brake AUDI A7 2017 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2017, Model line: A7, Model: AUDI A7 2017Pages: 284, PDF Size: 72.29 MB

Page 227 of 284

plus maximum load. The maxi

mum load includes the number of

passengers that the vehicle is in

tended to carry ("seating capaci

ty") with an assumed weight of

150 lbs. (68 kg) for each passen

ger at a designated seating posi

tion and the total weight of any luggage in the vehicle . If you tow

a trailer, the weight of the trailer

hitch and the tongue weight of

the loaded trailer must be includ

ed as part of the vehicle load .

The

Gross A xle Weight Rating

("GAWR") is the maximum load

that can be appl ied at each of the

vehicle's two axles.

The fact that there is an upper

limit to your vehicle's Gross Vehi

c le Weight Rating means that the

total weight of whatever is being

carried in the vehicle (including

the weight of a tra iler hitch and

the tongue weight of the loaded

trailer) is limited. The more pas

sengers in the vehicle or passen

gers who are heavier than the

standard weights assumed mean

that less weight can be carried as luggage.

; The Gross Vehicle We ight Rating

N

~ and the Gross Axle Weight Rating 0 co OJ ..

Wheels

are listed on the safety compli

ance sticker label located on the

driver's side B -pillar

¢ page 221,

fig . 192.

_& WAR NING

Overloading a vehicle can cause

loss of vehicle control, a crash

or other accident, serious per

sonal in jury, and even death.

-Carrying more weight than

your vehicle was designed to carry will prevent the vehicle

from handling properly and increase the risk of the loss of

vehicle control.

- The brakes on a vehicle that

has been overloaded may not

be able to stop the vehicle

within a safe distance.

-Tires on a vehicle that has

been overloaded can fail sud

denly, including a blowout and

sudden deflation, causing loss

of control and a crash.

-Always make sure that the to

tal load being transported -

including the weight of a trail

er hitch and the tongue

weight of a loaded trailer - does not make the vehicle

heavier than the vehicle's

Gross Vehicle Weight Rating .

225

Page 238 of 284

Care and cleaning

A WARNING

- Only wash the vehicle when the ignition is

off and follow the instructions from the car

wash operator to reduce the risk of acci

dents.

- To reduce the risk of cuts, protect yourself

from sharp metal components when wash

ing the underbody or the inside of the wheel

housings.

-After washing the vehicle, the braking effect

may be delayed due to mo isture on the

brake rotors or ice in the winter . This in

creases the risk of an acc ident. The brakes

must be d ried first w ith a few careful b rake

applications.

(D Note

- If yo u wash the ve hicle in an automatic car

wash, yo u m ust retract the rear spoiler if

necessary, and fold the exte rior mi rrors in

to reduce the risk of da mage. Power fo ld ing

ex ter ior mirro rs* m ust only be folded in and

out using the power folding func tion.

-

- To red uce the risk of pa int damage, do not

wash the vehicle in direct sun light .

- T o reduce the risk of damage to the s urface,

do not use insect removing sponges, kitchen

sponges o r similar items .

- Matte finish painted vehicle components:

-To reduce the risk of damage to the sur-

face, do not use polis hing agents or hard

wax .

- Never use protective wax. It can destroy

the matte finish effect .

- Do not place any stickers or magnetic

signs on vehicle parts painted with matte

finish paint. The paint could be damaged

when the stickers or magnets are re

moved.

@ For the sake of the environment

Only wash the veh icle in facili ties spec ially de

s igned for that pu rpose . This will reduce the

r isk of dirty wate r contam inated with o il from

ente ring the sewe r system.

Cleaning and care information

W hen clean ing and ca ring for ind ividua l vehicle

components, refer to the fo llow ing tables. The

i n formation conta ined there is s imply recom

mendations. For quest ions or for components t

h at are not listed, cons ult an autho rize d Aud i

dealer or au thor ized Aud i Servi ce Fac ility. Also

fo llow the informa tion found in <=> & .

Ext erior cleaning

Component Situation Solution

Windshield wiper

Deposits ¢ page 47, Cleaning windshield wiper blades

blades

Headlights /

Deposits Soft sponge wi th a m ild soap solution3>

Tail light s

Sensors /

Deposits Sensors: soft cloth with solvent-free cleaning solution

camera lens es Camera lenses: soft cloth w ith alcohol -free cleaning solu -

tion

Snow/ice Hand br ush/solvent-free de-icing spray

Wheels Road salt Water

Bra ke dust Acid-free special cleaning solution

Exhaust tail pipes Road salt Water, clea ning solution su itab le for s tainl ess stee l, if nee-

essa ry

236

Page 242 of 284

Emerg ency assis ta nce

Emergency assistance

General information

... Park the vehicle as far as possible from moving

traffic in the event of a breakdown. In the event

of a flat tire, park the vehicle on a level surface .

It you are on a steep hill, be especially careful.

.,. Set the parking brake .

.,. Switch the emergency flashers on .

... Set up the warning triangle

r=;,page 240 .

... Have the passengers exit the vehicle . They

should move to a safe place, for example be

hind a guard rail.

A WARNING

Follow the steps given above. This is for your

protection and the for the safety of other driv

ers.

Equipment

Warning triangle

A ppl ies to: ve hicles w ith warning triangle

Fig. 196 Luggage compartment lid : wa rnin g triangle

The warning triangle placed in the vehicle at the

factory is located in the luggage compartment.

... Turn the twist lock

r::;, fig. 196 and pull the cover

downward to open the cover .

.,. Remove the warning triangle from its holder.

The luggage compartment lid is only designed to

hold the warning triangle offered by the Audi

Genuine Accessories program.

240

Vehicle tool kit

Fig. 197 Luggage compartment: vehicle tool kit, tire mob i

lity kit and comp ressor

The vehicle tool kit, vehicle jack*, tire mobility

kit* and compressor are stored in the luggage

compartment under the cargo floor cover.

.,. Lift the cargo floor by the plastic handle .

.,. Tu rn the handle counter-clockwise and remove

the cover or the spare ti re*.

A WARNING

Improper use of the vehicle jack can cause se

rious personal injuries.

- Never use the screw driver hex head to

tighten wheel bolts, since the bolts cannot

attain the necessary tightening torque if you

use the hex head, potentially causing an ac

cident.

- The factory-supplied jack is intended only

for your vehicle model. Under no circum stances should it be used to lift heavy

veh icles or other loads; you risk injuring

yourself.

- Never start the engine when the veh icle is

raised, which could cause an accident.

- Support the vehicle securely with a ppropri

ate stands if work is to be performed under

neath the vehicle; otherwise, there is a po

tential risk for injury .

- Never use the jack supplied with your Aud i

on another vehicle, particularly on a heavier

one. The jack is only suitable for use on the

veh icle i t came with.

¢j) Tips

The vehicle jack* in your vehicle is mainte

nance-free.

Page 245 of 284

co

co

.... N

" N .... 0

00

\.J '

authorized Aud i dealer or authorized Audi

Service Facility for assistance.

@ For the sake of the environment

You can give the used tire sealant bottle to an

authorized Audi dealer or authorized A udi

Service Facility for disposal.

@ Tips

Remember to obtain a new bottle of sea lant

from an authorized Audi dea ler or authorized

Audi Service Facility after repairing a tire.

Replacing wheels

Before changing a wheel

Observe the following precautions for your own

and your passenger's safety when changing a

wheel.

.. After you experience a tire failure, pull the car

well away from moving traffic and try to reach

level ground before you stop c::> &.,.

.. All passengers should leave the car and move

to a safe location (for instance, beh ind the

guardrai l) ¢ ,&. .

.. Engage the

parking brake to prevent your vehi

cle from rolling unintentionally ¢,&. .

.. Move

selector lever to position P ¢ ,&. .

.. If you are towing a trailer, unhitch the trailer

from your vehicle .

.. Take the

jack and the spare tire* out of the lug

gage compartment ¢

page 240.

.8, WARNING

You or your passengers could be injured while

changing a wheel if you do not follow these

safety precautions:

- If you have a flat tire, move a safe distance

off the road. Turn off the engine, turn the

emergency flashers on and use other warn

ing devices to alert other motorists.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

Emergency assistance

- To help prevent the vehicle from moving

suddenly and possibly slipping off the jack,

always fully set the parking brake and block

the wheel diagonally opposite the wheel be

ing changed . When one front wheel is lifted

off the ground, placing the Automatic

Transmission in P (Park) wi ll

not prevent the

veh icle from moving.

- Before you change a wheel, be sure the

ground is leve l and firm. If necessary, use a

sturdy board under the jack.

- Always store the vehicle tool kit, the jack

and the replaced tire in the luggage com

pa rtment

¢page 135.

(D Tips

Before changing the wheel, you must activate

the jacking mode, so that the automatic con

trols for the Adaptive Air Suspension* do not

make it more difficult to lift the vehicle with

the jack ¢

page 245 .

Changing a wheel

When you change a wheel, follow the sequence

described below step-by-step and in exactly that

order.

1. Activate the vehicle jack mode*¢ page 245.

2. Remove the decorative wheel cover* or the

wheel bolt caps*. For more details see also

¢ page 244, Decorative wheel covers or

¢ page 244, Wheels with wheel bolt caps .

3. Loosen the wheel bolts ¢page 245.

4. Locate the proper mounting point for the

jack and align the jack below that point

¢page 245.

5. Raise the car with the jack¢ page 245 .

6. Remove the wheel with the flat tire and then

install

the spare ¢ page 247.

7. Tighten all whee l bolts lightly.

8.

Lower the vehicle with the jack.

9. Use the wheel bolt wrench and

firmly tighten

all wheel bolts

c::>page 245.

10. Replace the decorative wheel cover* or the

wheel bolt caps*.

11. Deactivate the vehicle jack mode* in the

MMI:

I CARI funct ion button> (C ar )* systems .,.

243

Page 247 of 284

co

co

.... N

" N .... 0 co <.,;) 'SI'

The caps are to protect and keep the wheel bolts

clean.

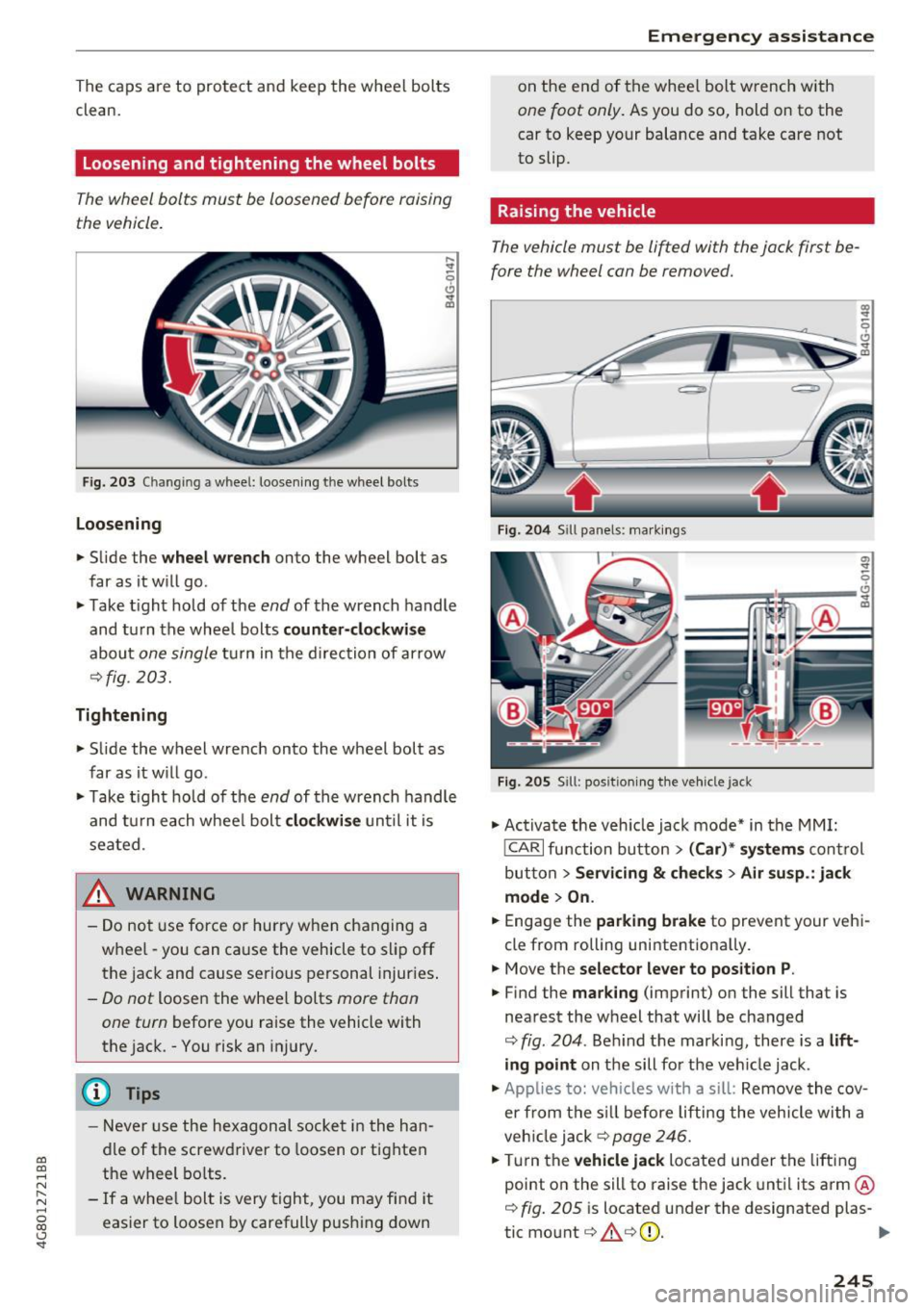

Loosening and tightening the wheel bolts

The whe el bolts must be loosen ed b efor e raising

the vehicle.

F ig. 20 3 Chan gin g a w hee l: l oose ning t he wheel bo lts

Loo sening

.. Slide the w he el wr enc h onto the wheel bolt as

far as it will go .

.. Take t ight hold of the

end of the wrench hand le

and turn the wheel bolts

c o unt er-clockwis e

about one single turn in the d irection of arrow

¢fig . 203.

Tightening

.. Slide the wheel wrench onto the wheel bolt as

far as it w ill go.

.. Take t ight hold of the

end of the wrench handle

and tu rn each whee l bolt

clockwi se unt il it is

seated .

& WARNING

- Do not use force or hurry when changing a

wheel -you can cause the vehicle to slip off

the jack and cause serious personal injuries .

-Do not loosen the wheel bolts more than

one turn

before you raise the vehicle w ith

the jack. - You risk an injury.

(D Tips

- Never use the hexagonal socket in the han

dle of the screwdriver to loosen o r tighten

the wheel bo lts .

- If a whee l bolt is very tight, you may find it

easier to loosen by carefully push ing down

Em ergen cy a ssis tanc e

on the end of the whee l bolt wrench with

one foot only . As you do so, hold on to the

car to keep your balance and take care not

to slip .

Raising the vehicle

The vehicl e must b e lift ed with the jock first be

fore the wheel can be removed.

F ig. 20 4 Sill pane ls: ma rkin gs

F ig. 205 S ill: pos it ion ing t he veh icle jac k

.. Activa te the veh icle jack mode* in the MMI:

!CARI function button > (Car )* sy stems control

button

> S erv ici ng & ch ecks > Air su sp .: jack

mode > On .

.. Engage the parking brake to prevent your vehi

cl e from rolling unintentiona lly .

.. Move the

selector le ver to p osit ion P .

.. Find the mar king (impr int) on the sill that is

nearest the wheel that will be changed

¢

fig . 204 . Behind the marking , there is a lift

ing poin t on the sill for the vehicle jack .

.. App lies to: veh icles with a s ill: Remove the cov

er from the s ill before lifting the vehicle with a

veh icle jack ¢

page 246.

.. Turn the vehicle jack located under the lift ing

point on the sill to raise the jack unt il its arm @

¢

fig. 205 i s locat ed und er the d esignat ed plas-

tic mount ¢

,&¢0. ..,.

245

Page 249 of 284

co

co

.... N

" N .... 0

00

<.,;) 'SI"

Taking the wheel off/installing the spare

Follow these instructions step-by-step for chang

ing the wheel.

Fig. 207 Changing a wheel: using the screwdriver hahd le

(with the blade removed} to turn the bolts

F ig. 208 Changing a wheel: alignment pin ins ide the top

hole

After you have loosened all wheel bo lts and

raised the vehicle

off the ground, remove and re

p lace the whee l as follows:

Removing th e wheel

" Use the hexagon al so cket in the screwdri ver

handle to completely remove the topmost

wheel bolt and set it aside on a

clean surface

¢fig. 207.

.. Screw the threaded end of the alignment pi n

from the tool kit hand-tight into the empty bolt

hole

¢ fig. 2oa1>.

" Then remove the other wheel bolts as described

above .

" Take

off the wheel leaving the a lignment pin in

the bolt ho le

¢ 0 .

l) Applies to vehicles with ceram ic brake rotors•: Use a sec

ond alignme nt pin• (stored in t he spa re wheel well mold

ing} for the lower hole , fo llow ing the descript ion for the

first alignment pin.

Em ergen cy a ssis tanc e

Putting on th e spar e wheel

" Lift the spare whee l and caref ully slide it over

the alignment pin to guide it in place¢(!).

.. Use the hexagona l socket in the screwdriver

handle to screw in and tighten all wheel bolts

slightly .

"Remove the alignment pin and insert and tight

en the remaining wheel bo lt slightly like the

rest .

.. Turn the jack hand le counter-clockw ise to lower

the vehicle unt il the ja ck is fully released.

" Use the wheel bo lt wrench to t ighten a ll wheel

bolts firmly¢

page 245. Tighten them cross

wise,

from one bo lt to the (approx imately) op

posite one, to keep the wheel centered.

(D Note

When removing or installing the wheel, the

rim could hit the brake rotor/ceramic brake

rotor* and damage the rotor . Work carefully

and have a second person he lp you.

(D Tips

Never use the hexagonal socket in the hand le

of the screwdriver to loosen or tighten the

whee l bolts.

- Pull the reversible blade from the screwdr iv

er before you use the hexagona l socket in

the handle to turn the wheel bolts.

- When mounting tires with unidirectional

t read de sign make sure the tread pattern is

pointed the right way

¢ page 248.

- The wheel bolts sho uld be clean and easy to

turn. Check for dirt and corrosion on the

mating surfaces of both the wheel and the

hub. Remove all dirt from these surfaces be

fore remounting the wheel.

247

Page 253 of 284

co

co

.... N

" N .... 0

00

<.,;) 'SI"

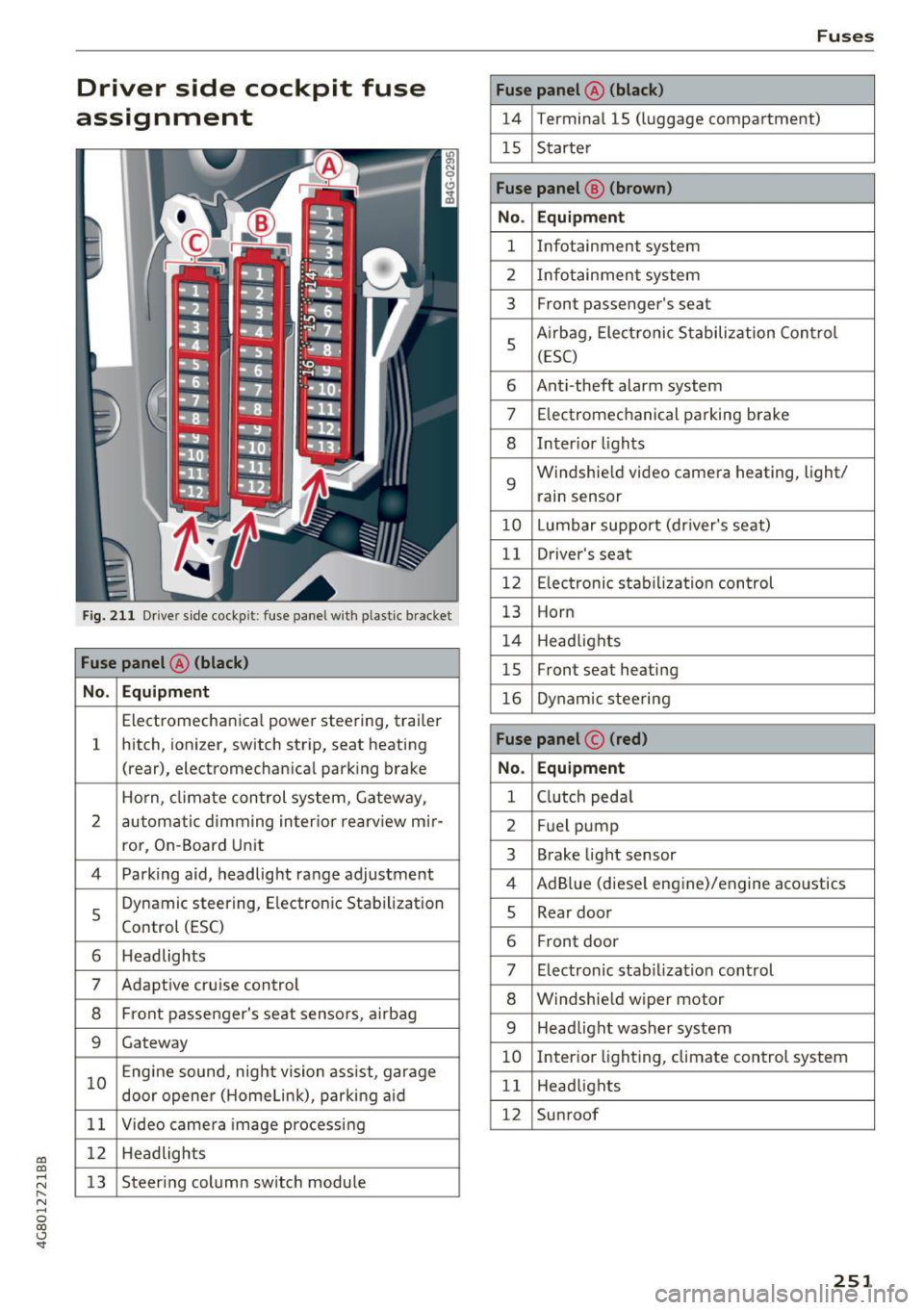

Driver side cockpit fuse

assignment

Fig. 2 11 Driver side cockp it: fuse panel wit h plastic bracket

Fuse panel @ (black)

No . Equipment

Electromecha nica l powe r steering, trailer

1 hitch, ionizer, switch st

rip, seat heating

(rear), electromechan ica l park ing brake

Ho rn, climate con trol system, Gateway,

2 automati

c dimm ing in ter ior rearv iew m ir-

ro r, On -Board Un it

4 Park ing aid, headlight ra nge adjustment

5

Dynamic steering, E lectron ic Stabilization

Control (ESC)

6 Headlights

7 Adapt ive cruise control

8 Front passenger's seat senso rs, a irbag

9 Gateway

10 Engine sound, night vision ass

ist, garage

door opene r (H ome link), parki ng aid

11 Video camera image processing

1 2 Headlights

13 Steering column sw

itch module

Fuses

Fuse panel @ (black)

14 Termina l 15 (luggage compartment)

15 S tarte r

Fuse panel @ (brown)

No . Equipment

1 Infotainment system

2 Infotainment system

3 Front passenger's seat

5

A

irbag, Elect ronic S tabilization Con trol

( E SC)

6 Ant

i-theft alarm system

7 Electromec hanical pa rking brake

8 Inter io r li ghts

9

Windshie ld video came ra heating, light/

rain sensor

10 Lumbar support (dr iver's seat)

11 Driver

's seat

12 Electronic st abilization con trol

13 Horn

1 4 Head lights

15 Front seat heating

16 Dynam ic steering

Fuse panel © (red)

No . Equipment

1 Clutch peda l

2 Fuel p ump

3 Brake

light sensor

4 AdB lue (diese l engine)/engine aco ustics

5 Rear door

6 Fr

ont door

7 Electronic stab ilization control

8 Windshie ld w iper motor

9 Head light washer system

10 Interio

r lighting, climate control system

1 1 Head lights

12 Sunroof

251

Page 254 of 284

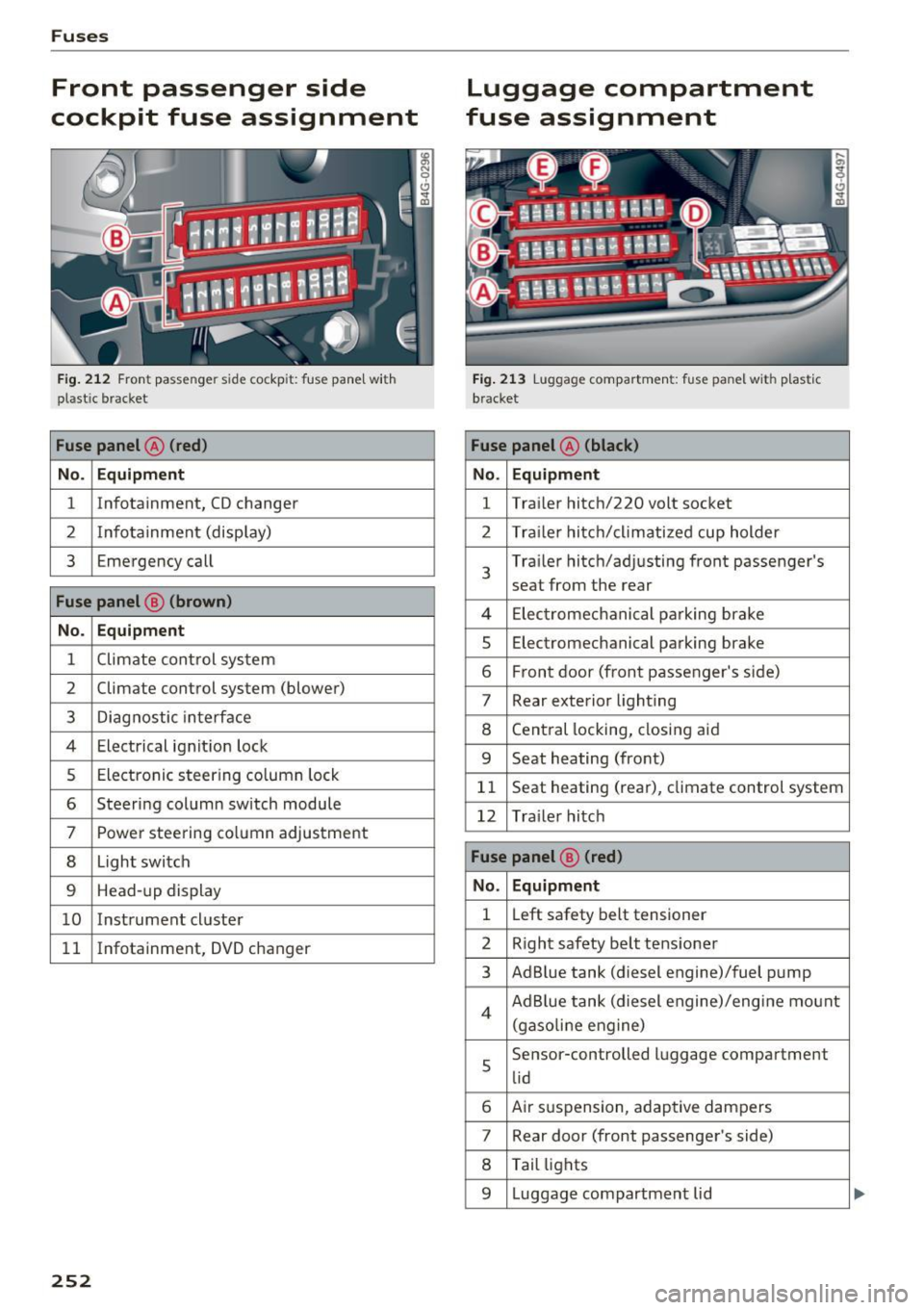

Fuses

Front passenger side

cockpit fuse assignment

Fig. 212 Front passenger side cockpit: fuse panel wit h

plastic bracket

Fuse panel @ (red)

No. Equipm ent

1 Infotainment, CD changer

2 Inf

ota inment (display)

3 Emergency call

Fuse panel @ (brown)

No. Equipment

1 Climate control system

2 Climate control

system (blower)

3 Diagnostic interface

4 Electrical ignit ion lock

5 Electronic steering column lock

6 Steering column switch module

7 Power steering column adjustment

8 Light switch

9 Head-up display

10 Instrument cl uster

11 Infotainment, DVD

changer

252

Luggage compartment

fuse assignment

Fig. 213 Luggage compa rtme nt: fuse panel with plast ic

bracket

Fuse panel @ (black)

No . Equipment

1 Tra

iler hitch/220 volt socket

2 Trailer hitch/climatized cup holder

3

Trailer hitch/adjusting front passenger's

seat from the rear

4 El ec trom echan ical parking brake

5 Electromechanical parking brake

6 Front door (front passenger's side)

7 Rear exterior lighting

8 Central locking, closing aid

9 Seat heating (fro nt)

11 Seat heating

(rear), climate control system

12 Trailer hitch

Fuse panel @ (red)

No. Equipment

1 L

eft safety belt tensioner

2 Right safety belt tensioner

3 Ad Blue tank (diesel engine)/fuel pump

4 Ad Blue tank (diesel engine)/engi ne mount

(gaso lin e eng ine)

5

Se nsor-controlled luggage compartment

lid

6 Air suspension, adaptive dampers

7 Rear door (front passenger's side)

8 Tail lights

9 Luggage compartment lid

Page 257 of 284

@ Tips

The discharged battery must be properly con

nected to the vehicle's electrical system .

When jump starting or charg ing the battery,

never connect the negative ground cable to

the battery negative post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negative ground cable to the negative ground

post of the battery manager control unit.

Use of jumper cables

Make sure to connect the jumper cable clamps in

exactly the order described below!

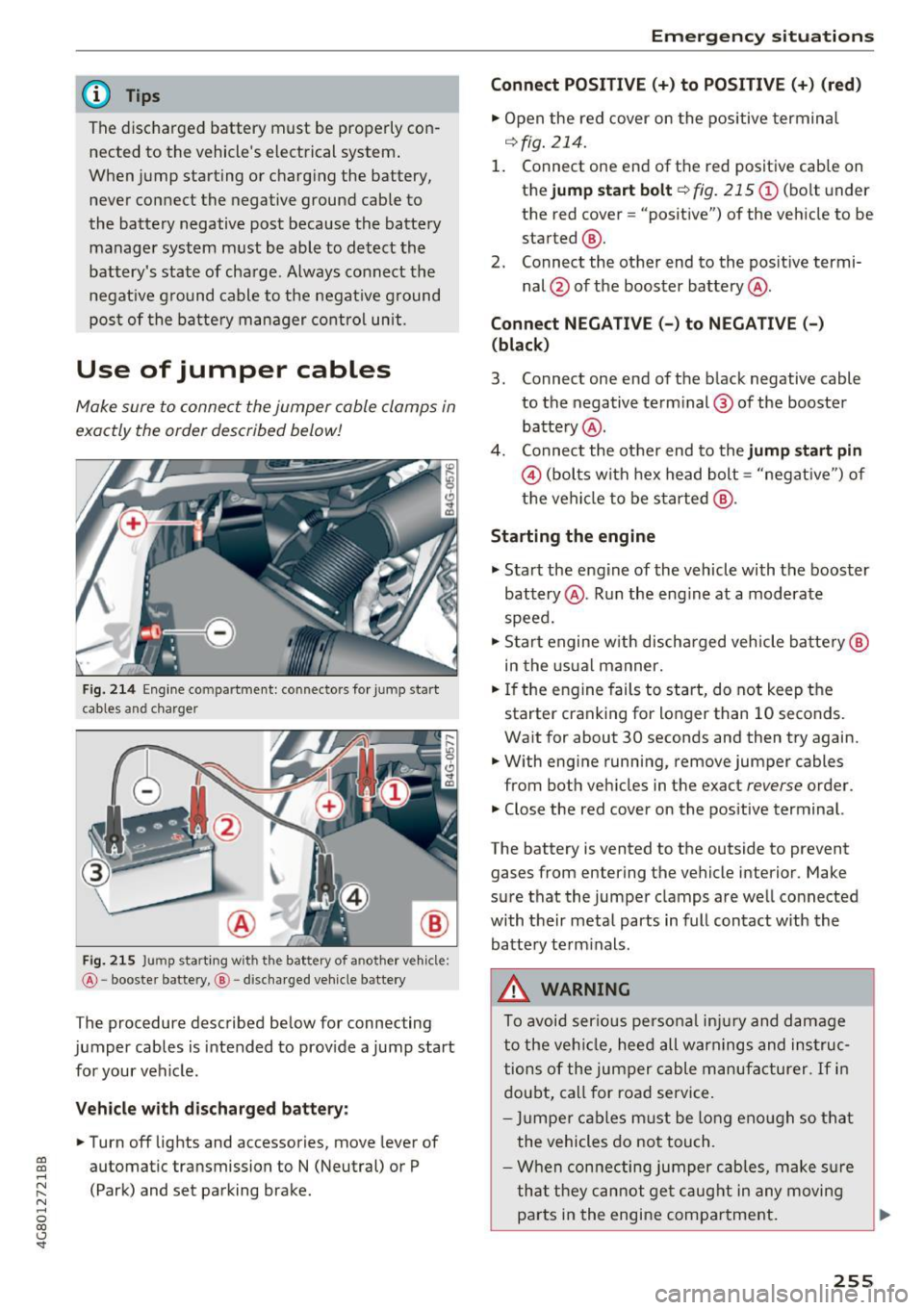

Fig. 214 Engine compartment: connectors fo r ju mp start

cables and charger

® @

Fig. 215 Jump starting with the battery of another vehicle:

@-booste r battery, @-discharged veh icle batte ry

The procedure described below for connecting

jumper cables is intended to provide a jump start

for your vehicle .

Vehicle with discharged battery:

.. Turn off lights and accessories, move lever of

~ automatic transmission to N (Neutral) or P ....

~ (Park) and set parking brake . N .... 0

00

<.,;) 'SI"

Emergency situations

Connect POSITIVE(+) to POSITIVE (+) (red)

.. Open the red cover on the pos itive terminal

qfig. 214.

1. Connect one end of the red posit ive cab le on

the jump start bolt~

fig. 215 (D (bolt under

the red cover= "positive") of the vehicle to be

started @.

2. Connect the other end to the positive termi- nal@ of the booster battery @.

Connect NEGATIVE (-) to NEGATIVE (-)

(black)

3. Connect one end of the black negative cable

to the negative terminal ® of the booster

battery @.

4. Connect the other end to the jump start pin

@ (bolts with hex head bolt= "negat ive'') of

the vehicle to be started @.

Starting the engine

.. Start the engine of the vehicle with the booster

battery @. Run the eng ine at a moderate

speed .

.. Start engine w ith discharged vehicle battery@

in the usual manner .

.. If the engine fails to start, do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again .

.. With engine running, remove jumper cables

from both vehicles in the exact

reverse order .

.. Close the red cover on the positive terminal.

The battery is vented to the outside to prevent gases from entering the vehicle interior . Make

sure that the jumper clamps are well connected

with their metal parts in full contact with the battery terminals .

_&. WARNING

To avoid serious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch .

- When connecting jumper cables, make sure

that they cannot get caught in any moving

parts in the engine compartment. ..,.

255

Page 258 of 284

Emergency situations

-Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c> page 199.

(D Note

Improper hook-up of jumper cables can ruin

the generator.

-Always connect POSITIVE(+) to POSITIVE

(+), and NEGATIVE(-) to NEGATIVE(-)

ground post of the battery manager control

unit.

- Check that all screw plugs on the battery

cells are screwed in firmly. If not, tighten

plugs prior to connecting clamp on negative

battery terminal.

- Please note that the procedure for connect

ing a jumper cable as described above ap

plies specifically to the case of your vehicle

being jump started . When you are giving a

jump start to another vehicle, do

not con

nect the negative (-) cable to the negative

(-) terminal on the discharged battery @

c> fig. 215. Instead, securely connect the

negative(-) cable to either a solid metal

component that is firmly bolted to the en

gine block or to the engine block itself. If

the battery that is being charged does not

vent to the outside, escaping battery gas

could ignite and explode!

Towing with a tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by com

mercial tow truck operators who know how to op

erate their equipment safely.

- Never tow your Audi. Towing will cause dam

age to the engine and transmission.

- Never wrap the safety chains or winch cables

around the brake lines.

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck.

- To load the vehicle on to the flat bed, use the

towing loop found in the vehicle tools and at-

256

tach to the front or rear anchorage

c>page 256 and ¢page 257.

A WARNING

A vehicle being towed is not safe for passen

gers . Never allow anyone to ride in a vehicle

being towed, for any reason.

Front towing loop

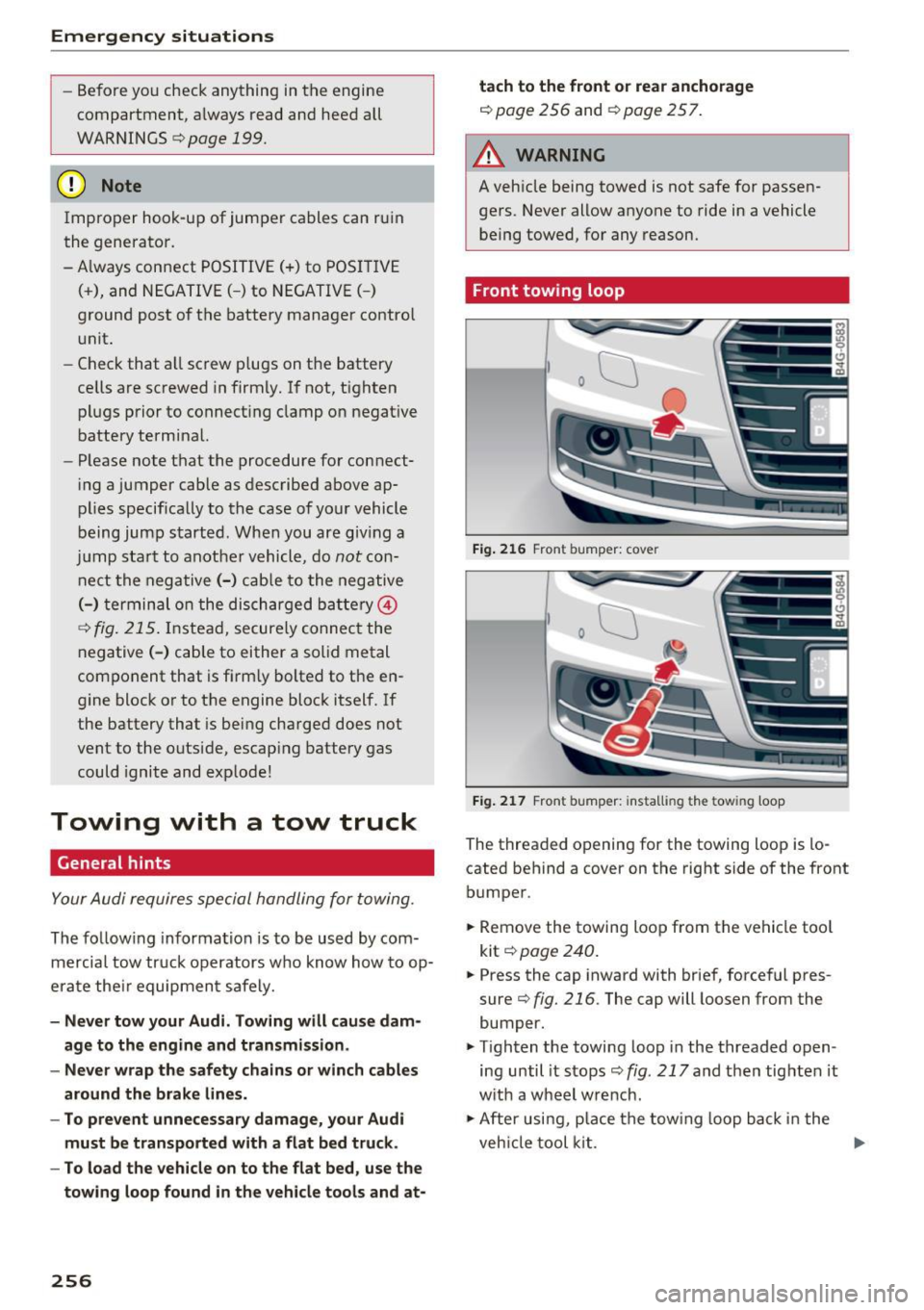

Fig. 216 Front bumper: cover

Fig. 217 Front bumpe r: install ing the tow ing loop

The threaded opening for the towing loop is lo

cated behind a cover on the right side of the front

bumper .

.. Remove the towing loop from the vehicle tool

kit

c> page 240.

.. Press the cap inward with brief, forceful pres

sure

¢fig. 216. The cap will loosen from the

bumper.

.. Tighten the towing loop in the threaded open

ing until it stops

¢ fig. 217 and then tighten it

with a wheel wrench .

.. After using, place the towing loop back in the

vehicle tool kit.

IJli>