technical data AUDI A6 2011 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2011, Model line: A6, Model: AUDI A6 2011Pages: 370, PDF Size: 87.15 MB

Page 323 of 370

What do I do now? Ill

----------------

& WARNING (con tinued)

Trans missio n in "P " (Pa rk) w ill not pre ve nt the vehicle from

mo ving .

• Befo re you ch an ge a wheel , be s ure the ground i s le ve l an d

firm . If ne cess ary, us e a sturdy b oard und er the jack.

• Aft er in st a llin g the sp are wheel , make sure that you repl ace

the flat tire /wheel in it s storage area prop erly and tight en the

knurled ret ain ing s crew se cu rel y.•

Changing a wheel

When you change a wheel, follow the sequence described

below step-by-step and in exactly that order .

1. Activate the vehicle jack mode (only vehicles with Adaptive

Air Suspension) =>

page 170.

2. Remove the decorative wheel cover *. For more details see

also =>

page 322, "Decorative wheel covers" .

3 . Loosen the

wheel bolts => page 322.

4. Locate the proper mo unti ng point for the jack and align

the jack below that point=>

page 323.

5. Lift the car with the jack=> page 323.

6. Remove the wheel with the flat tire and then install the

spare =>

page 324.

7. Tighten all wheel bolts lightly.

8 .

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly t ighten all wheel

bolts =>

page 322.

10. Replace the decorative wheel cover *.

Safety first

1 1. Deactivate the vehicle jack mode (only vehicles with

Adaptive Air Suspens ion) =>

page 170 .

& WARNING

Alwa ys re ad and f ollow all WARNINGS and information ~ & in

" Ra ising the vehicl e" on pag e

32 3 and ~ pag e 325. •

After changing a wheel

A wheel change is not complete without the doing the

following .

-Store and secure the wheel you replaced in the spare

wheel well .

- Replace the tools and the jack in the ir proper location.

- Check the tir e pr essur e on the spare wheel immediately

after mounting it .

- As soon as possib le, have the

tighten ing torques on a ll

wheel bolts checked with a torque wrench . The correct

tightening torque is 90 ft lb (120 Nm) .

- Have the flat tire

replaced as soon as possible.

[ i ] Tips

• If you not ic e that the wheel bolts are corroded and difficu lt to turn

wh ile chang ing a tire, they should be replaced before you check the

tightening torque .

• Drive at reduced speed until you have the tighten ing torques

checked. •

Vehicle care Do-it-yourself service Technical data

Page 325 of 370

What do I do now? -_______________ __.PfWII

& WARNING (continued)

• Do not loosen the wheel bolts more than one turn before you

raise the vehicle with the jack. -You risk an injury.

(I) Tips

• Never use the hexagonal socket in the handle of the screwdriver to

loosen o r tighten the wheel bolts .

• If a wheel bolt is very tight, you may find it easier to loosen by

carefully pushing down on the end of th e wheel bolt wrench with

one

foot only .

As you do so, hold on to the car to keep your balance and

take ca re not to slip .•

Raising the vehicle

The vehicle must be li~ed with the jack first before the

wheel can be removed.

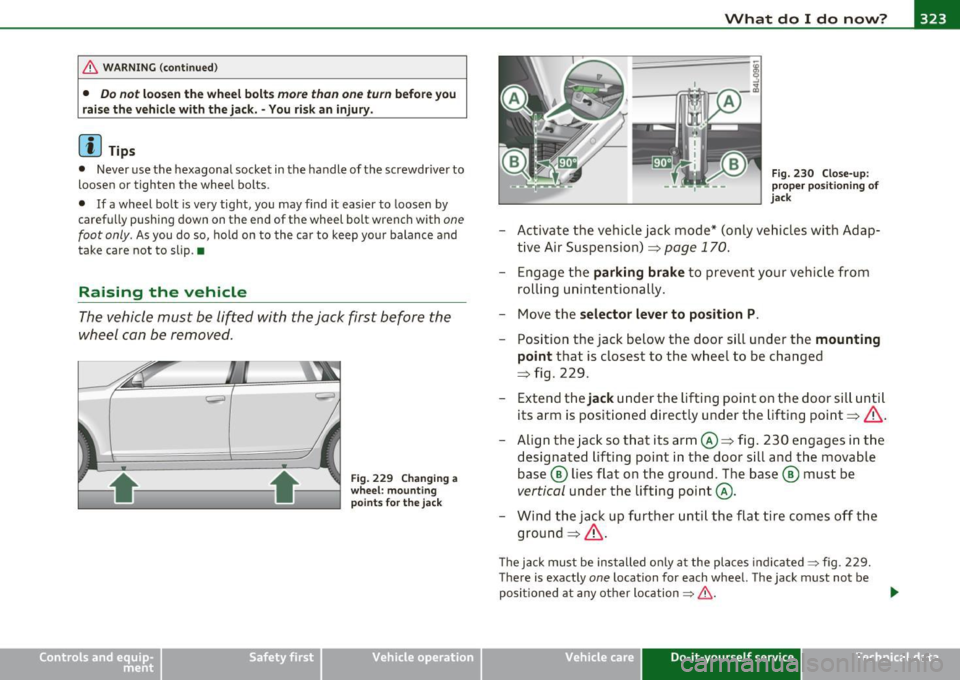

Fig. 229 Changing a

wheel: mounting

points for the jack

Vehicle OP-eration

Fig. 230 Close-up:

proper positioning of

jack

- Activate the vehicle jack mode* (only vehicles with Adap

tive Air Suspension)=>

page 170.

-Engage the parking brake to prevent your vehicle from

rolling unintentionally.

- Move the

selector lever to position P.

-Position the jack below the door sill under the mounting

point

that is closest to the wheel to be changed

=> fig . 229.

- Extend the

jack under the lifting point on the door sill until

its arm is positioned directly under the lifting point=>& .

- Align the jack so that its arm©=> fig. 230 engages in the

designated lifting point in the door sill and the movable

base ® lies flat on the ground. The base® must be

vertical under the lifting point@.

- Wind the jack up further until the flat tire comes off the

ground =>& .

The jack must be installed only at the places indicated=> fig . 229.

There is exactly

one location for each wheel. The jack must not be

positioned at any other location

~ & .

Vehicle care Do-it-yourself service iTechnical data

Page 327 of 370

What do I do now? -________________ Vf'.'11

- Screw the threaded end of the alignment pin from the

tool kit hand-tight into the empty bo lt hole~

page 324,

fig. 232.

- Then re m ove the o ther wheel bolts as described above.

- Take off t he w heel leaving the alignment pin i n the bolt

hole.

Putting on the spare wheel

- Lift the spare wheel and carefully slide it over the alig n

ment pi n to guide it in p lace .

- Use the hexagona l socket in the screwdriver handle to

screw in and tighte n all w heel bolts

slightly.

- Remove the alig nment pi n and inse rt an d tighten the

remaining wheel bolt slig htly like the rest.

- Turn the jac k han dle counter-c lockwise to lower the

ve hicle u ntil the jack is fully released.

- Use the wheel bolt wrench to t ighten all whee l bolts firmly

~ page 322. Ti ghten them crosswise, from one bolt to

the (approximately) opposite one, to keep the w heel

centered.

[I] Tips

Never use the hexagonal socket i n the handle of the screwdriver to

loosen or tighten the wheel bolts.

• Pull the reve rsible blade from the screwdriver before yo u use the

hexagonal socket in the handle to t urn the whee l bolts.

• When mounting tires with

unidirectional tread design make sure

t he tread pa ttern is po inted the right way~

page 325.

Safety first

• The wheel bolts should be clea n and easy to turn. Check for dirt

and cor rosion on the mat ing surfa ces o f bo th the whee l and the hub.

Remove all d irt from these surfaces before remounting the wheel. •

Tires with unidirectional tread design

Tires with unidirectional tread design must be mounted

with their trea d pattern pointed in the right direction .

Using a spare tire with a tread pattern intended for

use in a specific direction

When using a spare tire w ith a tread pattern intended for use in a

specific direction, p lease note the fo llow ing:

• T he direct ion of rotation is marked by an ar row on the s ide of the

tire.

• If the spare tire has to be installed in the incor rect d irect ion, use

the spare tire only tempo rari ly since the tire wi ll not be ab le to

achieve its optimum pe rforma nce charact erist ics with rega rd to

aquaplaning, noise and wear.

• We recommend that you pay particular attention to this fact

during wet weather and that you adjust your speed to match road

condit ions.

• Replace the flat t ire with a new one and have it installed on your

vehicle as soon as possible to restore the handling advantages of a

unidirect iona l tire .•

Notes on wheel changing

Please read the information~ page 307, "New tires and replacing

t ires and wheels" if yo u are go ing to use a spa re t ire wh ich is d iffe rent

from the tires on yo ur vehicle .

After you c hange a ti re:

• Check the tire pressure on the spa re immediately after installa-

tion. ..,

Vehicle care Do-it-yourself service Technical data

Page 329 of 370

______________________________________________ F _u_s _e_ s_ a_ n_ d _ b _u_l_b _ s _ ___.9I

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips that have

burned through .

Fig. 233 Left cockpi t:

f use panel cover

The fuses are located at the front left and right of the cockpit

and behind the trim on the right side of the luggage compart

ment .

- Turn off the ignition and the affected electr ical

consumers.

- Check the following table to see which fuse belongs to the

consumer.

- Remove the appropriate cover.

- To remove the purple plastic clip if necessary

4

), hold onto

it at the small side and pull it out of the fuse panel.

4J You can dispose of the p last ic cli p after remov ing it .

Vehicle OP-eration

- Remove the clamp from the rear side of the fuse cover

=> fig. 233.

-Remove the fuse using the clamp and replace the blown

fuse with an identical new one.

& WARNING

Do not repair fuses and never replace a blown fuse with one that

has a higher amp rating. This can cause damage to the electrical

system and a fire.

0 Note

If a new fuse burns out again after shortly have you have installed it,

have the electrical system checked by your authorized Aud i dea ler.

[I) Tips

• The follow ing tab le does not list fuse locations that are not used .

• Th e crank in the cover is used for emergency operation of the

power roof*.•

Vehicle care Do-it-yourself service iTechnical data

Page 331 of 370

______________________________________________ F _u_s _e_ s_ a_ n_ d _ b _u_l_b _ s_---J _

Fuse assignment, cockpit passenger's side

No . Consumer

Fu se pa nel (bl ack )

1 Control module Convenience key

2 Cigarette lighter front

3 Tire pressure monitoring system

4 Electrical outlet front (center console)

5 Intelligent power module passenger

(glove box lock)

6 Door control module right-s ide

7 Sunroof

8 A/C cont rols

9 Heated seats, front

10 MMI

11 Seat adjustment (passenger)

12 Communication

Fu se pan el (brown )

1 Electr ic fuel pump

Fig . 235 Cockp it

passenger 's side : fuse

pa nel layo ut

Amps

15

20

5

20

15

15

-

20 1 0

30

7 ,5

10

5

20/30

Vehicle OP-eration

No. Consume r .,

2 Adaptive Air Suspension

3 Lane assist

4 Audi side assist

S Adaptive Air Suspens ion

6 Shift gate automatic transmission/clutch switch Parking System

9

10 Control module Gateway

Automatic headlight range control (a

uxiliary

driving lights) , headl ight electronics, right -side

Airbag

11 Heated rear seats

12 Telephone

Amps

15

10

5

5

5

5

5

5

5

5

5

Fuse assignment , luggage compartment

right

F ig. 236 R ight

luggage compartment:

fuse pane l layo ut

Re ad nu mber s of the fuses in the l ug ga ge comp art men t sta rti ng

from below ~ fig . 236.

•

Vehicle care Do-it-yourself service Technical data

Page 333 of 370

Fuses and bulbs -________________ Ef"I

& WARNING (co ntinued )

• Only an authorized Audi dealer o r other qualified workshop

should change the bulb s in gas dis charge lamps .

& WARNING

There are parts with sharp edges on the openings and on the bulb

holders that can cause serious cuts .

• If you are uncertain about what to do , have the work

performed by an auth orized Audi dealer or other qualified work

shop. Serious personal injury may result from imp roperly

performed work.

[ i ] Tips

• If you m ust rep lace the lig ht bulbs yo ursel f, a lways remember

tha t the eng ine compartment of any vehicle is a hazardous area to

work in . Always rea d and hee d all WAR NINGS ~

page 271, "Engine

compartment"~ &.

• It is bes t to ask yo ur au thorize d Audi dea ler wheneve r you need to

change a bulb .•

Safety first Vehicle care Do-it-yourself service Technical data

Page 335 of 370

_____________________________________________ E_ m___;, e_r-=g ~ e_ n_c,_:!y:.__: s_i:..:t ..:..u :..:a;;,. t.:.; i...: o :..: n...:..:. s _ __,J_

& WA RNING (co ntinued )

• Before you che ck anything in the engine compartment , always

read and heed all WARNINGS~

page 271, "Engine compart

ment ".

0 Note

• App lying a higher vo ltage booster battery will cause expensive

damage to sens itive e lec tron ic component s, such as contro l units,

re lays, rad io, etc.

• Th ere must be no electrical contac t between the vehicles as othe r

wise current could a lready start to flow as soon as the posit ive(+)

t erm inals are con nected.

[I] Tips

• Th e discharged ba tte ry mus t be properly co nnecte d to the

vehicle's electrical system . When jump starting or charging the

bat tery, never connec t the negat ive ground cable to the batte ry nega

tive post because the battery manager system must be able to detect

t he battery's state of charge . Always connect the negative ground

cable to the negative ground post of the battery manage r contro l

unit. •

Vehicle OP-eration

Use of jumper cables

Make sure to conne ct the jumper c able clamps in e xactly

the order described bel ow!

Fig. 237 Engine

c omp artment : C on nec

t o rs for jum per cable s

a nd ch arger

F ig . 238 J ump

sta rting wit h the

battery of anot her

v ehi cle: A -disch arged

v eh icle battery , B -

boo ster battery

Th e pro ce dur e descr ibed b elow f or con necting j ump er cabl es

is int en de d to provide a jum p star t for yo ur vehi cle.

Vehicle with discharged battery:

-Turn off lig hts a nd accessories, move lever o f au tomat ic

t ransmission to

N (N eutral) o r P (P ark) and se t parking

b rake.

~

Vehicle care Do-it-yourself service iTechnical data

Page 337 of 370

Emergency situations --------------=---:.--___.VPII

Emergency towing with

commercial tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by commercial tow truck

operators who know how to operate their equipment safely.

• Never tow your Audi, towing will cause damage to the engine

and transmission.

• Never wrap the safety chains or winch cables around the brake

lines.

• To prevent unnecessary damage, your Audi must be transported

with a flat bed truck.

• To load the vehicle on to the flat bed, use the towing loop found

in the vehicle tools and attach to the front or rear anchorage

=> page 335 and=> page 336 .

& WARNING

A vehicle being towed is not safe for passengers. Never allow

anyone to ride in a vehicle being towed, for any reason. •

Vehicle OP-eration

Front towing loop

Do not install the front towing loop until it is needed.

Fig. 239 Front

bumper: removing the

cover cap

Fig. 240 Front

bumper: screwing in

the towing loop

The towing loop fits into the threaded hole located on the

right side of the front bumper and covered by a small cover

when not in use.

- Remove the towing loop from the vehicle toolkit

=> page 318.

- Press the cover in by applying short sharp pressure to the

bottom part to release it from the bumper=> fig. 239.

- Screw the towing loop tightly into the threaded hole as far

as it will

go => fig. 240. ~

Vehicle care Do-it-yourself service iTechnical data

Page 339 of 370

_____________________________________________ E_ m __ e_r-=g =- e_ n_c -==y "- s_i_ t _u _a _ t_ i_ o _ n_ s _ __.lfll

- Attach the winch hook to the rear tow line eye previously

installed .

[I] Tips

Check carefu lly to make sure the hook -up is secure befo re moving the

car up the flatbed truck ramp. •

Lifting vehicle

Lifting with workshop hoist and with floor

jack

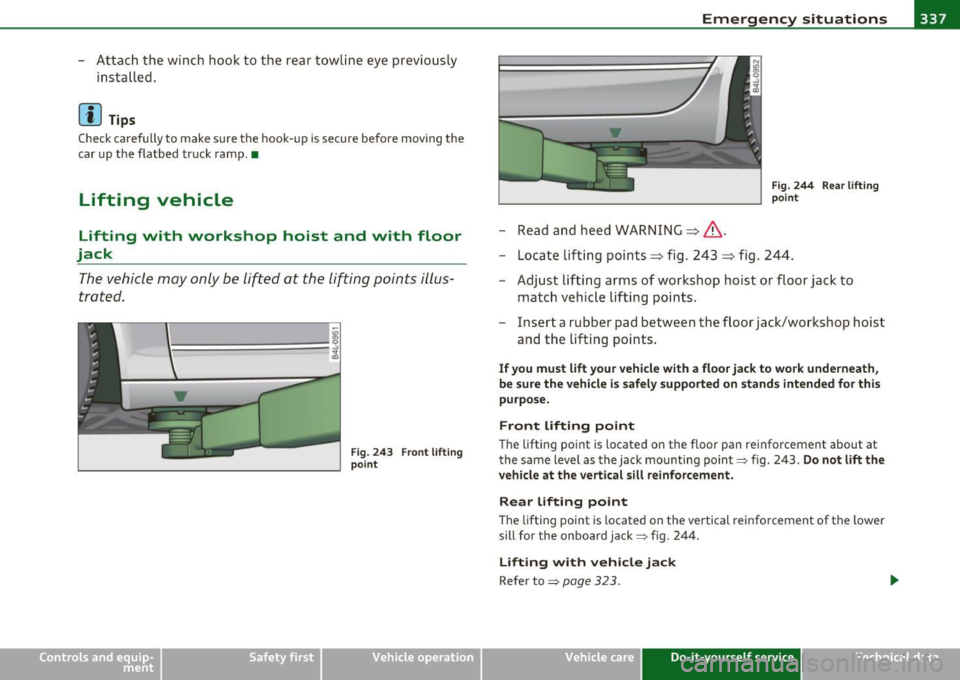

The vehicle may only be lifted at the lifting points illus

tr ated.

i

\= === === ===== .:, ti!

Fig . 2 4 3 Front lifting

p oin t

Vehicle OP-eration

Fig . 2 44 R ea r li ft ing

po int

- Rea d an d heed WAR NIN G :::> & .

- Loca te lifting poi nts :::> fig. 2 43 :::> fig . 244 .

- Adjust lifti ng arms of wor kshop ho ist or floor jac k to

match vehic le liftin g po ints.

- Inse rt a rubber pad between the floor jac k/wo rksh op hoist

an d the lif ting points.

If you must lift your vehicle with a floo r jack to wo rk underneath ,

be sure the vehicle is safely supported on stand s intended for thi s

purpose.

Front lifting po int

Th e lifting point is located o n the floor pan re inforcement about at

the same level as the jack mounting point=:> fig. 243 .

Do not lift the

vehicle at the vertical sill reinfo rcement.

Rear lifting po int

Th e lifting point is located on the ve rtical reinforcement of the lower

sill for the onboard jack=:> fig . 244 .

Lifting with vehicle jack

Refer to =:> page 323.

Vehicle care Do-it-yourself service iTechnical data

Page 341 of 370

_____________________________________________ E_ m_ e_r-= g ::.. e_ n_c-= y'- s_ i_t _u _a_ t_ i_ o _ n_ s __ _

Safety first Vehicle care Do-it-yourself service Technical data