differential AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 44 of 71

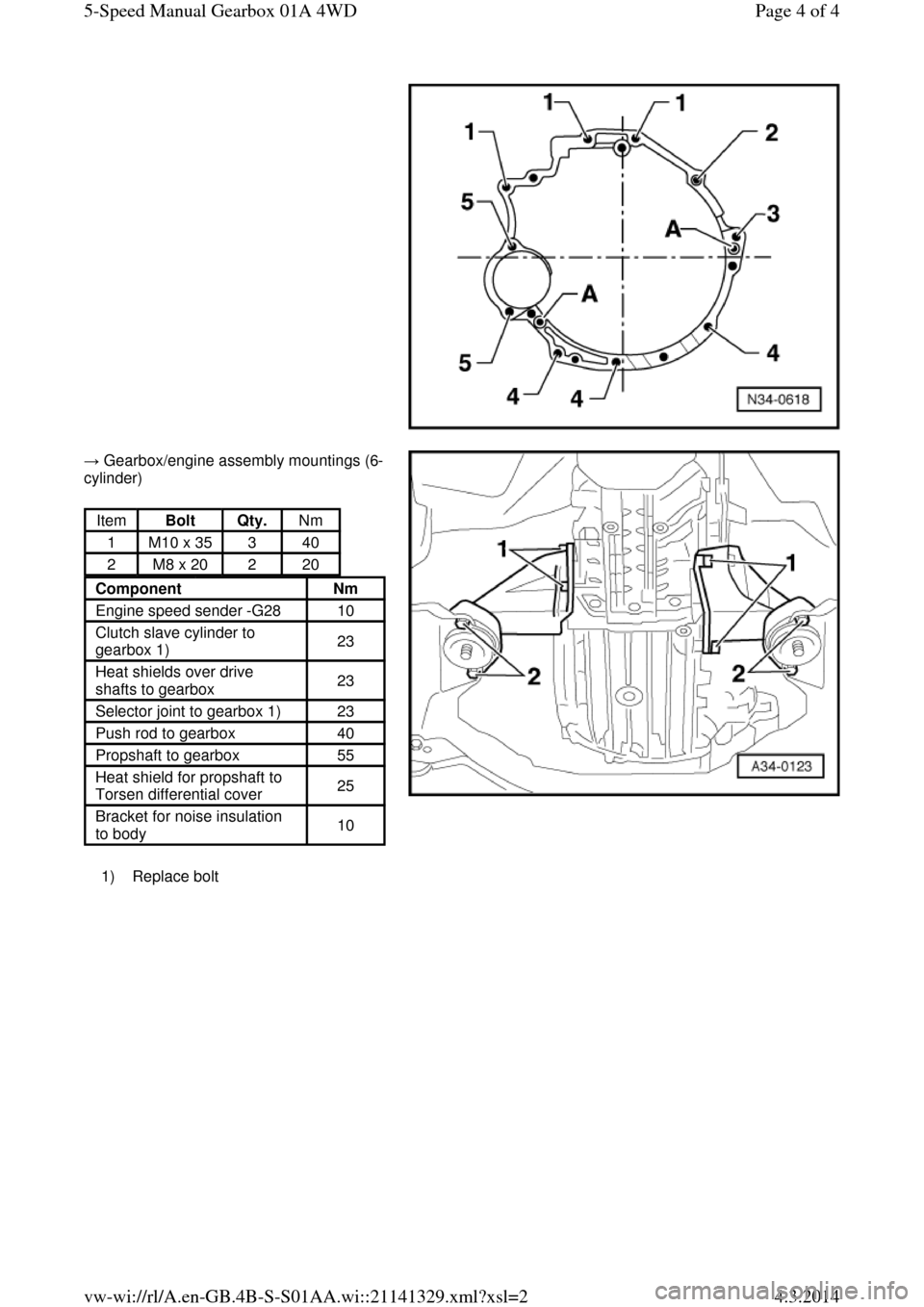

→ Gearbox/engine assembly mountings (6-

cylinder) 1) Replace bolt Item Bolt Qty. Nm

1 M10 x 35 3 40

2 M8 x 20 2 20 Component Nm

Engine speed sender -G28 10

Clutch slave cylinder to

gearbox 1) 23

Heat shields over drive

shafts to gearbox 23

Selector joint to gearbox 1) 23

Push rod to gearbox 40

Propshaft to gearbox 55

Heat shield for propshaft to

Torsen differential cover 25

Bracket for noise insulation

to body 10 Page 4 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 45 of 71

Removing and installing cover with Torsen differential Removing and installing cover with Torsen differential

● Gearbox installed

Removing

Vehicles with 4-cylinder engine:

‒ Remove rear section of exhaust system from clamp(s):

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system

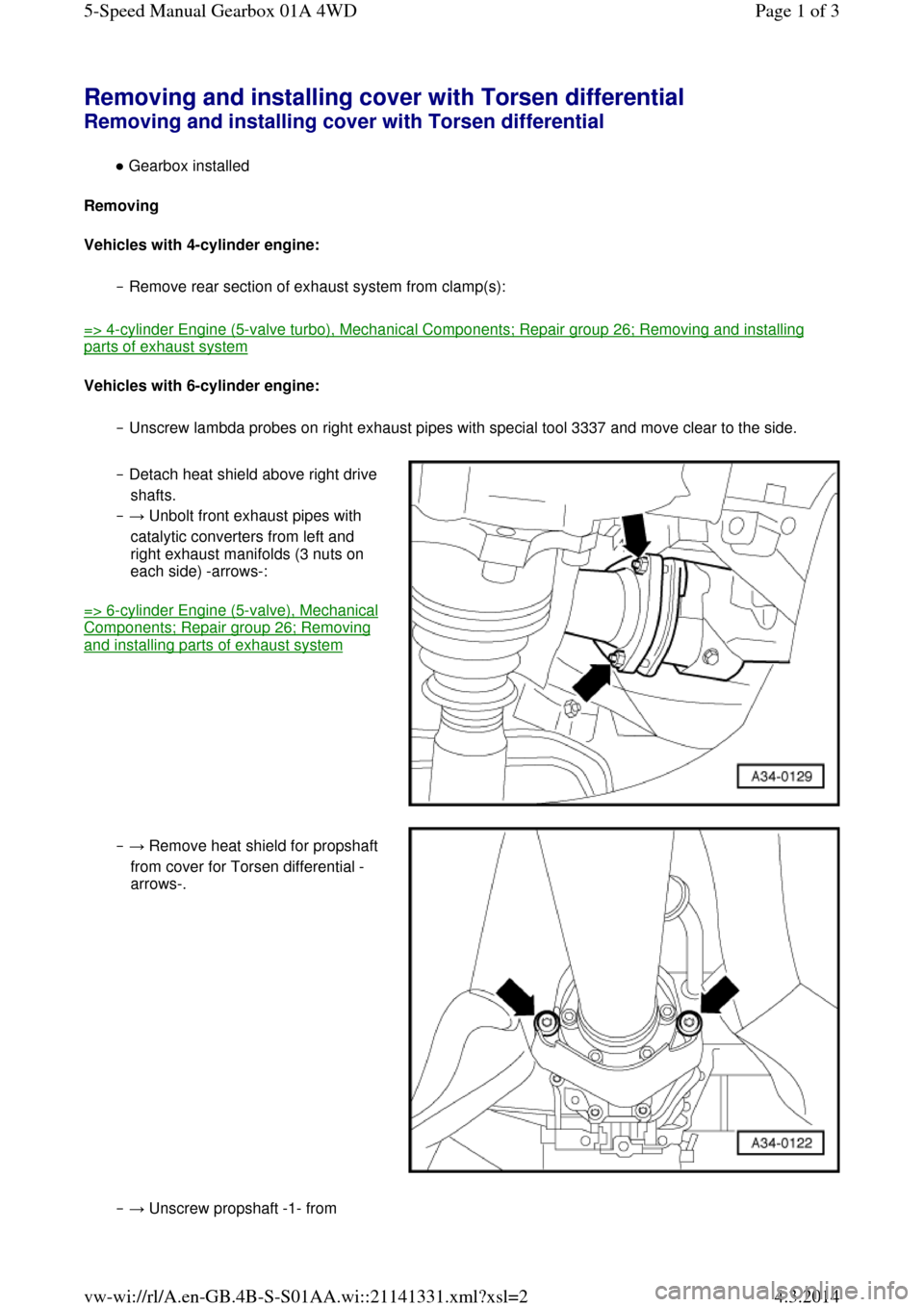

Vehicles with 6-cylinder engine:

‒ Unscrew lambda probes on right exhaust pipes with special tool 3337 and move clear to the side. ‒ Detach heat shield above right drive

shafts.

‒ → Unbolt front exhaust pipes with

catalytic converters from left and

right exhaust manifolds (3 nuts on

each side) -arrows-:

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system ‒ → Remove heat shield for propshaft

from cover for Torsen differential -

arrows-. ‒ → Unscrew propshaft -1- from Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141331.xml?xsl=2

Page 46 of 71

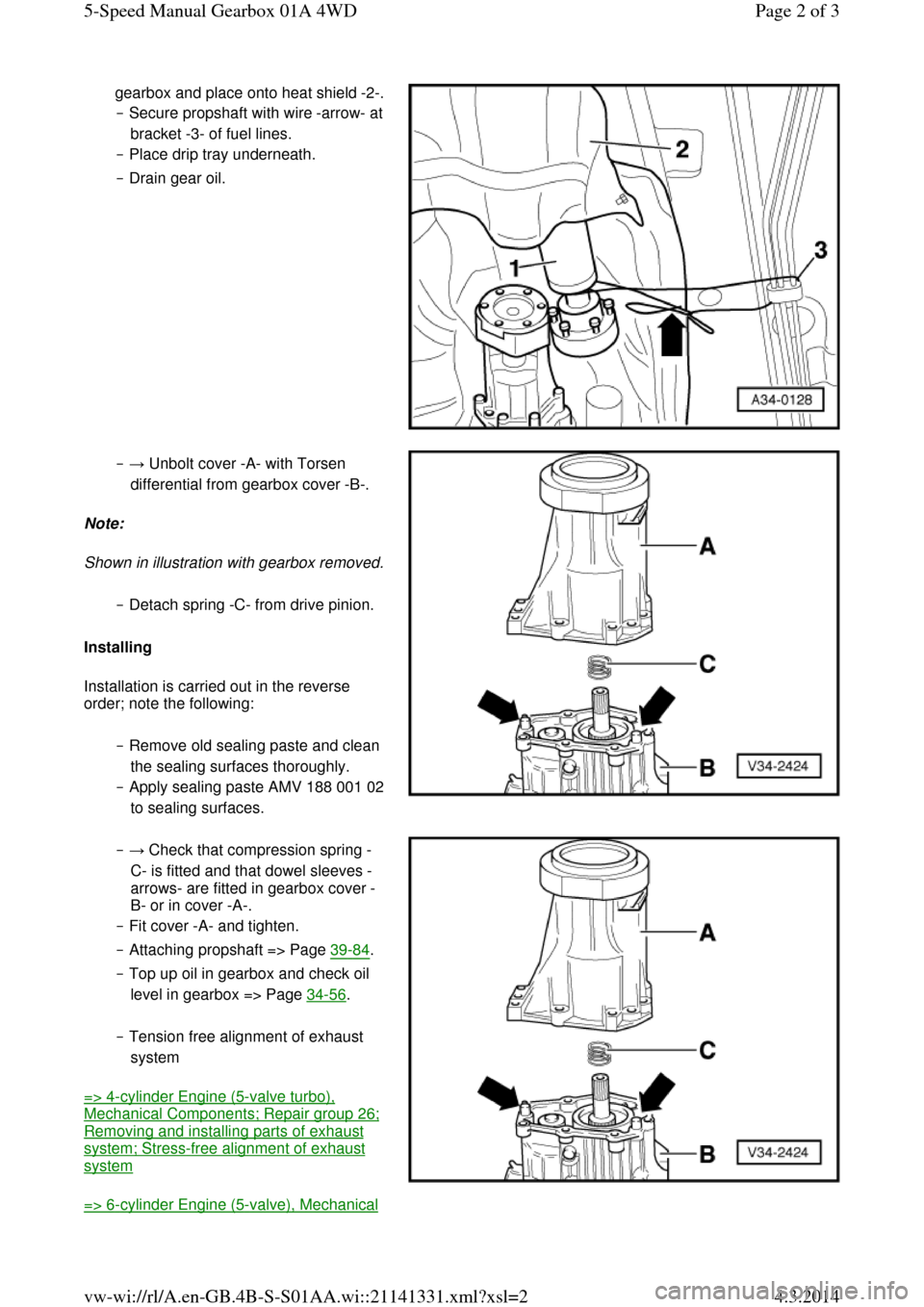

gearbox and place onto heat shield -2-. ‒ Secure propshaft with wire -arrow- at bracket -3- of fuel lines.

‒ Place drip tray underneath.

‒ Drain gear oil. ‒ → Unbolt cover -A- with Torsen

differential from gearbox cover -B-.

Note:

Shown in illustration with gearbox removed. ‒ Detach spring -C- from drive pinion.

Installing

Installation is carried out in the reverse

order; note the following:

‒ Remove old sealing paste and clean

the sealing surfaces thoroughly.

‒ Apply sealing paste AMV 188 001 02 to sealing surfaces. ‒ → Check that compression spring -

C- is fitted and that dowel sleeves -

arrows- are fitted in gearbox cover -

B- or in cover -A-.

‒ Fit cover -A- and tighten.

‒ Attaching propshaft => Page 39-84.

‒ Top up oil in gearbox and check oil

level in gearbox => Page 34-56.

‒ Tension free alignment of exhaust

system

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141331.xml?xsl=2

Page 47 of 71

Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

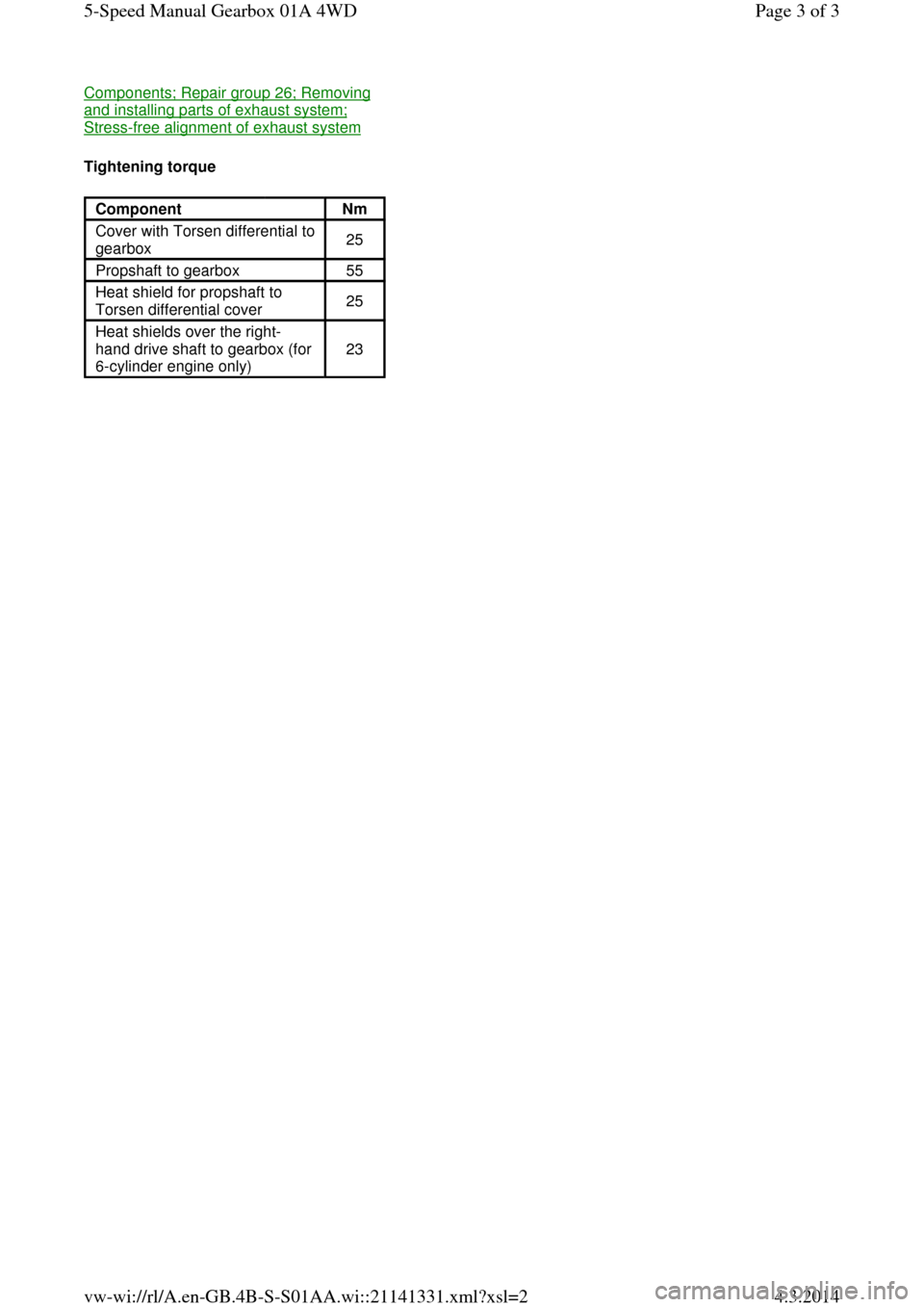

Tightening torque

Component Nm

Cover with Torsen differential to

gearbox 25

Propshaft to gearbox 55

Heat shield for propshaft to

Torsen differential cover 25

Heat shields over the right-

hand drive shaft to gearbox (for

6-cylinder engine only) 23 Page 3 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141331.xml?xsl=2

Page 54 of 71

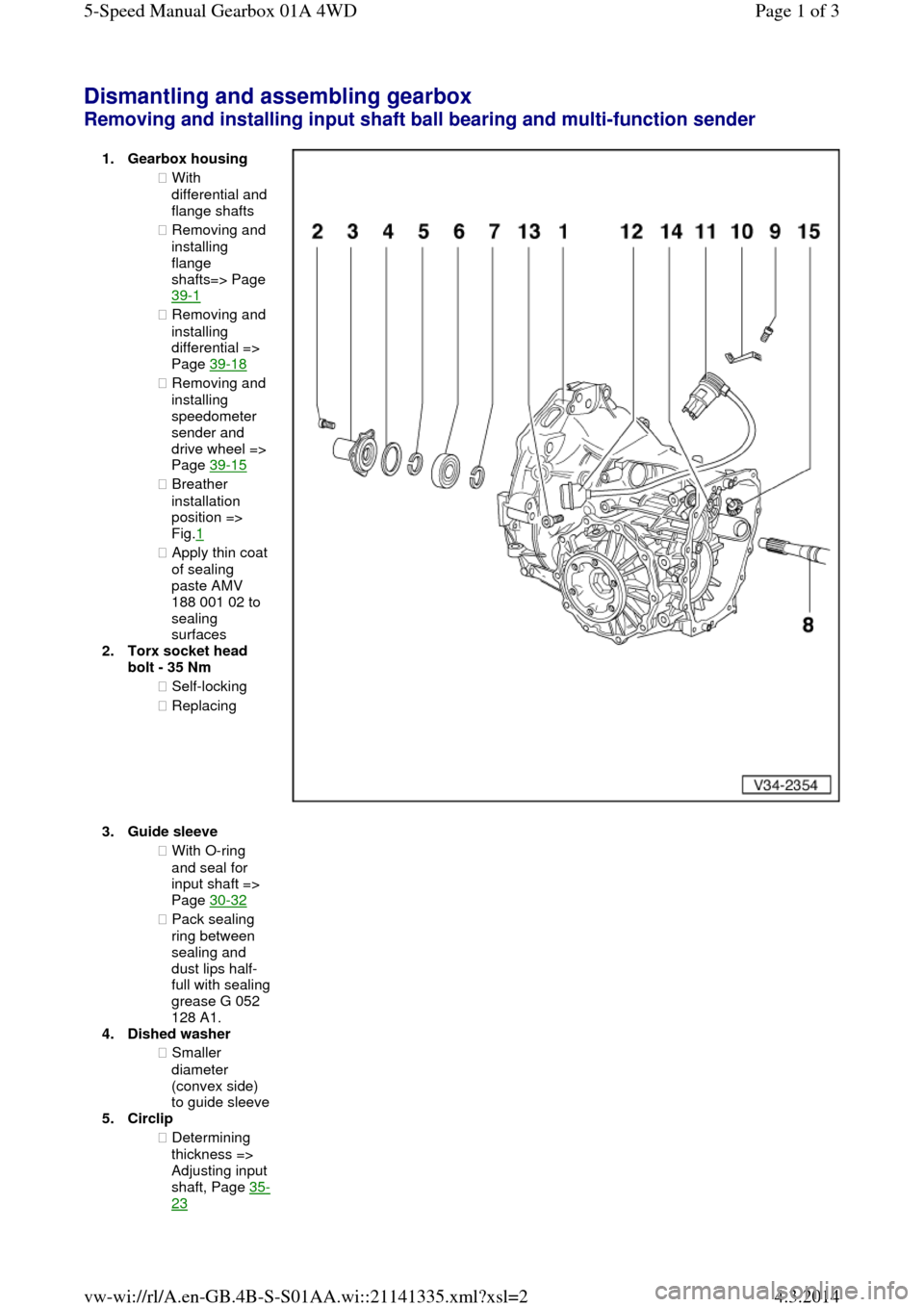

Dismantling and assembling gearbox Removing and installing input shaft ball bearing and multi-function sender 1.Gearbox housing ◆ With differential and flange shafts

◆ Removing and

installing

flange

shafts=> Page

39-1

◆ Removing and

installing

differential =>

Page 39-18

◆ Removing and

installing

speedometer

sender and

drive wheel =>

Page 39-15

◆ Breather

installation

position =>

Fig.1

◆ Apply thin coat of sealing

paste AMV

188 001 02 to

sealing

surfaces

2.Torx socket head

bolt - 35 Nm

◆ Self-locking

◆ Replacing

3.Guide sleeve ◆ With O-ring

and seal for

input shaft =>

Page 30-32

◆ Pack sealing

ring between

sealing and

dust lips half-full with sealing grease G 052

128 A1.

4.Dished washer

◆ Smaller

diameter

(convex side) to guide sleeve 5.Circlip

◆ Determining

thickness => Adjusting input shaft, Page 35-23 Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141335.xml?xsl=2

Page 57 of 71

Dismantling and assembling gearbox Removing and installing input shaft ball bearing, multi-function sender, input

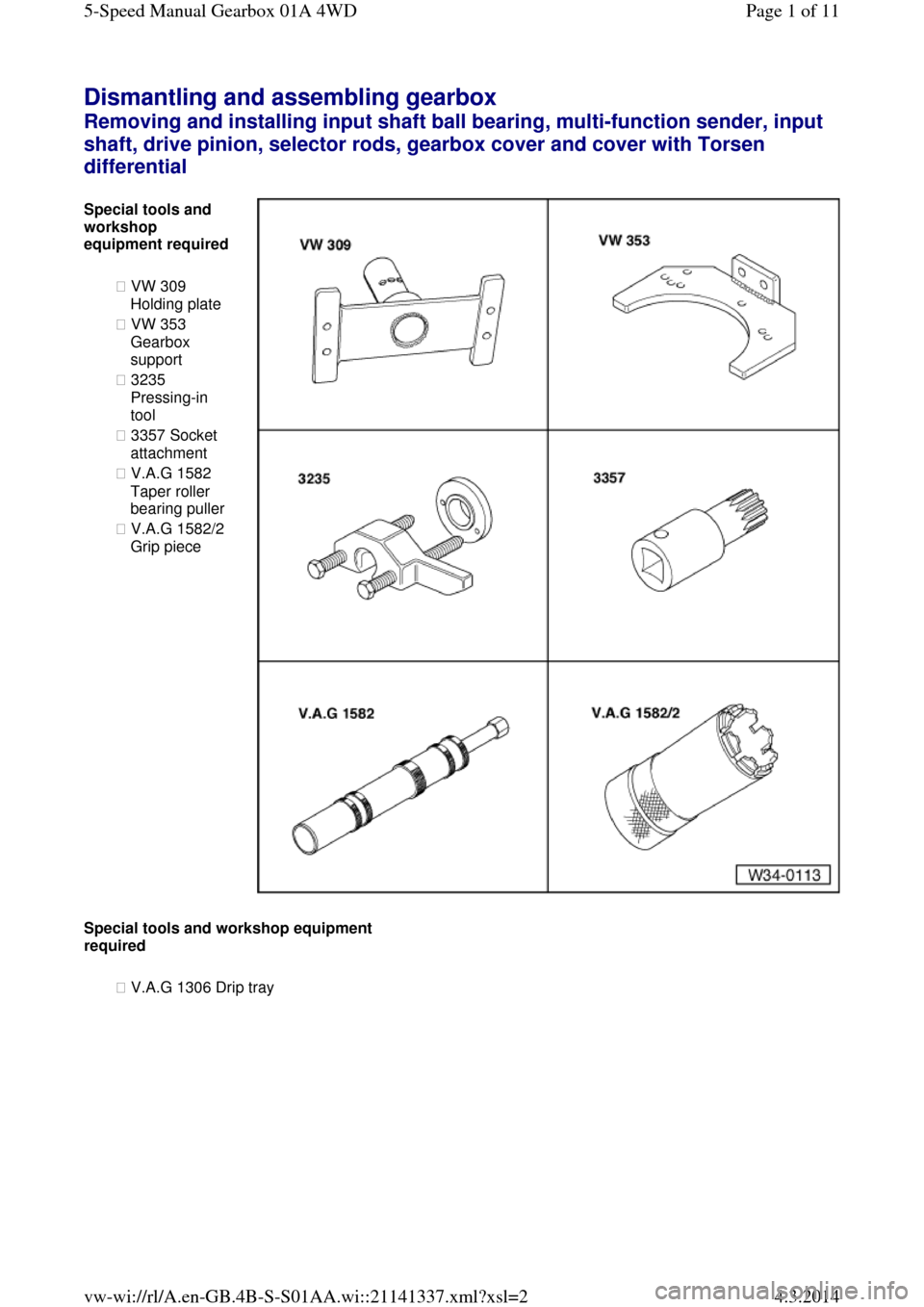

shaft, drive pinion, selector rods, gearbox cover and cover with Torsen differential Special tools and workshop

equipment required

◆ VW 309

Holding plate

◆ VW 353

Gearbox

support

◆ 3235

Pressing-in

tool

◆ 3357 Socket

attachment

◆ V.A.G 1582

Taper roller

bearing puller

◆ V.A.G 1582/2

Grip piece Special tools and workshop equipment required

◆ V.A.G 1306 Drip tray Page 1 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 58 of 71

◆ V.A.G 1331 Torque wrench

◆ Sealant AMV 188 001 02 Notes:

◆ It is not necessary to remove the

differential to remove the above-

mentioned components => Page 34-74.

◆ Removal is only necessary when

adjustments have to be carried out

=> adjustment overview, Page 39-45.

Removing

‒ Place drip tray V.A.G 1306

underneath the gearbox.

‒ Drain gearbox oil using socket

attachment 3357.

‒ → Secure gearbox in assembly

stand VW 540. Page 2 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 60 of 71

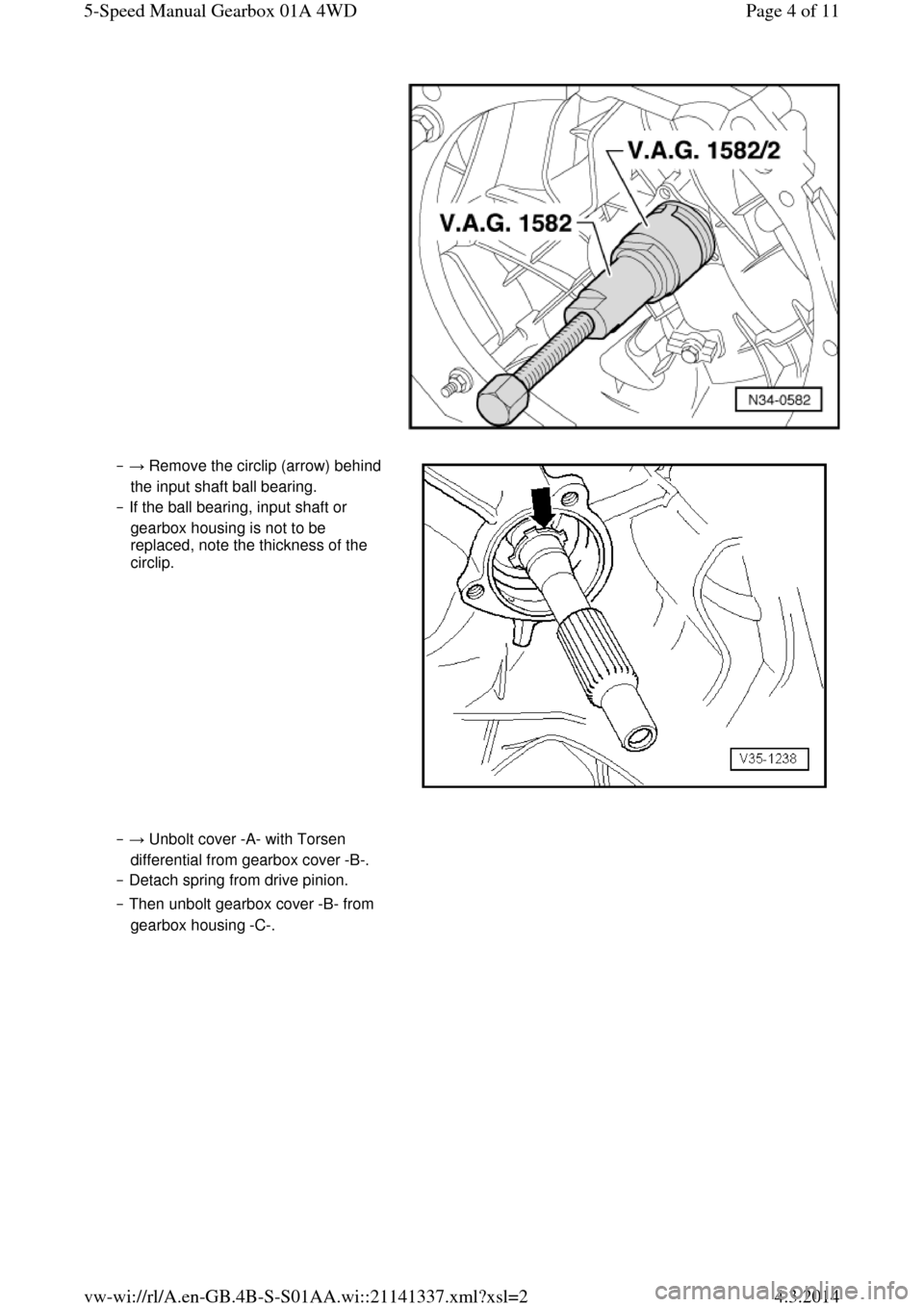

‒ → Remove the circlip (arrow) behind

the input shaft ball bearing.

‒ If the ball bearing, input shaft or

gearbox housing is not to be

replaced, note the thickness of the

circlip. ‒ → Unbolt cover -A- with Torsen

differential from gearbox cover -B-.

‒ Detach spring from drive pinion.

‒ Then unbolt gearbox cover -B- from

gearbox housing -C-. Page 4 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 66 of 71

cover -A- are fitted in gearbox cover -

B- (arrows).

‒ Fit spring -C-.

‒ Apply thin coat of sealant AMV 188

001 02 to sealing surfaces.

‒ Fit cover with Torsen differential -A-

on gearbox cover -B-. ‒ → Fit rear input shaft ball bearing

circlip (arrow).

‒ Push the ball bearing onto the input

shaft.

‒ Installation position: closed

side of ball cage faces

towards gearbox housing ‒ → Press in ball bearing:

‒ Push thrust pad -A- of pressing-in

tool onto input shaft.

‒ Position pressing-in tool behind

splines for clutch plate.

‒ Screw in the bolts -B- until they make contact.

‒ The bolts bear against the

indentations in thrust pad -A-. ‒ Press in ball bearing onto its seat by

alternately tightening the bolts (1/2

turn at a time). ‒ → Now fit the front circlip -D- for the Page 10 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

Page 68 of 71

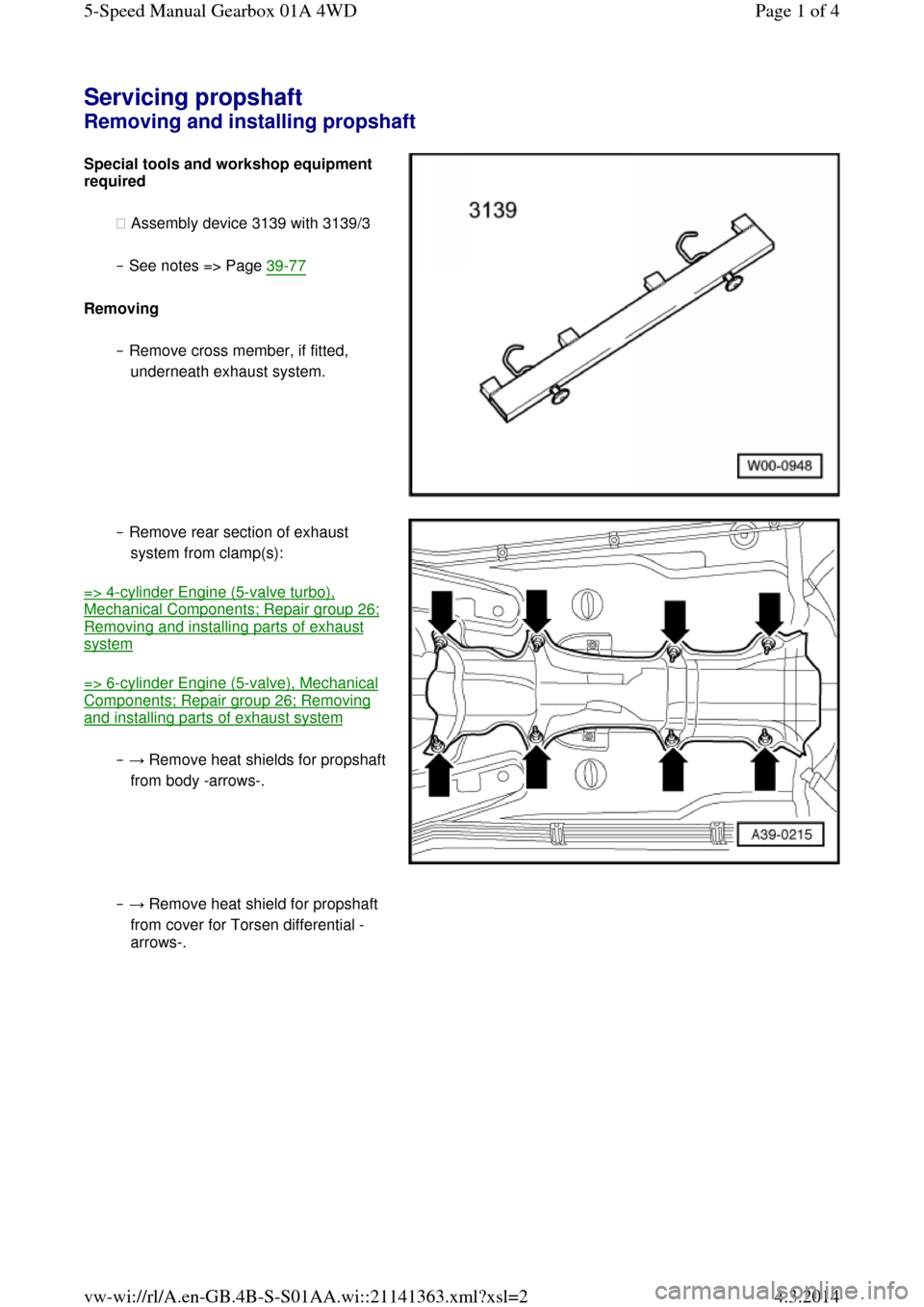

Servicing propshaft Removing and installing propshaft Special tools and workshop equipment required

◆ Assembly device 3139 with 3139/3

‒ See notes => Page 39-77

Removing

‒ Remove cross member, if fitted,

underneath exhaust system. ‒ Remove rear section of exhaust

system from clamp(s):

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system

‒ → Remove heat shields for propshaft from body -arrows-. ‒ → Remove heat shield for propshaft

from cover for Torsen differential -

arrows-. Page 1 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141363.xml?xsl=2