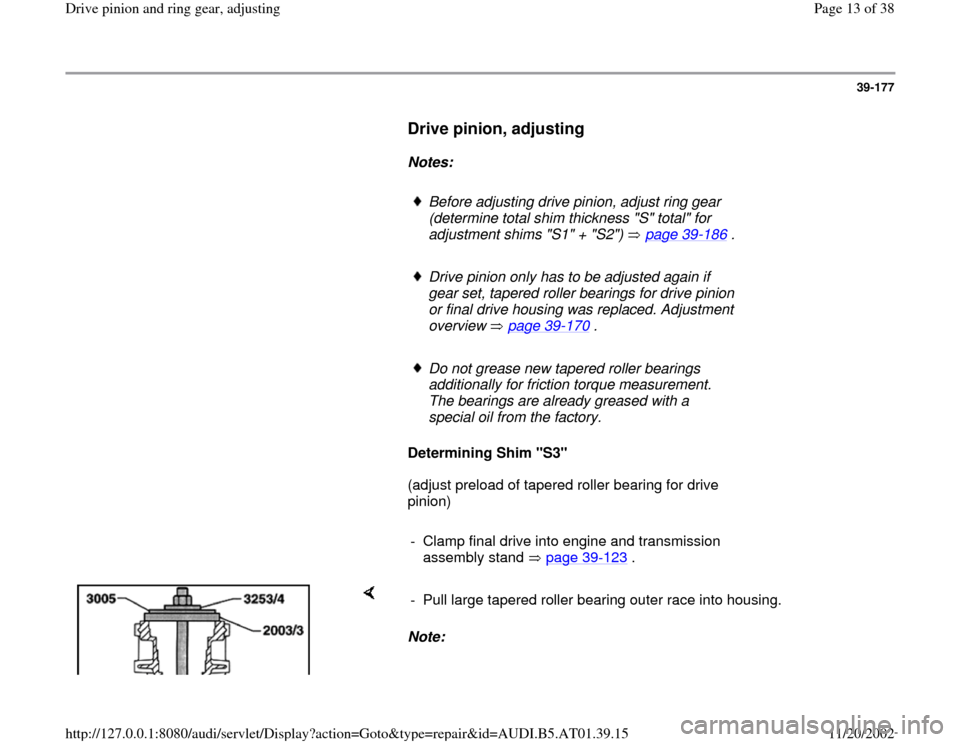

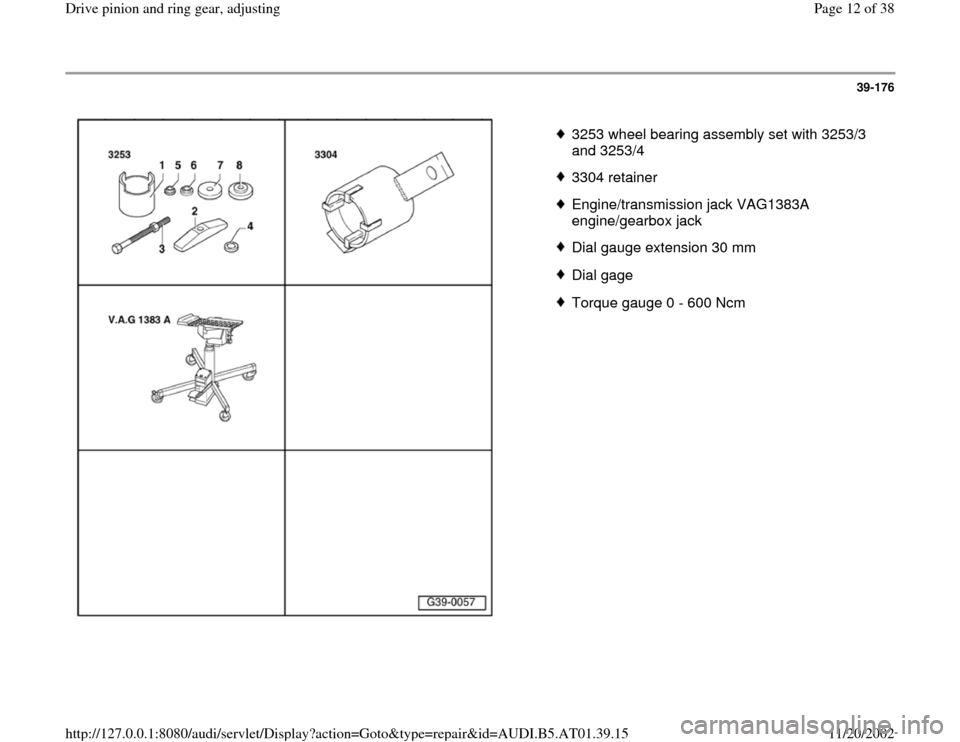

39-177

Drive pinion, adjusting

Notes:

Before adjusting drive pinion, adjust ring gear

(determine total shim thickness "S" total" for

adjustment shims "S1" + "S2") page 39

-186

.

Drive pinion only has to be adjusted again if

gear set, tapered roller bearings for drive pinion

or final drive housing was replaced. Adjustment

overview page 39

-170

.

Do not grease new tapered roller bearings

additionally for friction torque measurement.

The bearings are already greased with a

special oil from the factory.

Determining Shim "S3"

(adjust preload of tapered roller bearing for drive

pinion)

- Clamp final drive into engine and transmission

assembly stand page 39

-123

.

Note: - Pull large tapered roller bearing outer race into housing.

Pa

ge 13 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 14 of 38

On 3253/4 pressure disc, marking "Oben" points toward nut on installation

device

Pa

ge 14 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

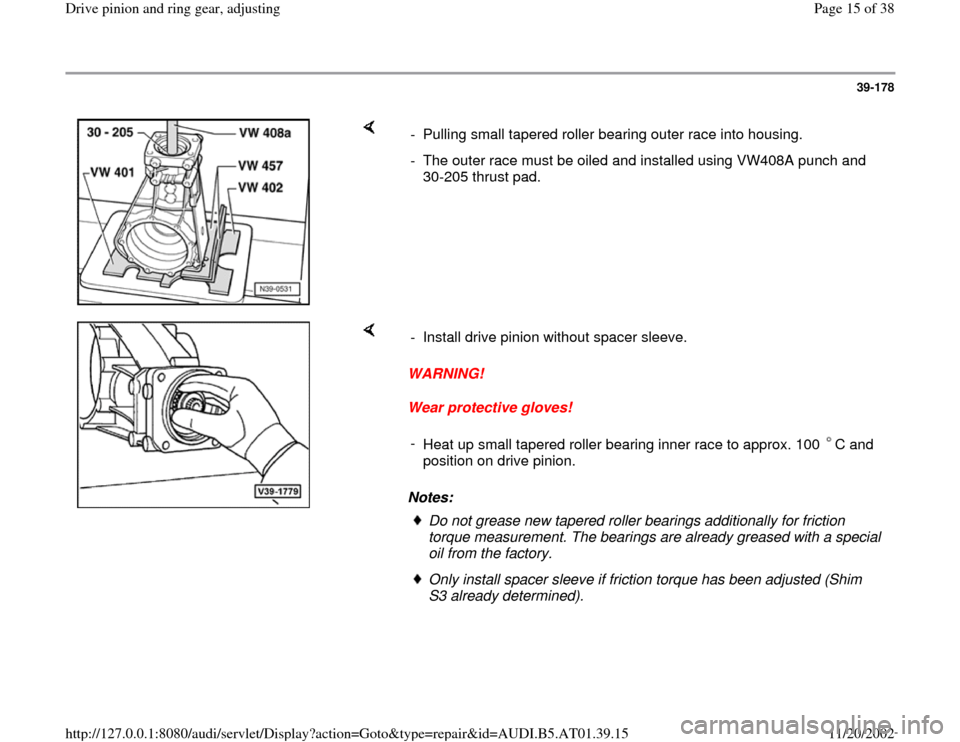

Page 15 of 38

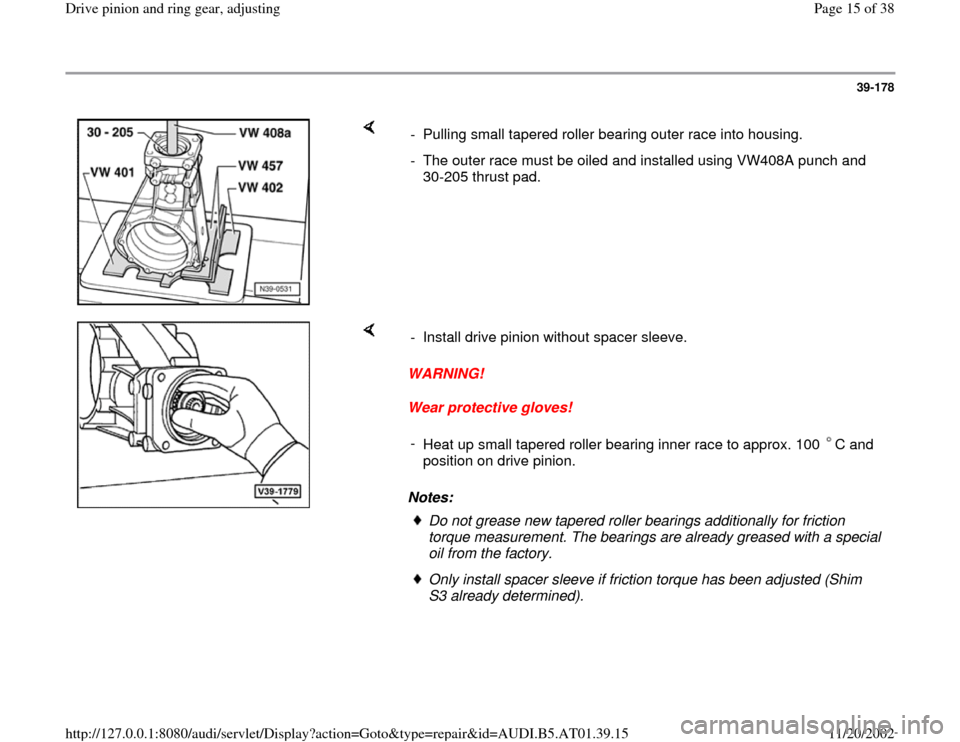

39-178

- Pulling small tapered roller bearing outer race into housing.

- The outer race must be oiled and installed using VW408A punch and

30-205 thrust pad.

WARNING!

Wear protective gloves!

Notes: - Install drive pinion without spacer sleeve.

-

Heat up small tapered roller bearing inner race to approx. 100 C and

position on drive pinion.

Do not grease new tapered roller bearings additionally for friction

torque measurement. The bearings are already greased with a special

oil from the factory. Only install spacer sleeve if friction torque has been adjusted (Shim

S3 already determined).

Pa

ge 15 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

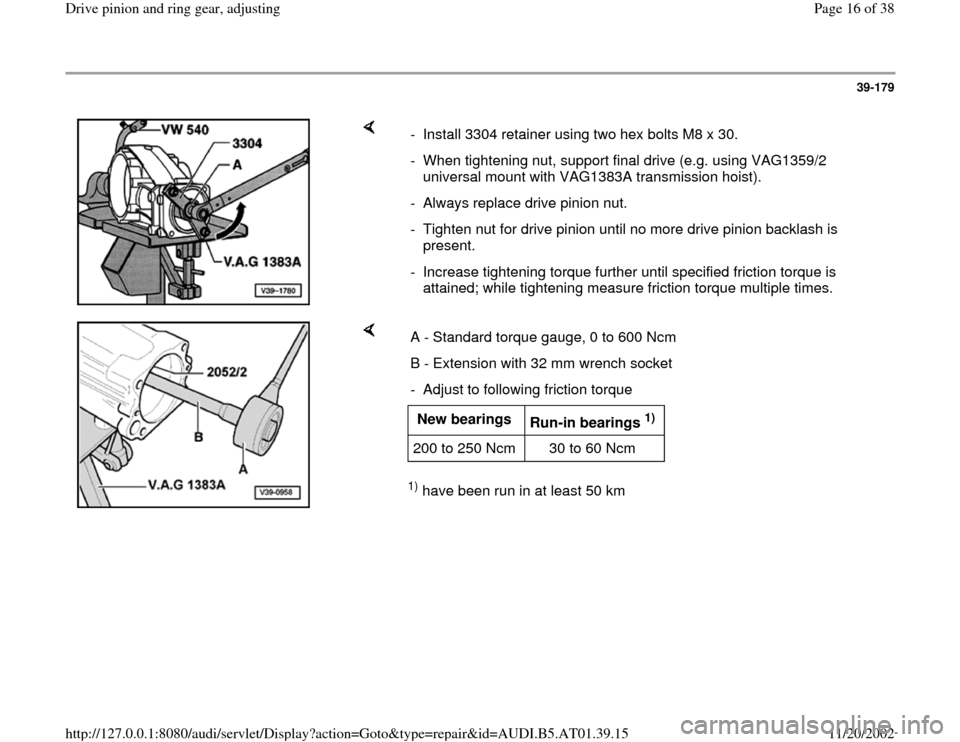

Page 16 of 38

39-179

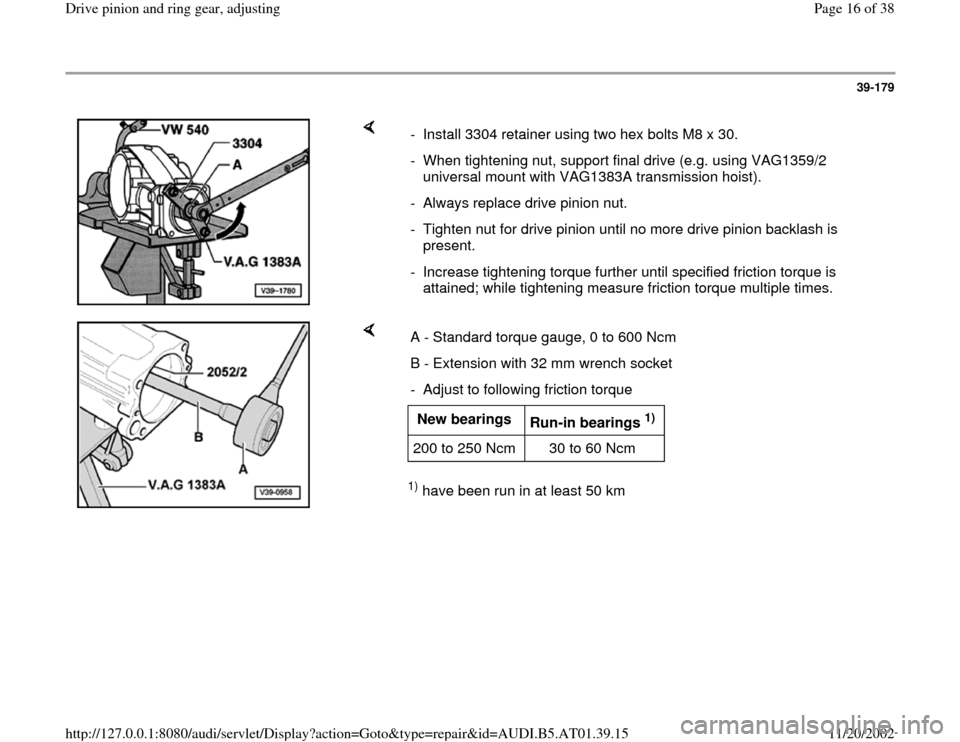

- Install 3304 retainer using two hex bolts M8 x 30.

- When tightening nut, support final drive (e.g. using VAG1359/2

universal mount with VAG1383A transmission hoist).

- Always replace drive pinion nut.

- Tighten nut for drive pinion until no more drive pinion backlash is

present.

- Increase tightening torque further until specified friction torque is

attained; while tightening measure friction torque multiple times.

1) have been run in at least 50 km A - Standard torque gauge, 0 to 600 Ncm

B - Extension with 32 mm wrench socket

- Adjust to following friction torqueNew bearings

Run-in bearings

1)

200 to 250 Ncm 30 to 60 Ncm

Pa

ge 16 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

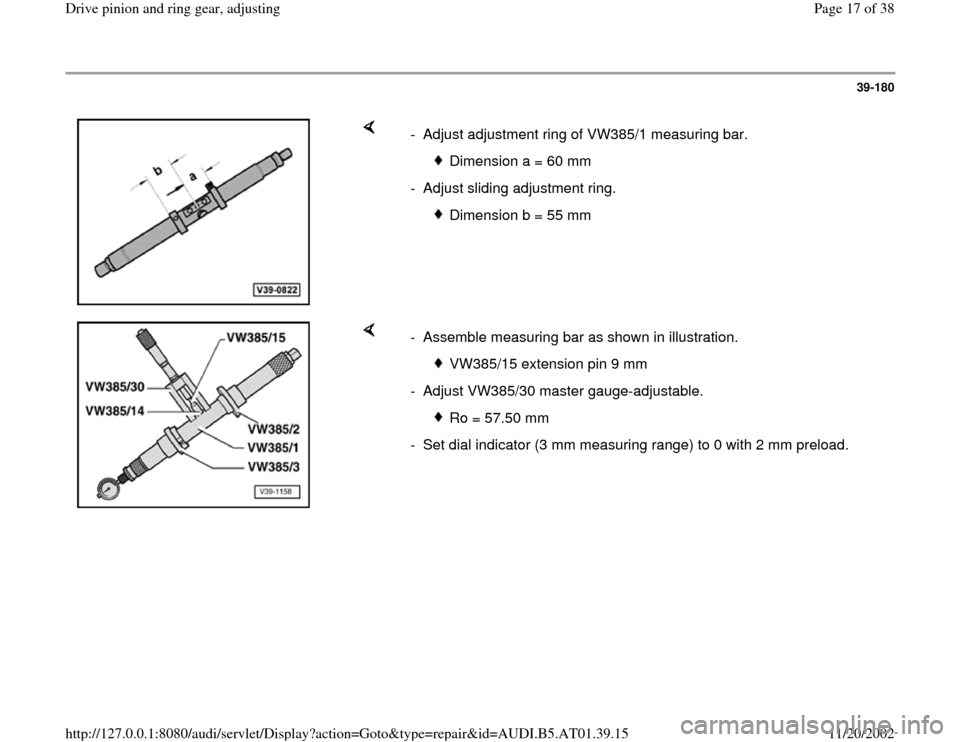

Page 17 of 38

39-180

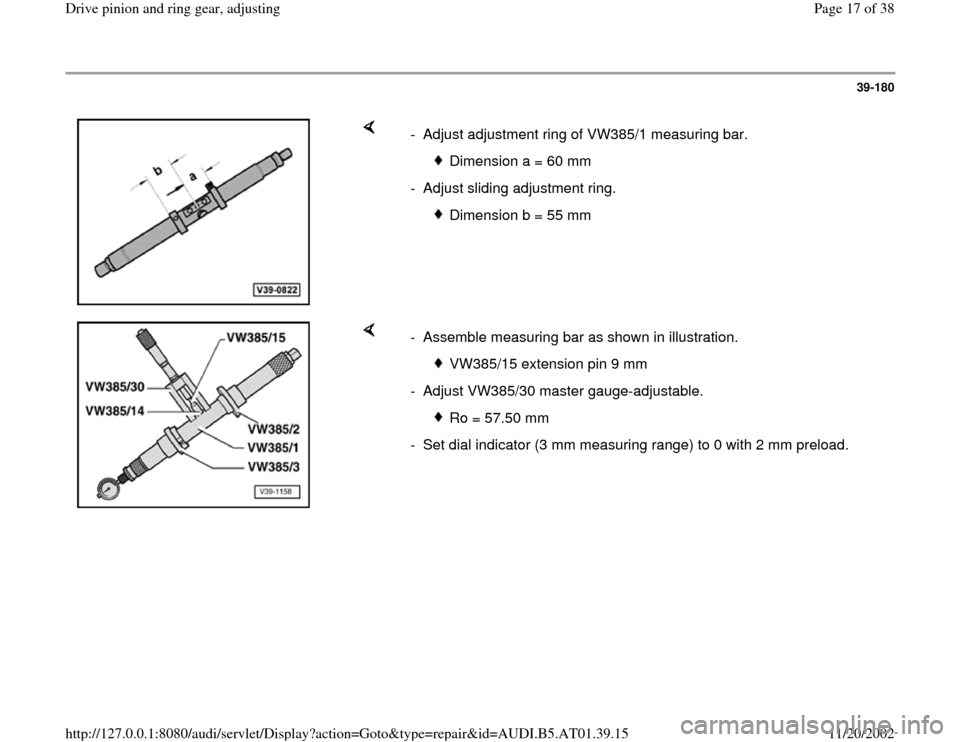

- Adjust adjustment ring of VW385/1 measuring bar.

Dimension a = 60 mm

- Adjust sliding adjustment ring.

Dimension b = 55 mm

- Assemble measuring bar as shown in illustration.

VW385/15 extension pin 9 mm

- Adjust VW385/30 master gauge-adjustable.

Ro = 57.50 mm

- Set dial indicator (3 mm measuring range) to 0 with 2 mm preload.

Pa

ge 17 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

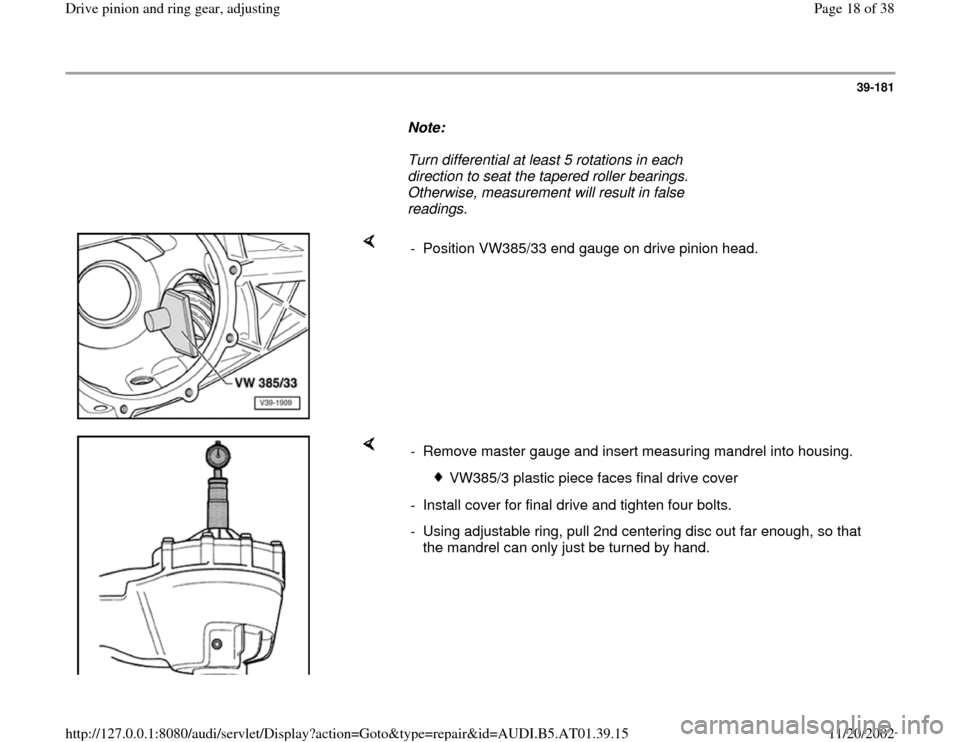

Page 18 of 38

39-181

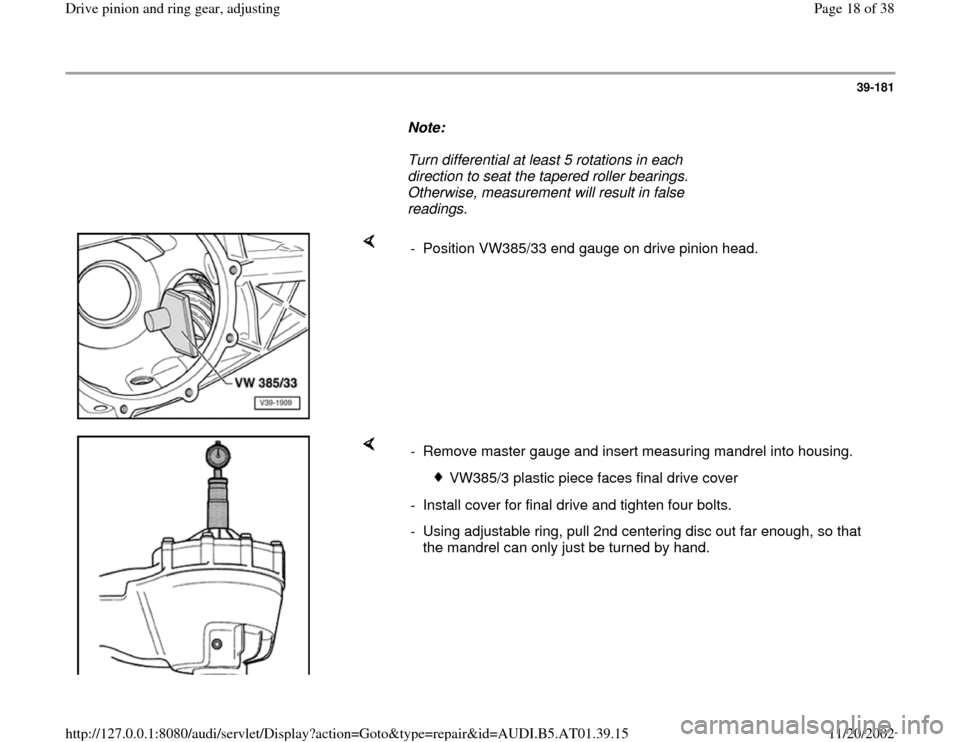

Note:

Turn differential at least 5 rotations in each

direction to seat the tapered roller bearings.

Otherwise, measurement will result in false

readings.

- Position VW385/33 end gauge on drive pinion head.

- Remove master gauge and insert measuring mandrel into housing.

VW385/3 plastic piece faces final drive cover

- Install cover for final drive and tighten four bolts.

- Using adjustable ring, pull 2nd centering disc out far enough, so that

the mandrel can only just be turned by hand.

Pa

ge 18 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 19 of 38

39-182

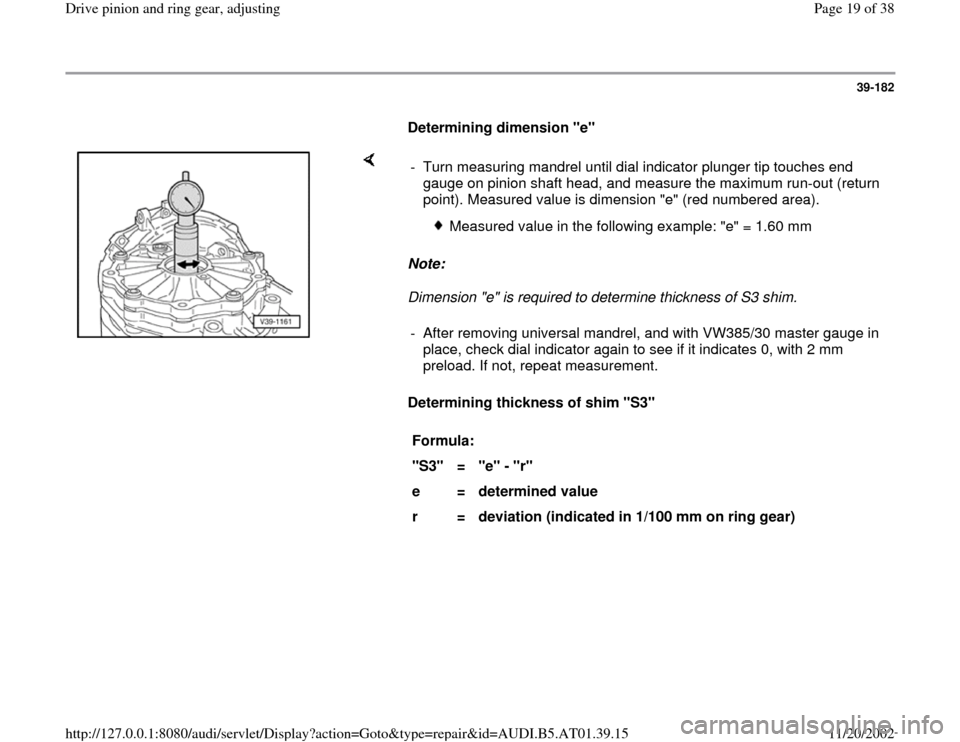

Determining dimension "e"

Note:

Dimension "e" is required to determine thickness of S3 shim.

Determining thickness of shim "S3" - Turn measuring mandrel until dial indicator plunger tip touches end

gauge on pinion shaft head, and measure the maximum run-out (return

point). Measured value is dimension "e" (red numbered area).

Measured value in the following example: "e" = 1.60 mm

- After removing universal mandrel, and with VW385/30 master gauge in

place, check dial indicator again to see if it indicates 0, with 2 mm

preload. If not, repeat measurement.

Formula:

"S3"

=

"e" - "r"

e

=

determined value

r

=

deviation (indicated in 1/100 mm on ring gear)

Pa

ge 19 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Page 20 of 38

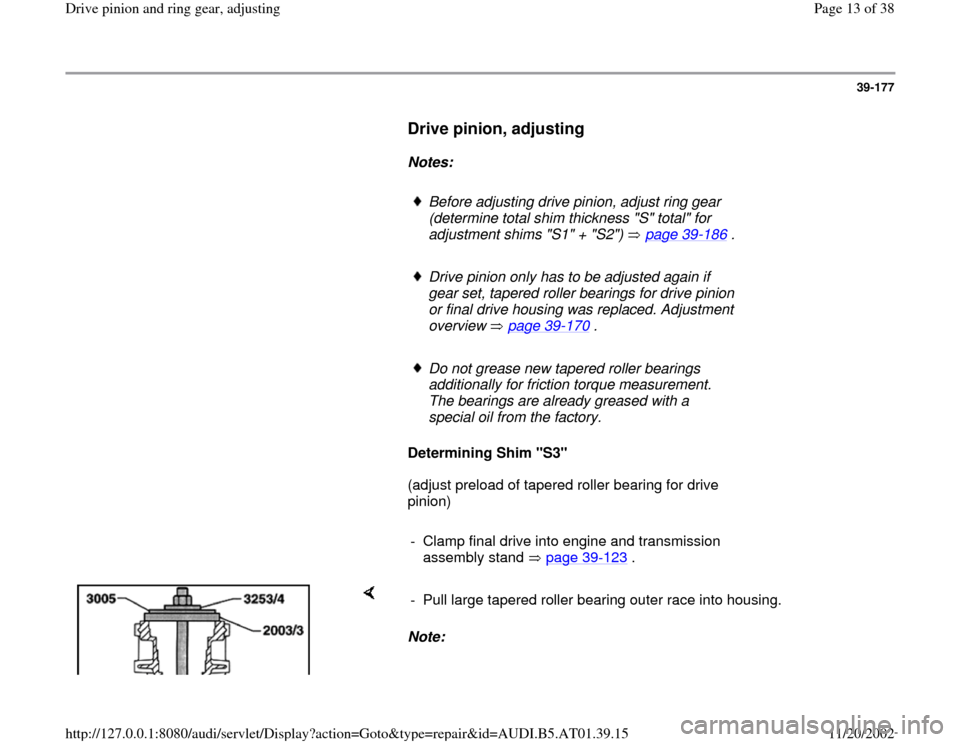

39-183

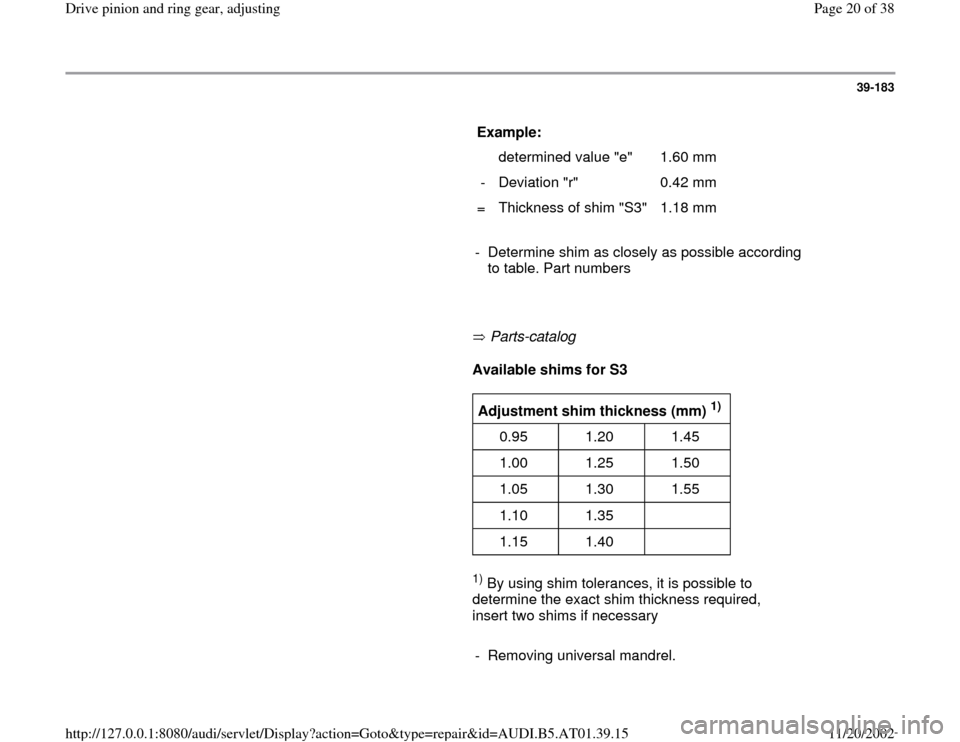

Example:

determined value "e" 1.60 mm

- Deviation "r" 0.42 mm

= Thickness of shim "S3" 1.18 mm

- Determine shim as closely as possible according

to table. Part numbers

Parts-catalog

Available shims for S3

Adjustment shim thickness (mm)

1)

0.95 1.20 1.45

1.00 1.25 1.50

1.05 1.30 1.55

1.10 1.35

1.15 1.40

1) By using shim tolerances, it is possible to

determine the exact shim thickness required,

insert two shims if necessary

- Removing universal mandrel.

Pa

ge 20 of 38 Drive

pinion and rin

g gear, ad

justin

g

11/20/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.AT01.39.15

Trending: gearbox, transmission oil, engine, lock, length, torque, tow