oil AUDI A8 1998 D2 / 1.G AHA ATQ Engines Cylinder Block Crankshaft And Flywheel Component Service Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: A8, Model: AUDI A8 1998 D2 / 1.GPages: 33, PDF Size: 0.75 MB

Page 1 of 33

13-4

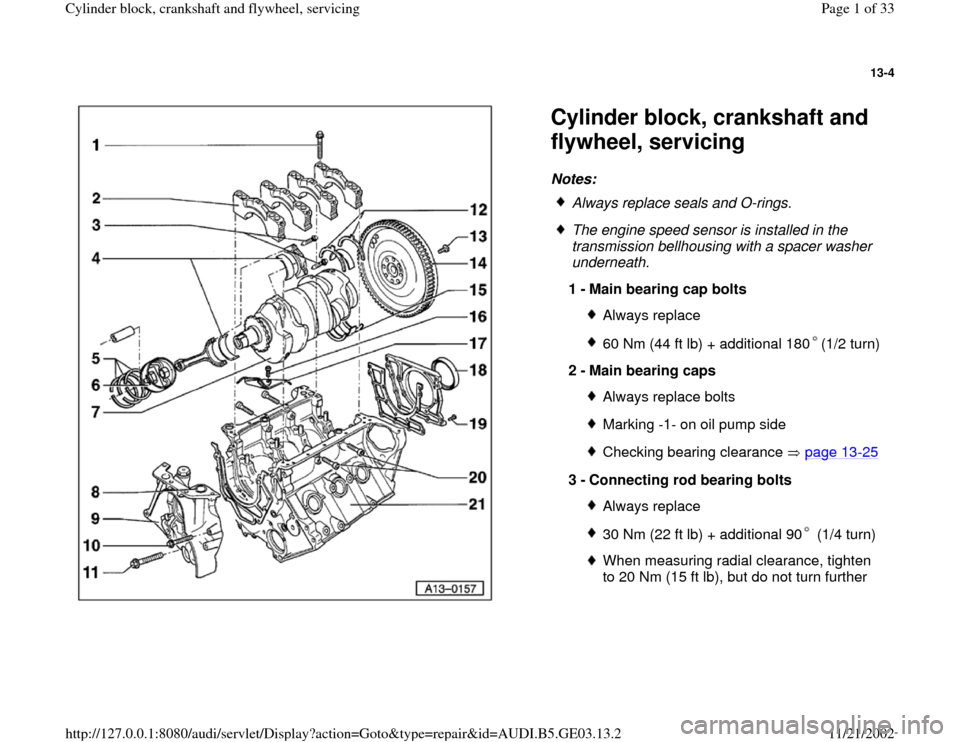

Cylinder block, crankshaft and

flywheel, servicing Notes:

Always replace seals and O-rings.

The engine speed sensor is installed in the

transmission bellhousing with a spacer washer

underneath.

1 -

Main bearing cap bolts

Always replace60 Nm (44 ft lb) + additional 180 (1/2 turn)

2 -

Main bearing caps

Always replace boltsMarking -1- on oil pump sideChecking bearing clearance page 13

-25

3 -

Connecting rod bearing bolts

Always replace30 Nm (22 ft lb) + additional 90 (1/4 turn)When measuring radial clearance, tighten

to 20 Nm (15 ft lb), but do not turn further

Pa

ge 1 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 2 of 33

13-5

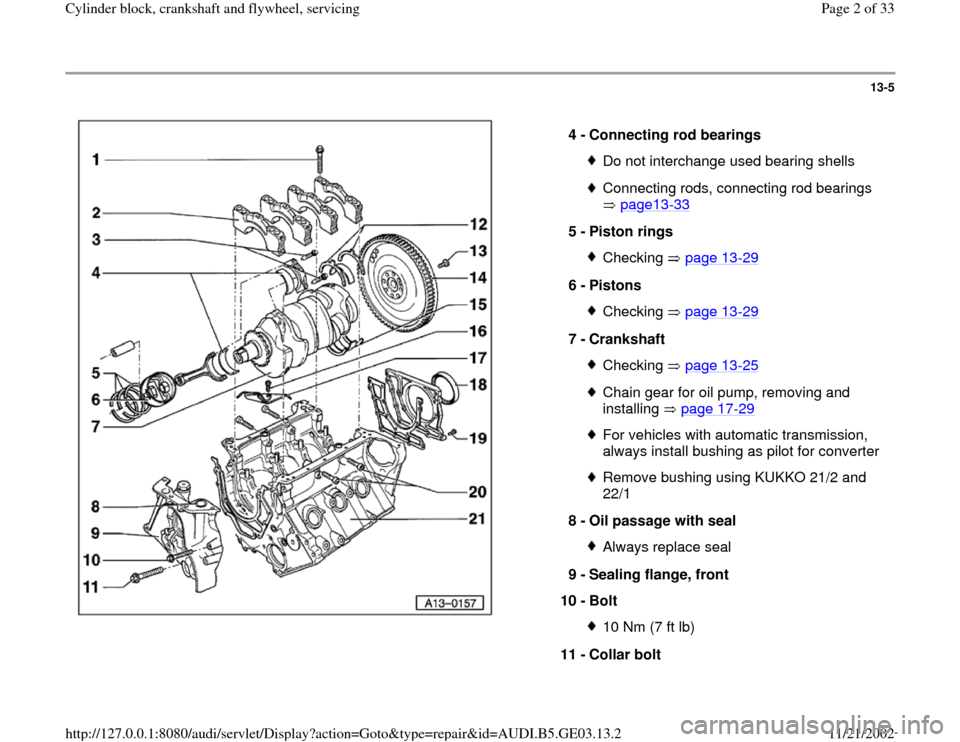

4 -

Connecting rod bearings

Do not interchange used bearing shellsConnecting rods, connecting rod bearings

page13

-33

5 -

Piston rings

Checking page 13

-29

6 -

Pistons

Checking page 13

-29

7 -

Crankshaft

Checking page 13

-25

Chain gear for oil pump, removing and

installing page 17

-29

For vehicles with automatic transmission,

always install bushing as pilot for converter Remove bushing using KUKKO 21/2 and

22/1

8 -

Oil passage with seal Always replace seal

9 -

Sealing flange, front

10 -

Bolt 10 Nm (7 ft lb)

11 -

Collar bolt

Pa

ge 2 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 4 of 33

13-6

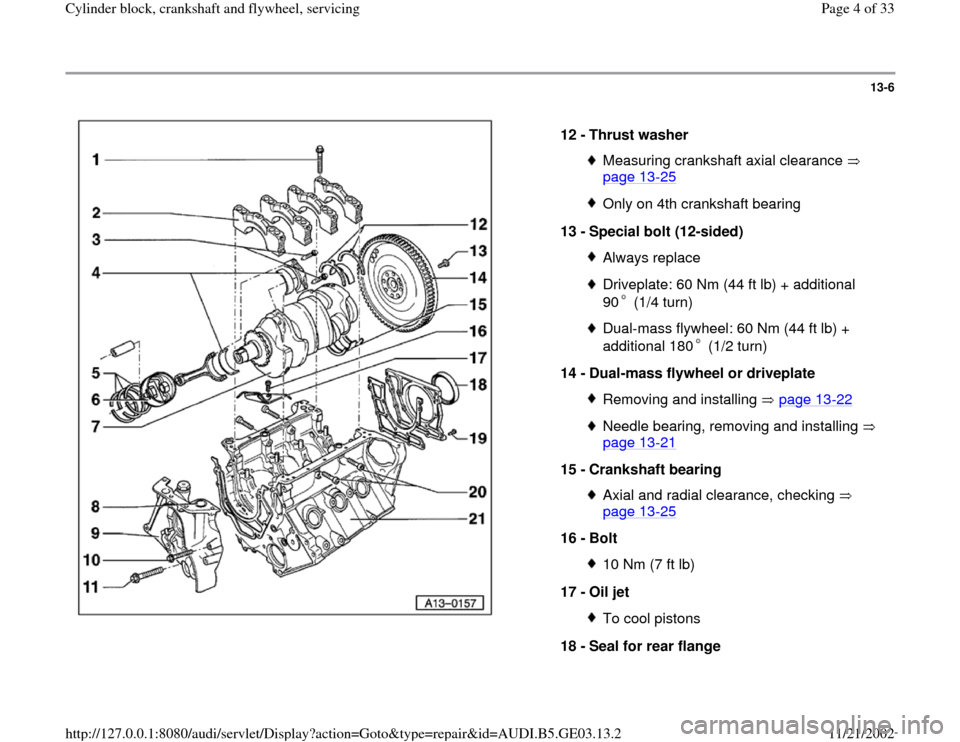

12 -

Thrust washer

Measuring crankshaft axial clearance

page 13

-25

Only on 4th crankshaft bearing

13 -

Special bolt (12-sided) Always replaceDriveplate: 60 Nm (44 ft lb) + additional

90 (1/4 turn) Dual-mass flywheel: 60 Nm (44 ft lb) +

additional 180 (1/2 turn)

14 -

Dual-mass flywheel or driveplate

Removing and installing page 13

-22

Needle bearing, removing and installing

page 13

-21

15 -

Crankshaft bearing

Axial and radial clearance, checking

page 13

-25

16 -

Bolt

10 Nm (7 ft lb)

17 -

Oil jet To cool pistons

18 -

Seal for rear flange

Pa

ge 4 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 13 of 33

13-14

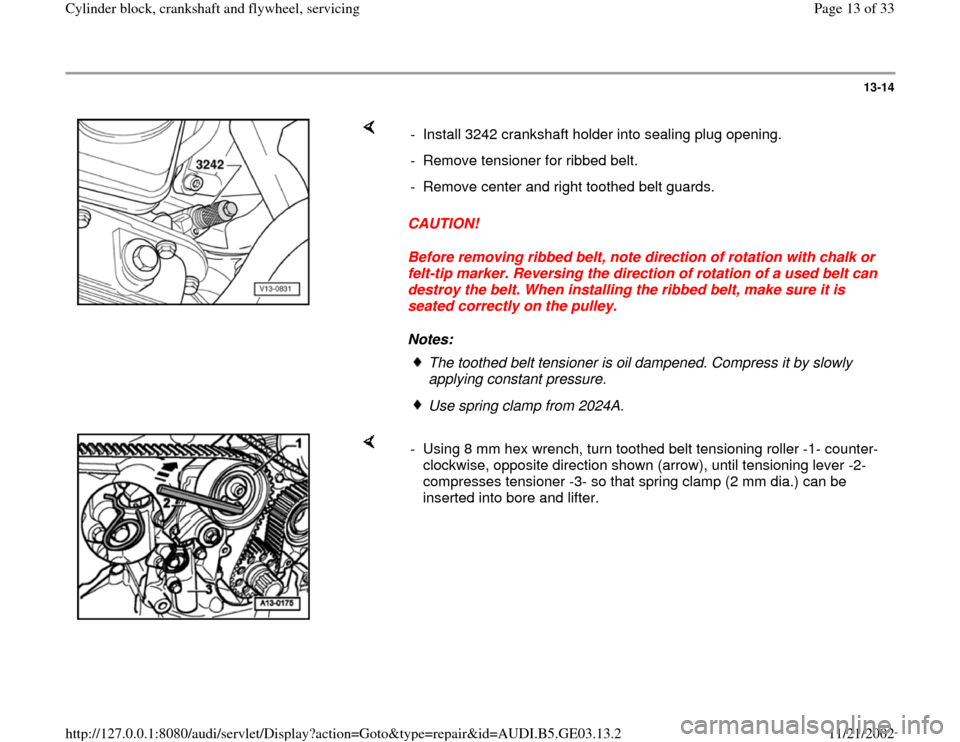

CAUTION!

Before removing ribbed belt, note direction of rotation with chalk or

felt-tip marker. Reversing the direction of rotation of a used belt can

destroy the belt. When installing the ribbed belt, make sure it is

seated correctly on the pulley.

Notes: - Install 3242 crankshaft holder into sealing plug opening.

- Remove tensioner for ribbed belt.

- Remove center and right toothed belt guards.

The toothed belt tensioner is oil dampened. Compress it by slowly

applying constant pressure. Use spring clamp from 2024A.

- Using 8 mm hex wrench, turn toothed belt tensioning roller -1- counter-

clockwise, opposite direction shown (arrow), until tensioning lever -2-

compresses tensioner -3- so that spring clamp (2 mm dia.) can be

inserted into bore and lifter.

Pa

ge 13 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 18 of 33

13-19

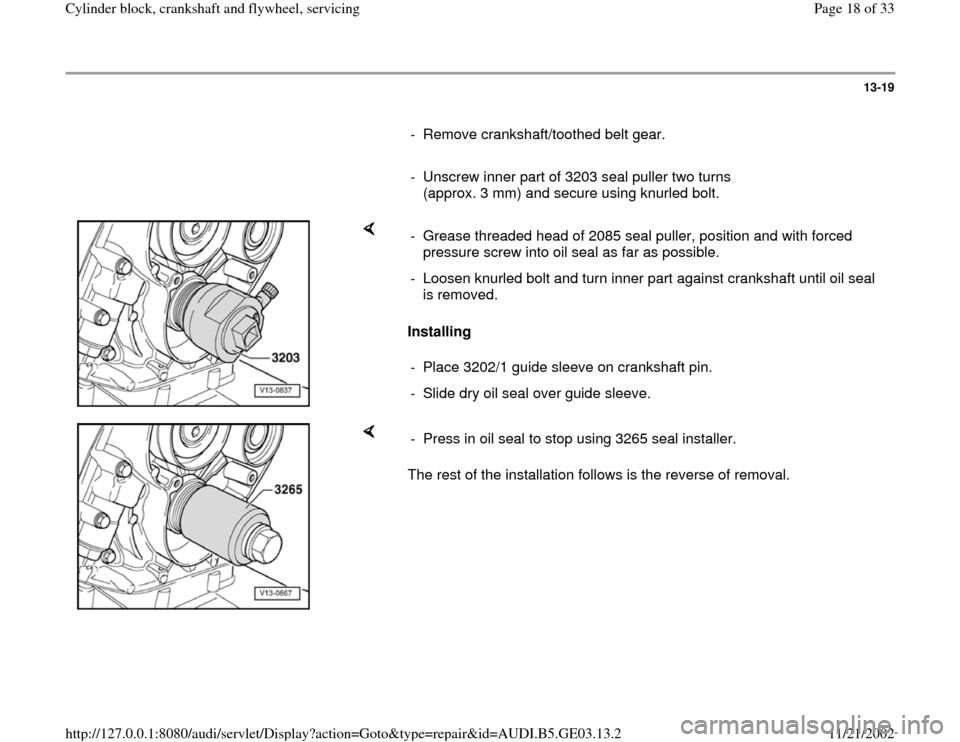

- Remove crankshaft/toothed belt gear.

- Unscrew inner part of 3203 seal puller two turns

(approx. 3 mm) and secure using knurled bolt.

Installing - Grease threaded head of 2085 seal puller, position and with forced

pressure screw into oil seal as far as possible.

- Loosen knurled bolt and turn inner part against crankshaft until oil seal

is removed.

- Place 3202/1 guide sleeve on crankshaft pin.

- Slide dry oil seal over guide sleeve.

The rest of the installation follows is the reverse of removal. - Press in oil seal to stop using 3265 seal installer.

Pa

ge 18 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 19 of 33

13-20

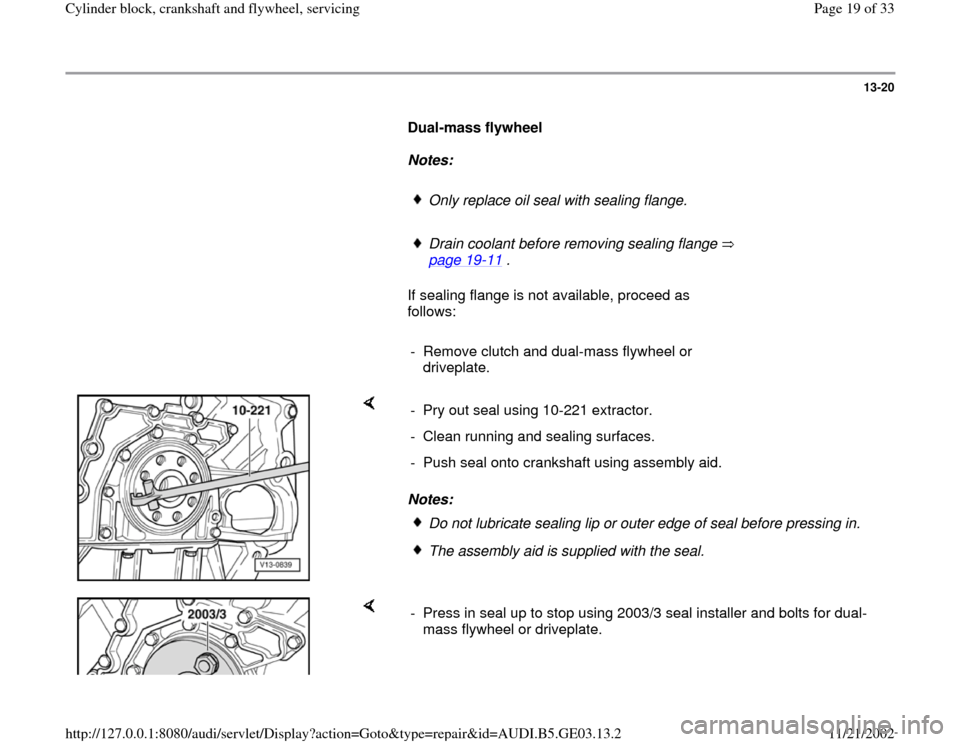

Dual-mass flywheel

Notes:

Only replace oil seal with sealing flange.

Drain coolant before removing sealing flange

page 19

-11

.

If sealing flange is not available, proceed as

follows:

- Remove clutch and dual-mass flywheel or

driveplate.

Notes: - Pry out seal using 10-221 extractor.

- Clean running and sealing surfaces.

- Push seal onto crankshaft using assembly aid.

Do not lubricate sealing lip or outer edge of seal before pressing in.The assembly aid is supplied with the seal.

- Press in seal up to stop using 2003/3 seal installer and bolts for dual-

mass flywheel or driveplate.

Pa

ge 19 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 24 of 33

13-25

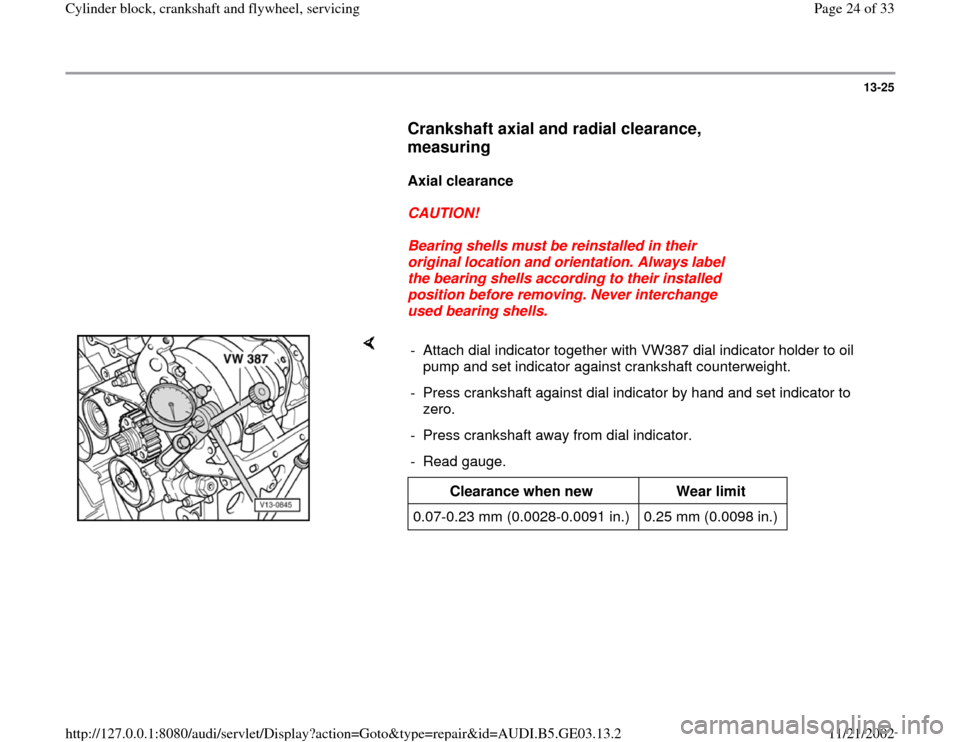

Crankshaft axial and radial clearance,

measuring

Axial clearance

CAUTION!

Bearing shells must be reinstalled in their

original location and orientation. Always label

the bearing shells according to their installed

position before removing. Never interchange

used bearing shells.

- Attach dial indicator together with VW387 dial indicator holder to oil

pump and set indicator against crankshaft counterweight.

- Press crankshaft against dial indicator by hand and set indicator to

zero.

- Press crankshaft away from dial indicator.

- Read gauge.

Clearance when new

Wear limit

0.07-0.23 mm (0.0028-0.0091 in.) 0.25 mm (0.0098 in.)

Pa

ge 24 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 26 of 33

13-27

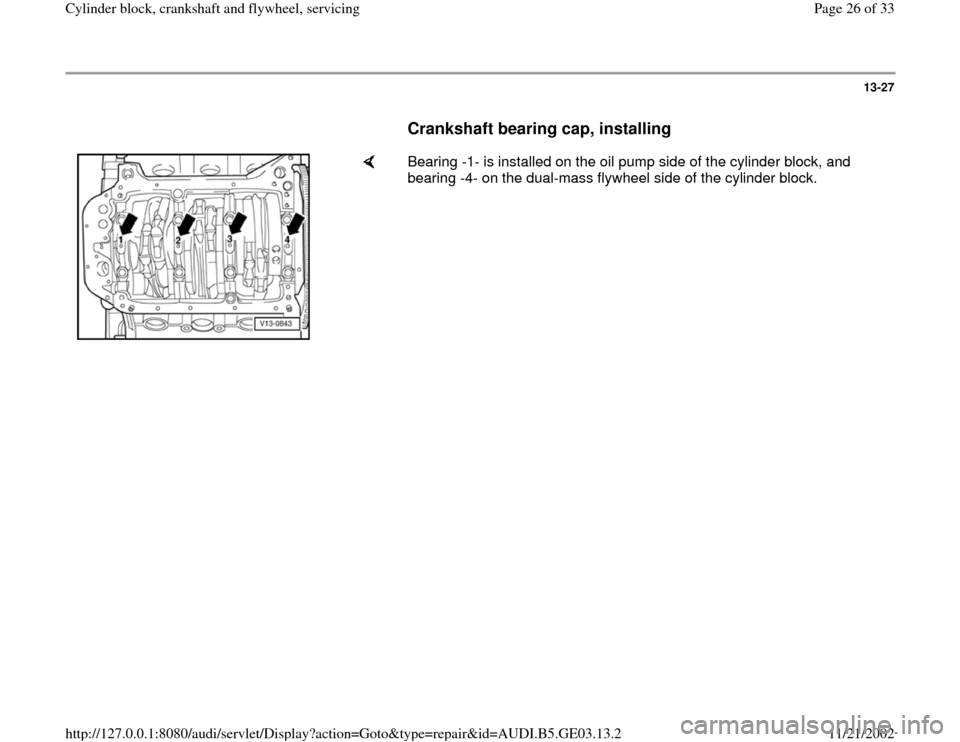

Crankshaft bearing cap, installing

Bearing -1- is installed on the oil pump side of the cylinder block, and

bearing -4- on the dual-mass flywheel side of the cylinder block.

Pa

ge 26 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2

Page 30 of 33

13-31

Checking piston ring end gap

Engine codes AHA, ATQ - Insert ring at right angle from top and slide down into lower cylinder

opening until approx. 15 mm from lower edge of cylinder. Piston ring

End gap, new mm. (in.)

Wear limit mm.

(in.)

1

(compression) 0.35-0.50 mm (0.014-0.020

in.) 1.0 mm (0.039 in.)

2

(compression) 0.50-0.70 mm (0.020-0.028

in.) 1.4 mm (0.043 in.)

3 (oil scraper) 0.25-0.50 mm (0.010-0.020

in.) 0.8 mm (0.031 in.)

Pa

ge 30 of 33 C

ylinder block, crankshaft and fl

ywheel, servicin

g

11/21/2002 htt

p://127.0.0.1:8080/audi/servlet/Dis

play?action=Goto&t

yp

e=re

pair&id=AUDI.B5.GE03.13.2