tow AUDI A6 2000 C5 / 2.G Changing Clutch 5Speed Manual Gearbox

[x] Cancel search | Manufacturer: AUDI, Model Year: 2000, Model line: A6, Model: AUDI A6 2000 C5 / 2.GPages: 71, PDF Size: 1.82 MB

Page 1 of 71

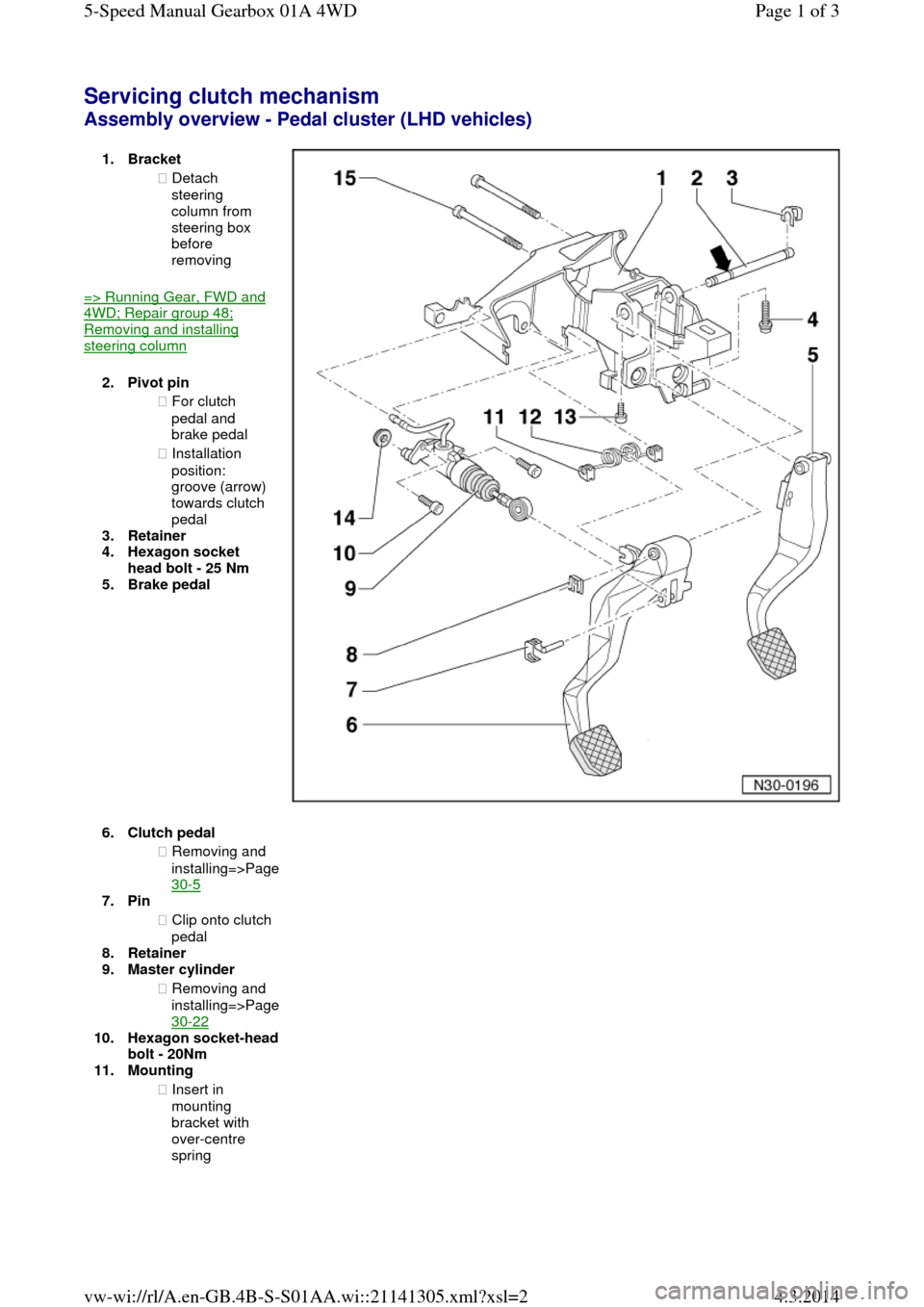

Servicing clutch mechanism Assembly overview - Pedal cluster (LHD vehicles) 1.Bracket ◆ Detach

steering

column from

steering box

before

removing

=> Running Gear, FWD and 4WD; Repair group 48; Removing and installing steering column

2.Pivot pin

◆ For clutch

pedal and

brake pedal

◆ Installation

position:

groove (arrow)

towards clutch

pedal

3.Retainer

4.Hexagon socket

head bolt - 25 Nm

5.Brake pedal

6.Clutch pedal ◆ Removing and installing=>Page 30-5

7.Pin

◆ Clip onto clutch

pedal

8.Retainer

9.Master cylinder

◆ Removing and installing=>Page 30-22

10.Hexagon socket-head bolt - 20Nm

11.Mounting

◆ Insert in

mounting

bracket with

over-centre

spring Page 1 of 35-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141305.xml?xsl=2

Page 9 of 71

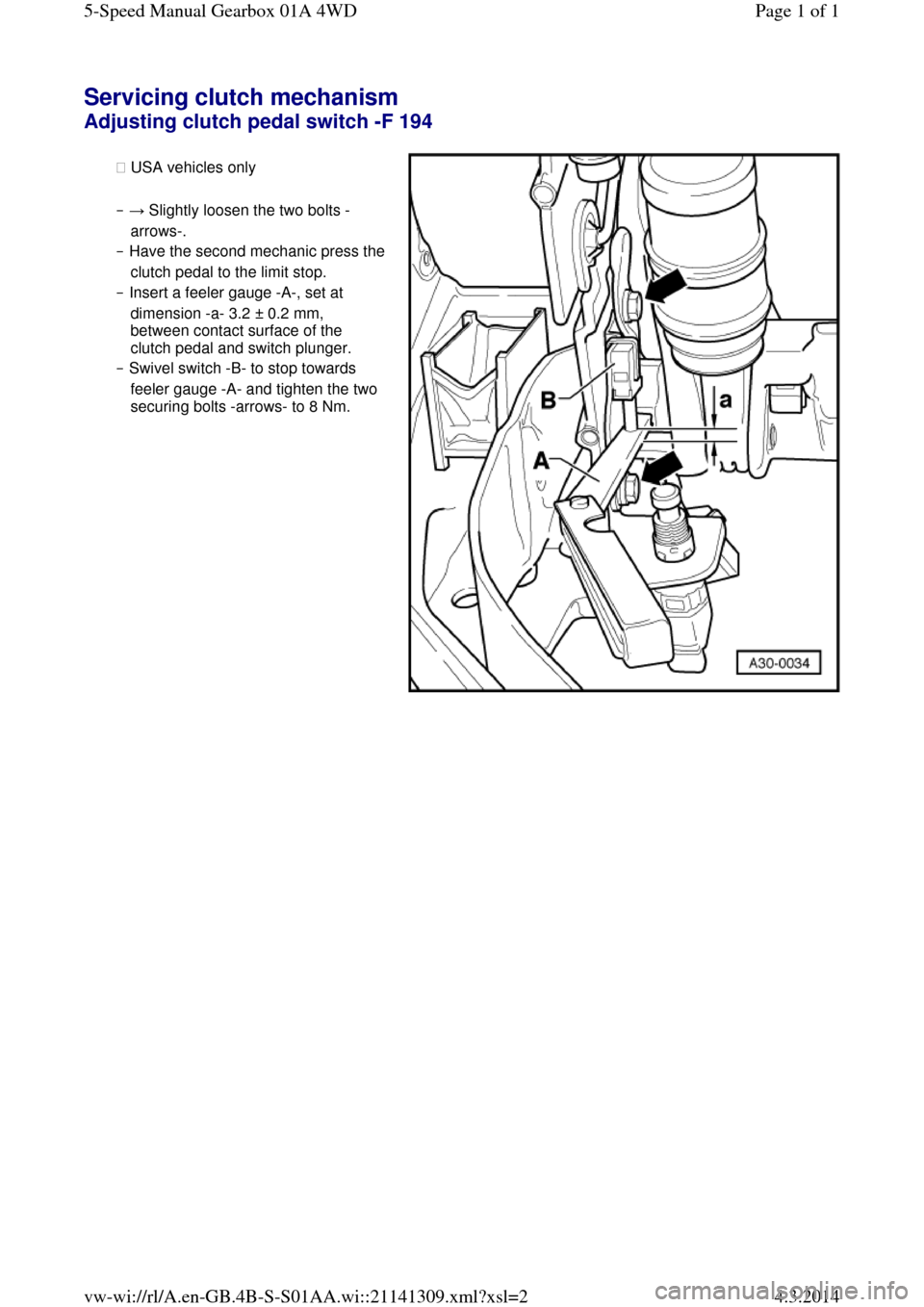

Servicing clutch mechanism Adjusting clutch pedal switch -F 194 ◆ USA vehicles only

‒ → Slightly loosen the two bolts -

arrows-.

‒ Have the second mechanic press the clutch pedal to the limit stop.

‒ Insert a feeler gauge -A-, set at

dimension -a- 3.2 ± 0.2 mm,

between contact surface of the

clutch pedal and switch plunger.

‒ Swivel switch -B- to stop towards

feeler gauge -A- and tighten the two

securing bolts -arrows- to 8 Nm. Page 1 of 15-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141309.xml?xsl=2

Page 16 of 71

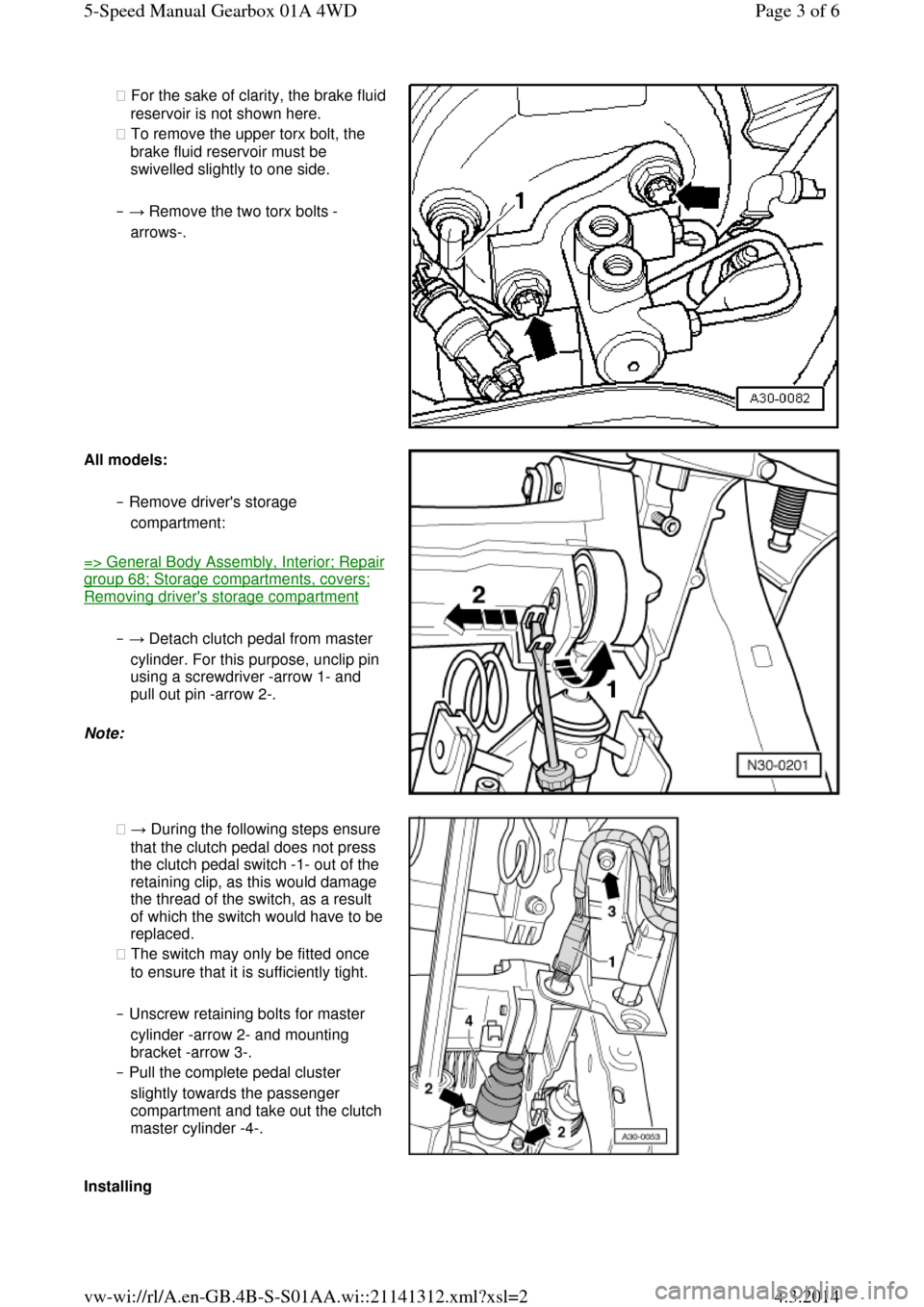

◆ For the sake of clarity, the brake fluid reservoir is not shown here.

◆ To remove the upper torx bolt, the

brake fluid reservoir must be

swivelled slightly to one side.

‒ → Remove the two torx bolts -

arrows-. All models: ‒ Remove driver's storage

compartment: => General Body Assembly, Interior; Repair group 68; Storage compartments, covers; Removing driver's storage compartment

‒ → Detach clutch pedal from master

cylinder. For this purpose, unclip pin

using a screwdriver -arrow 1- and

pull out pin -arrow 2-.

Note: ◆ → During the following steps ensure

that the clutch pedal does not press

the clutch pedal switch -1- out of the

retaining clip, as this would damage

the thread of the switch, as a result of which the switch would have to be replaced.

◆ The switch may only be fitted once

to ensure that it is sufficiently tight.

‒ Unscrew retaining bolts for master

cylinder -arrow 2- and mounting

bracket -arrow 3-.

‒ Pull the complete pedal cluster

slightly towards the passenger compartment and take out the clutch master cylinder -4-. Installing Page 3 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141312.xml?xsl=2

Page 17 of 71

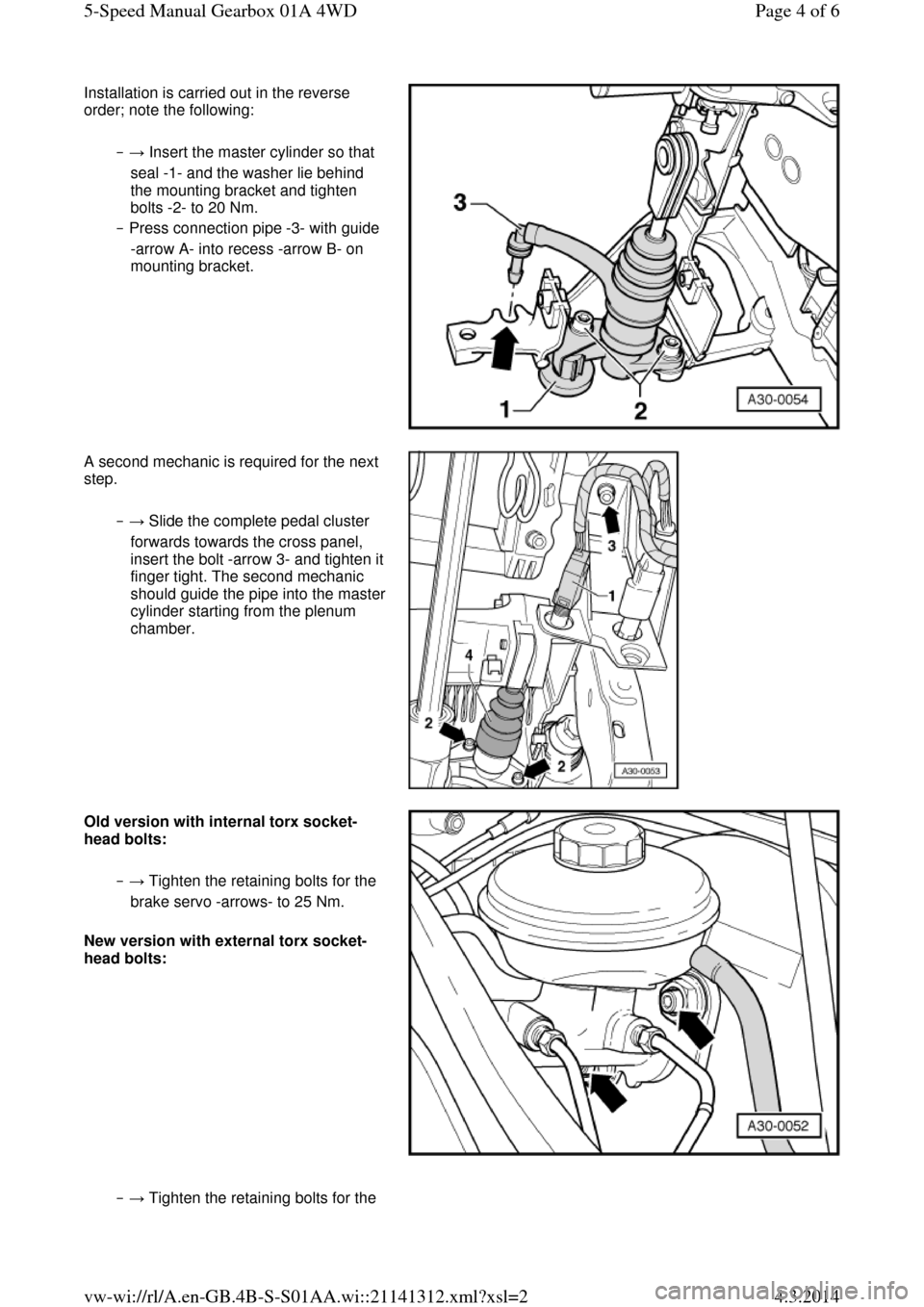

Installation is carried out in the reverse

order; note the following:

‒ → Insert the master cylinder so that

seal -1- and the washer lie behind

the mounting bracket and tighten

bolts -2- to 20 Nm.

‒ Press connection pipe -3- with guide

-arrow A- into recess -arrow B- on

mounting bracket. A second mechanic is required for the next

step.

‒ → Slide the complete pedal cluster

forwards towards the cross panel,

insert the bolt -arrow 3- and tighten it finger tight. The second mechanic should guide the pipe into the master cylinder starting from the plenum

chamber. Old version with internal torx socket-head bolts:

‒ → Tighten the retaining bolts for the

brake servo -arrows- to 25 Nm.

New version with external torx socket-

head bolts: ‒ → Tighten the retaining bolts for the Page 4 of 65-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141312.xml?xsl=2

Page 29 of 71

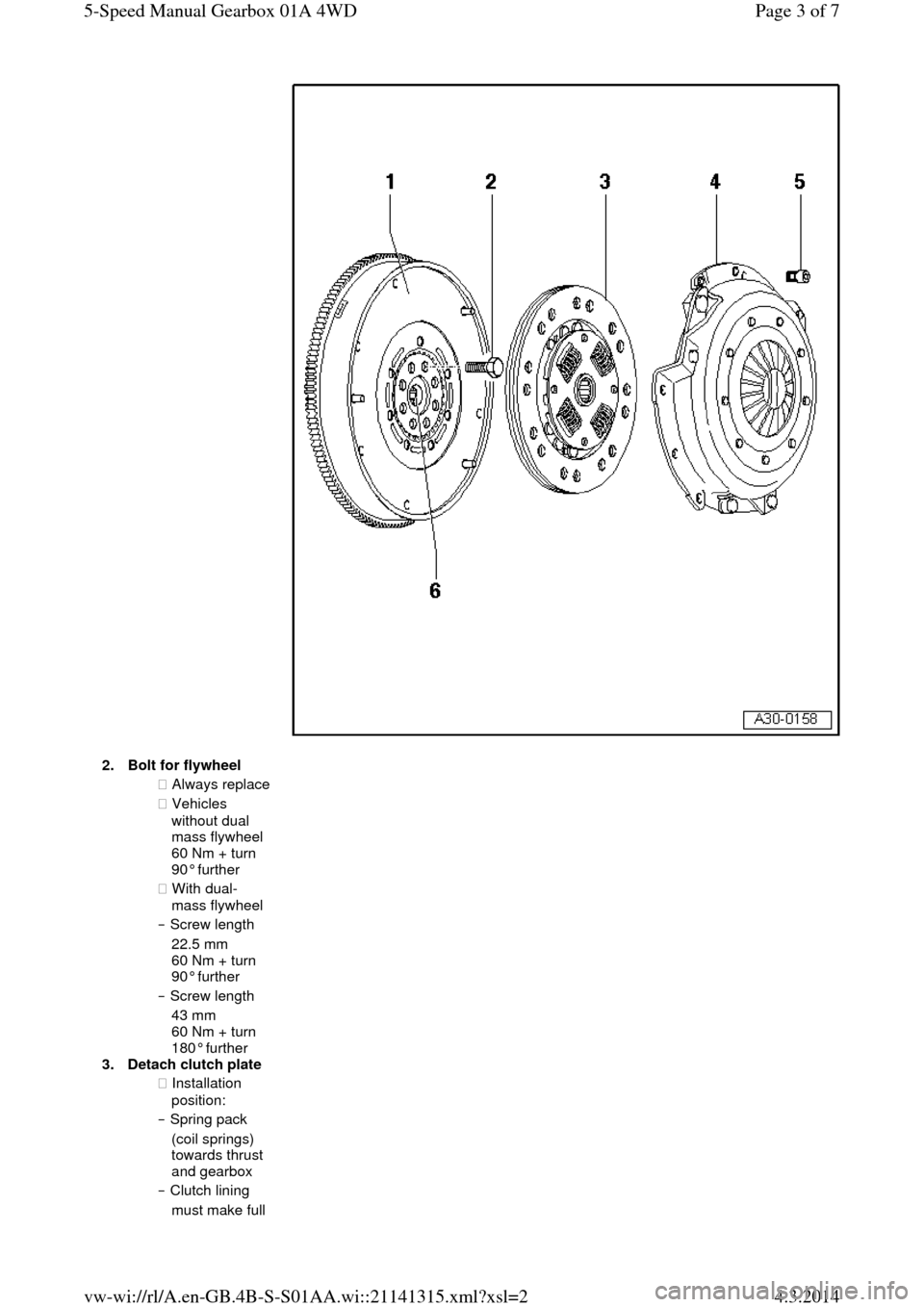

2.Bolt for flywheel ◆ Always replace ◆ Vehicles

without dual

mass flywheel

60 Nm + turn

90° further

◆ With dual-

mass flywheel ‒ Screw length

22.5 mm

60 Nm + turn

90° further

‒ Screw length

43 mm

60 Nm + turn

180° further

3.Detach clutch plate

◆ Installation

position:

‒ Spring pack

(coil springs)

towards thrust

and gearbox

‒ Clutch lining

must make full Page 3 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

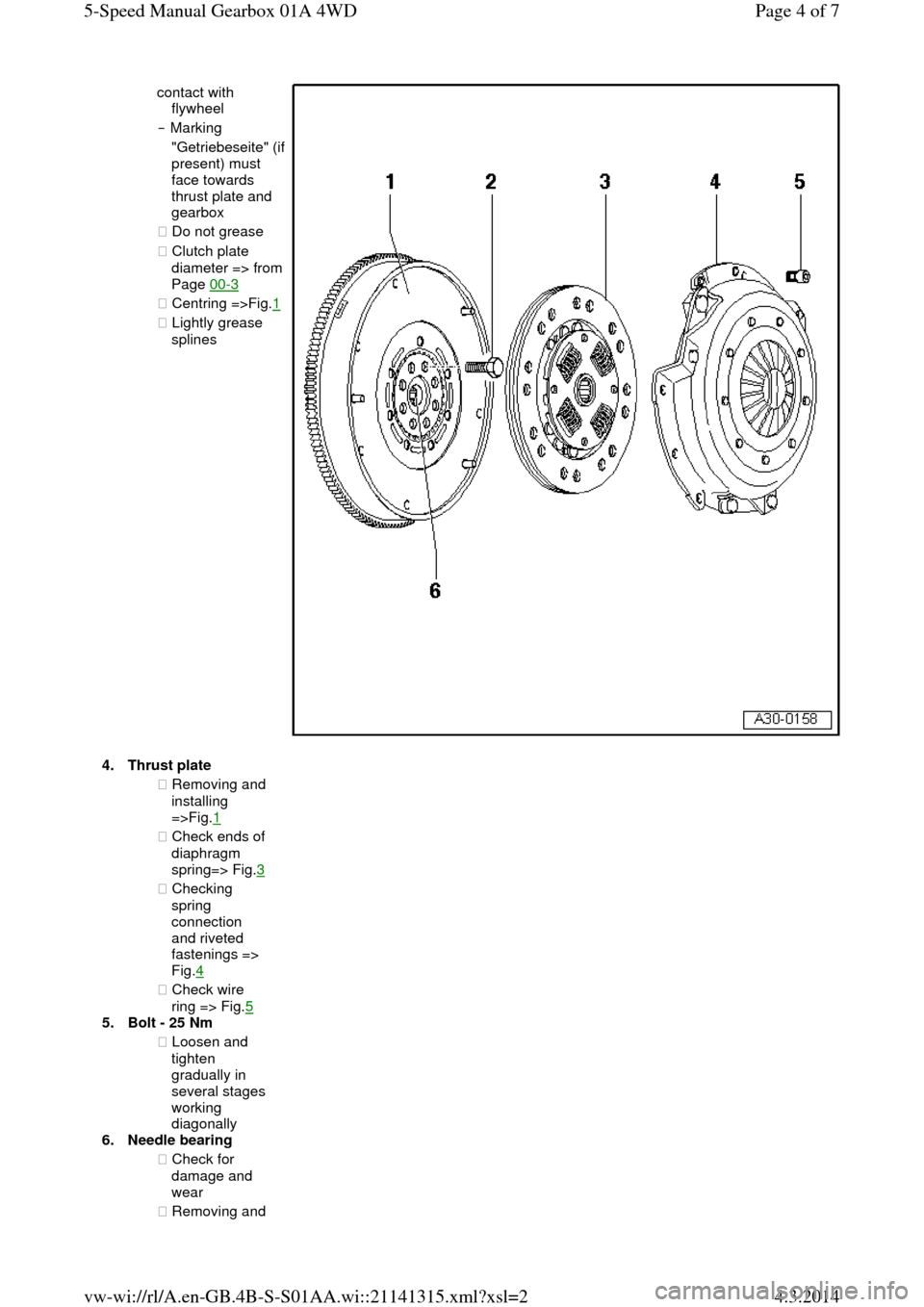

Page 30 of 71

contact with

flywheel

‒ Marking "Getriebeseite" (if present) must

face towards

thrust plate and

gearbox

◆ Do not grease

◆ Clutch plate diameter => from Page 00-3

◆ Centring =>Fig.1 ◆ Lightly grease

splines 4.Thrust plate ◆ Removing and

installing

=>Fig.1

◆ Check ends of

diaphragm

spring=> Fig.3 ◆ Checking

spring

connection

and riveted

fastenings =>

Fig.4

◆ Check wire

ring => Fig.5

5.Bolt - 25 Nm

◆ Loosen and

tighten

gradually in

several stages

working

diagonally

6.Needle bearing

◆ Check for

damage and

wear

◆ Removing and Page 4 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

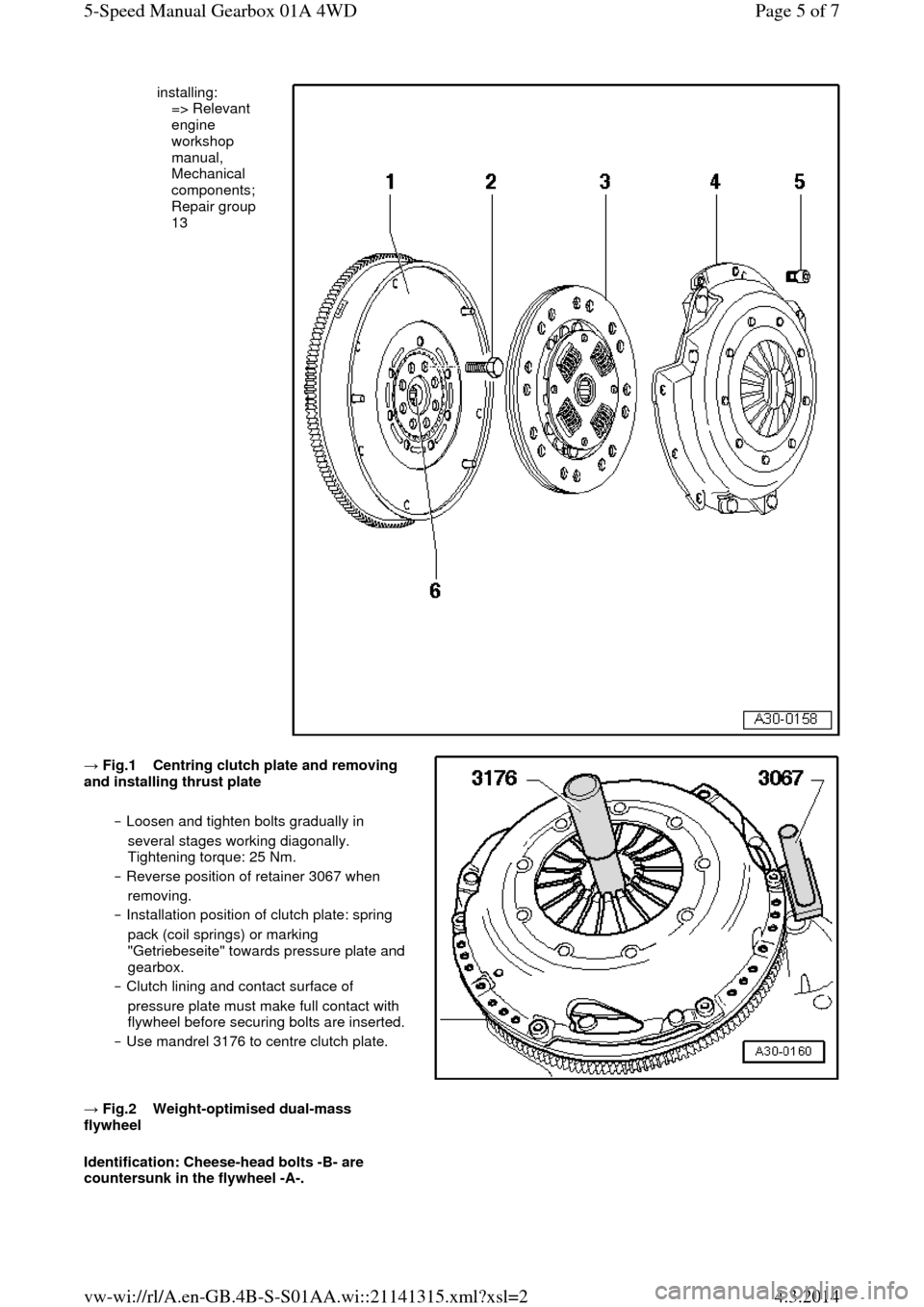

Page 31 of 71

installing:

=> Relevant

engine

workshop

manual,

Mechanical

components;

Repair group

13 → Fig.1 Centring clutch plate and removing and installing thrust plate

‒ Loosen and tighten bolts gradually in

several stages working diagonally.

Tightening torque: 25 Nm.

‒ Reverse position of retainer 3067 when

removing.

‒ Installation position of clutch plate: spring

pack (coil springs) or marking

"Getriebeseite" towards pressure plate and

gearbox.

‒ Clutch lining and contact surface of

pressure plate must make full contact with

flywheel before securing bolts are inserted. ‒ Use mandrel 3176 to centre clutch plate.

→ Fig.2 Weight-optimised dual-mass flywheel

Identification: Cheese-head bolts -B- are

countersunk in the flywheel -A-. Page 5 of 75-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141315.xml?xsl=2

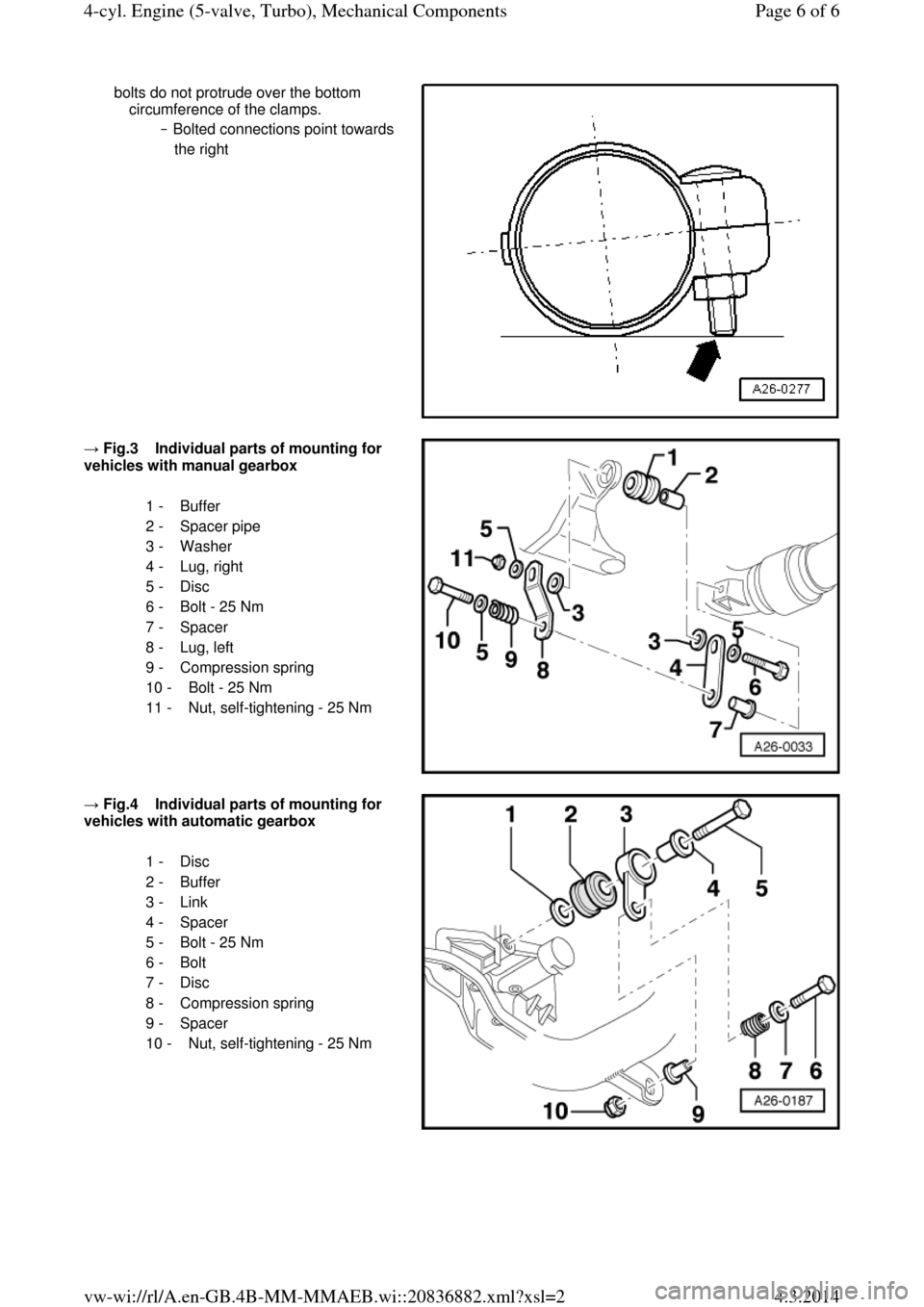

Page 53 of 71

bolts do not protrude over the bottom

circumference of the clamps.

‒ Bolted connections point towards

the right → Fig.3 Individual parts of mounting for vehicles with manual gearbox

1 - Buffer

2 - Spacer pipe

3 - Washer

4 - Lug, right

5 - Disc

6 - Bolt - 25 Nm

7 - Spacer

8 - Lug, left

9 - Compression spring

10 - Bolt - 25 Nm

11 - Nut, self-tightening - 25 Nm

→ Fig.4 Individual parts of mounting for vehicles with automatic gearbox

1 - Disc

2 - Buffer

3 - Link

4 - Spacer

5 - Bolt - 25 Nm

6 - Bolt

7 - Disc

8 - Compression spring

9 - Spacer

10 - Nut, self-tightening - 25 Nm Page 6 of 64-cyl. Engine (5-valve, Turbo), Mechanical Components4.3.2014vw-wi://rl/A.en-GB.4B-MM-MMAEB.wi::20836882.xml?xsl=2

Page 66 of 71

cover -A- are fitted in gearbox cover -

B- (arrows).

‒ Fit spring -C-.

‒ Apply thin coat of sealant AMV 188

001 02 to sealing surfaces.

‒ Fit cover with Torsen differential -A-

on gearbox cover -B-. ‒ → Fit rear input shaft ball bearing

circlip (arrow).

‒ Push the ball bearing onto the input

shaft.

‒ Installation position: closed

side of ball cage faces

towards gearbox housing ‒ → Press in ball bearing:

‒ Push thrust pad -A- of pressing-in

tool onto input shaft.

‒ Position pressing-in tool behind

splines for clutch plate.

‒ Screw in the bolts -B- until they make contact.

‒ The bolts bear against the

indentations in thrust pad -A-. ‒ Press in ball bearing onto its seat by

alternately tightening the bolts (1/2

turn at a time). ‒ → Now fit the front circlip -D- for the Page 10 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2

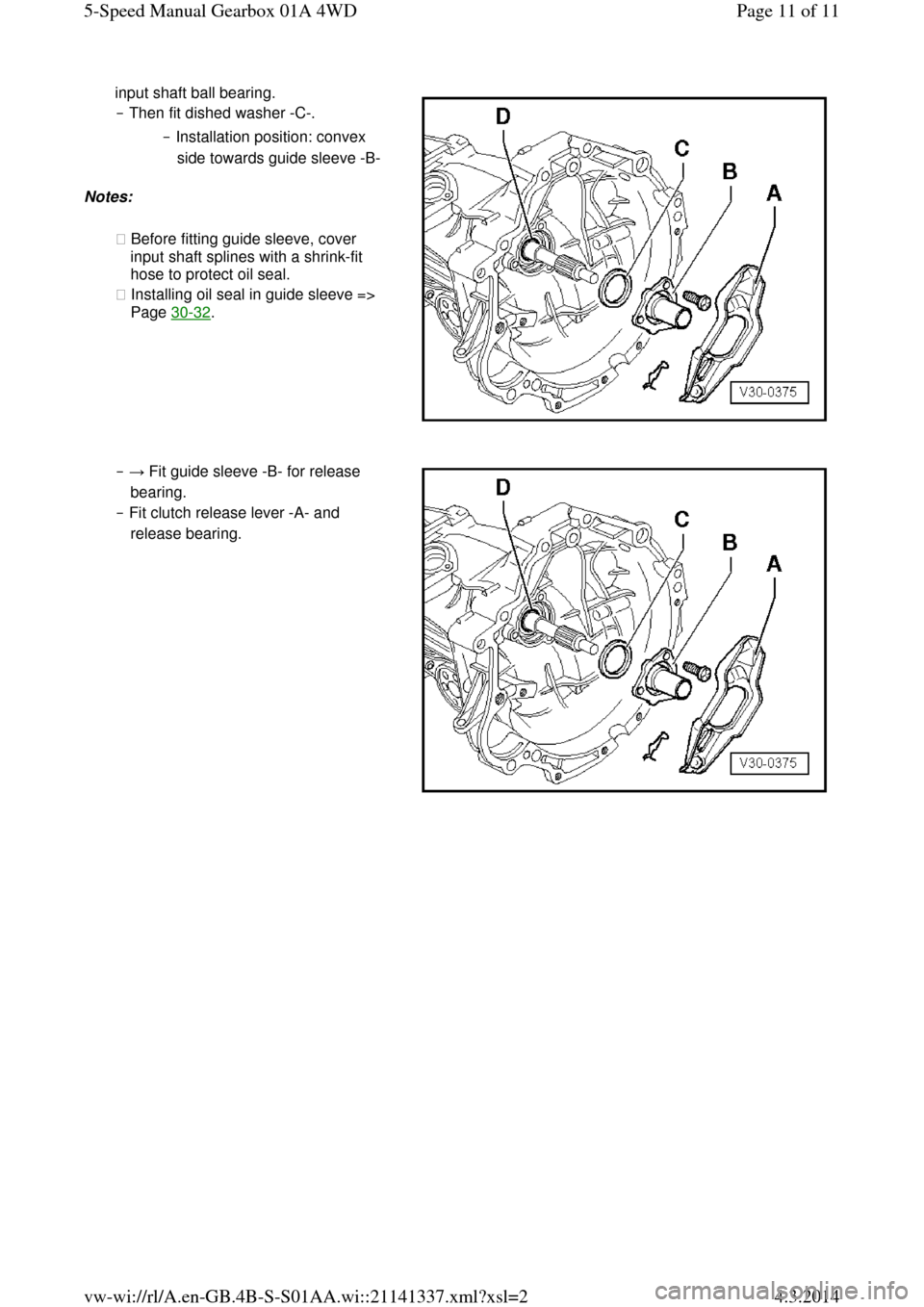

Page 67 of 71

input shaft ball bearing.

‒ Then fit dished washer -C-.

‒ Installation position: convex

side towards guide sleeve -B- Notes:

◆ Before fitting guide sleeve, cover

input shaft splines with a shrink-fit

hose to protect oil seal.

◆ Installing oil seal in guide sleeve =>

Page 30-32. ‒ → Fit guide sleeve -B- for release

bearing.

‒ Fit clutch release lever -A- and

release bearing. Page 11 of 115-Speed Manual Gearbox 01A 4WD4.3.2014vw-wi://rl/A.en-GB.4B-S-S01AA.wi::21141337.xml?xsl=2