gearbox lever AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 13 of 71

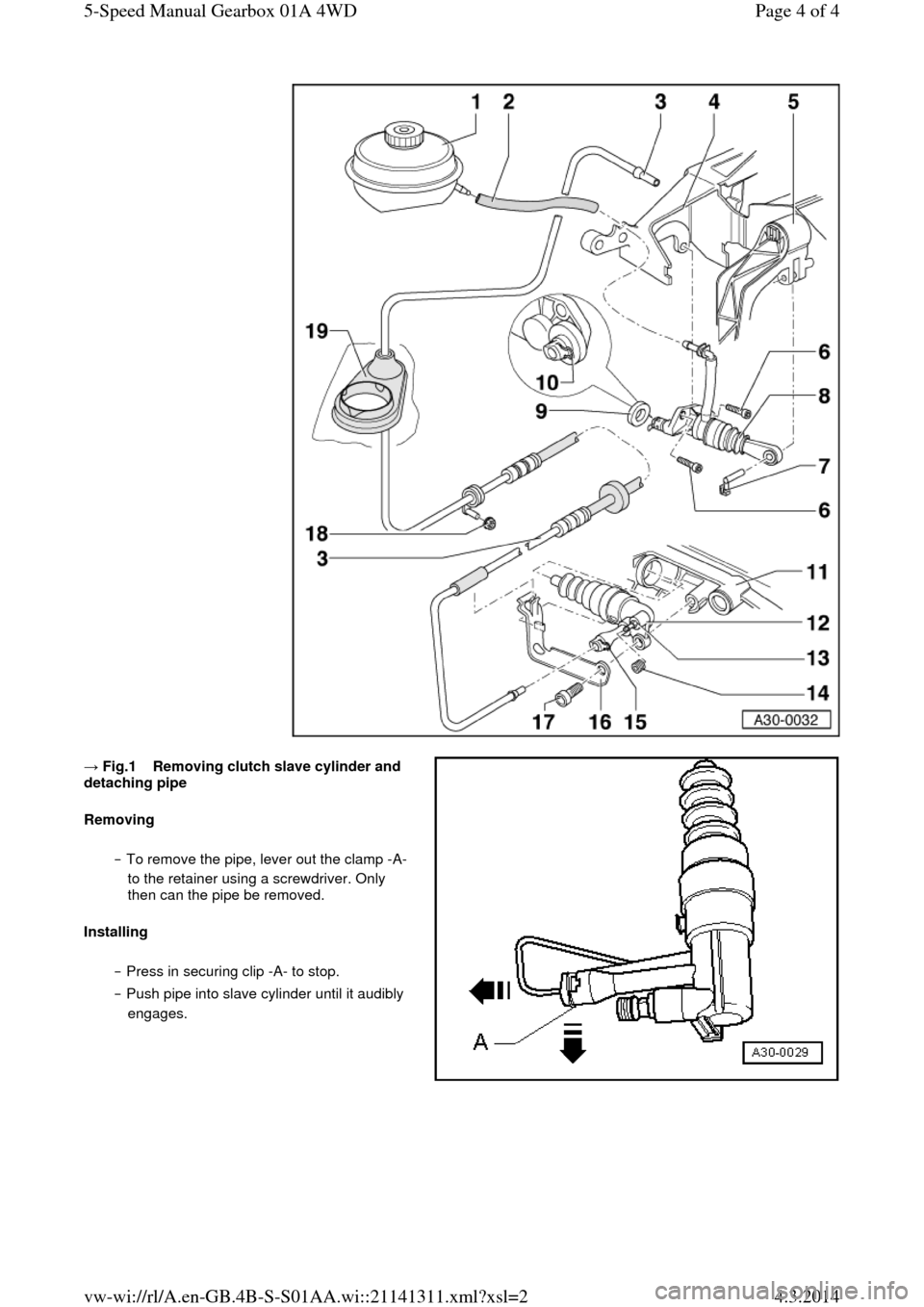

→ Fig.1 Removing clutch slave cylinder and detaching pipe

Removing

‒ To remove the pipe, lever out the clamp -A-

to the retainer using a screwdriver. Only

then can the pipe be removed.

Installing

‒ Press in securing clip -A- to stop.

‒ Push pipe into slave cylinder until it audibly

engages. Page 4 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141311.xml?xsl=2

Page 14 of 71

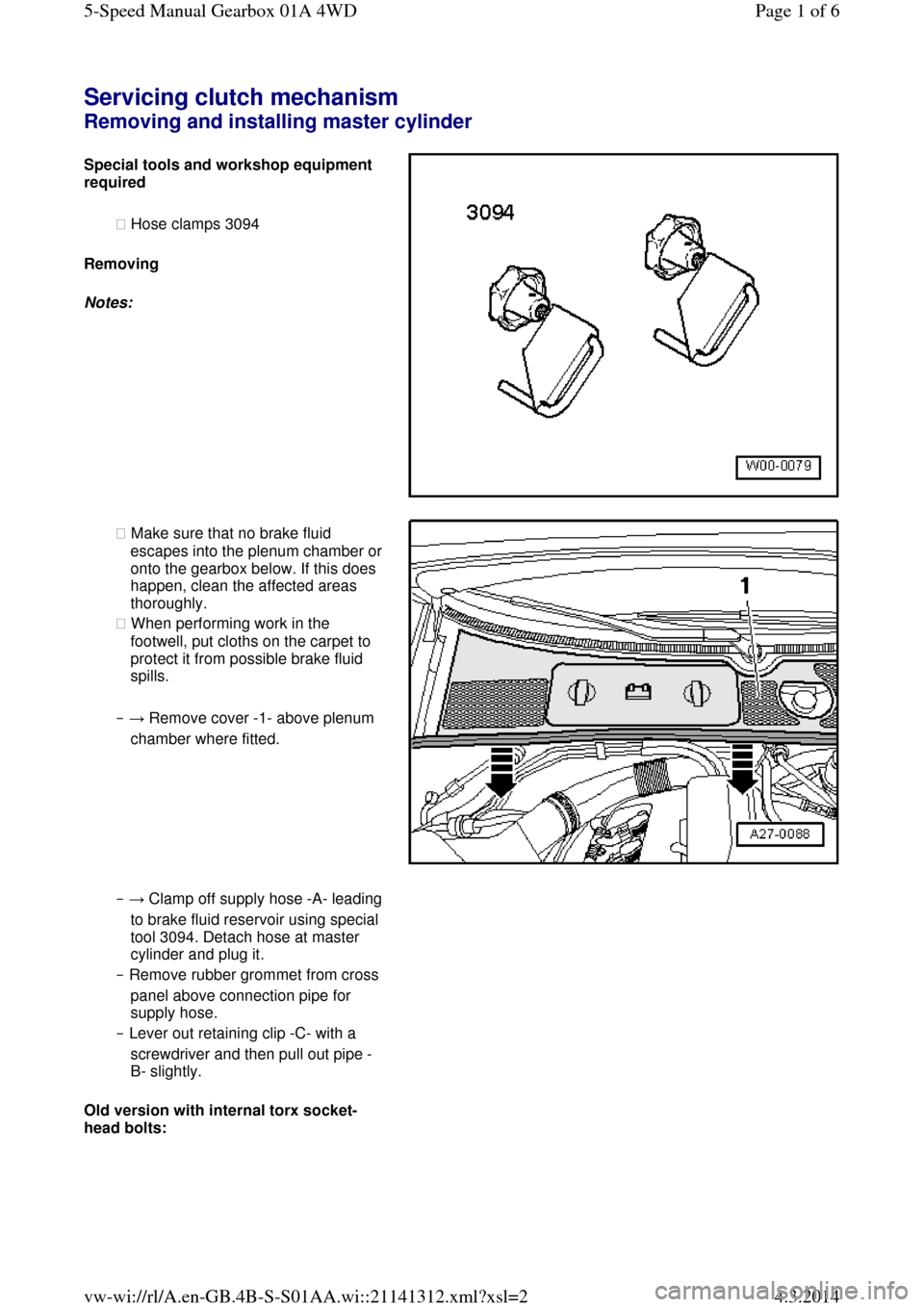

Servicing clutch mechanism Removing and installing master cylinder Special tools and workshop equipment required

◆ Hose clamps 3094

Removing

Notes: ◆ Make sure that no brake fluid escapes into the plenum chamber or onto the gearbox below. If this does

happen, clean the affected areas

thoroughly.

◆ When performing work in the

footwell, put cloths on the carpet to

protect it from possible brake fluid

spills.

‒ → Remove cover -1- above plenum

chamber where fitted. ‒ → Clamp off supply hose -A- leading to brake fluid reservoir using special

tool 3094. Detach hose at master

cylinder and plug it.

‒ Remove rubber grommet from cross

panel above connection pipe for

supply hose.

‒ Lever out retaining clip -C- with a

screwdriver and then pull out pipe -

B- slightly.

Old version with internal torx socket-

head bolts: Page 1 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141312.xml?xsl=2

Page 22 of 71

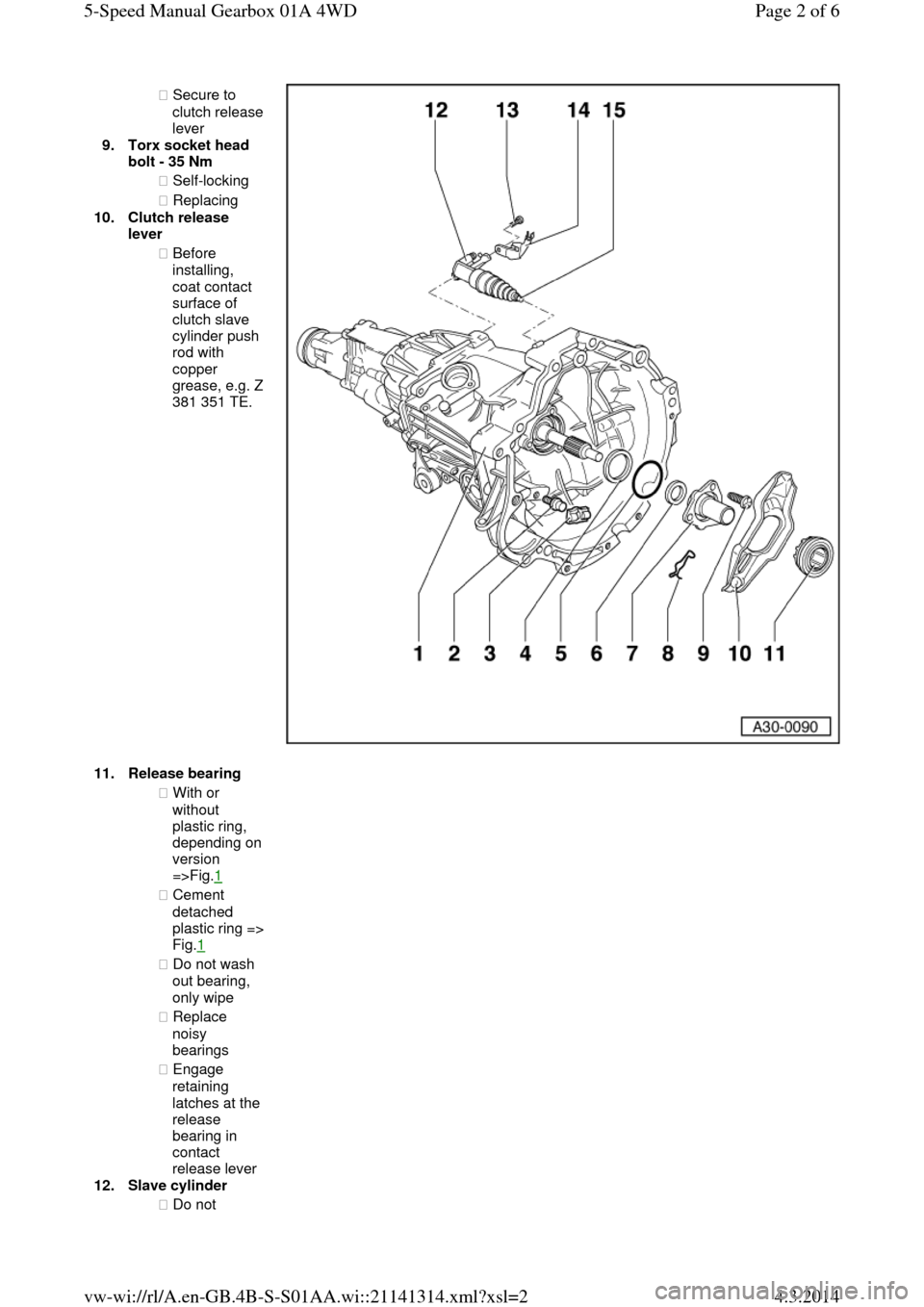

◆ Secure to clutch release lever

9.Torx socket head

bolt - 35 Nm

◆ Self-locking

◆ Replacing

10.Clutch release

lever

◆ Before

installing,

coat contact

surface of

clutch slave

cylinder push

rod with

copper grease, e.g. Z 381 351 TE. 11.Release bearing ◆ With or

without

plastic ring, depending on version

=>Fig.1

◆ Cement

detached plastic ring => Fig.1

◆ Do not wash

out bearing,

only wipe

◆ Replace

noisy

bearings

◆ Engage

retaining

latches at the

release

bearing in

contact

release lever 12.Slave cylinder

◆ Do not Page 2 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 25 of 71

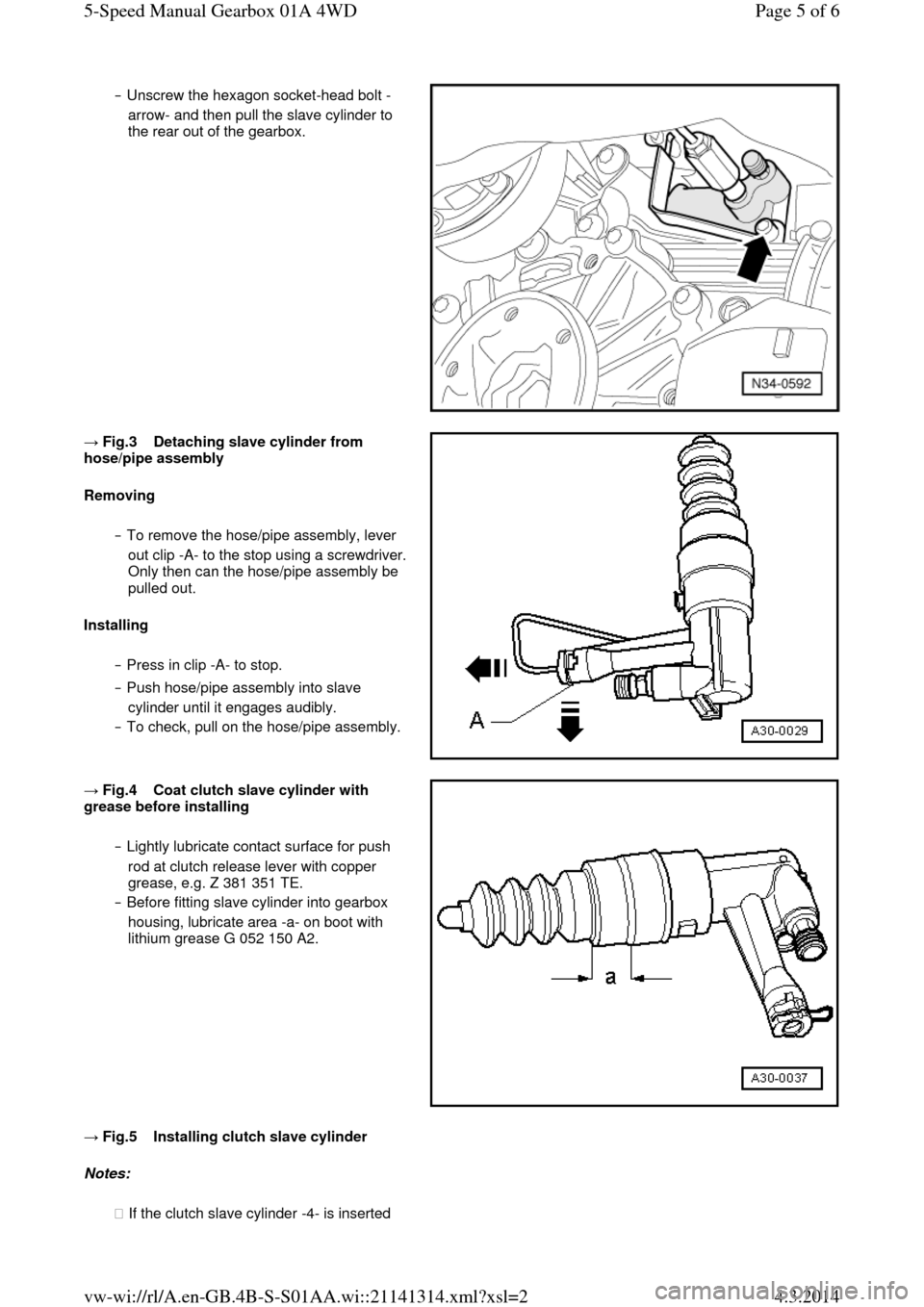

‒ Unscrew the hexagon socket-head bolt -

arrow- and then pull the slave cylinder to

the rear out of the gearbox. → Fig.3 Detaching slave cylinder from hose/pipe assembly

Removing

‒ To remove the hose/pipe assembly, lever

out clip -A- to the stop using a screwdriver. Only then can the hose/pipe assembly be

pulled out.

Installing

‒ Press in clip -A- to stop.

‒ Push hose/pipe assembly into slave

cylinder until it engages audibly.

‒ To check, pull on the hose/pipe assembly. → Fig.4 Coat clutch slave cylinder with grease before installing

‒ Lightly lubricate contact surface for push

rod at clutch release lever with copper

grease, e.g. Z 381 351 TE.

‒ Before fitting slave cylinder into gearbox

housing, lubricate area -a- on boot with

lithium grease G 052 150 A2. → Fig.5 Installing clutch slave cylinder Notes:

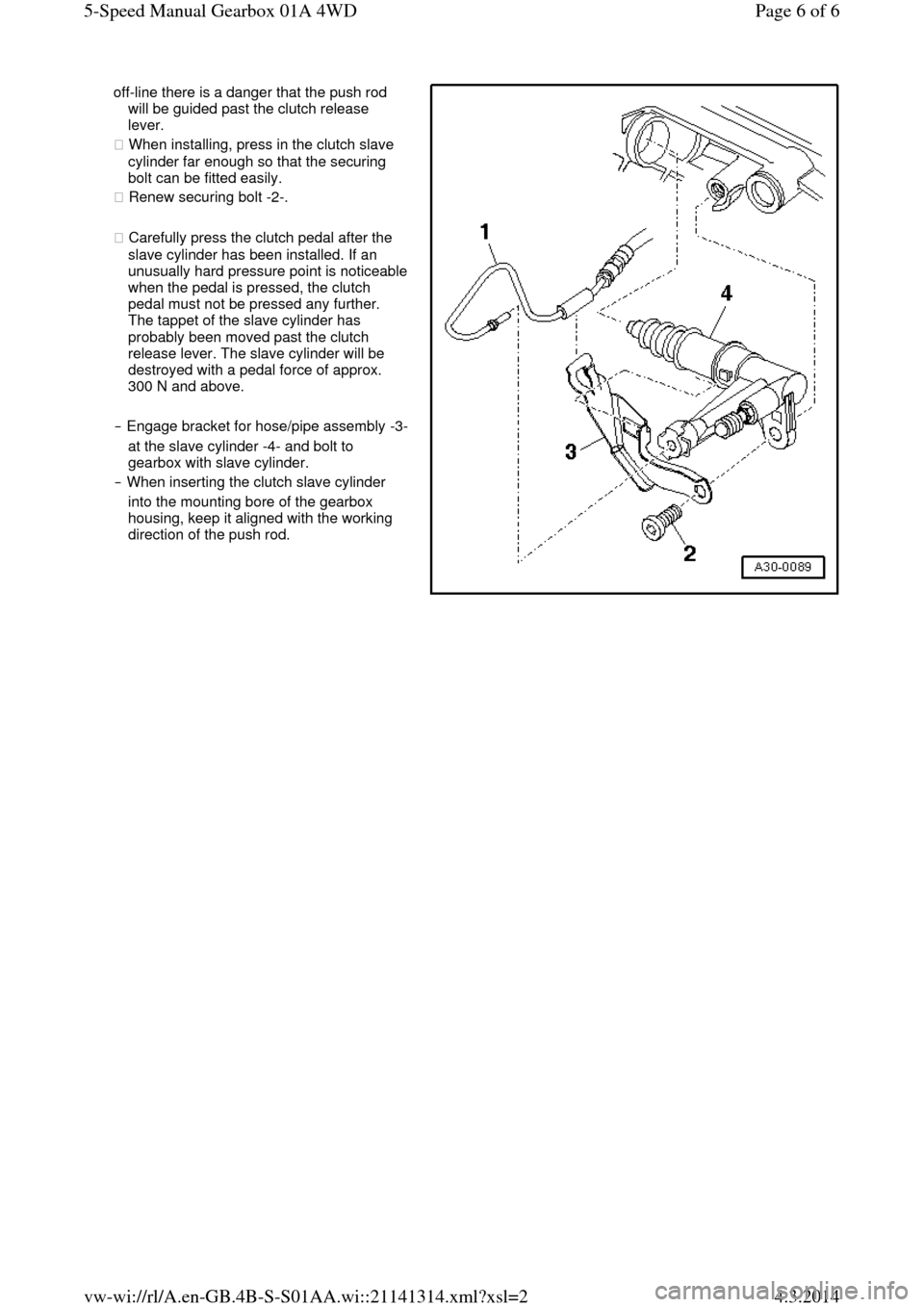

◆ If the clutch slave cylinder -4- is inserted Page 5 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 26 of 71

off-line there is a danger that the push rod

will be guided past the clutch release

lever.

◆ When installing, press in the clutch slave

cylinder far enough so that the securing

bolt can be fitted easily.

◆ Renew securing bolt -2-.

◆ Carefully press the clutch pedal after the

slave cylinder has been installed. If an unusually hard pressure point is noticeable when the pedal is pressed, the clutch

pedal must not be pressed any further.

The tappet of the slave cylinder has

probably been moved past the clutch

release lever. The slave cylinder will be

destroyed with a pedal force of approx.

300 N and above.

‒ Engage bracket for hose/pipe assembly -3- at the slave cylinder -4- and bolt to

gearbox with slave cylinder.

‒ When inserting the clutch slave cylinder

into the mounting bore of the gearbox

housing, keep it aligned with the working

direction of the push rod. Page 6 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141314.xml?xsl=2

Page 34 of 71

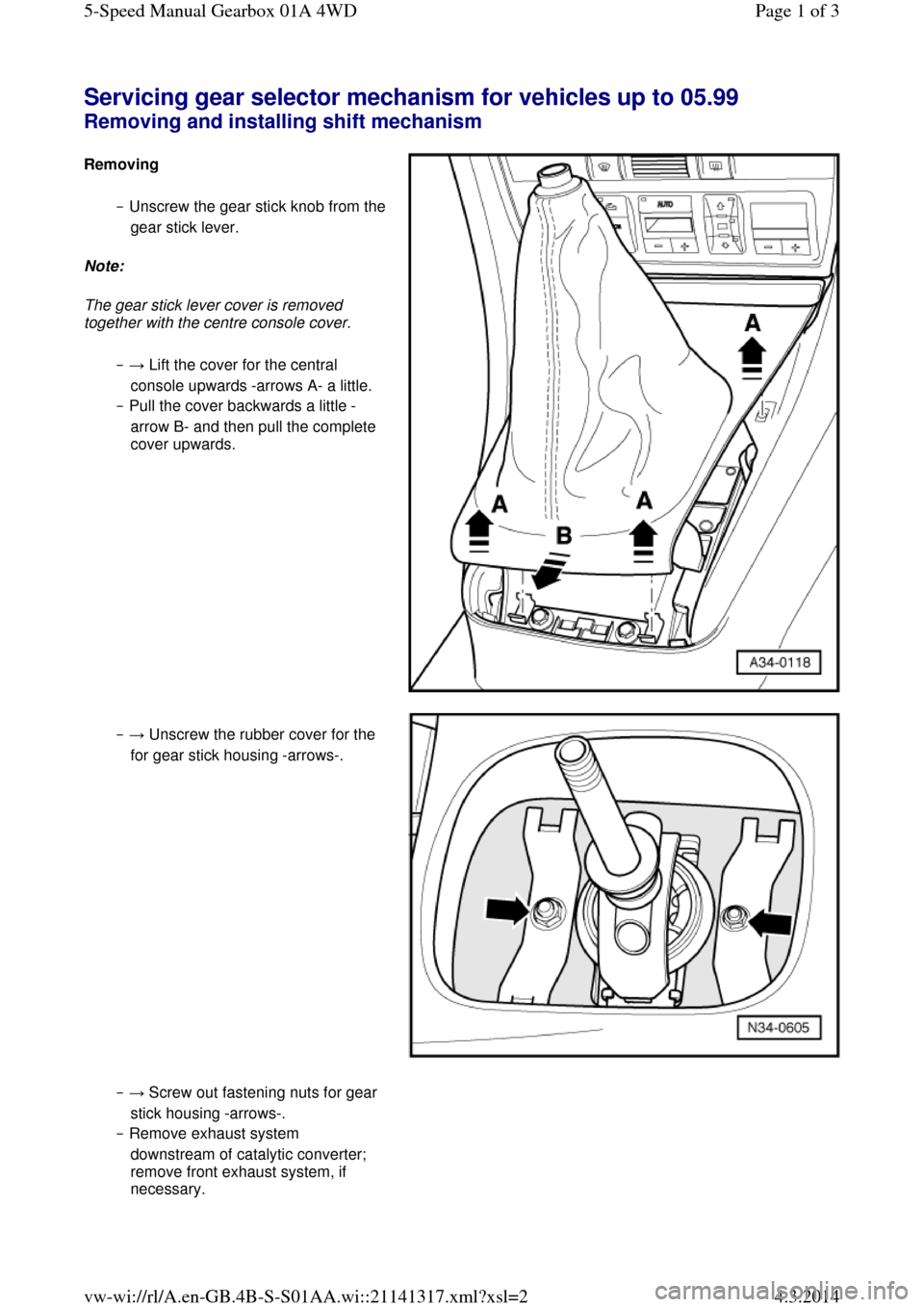

Servicing gear selector mechanism for vehicles up to 05.99 Removing and installing shift mechanism Removing ‒ Unscrew the gear stick knob from the gear stick lever.

Note:

The gear stick lever cover is removed

together with the centre console cover.

‒ → Lift the cover for the central

console upwards -arrows A- a little.

‒ Pull the cover backwards a little -

arrow B- and then pull the complete

cover upwards. ‒ → Unscrew the rubber cover for the

for gear stick housing -arrows-. ‒ → Screw out fastening nuts for gear

stick housing -arrows-.

‒ Remove exhaust system

downstream of catalytic converter;

remove front exhaust system, if

necessary. Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 36 of 71

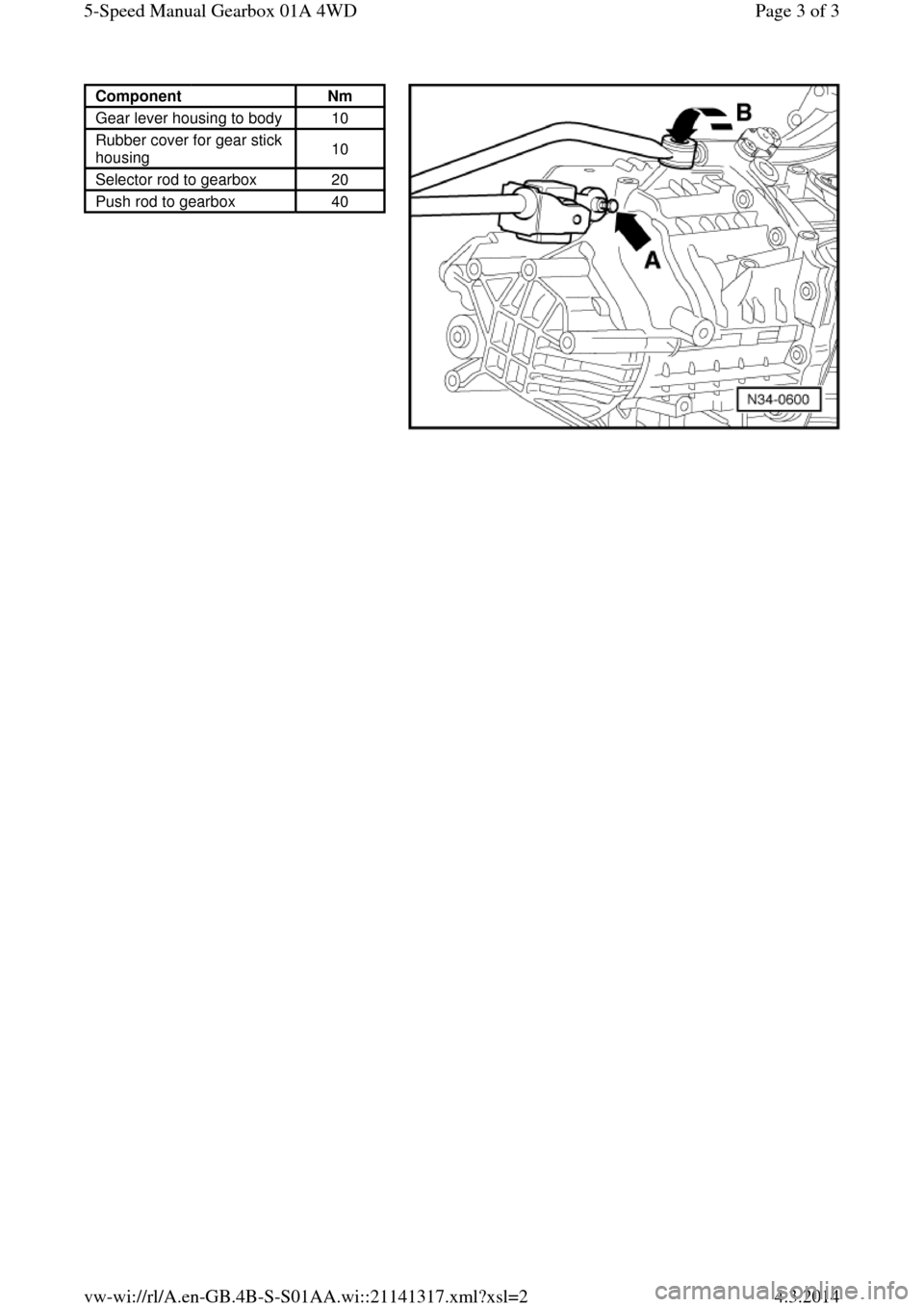

Component Nm

Gear lever housing to body 10

Rubber cover for gear stick

housing 10

Selector rod to gearbox 20

Push rod to gearbox 40 Page 3 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141317.xml?xsl=2

Page 37 of 71

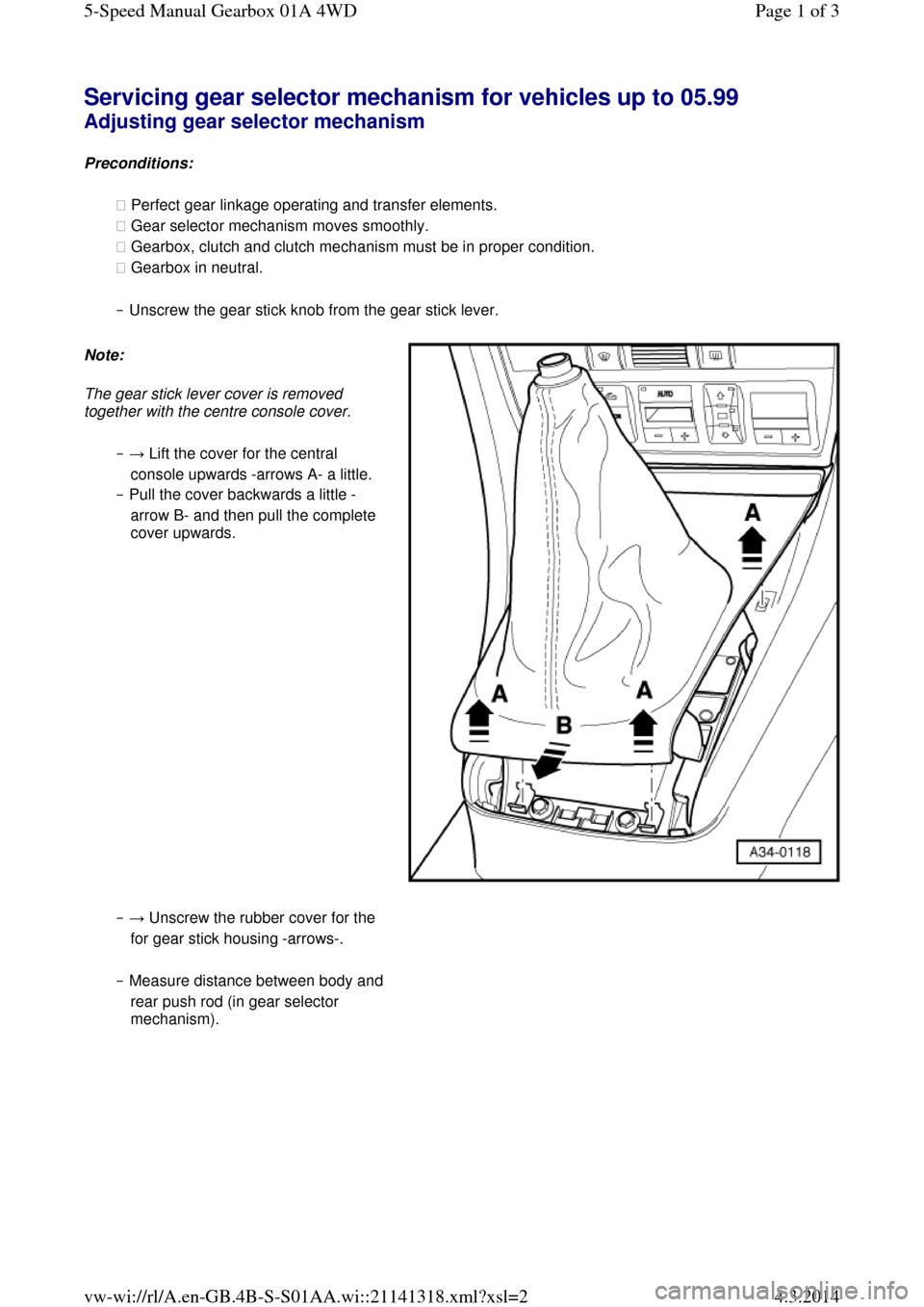

Servicing gear selector mechanism for vehicles up to 05.99 Adjusting gear selector mechanism

Preconditions:

◆ Perfect gear linkage operating and transfer elements.

◆ Gear selector mechanism moves smoothly.

◆ Gearbox, clutch and clutch mechanism must be in proper condition.

◆ Gearbox in neutral.

‒ Unscrew the gear stick knob from the gear stick lever. Note:

The gear stick lever cover is removed

together with the centre console cover.

‒ → Lift the cover for the central

console upwards -arrows A- a little.

‒ Pull the cover backwards a little -

arrow B- and then pull the complete

cover upwards.

‒ → Unscrew the rubber cover for the

for gear stick housing -arrows-.

‒ Measure distance between body and rear push rod (in gear selector

mechanism). Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141318.xml?xsl=2

Page 41 of 71

Removing gearbox Installing

Installation is carried out in the reverse order; note the following:

‒ Clean input shaft splines and (in the case of used clutch plates) the hub splines. Remove corrosion and apply only a very thin coating of grease G 000 100 to the splines. Do not grease guide sleeve. It should be possible to push the clutch

plate back and forth slightly.

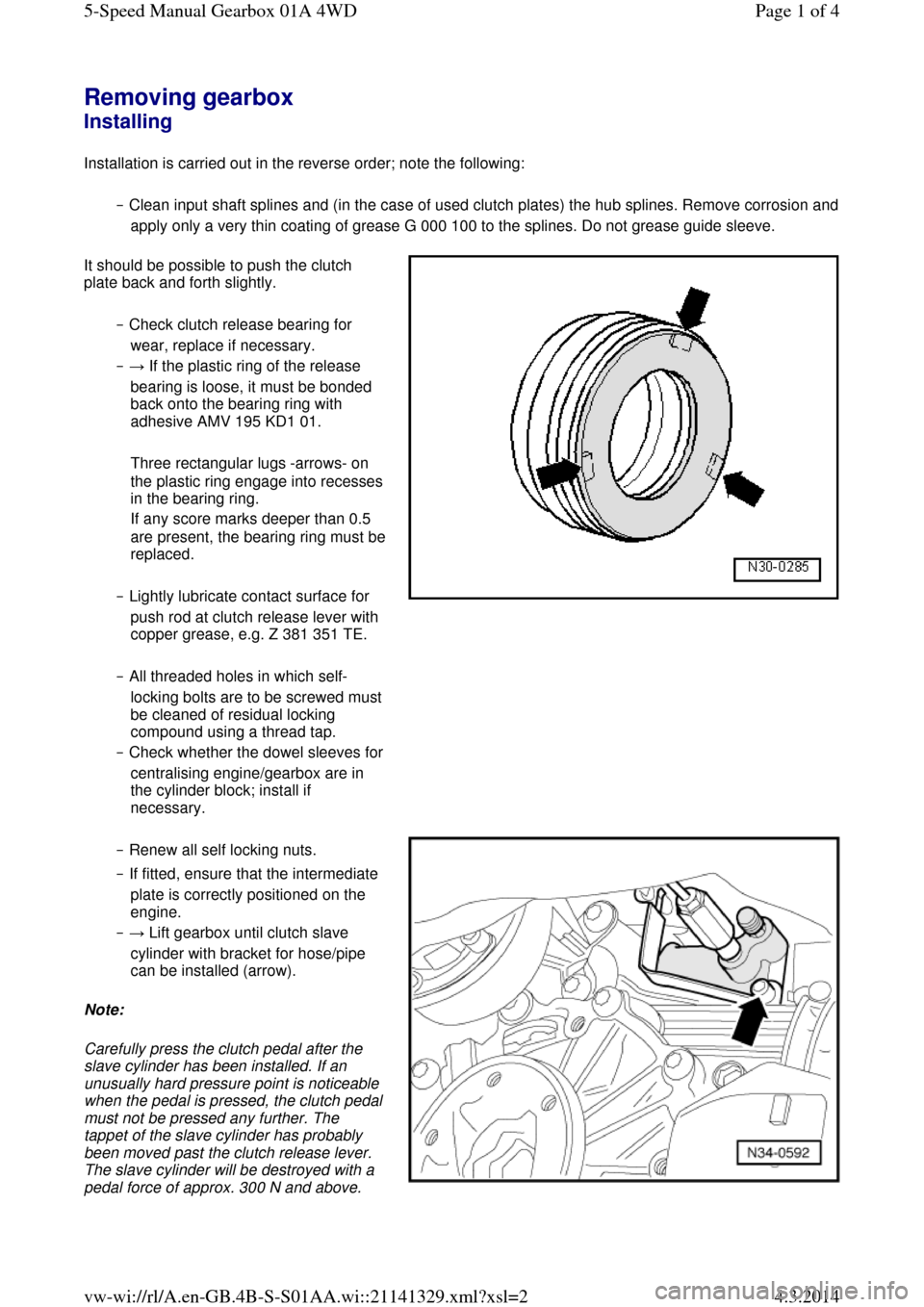

‒ Check clutch release bearing for

wear, replace if necessary.

‒ → If the plastic ring of the release

bearing is loose, it must be bonded

back onto the bearing ring with

adhesive AMV 195 KD1 01.

Three rectangular lugs -arrows- on the plastic ring engage into recesses in the bearing ring.

If any score marks deeper than 0.5 are present, the bearing ring must be replaced.

‒ Lightly lubricate contact surface for

push rod at clutch release lever with

copper grease, e.g. Z 381 351 TE.

‒ All threaded holes in which self-locking bolts are to be screwed must be cleaned of residual locking

compound using a thread tap.

‒ Check whether the dowel sleeves for centralising engine/gearbox are in

the cylinder block; install if

necessary. ‒ Renew all self locking nuts.

‒ If fitted, ensure that the intermediate

plate is correctly positioned on the

engine.

‒ → Lift gearbox until clutch slave

cylinder with bracket for hose/pipe

can be installed (arrow).

Note:

Carefully press the clutch pedal after the

slave cylinder has been installed. If an

unusually hard pressure point is noticeable when the pedal is pressed, the clutch pedal must not be pressed any further. The

tappet of the slave cylinder has probably

been moved past the clutch release lever.

The slave cylinder will be destroyed with a pedal force of approx. 300 N and above. Page 1 of 45-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141329.xml?xsl=2

Page 59 of 71

‒ → Detach clutch release lever -A-

with release bearing.

Notes:

◆ Before pulling off guide sleeve, cover input shaft splines with a shrink-fit

hose to protect oil seal.

◆ Removing oil seal from guide sleeve

=> Page 30-32.

‒ Unscrew guide sleeve -B-.

‒ Remove dished washer -C-.

‒ Remove circlip -D- in front of input

shaft ball bearing. ‒ If the ball bearing, input shaft or

gearbox housing is not to be

replaced, note the thickness of the

circlip.

‒ → Pull the input shaft ball bearing

out of the gearbox housing. Page 3 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2