engine AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 7 of 71

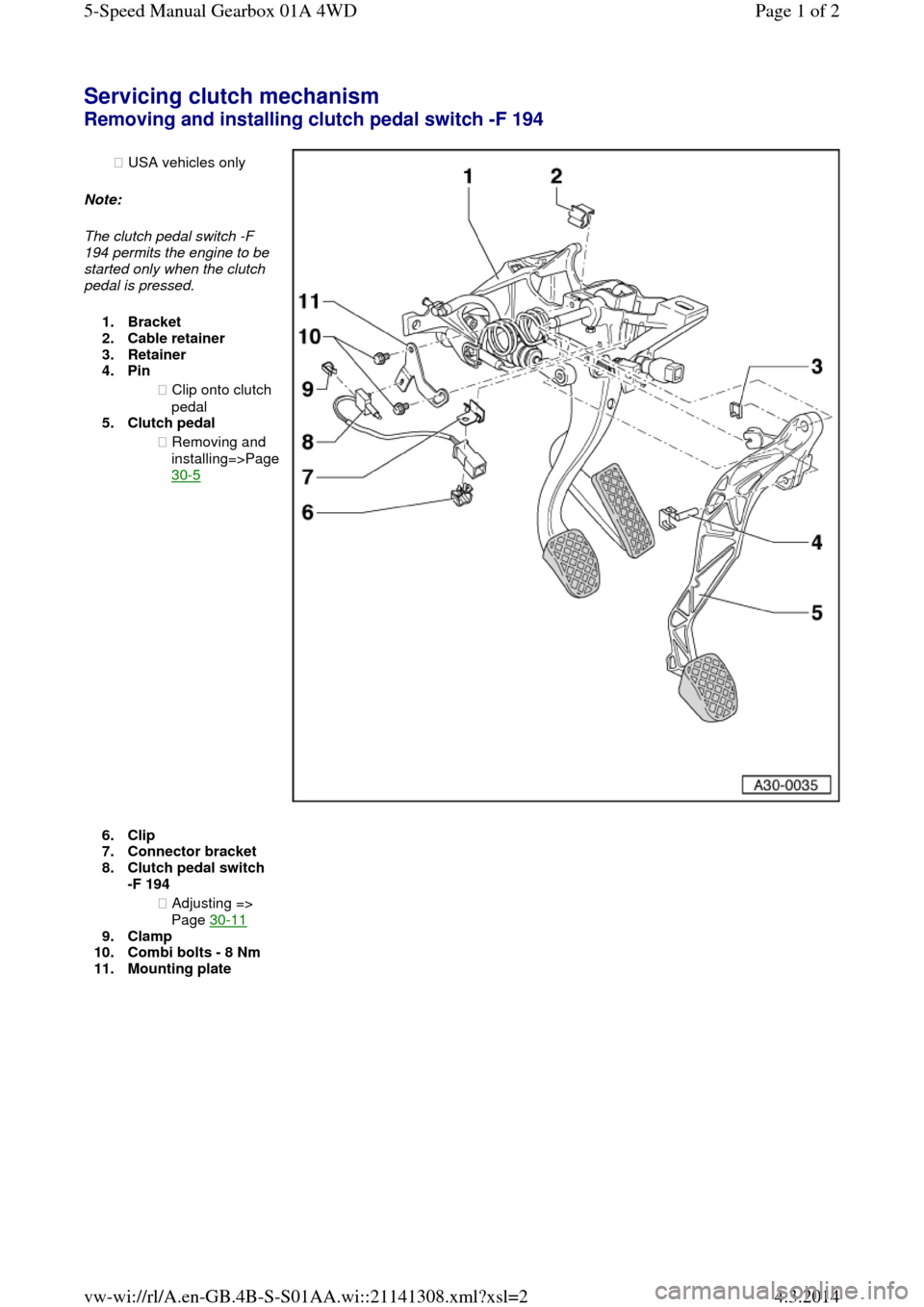

Servicing clutch mechanism Removing and installing clutch pedal switch -F 194 ◆ USA vehicles only

Note:

The clutch pedal switch -F

194 permits the engine to be

started only when the clutch pedal is pressed.

1.Bracket

2.Cable retainer

3.Retainer

4.Pin

◆ Clip onto clutch

pedal

5.Clutch pedal

◆ Removing and installing=>Page 30-5

6.Clip 7.Connector bracket

8.Clutch pedal switch

-F 194

◆ Adjusting =>

Page 30-11

9.Clamp

10.Combi bolts - 8 Nm

11.Mounting plate Page 1 of 25-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141308.xml?xsl=2

Page 27 of 71

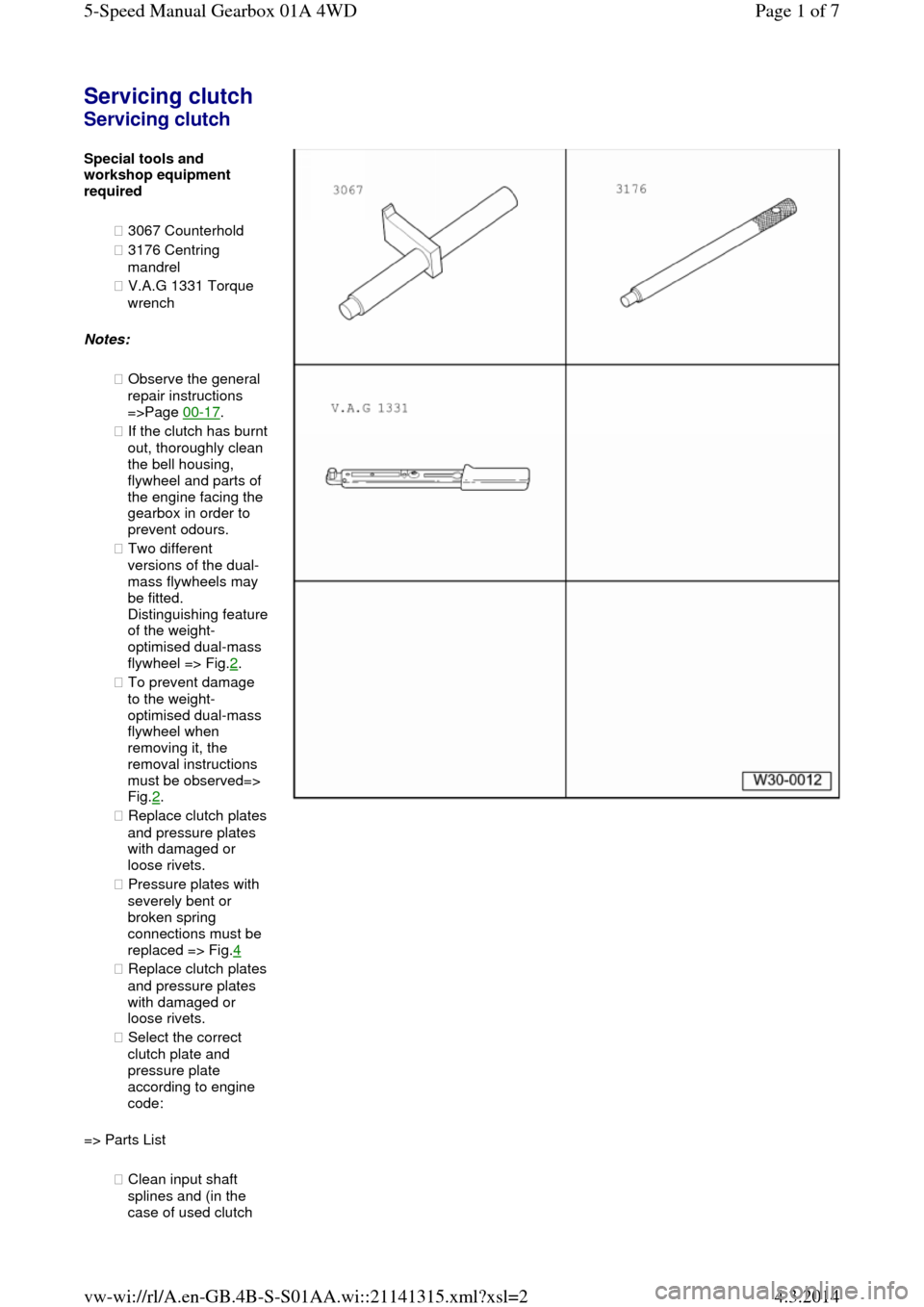

Servicing clutch Servicing clutch Special tools and workshop equipment

required

◆ 3067 Counterhold

◆ 3176 Centring

mandrel

◆ V.A.G 1331 Torque

wrench

Notes:

◆ Observe the general

repair instructions

=>Page 00-17.

◆ If the clutch has burnt out, thoroughly clean

the bell housing,

flywheel and parts of

the engine facing the

gearbox in order to

prevent odours.

◆ Two different

versions of the dual-

mass flywheels may

be fitted. Distinguishing feature of the weight-

optimised dual-mass

flywheel => Fig.2.

◆ To prevent damage

to the weight-

optimised dual-mass

flywheel when

removing it, the

removal instructions

must be observed=>

Fig.2.

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Pressure plates with

severely bent or

broken spring

connections must be

replaced => Fig.4

◆ Replace clutch plates and pressure plates

with damaged or

loose rivets.

◆ Select the correct

clutch plate and

pressure plate

according to engine

code:

=> Parts List

◆ Clean input shaft

splines and (in the

case of used clutch Page 1 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 28 of 71

plates) the hub splines.

Remove corrosion

and apply only a very thin coating of grease G 000 100 to the

splines. Then move clutch plate to and for on input shaft until

hub moves freely on

shaft. Excess grease

must be removed.

◆ Pressure plates are

protected against

corrosion and

greased. Only the

contact surface may be cleaned, otherwise the service life of the

clutch will be

considerably

reduced.

◆ Tighten securing

bolts in small steps in

diagonal sequence to

avoid damaging

centring holes in

pressure plate and

centring pins on

flywheel.

‒ Remove the gearbox

to work on the

clutch=>Page 34-35.

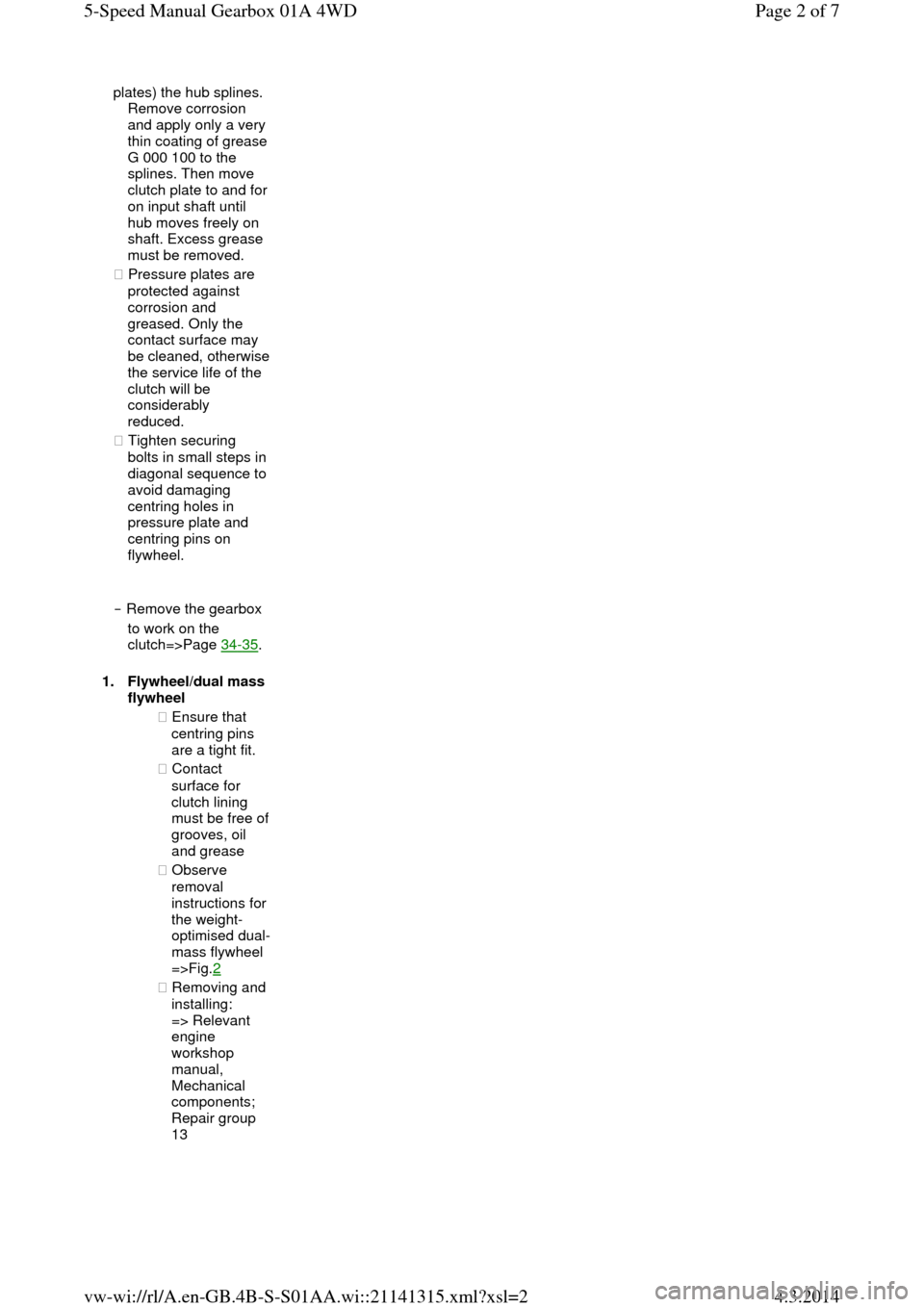

1.Flywheel/dual mass

flywheel

◆ Ensure that

centring pins

are a tight fit.

◆ Contact

surface for

clutch lining must be free of grooves, oil

and grease

◆ Observe

removal

instructions for

the weight-

optimised dual-

mass flywheel

=>Fig.2

◆ Removing and

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 Page 2 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 31 of 71

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

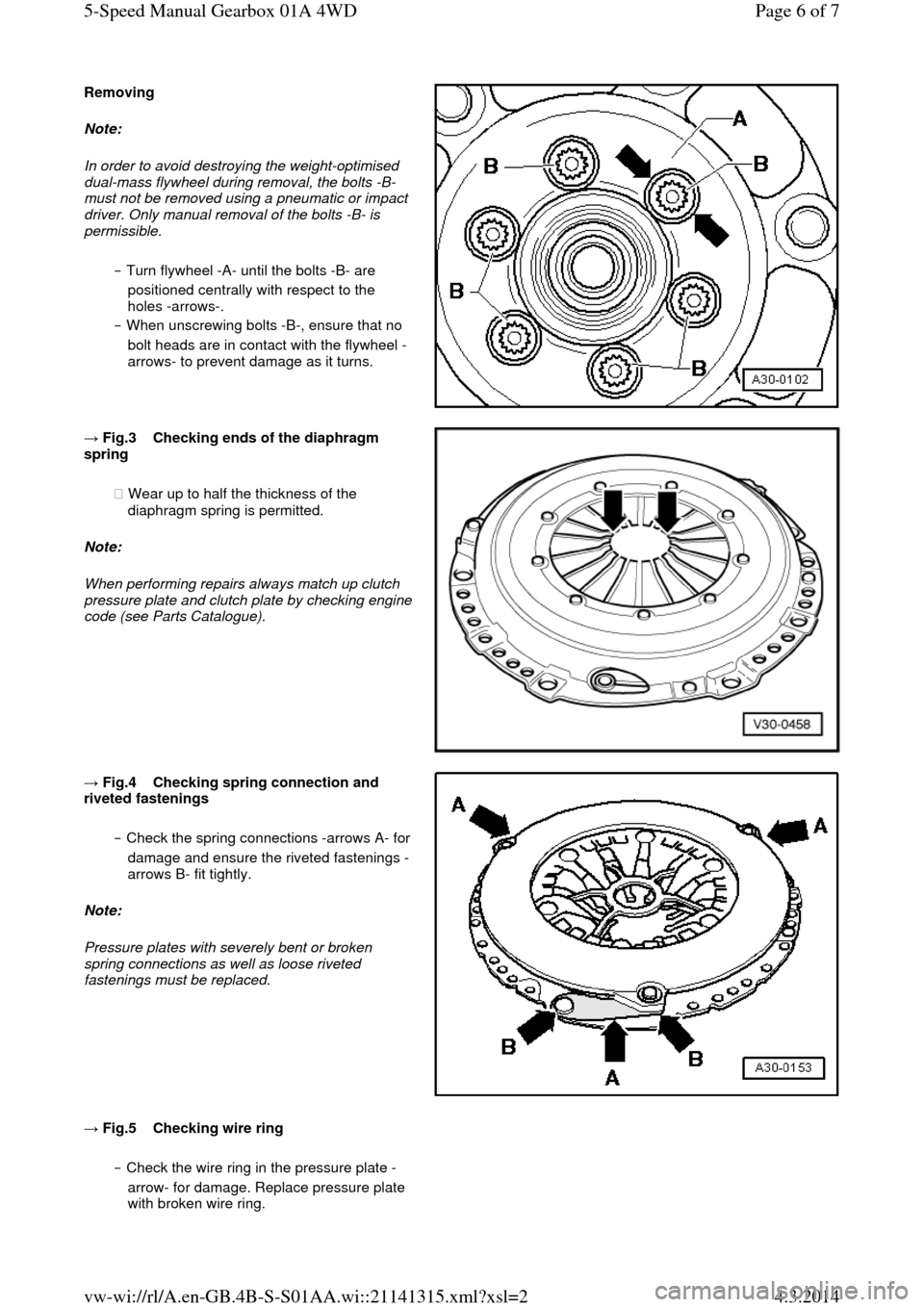

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 32 of 71

Removing Note:

In order to avoid destroying the weight-optimised

dual-mass flywheel during removal, the bolts -B-

must not be removed using a pneumatic or impact

driver. Only manual removal of the bolts -B- is permissible.

‒ Turn flywheel -A- until the bolts -B- are

positioned centrally with respect to the

holes -arrows-.

‒ When unscrewing bolts -B-, ensure that no

bolt heads are in contact with the flywheel -

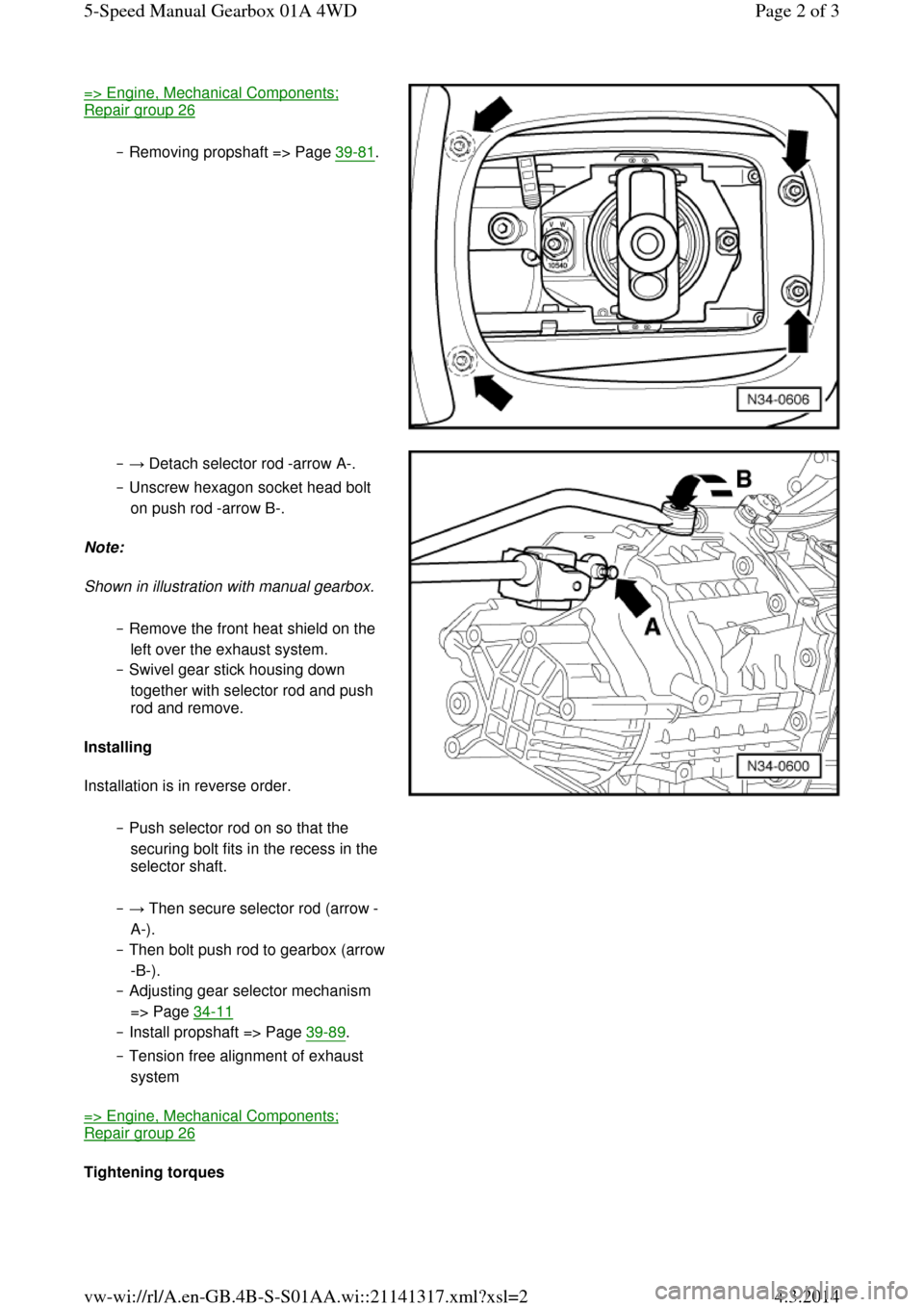

arrows- to prevent damage as it turns. → Fig.3 Checking ends of the diaphragm spring

◆ Wear up to half the thickness of the

diaphragm spring is permitted.

Note:

When performing repairs always match up clutch pressure plate and clutch plate by checking engine code (see Parts Catalogue).

→ Fig.4 Checking spring connection and riveted fastenings

‒ Check the spring connections -arrows A- for damage and ensure the riveted fastenings -

arrows B- fit tightly.

Note:

Pressure plates with severely bent or broken

spring connections as well as loose riveted

fastenings must be replaced.

→ Fig.5 Checking wire ring ‒ Check the wire ring in the pressure plate -

arrow- for damage. Replace pressure plate

with broken wire ring. Page 6 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

Page 35 of 71

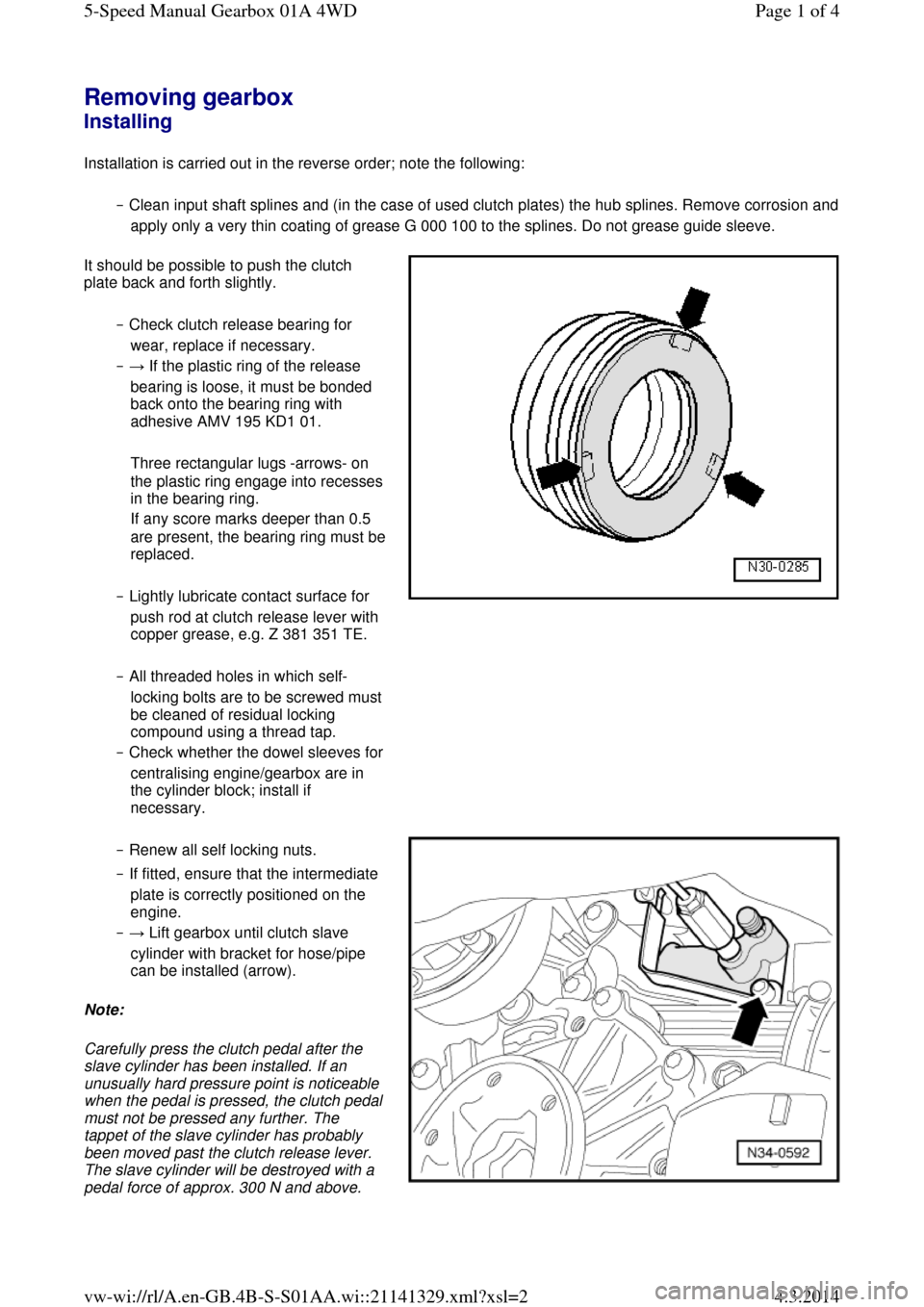

=> Engine, Mechanical Components; Repair group 26

‒ Removing propshaft => Page 39-81. ‒ → Detach selector rod -arrow A-.

‒ Unscrew hexagon socket head bolt

on push rod -arrow B-.

Note:

Shown in illustration with manual gearbox.

‒ Remove the front heat shield on the

left over the exhaust system.

‒ Swivel gear stick housing down

together with selector rod and push

rod and remove.

Installing

Installation is in reverse order.

‒ Push selector rod on so that the

securing bolt fits in the recess in the

selector shaft. ‒ → Then secure selector rod (arrow -

A-).

‒ Then bolt push rod to gearbox (arrow -B-).

‒ Adjusting gear selector mechanism

=> Page 34-11

‒ Install propshaft => Page 39-89.

‒ Tension free alignment of exhaust

system

=> Engine, Mechanical Components; Repair group 26

Tightening torques Page 2 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 41 of 71

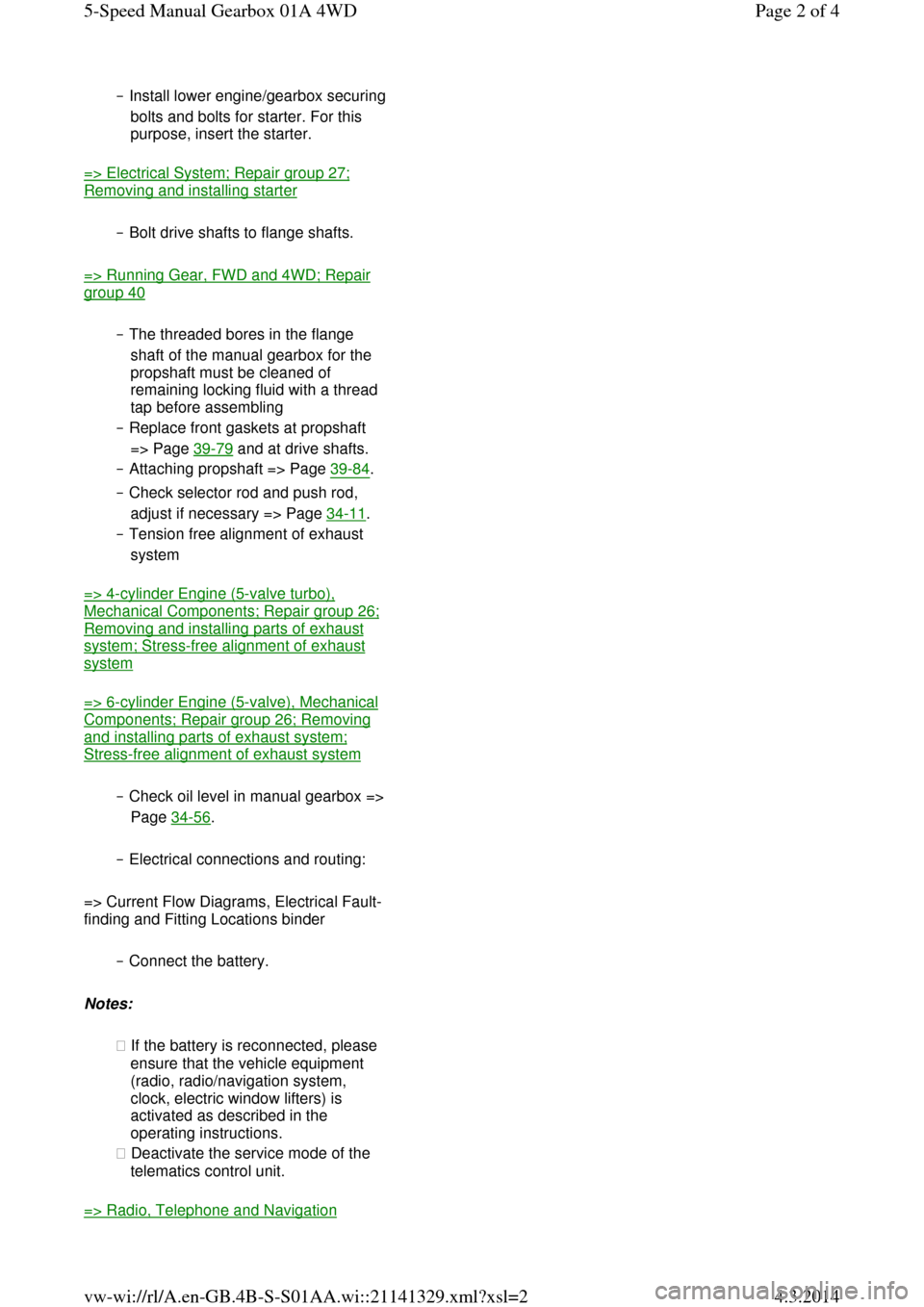

Removing gearbox Installing

Installation is carried out in the reverse order; note the following:

‒ Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease G 000 100 to the splines. Do not grease guide sleeve. It should be possible to push the clutch

plate back and forth slightly.

‒ Check clutch release bearing for

wear, replace if necessary.

‒ → If the plastic ring of the release

bearing is loose, it must be bonded

back onto the bearing ring with

adhesive AMV 195 KD1 01.

Three rectangular lugs -arrows- on the plastic ring engage into recesses in the bearing ring.

If any score marks deeper than 0.5 are present, the bearing ring must be replaced.

‒ Lightly lubricate contact surface for

push rod at clutch release lever with

copper grease, e.g. Z 381 351 TE.

‒ All threaded holes in which self-locking bolts are to be screwed must be cleaned of residual locking

compound using a thread tap.

‒ Check whether the dowel sleeves for centralising engine/gearbox are in

the cylinder block; install if

necessary. ‒ Renew all self locking nuts.

‒ If fitted, ensure that the intermediate

plate is correctly positioned on the

engine.

‒ → Lift gearbox until clutch slave

cylinder with bracket for hose/pipe

can be installed (arrow).

Note:

Carefully press the clutch pedal after the

slave cylinder has been installed. If an

unusually hard pressure point is noticeable when the pedal is pressed, the clutch pedal must not be pressed any further. The

tappet of the slave cylinder has probably

been moved past the clutch release lever.

The slave cylinder will be destroyed with a pedal force of approx. 300 N and above. Page 1 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 42 of 71

‒ Install lower engine/gearbox securing bolts and bolts for starter. For this

purpose, insert the starter.

=> Electrical System; Repair group 27; Removing and installing starter

‒ Bolt drive shafts to flange shafts.

=> Running Gear, FWD and 4WD; Repair group 40

‒ The threaded bores in the flange

shaft of the manual gearbox for the

propshaft must be cleaned of

remaining locking fluid with a thread

tap before assembling

‒ Replace front gaskets at propshaft

=> Page 39-79 and at drive shafts.

‒ Attaching propshaft => Page 39-84.

‒ Check selector rod and push rod,

adjust if necessary => Page 34-11.

‒ Tension free alignment of exhaust

system

=> 4-cylinder Engine (5-valve turbo), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

=> 6-cylinder Engine (5-valve), Mechanical Components; Repair group 26; Removing and installing parts of exhaust system; Stress-free alignment of exhaust system

‒ Check oil level in manual gearbox => Page 34-56.

‒ Electrical connections and routing:

=> Current Flow Diagrams, Electrical Fault-

finding and Fitting Locations binder

‒ Connect the battery.

Notes:

◆ If the battery is reconnected, please

ensure that the vehicle equipment

(radio, radio/navigation system,

clock, electric window lifters) is

activated as described in the

operating instructions.

◆ Deactivate the service mode of the

telematics control unit.

=> Radio, Telephone and Navigation Page 2 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 43 of 71

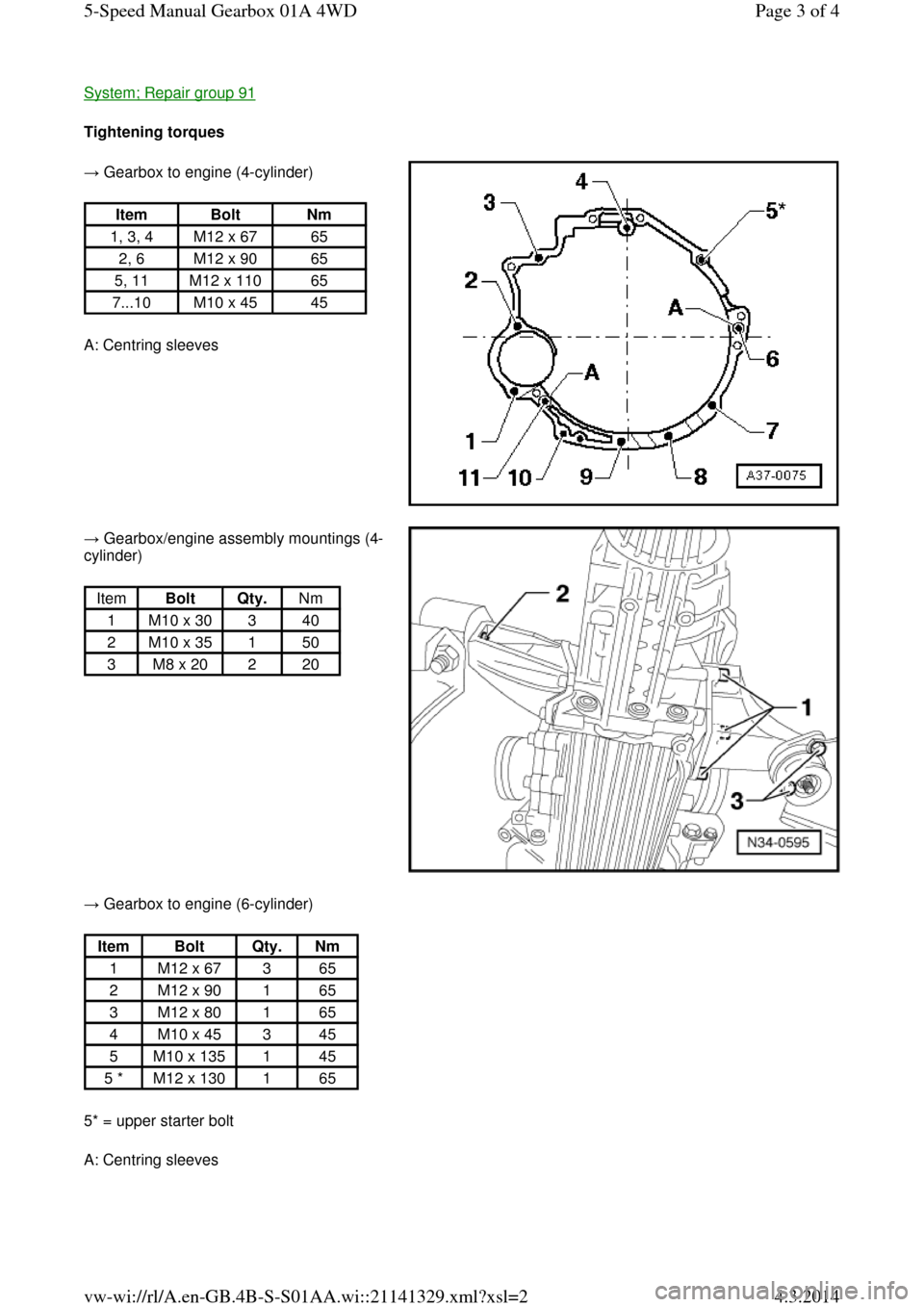

System; Repair group 91 Tightening torques → Gearbox to engine (4-cylinder)

A: Centring sleeves Item Bolt Nm

1, 3, 4 M12 x 67 65

2, 6 M12 x 90 65

5, 11 M12 x 110 65

7...10 M10 x 45 45 → Gearbox/engine assembly mountings (4-

cylinder)

Item Bolt Qty. Nm

1 M10 x 30 3 40

2 M10 x 35 1 50

3 M8 x 20 2 20 → Gearbox to engine (6-cylinder)

5* = upper starter bolt

A: Centring sleeves Item Bolt Qty. Nm

1 M12 x 67 3 65

2 M12 x 90 1 65

3 M12 x 80 1 65

4 M10 x 45 3 45

5 M10 x 135 1 45

5 * M12 x 130 1 65 Page 3 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 44 of 71

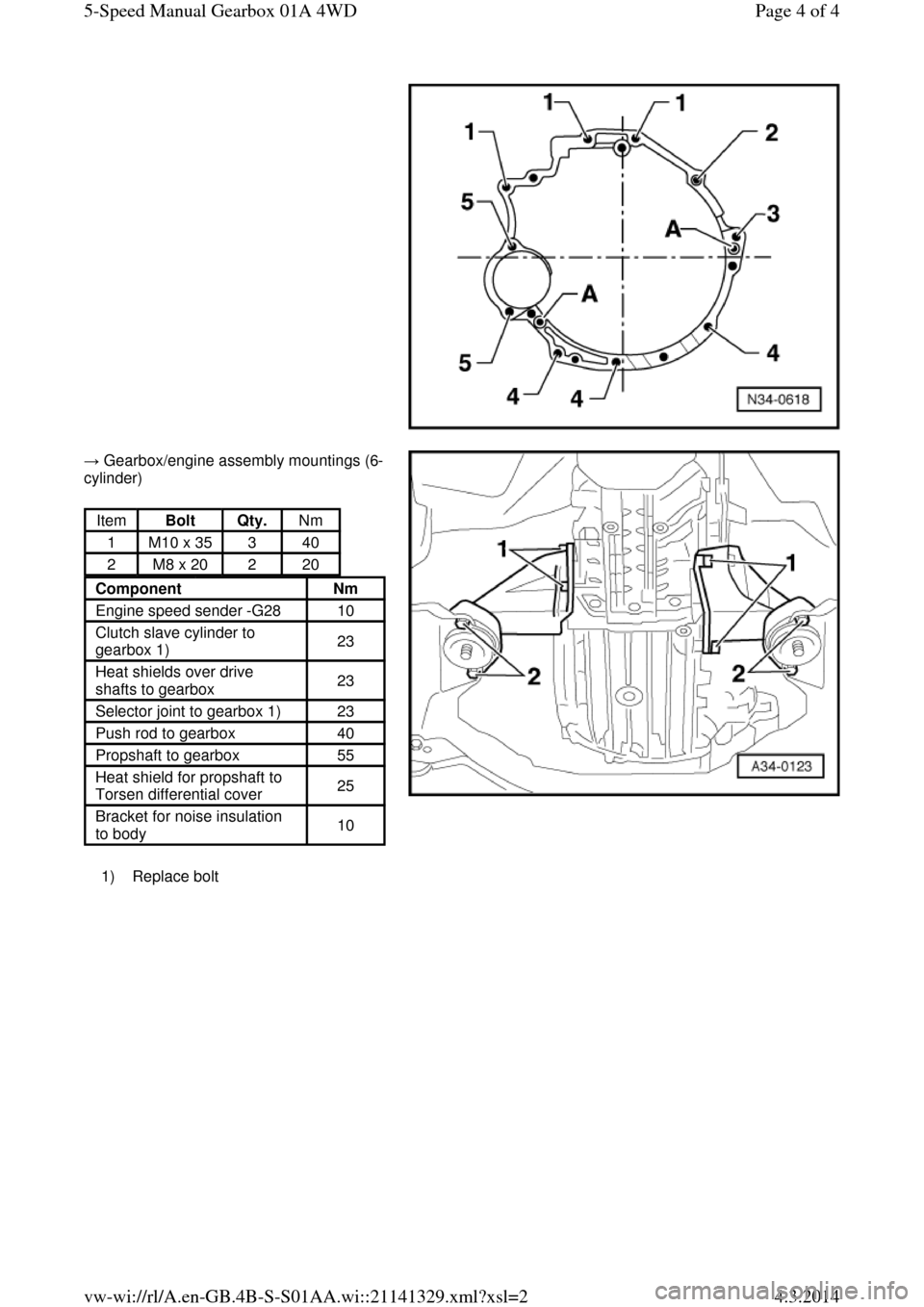

→ Gearbox/engine assembly mountings (6-

cylinder) 1) Replace bolt Item Bolt Qty. Nm

1 M10 x 35 3 40

2 M8 x 20 2 20 Component Nm

Engine speed sender -G28 10

Clutch slave cylinder to

gearbox 1) 23

Heat shields over drive

shafts to gearbox 23

Selector joint to gearbox 1) 23

Push rod to gearbox 40

Propshaft to gearbox 55

Heat shield for propshaft to

Torsen differential cover 25

Bracket for noise insulation

to body 10 Page 4 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2