light AUDI A6 1999 C5 / 2.G AEB ATW Engines Valvetrain Servicing Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1999, Model line: A6, Model: AUDI A6 1999 C5 / 2.GPages: 51, PDF Size: 0.8 MB

Page 6 of 51

15-35

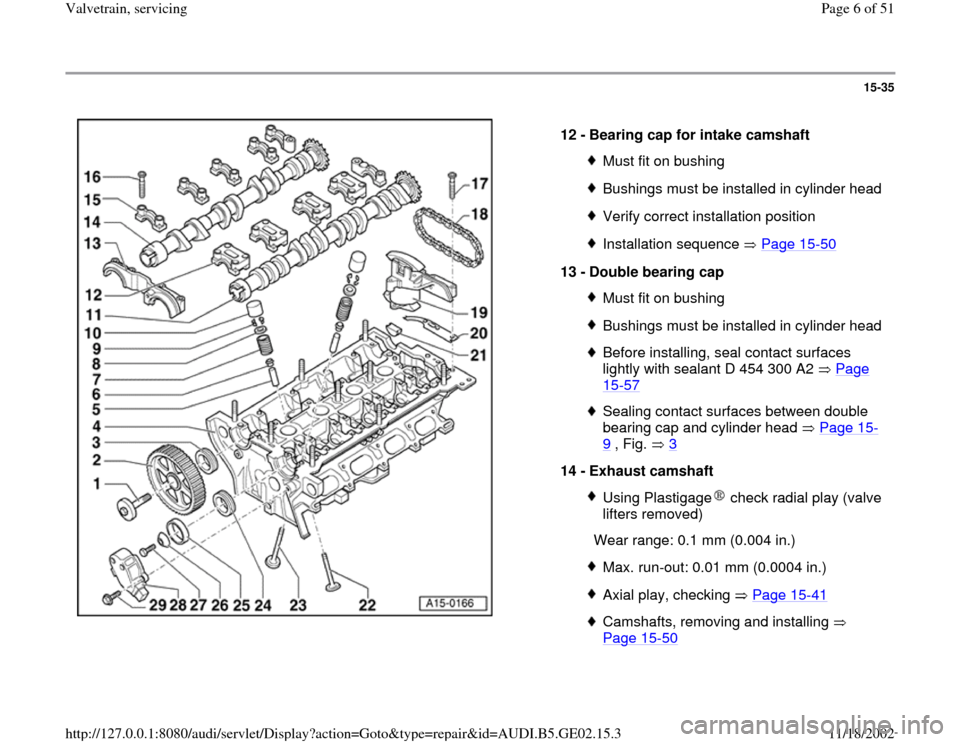

12 -

Bearing cap for intake camshaft

Must fit on bushingBushings must be installed in cylinder headVerify correct installation positionInstallation sequence Page 15

-50

13 -

Double bearing cap

Must fit on bushingBushings must be installed in cylinder headBefore installing, seal contact surfaces

lightly with sealant D 454 300 A2 Page 15

-57

Sealing contact surfaces between double

bearing cap and cylinder head Page 15

-

9 , Fig. 3

14 -

Exhaust camshaft

Using Plastigage check radial play (valve

lifters removed)

Wear range: 0.1 mm (0.004 in.)

Max. run-out: 0.01 mm (0.0004 in.)Axial play, checking Page 15

-41

Camshafts, removing and installing

Page 15

-50

Pa

ge 6 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 17 of 51

15-44

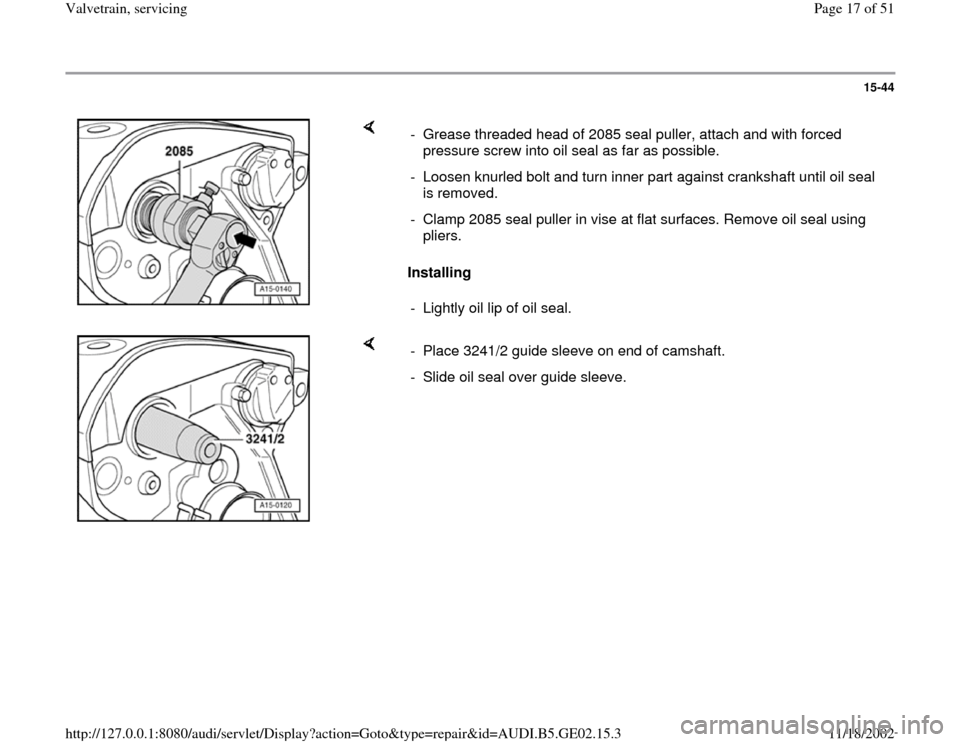

Installing - Grease threaded head of 2085 seal puller, attach and with forced

pressure screw into oil seal as far as possible.

- Loosen knurled bolt and turn inner part against crankshaft until oil seal

is removed.

- Clamp 2085 seal puller in vise at flat surfaces. Remove oil seal using

pliers.

- Lightly oil lip of oil seal.

- Place 3241/2 guide sleeve on end of camshaft.

- Slide oil seal over guide sleeve.

Pa

ge 17 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 21 of 51

15-48

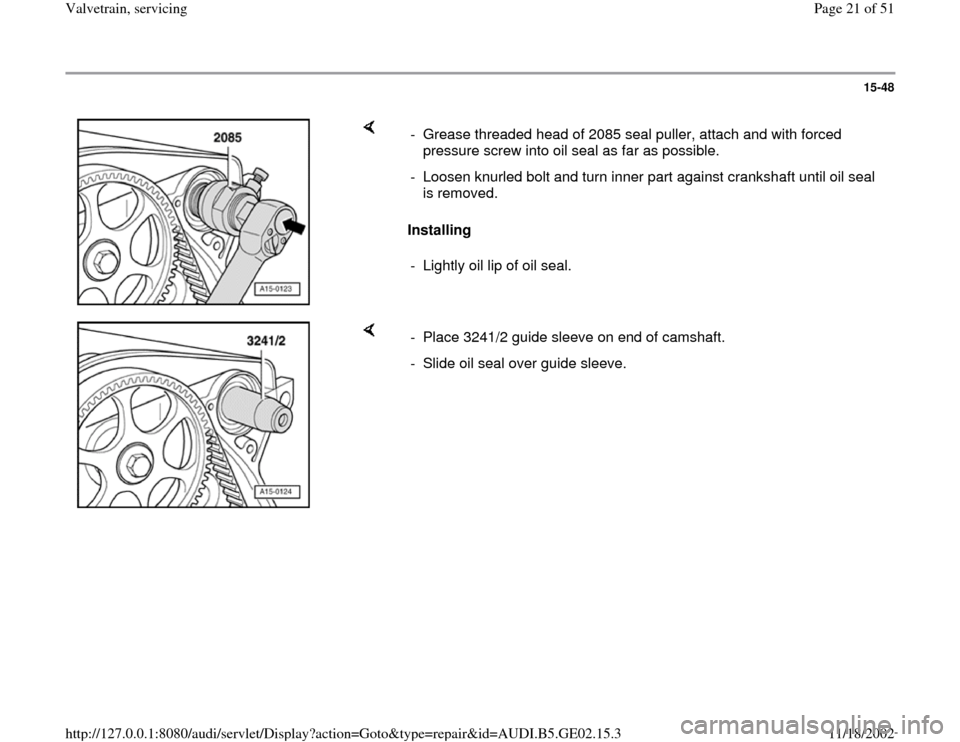

Installing - Grease threaded head of 2085 seal puller, attach and with forced

pressure screw into oil seal as far as possible.

- Loosen knurled bolt and turn inner part against crankshaft until oil seal

is removed.

- Lightly oil lip of oil seal.

- Place 3241/2 guide sleeve on end of camshaft.

- Slide oil seal over guide sleeve.

Pa

ge 21 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 26 of 51

15-52

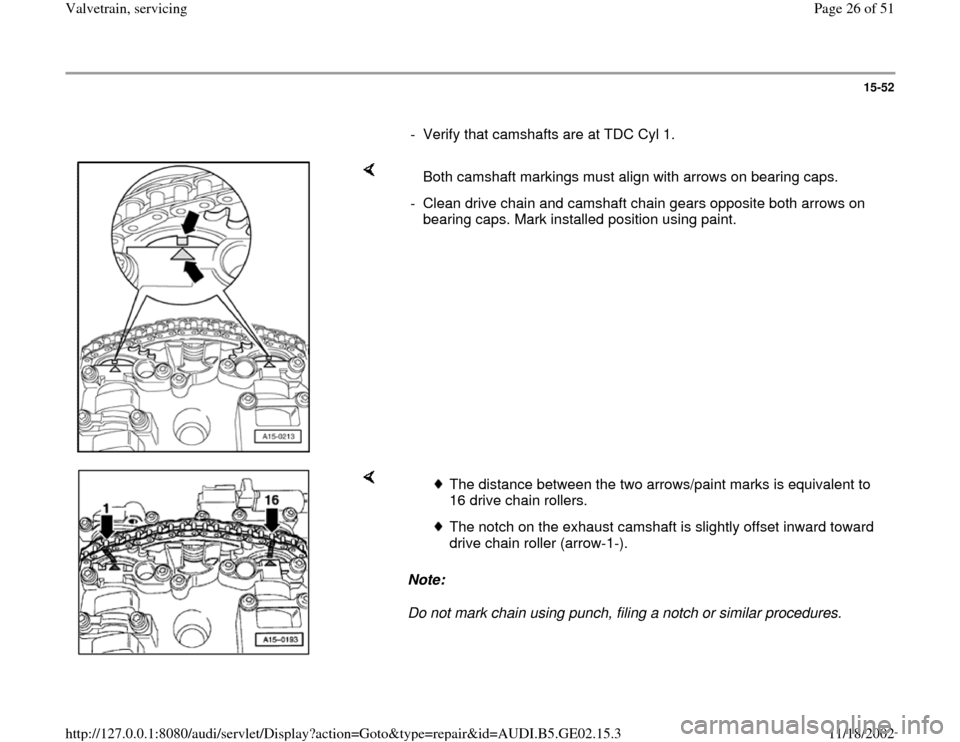

- Verify that camshafts are at TDC Cyl 1.

Both camshaft markings must align with arrows on bearing caps.

- Clean drive chain and camshaft chain gears opposite both arrows on

bearing caps. Mark installed position using paint.

Note:

Do not mark chain using punch, filing a notch or similar procedures.

The distance between the two arrows/paint marks is equivalent to

16 drive chain rollers.

The notch on the exhaust camshaft is slightly offset inward toward

drive chain roller (arrow-1-).

Pa

ge 26 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 28 of 51

15-54

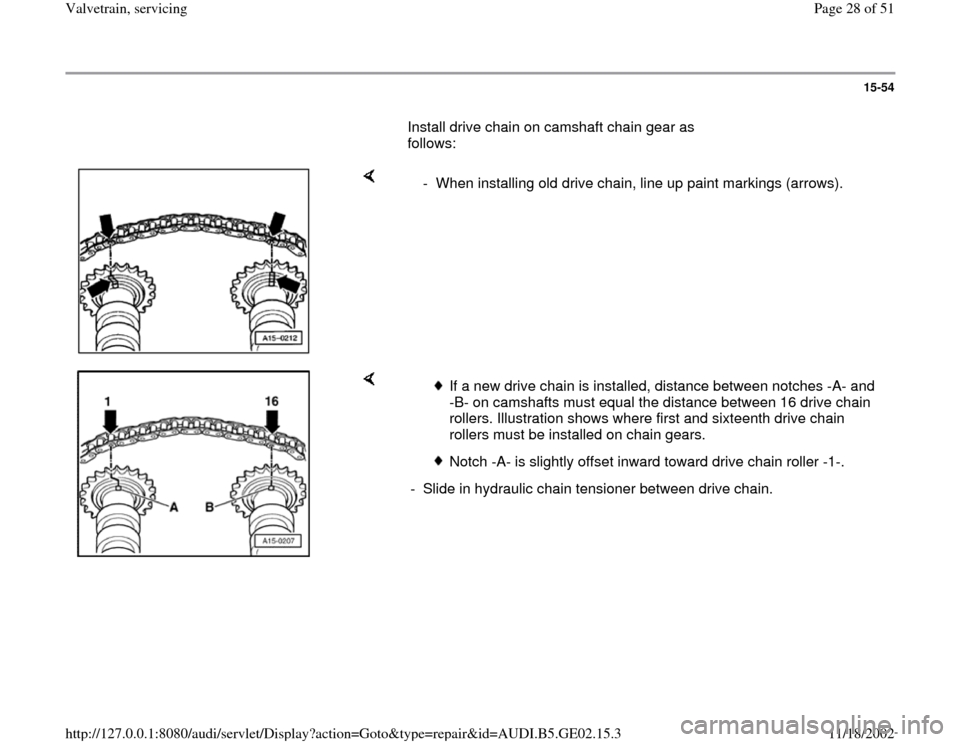

Install drive chain on camshaft chain gear as

follows:

- When installing old drive chain, line up paint markings (arrows).

If a new drive chain is installed, distance between notches -A- and

-B- on camshafts must equal the distance between 16 drive chain

rollers. Illustration shows where first and sixteenth drive chain

rollers must be installed on chain gears.

Notch -A- is slightly offset inward toward drive chain roller -1-.

- Slide in hydraulic chain tensioner between drive chain.

Pa

ge 28 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 30 of 51

15-56

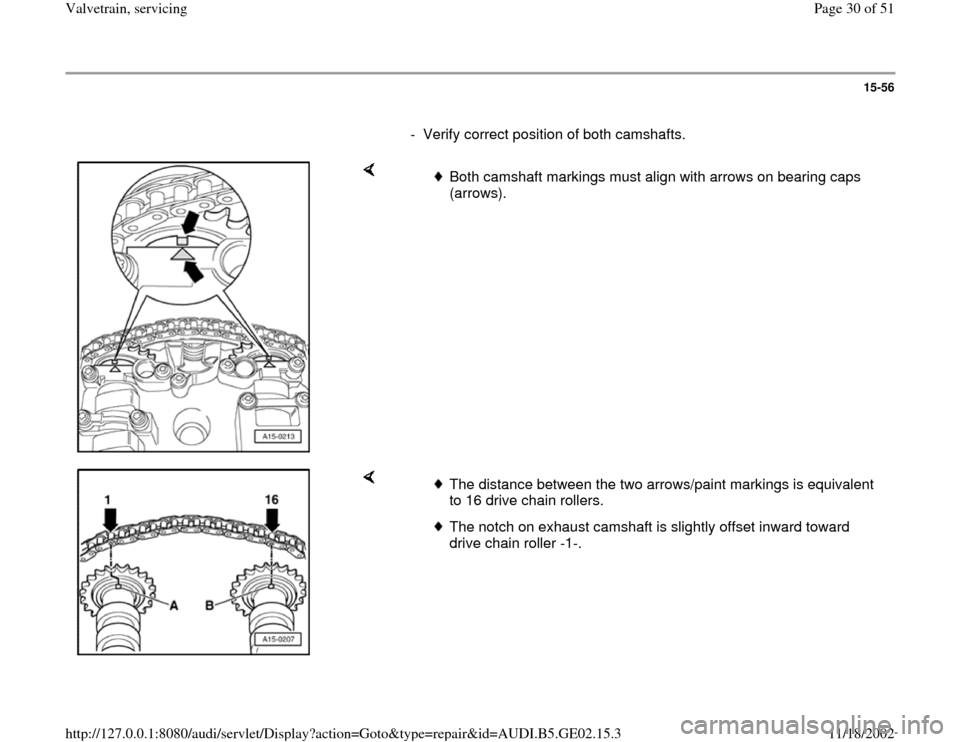

- Verify correct position of both camshafts.

Both camshaft markings must align with arrows on bearing caps

(arrows).

The distance between the two arrows/paint markings is equivalent

to 16 drive chain rollers.

The notch on exhaust camshaft is slightly offset inward toward

drive chain roller -1-.

Pa

ge 30 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 31 of 51

15-57

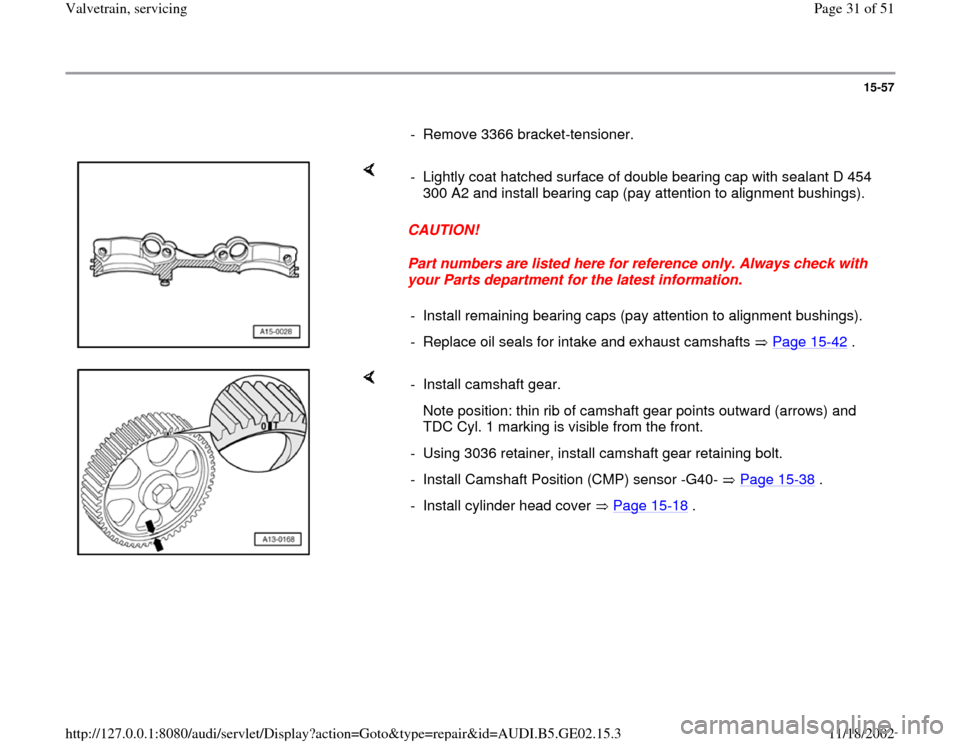

- Remove 3366 bracket-tensioner.

CAUTION!

Part numbers are listed here for reference only. Always check with

your Parts department for the latest information. - Lightly coat hatched surface of double bearing cap with sealant D 454

300 A2 and install bearing cap (pay attention to alignment bushings).

- Install remaining bearing caps (pay attention to alignment bushings).

- Replace oil seals for intake and exhaust camshafts Page 15

-42

.

- Install camshaft gear.

Note position: thin rib of camshaft gear points outward (arrows) and

TDC Cyl. 1 marking is visible from the front.

- Using 3036 retainer, install camshaft gear retaining bolt.

- Install Camshaft Position (CMP) sensor -G40- Page 15

-38

.

- Install cylinder head cover Page 15

-18

.

Pa

ge 31 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 39 of 51

15-63

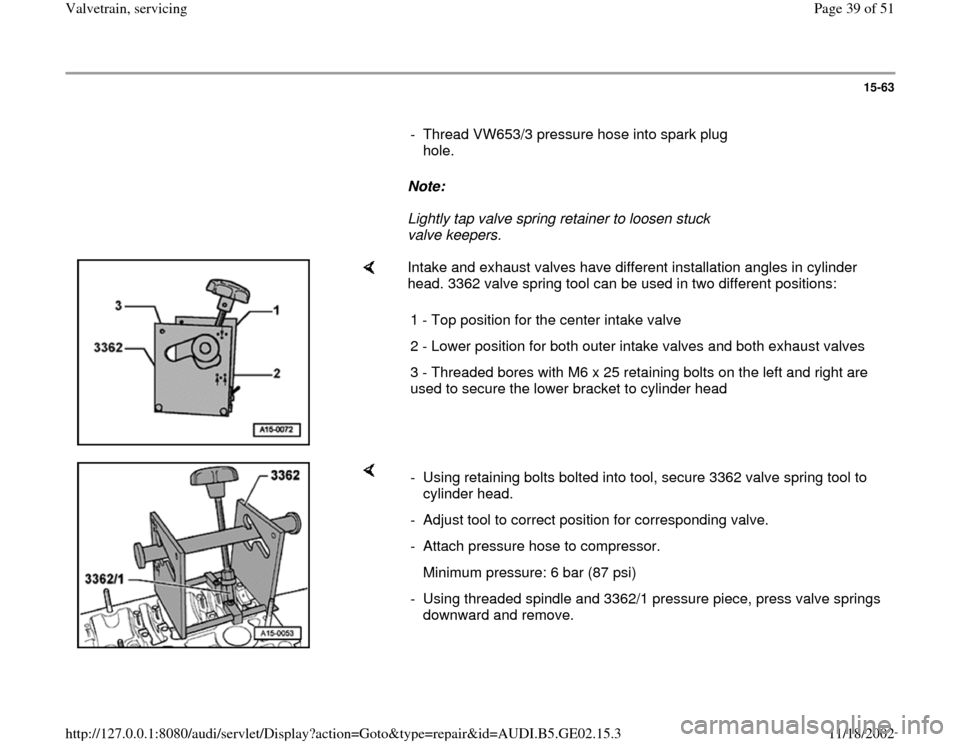

- Thread VW653/3 pressure hose into spark plug

hole.

Note:

Lightly tap valve spring retainer to loosen stuck

valve keepers.

Intake and exhaust valves have different installation angles in cylinder

head. 3362 valve spring tool can be used in two different positions:

1 - Top position for the center intake valve

2 - Lower position for both outer intake valves and both exhaust valves

3 - Threaded bores with M6 x 25 retaining bolts on the left and right are

used to secure the lower bracket to cylinder head

- Using retaining bolts bolted into tool, secure 3362 valve spring tool to

cylinder head.

- Adjust tool to correct position for corresponding valve.

- Attach pressure hose to compressor.

Minimum pressure: 6 bar (87 psi)

- Using threaded spindle and 3362/1 pressure piece, press valve springs

downward and remove.

Pa

ge 39 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3

Page 41 of 51

15-65

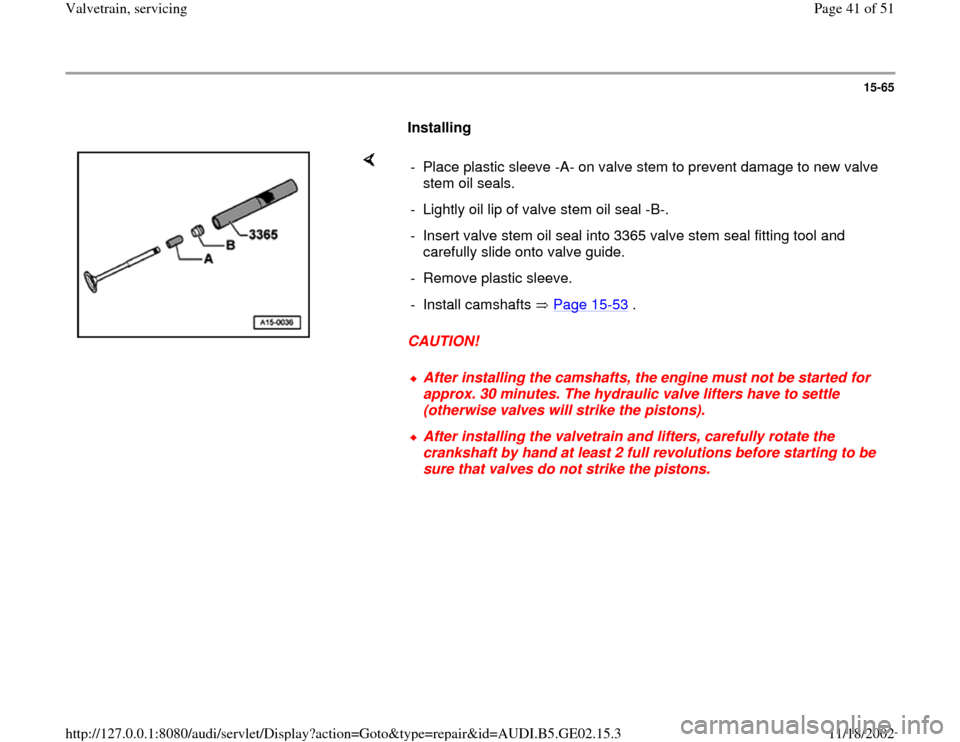

Installing

CAUTION! - Place plastic sleeve -A- on valve stem to prevent damage to new valve

stem oil seals.

- Lightly oil lip of valve stem oil seal -B-.

- Insert valve stem oil seal into 3365 valve stem seal fitting tool and

carefully slide onto valve guide.

- Remove plastic sleeve.

- Install camshafts Page 15

-53

.

After installing the camshafts, the engine must not be started for

approx. 30 minutes. The hydraulic valve lifters have to settle

(otherwise valves will strike the pistons). After installing the valvetrain and lifters, carefully rotate the

crankshaft by hand at least 2 full revolutions before starting to be

sure that valves do not strike the pistons.

Pa

ge 41 of 51 Valvetrain, servicin

g

11/18/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE02.15.3