brake AUDI Q3 2016 Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2016, Model line: Q3, Model: AUDI Q3 2016Pages: 252, PDF Size: 62.81 MB

Page 206 of 252

Wheels

position and the total weight of

any luggage in the vehicle. If you

tow a trailer, the weight of the trailer hitch and the tongue

weight of the loaded trailer must be included as part of the vehicle

load.

The

Gross Axle Weight Rating

("GAWR") is the maximum load

that can be applied at each of the

vehicle's two axles.

The fact that there is an upper

limit to your vehicle's Gross Vehi

cle Weight Rating means that the

total weight of whatever is being

carried in the vehicle (including

the weight of a trailer hitch and

the tongue weight of the loaded

trailer) is limited. The more pas

sengers in the vehicle or passen

gers who are heavier than the

standard weights assumed mean

that less weight can be carried as luggage.

The Gross Vehicle Weight Rating

and the Gross Axle Weight Rating

are listed on the safety compli

ance sticker label located on the

driver's side B-pillar

~ page 201,

fig . 158 .

204

_& WARNING

Overloading a vehicle can cause

loss of vehicle control, a crash

or other accident, serious per

sonal injury, and even death.

-Carrying more weight than

your vehicle was designed to carry will prevent the vehicle

from handling properly and

increase the risk of the loss of

vehicle control.

-The brakes on a vehicle that has been overloaded may not

be able to stop the vehicle

within a safe distance.

-Tires on a vehicle that has

been overloaded can fail sud

denly, including a blowout and

sudden deflation, causing loss of control and a crash.

-Always make sure that the to

tal load being transported -

including the weight of a trail

er hitch and the tongue

weight of a loaded trailer -

does not make the vehicle

heavier than the vehicle's

Gross Vehicle Weight Rating.

Page 213 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

Emergency assistance

General information

.. Park the vehicle as far as poss ible from moving

traffic in the event of a flat tire. In the event of

a flat tire, park the vehicle on a level surface. It

you are on a steep incline, be especially careful.

.. Set the parking brake .

.. Switch the emergency flashe rs on .

.. Put on a reflective vest, if available .

.. Set up the warn ing triang le, if available .

.. Have the passengers exi t the veh icle. They

sho uld move to a safe place, for example be

hind a guard rail.

_& WARNING

Pay attention to the steps above . They are for

your protection and the for the safety of other drivers.

_& WARNING

Improper use of the vehicle jack can cause se

rious personal injuries.

- Never use the screw driver hex head to

t ighten whee l bolts, since the bolts cannot

attain the necessary tighten ing torque if you

use the hex head, potentially causing an ac

c ident.

- The factory-supplied jack is intended only

for your vehicle model. Under no circum

stances should it be used to lift heavy

vehicles o r other loads; yo u ris k inju ring

yo urself.

- Never start the engine when the vehicle is

ra ised, which could cause a n accident.

- Support the veh icle secure ly with app ropr i

a te s tan ds if wor k is to be performed under

neath t he vehicle; otherwise, the re is a po

tent ial ris k for i njur y.

- Never use the jack s upplied with yo ur Audi

on another vehicle, pa rtic ularly o n a heav ie r

one. The jack is only suitable for u se on the

vehicle it came wit h.

Emergen cy a ssis tanc e

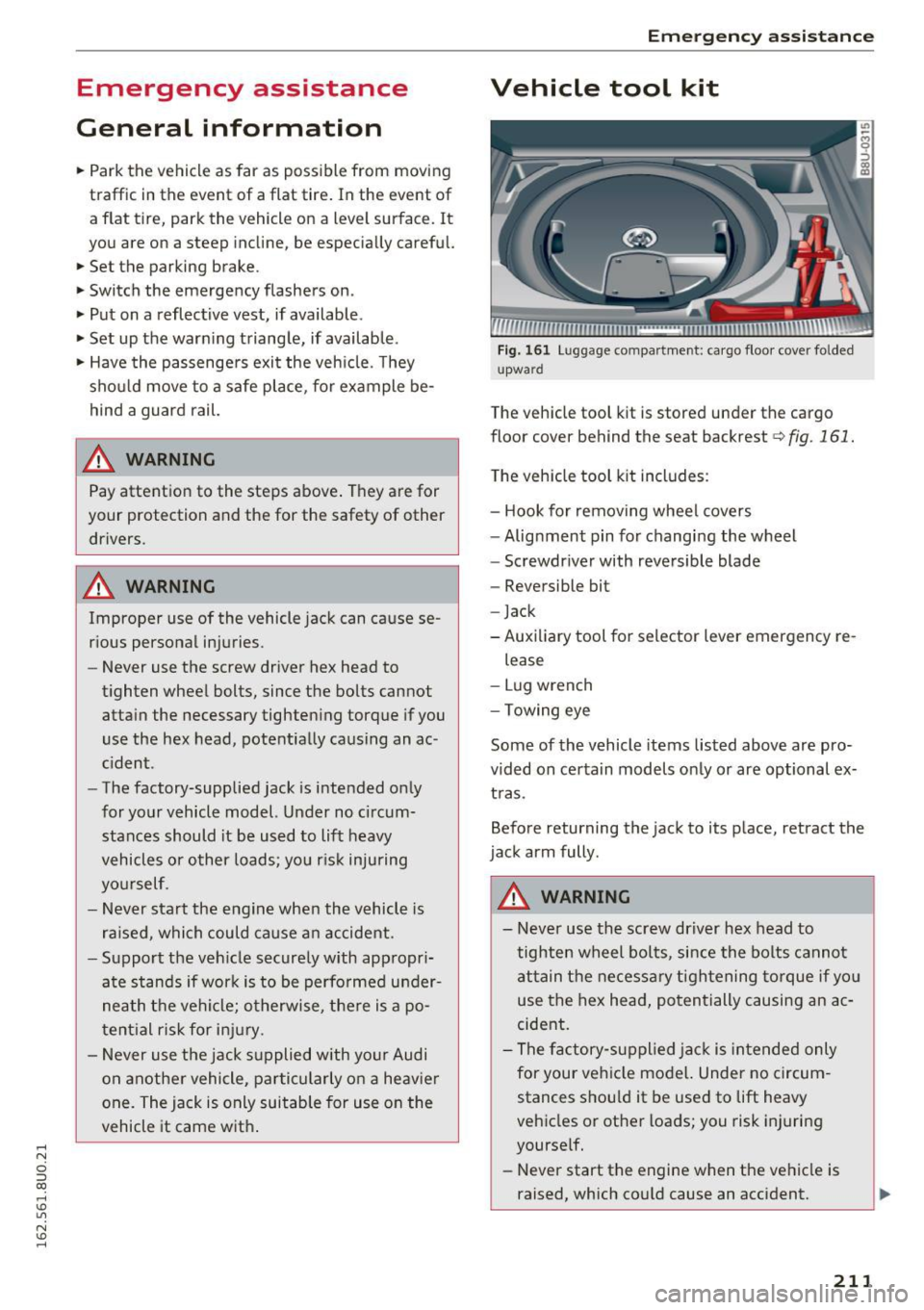

Vehicle tool kit

Fig. 161 Lu ggage compa rtment: cargo floor cover fo lded

u pwa rd

The vehicle tool kit is stored under the cargo

floor cover behind the seat backrest

q fig. 161.

The veh icle tool k it includes :

- Hook for remov ing wheel covers

- Alig nment pin for changing the w heel

- Screwdr iver with reversible blade

- Reversible bit

- Jack

- Auxiliary tool for selector lever emergency re -

lease

- Lug wrench

- Towing eye

Some of the vehicle items listed above are pro

vided on certa in models on ly or are optional ex

t ras.

Befo re returning the jack to its place, retract the

jack arm fully .

_& WARNING

---= -

-Never use the screw driver hex head to

tighten wheel bo lts, since the bolts cannot

at tain t he necess ary tightening to rque if yo u

use the hex head, po ten tially causing an ac

cident.

- T he factory-su pplied jac k is in tended only

for your ve hicle mode l. Under no circum

stances shou ld it be used to lift heavy

ve hicles or othe r loads; you risk injuring

yourse lf .

- Never start the engine when the ve hicle is

raised, which cou ld cause an accident .

211

Page 215 of 252

The spare tire is intended for short-term use on

ly. Have the damaged tire checked and replaced,

if necessary, by an author ized Audi dealer or au

thor ized Audi Service Facility as soon as possib le.

There are some restrictions on the use of the

compact spare tire . The compact spare tire has

been designed specif ically for your type of veh i

cle . Do not replace it with the spare tire from an

other type of vehicle.

R emo ving th e spar e tire

... Remove the cargo floor .

... Remove the wing bolt and then remove the re-

tainer underneath it.

... Remove the subwoofer*

¢ page 212.

... Remove the spare tire.

Snow cha in s

For technical reasons, the use of snow chains on

the compact spare tire is not permitted.

If you have to drive with snow chains and a front

tire fails, mount the spare wheel in place of a

rear tire. Install the snow chains on the rear tire

that you removed, and install that in p lace of the

front tire that failed.

A WARNING

- Never use the spare t ire if it is damaged or if

it is worn down to the tread wear indicators.

- If the spare tire is more than 6 years o ld,

use it only in an emergency and with ex

treme caution and carefu l dr iving.

- The spare tire is intended on ly for tempora

ry and short-term use. It shou ld be replaced

as soon as possible with the normal wheel

and t ire.

- After mounting the compact spare t ire, the

t ire pressure must be checked as soon as

poss ible. The t ire pressure of the compact

spare tire must be 4.2 bar; otherwise, yo u

risk having an accident.

- Do not d rive faster than 50 mph (80 km/h).

Yo u risk hav ing an accident.

- Avoid full-throttle accelerat ion, heavy b rak

ing, and fast cornering. You risk having an

acc ident.

Em ergenc y ass is tanc e

-Never drive using more than one spare

wheel and tire. You r isk having an accident.

- Normal summer or winter tires must not be

mounted on the compact spare wheel rim.

- For technical reasons, the use of tire chains

on the spare tire is not permitted. If it is

necessary to drive w ith tire chains, the spare

wheel must be mounted on the front axle in

the event of a flat in a rear t ire. The newly

ava ilable front wheel must then be installed

in place of the rear wheel with the flat tire.

I nstalling the tire chain befo re mounting

the wheel and tire is recommended .

- Loose items in the passenger compartment

can cause se rious personal injury during

ha rd bra king or i n an accident. Never store

the spare tire or jack and tools in the pas

senger compartment.

Replacing wheels

Before changing a wheel

Observe the following precautions for your own

and your passenger's safety when changing a

wheel.

... After you experience a tire failure, pull the car

well away from moving traffic and try to reach

lev el ground before you stop¢ page 211,

¢ .&_.

... All passengers should le av e the car and move

to a safe location (for instance, behind the

gua rdrail)

c:::> .lll ·

... Engage the parking brake to prevent your veh i

cle from rolling unintentiona lly

c:::> .&_ .

... Move the selector le ver to the P po sit ion .

... If you are towing a trai ler: unhitch the trailer

from your vehicle.

... Take the

jack ¢ page 211 and the spa re ti re

¢page 212 out of the luggage compartment.

A WARNING

You or your passengers could be injured while

changing a whee l if you do not follow these

safety pre caut ions:

- If you have a flat tire, move a safe distance

off the road. Turn off the eng ine, turn the

213

Page 216 of 252

Emerg enc y assis ta nc e

emergency flashers on and use other

warning dev ices to alert other motorists.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- To help prevent the vehicle from moving

sudden ly and possibly slipp ing off the jack,

always fully set the parking brake and block

the wheel diagonally oppos ite the wheel be

ing changed with the folding chocks or oth

er objects. When one front wheel is lifted

off t he g ro u nd, plac ing the Automatic

T ransmission in "P" (Park) will

not prevent

the vehicle from moving.

- Before you change a wheel, be su re the

ground is level and firm. If necessary, use a

stu rdy board under the jack.

- Always store the veh icle tool k it, the jack

and the replaced tire in the luggage com

partment

r=> page 100.

(D Note

If you are cha nging the wheel on a steep in

cline, use the folding choc k

r=> page 212 to

block the oppos ite wheel to preven t the vehi

cle from moving .

(D Tips

Obey all laws.

Changing a wheel

When you change a wheel, follow the sequence

described below step-by-step and in exactly that

order.

1. Remove the dec orati ve w heel co ver* or the

wh eel bolt cap s*. For more deta ils see also

r=> page 215.

2. Loosen the wh eel b olt s r=> page 215 .

3. Locate the proper mounting point for the

jack and align the jack below that point

r=> page 216.

4. Lift the car with the jack r=> page 216.

S. Remove the wheel with th e fla t ti re and then

i nstall the

s p are t ire r=> page 217.

6. Tighten all wheel bo lts lightly .

7 .

Lower the veh icle w ith the jack.

214

8 . Use the whee l bolt wrench and firml y tighten

all wheel bo lts in a crisscross pattern

r=> page 215.

9. Replace the deco rative whee l co ver* or the

wheel bolt c aps* .

A WARNING

Always read and follow all WARNINGS and in

formation

r=> .&. in Raising the vehicle on

page 216

and r=> page 218.

After changing a wheel

A wheel change is not complete without the do

ing the following .

.,. Always store the vehicle too l kit, the jack* and

the replaced tire in the luggage compartment

¢ page 100 .

.,. Check the tire pres su re of the spare t ire as soon

as poss ible .

.,. As soon as possib le, have the

tigh tening tor

que s

on a ll wheel bolts checked with a torque

wrench. The correct tightening torque is

105 ft

lbs.

(140 Nm) .

.,. Have the flat tire

re pl ac ed as soon as poss ib le .

(D Tips

- If you notice that the wheel bo lts a re cor

roded and difficult to turn while changing a

t ire, they shou ld be replaced before you

check the t ightening torque.

- Drive at reduced speed until you have the

t ightening torques checked .

Page 218 of 252

Emerg ency assis ta nce

Raising the vehicle

The vehicle must be li~ed with the jack first be

fore the wheel can be removed .

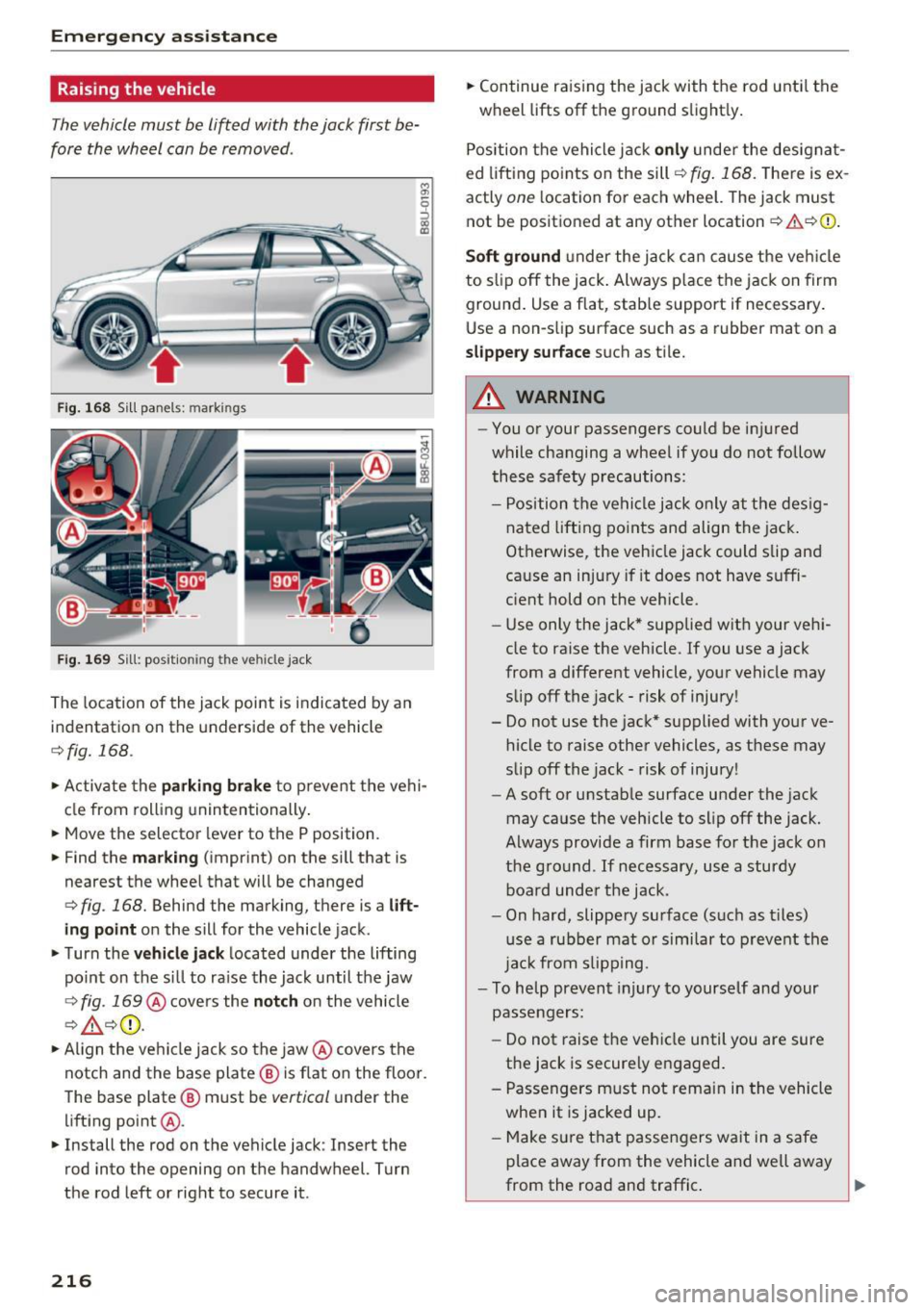

Fig. 168 Sill panels : mark in gs

Fig. 169 Sill : pos itio nin g th e ve hicle jack

The location of the jack point is indicated by an

indentation on the underside of the vehicle

¢ fig. 168 .

,.. Activate the parking brake to prevent the vehi

cle from rolling unintentionally .

,.. Move the selector lever to the P position.

,.. Find the

m arki ng (imprint) on the sill that is

nearest the wheel that will be changed

c> fig . 168. Behind the marking, there is a li ft

i ng po int

on the sill for the vehicle jack.

,.. Turn the

veh icl e jack located under the lifting

point on the s ill to ra ise the jack until the jaw

c> fig . 169 @cove rs the no tch on the vehicle

c> ,&. ¢0.

,.. Align the vehicle jack so the jaw @covers the

notch and the base plate @ is flat on the floor .

The base plate @ must be

vertical under the

lifting point @.

,.. Install the rod on the vehicle jack : Insert the

rod into the opening on the handwheel. Turn

the rod left or right to secure it .

216

,.. Continue raising the jack with the rod until the

wheel lifts off the ground slight ly.

Position the vehicle jack

only under the designat

ed lifting points on the sill

c> fig. 168. T here is ex

actly

one l ocation fo r each wheel. The jack must

not be positioned at any other location

c> ,1. ¢(D .

So ft gr ound under the jack can cause the ve hicle

to slip off the jack . Always p lace the jack on firm

ground. Use a flat, stab le support if necessary .

Use a non-slip surface such as a rubber mat on a

s lipp ery s urface such as tile.

A WARNING -

-You or your passengers could be injured

while changing a wheel if you do not follow

these safety precautions:

- Position the vehicle jack only at the des ig

nated lifting points and align the jack .

Otherwise, the vehicle jack could slip and

cause an injury if it does not have suffi

cient hold on the vehicle.

- Use only the jack* supplied w ith your veh i

cle to raise the vehicle . If you use a jack

from a different vehicle, your vehicle may

slip off the jack - risk of injury!

- Do not use the jack* supplied with your ve

hicle to raise other vehicles, as these may

slip off the jack - risk of injury!

- A soft or unstab le surface under the jack

may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on

the gro und .

If necessary, use a sturdy

board unde r the jack.

- On hard, slippery surface (such as t iles)

use a rubber mat or similar to prevent the

jac k from slipp ing .

- To help prevent injury to yourself and your

passengers:

- Do not raise the vehicle until you are sure

the jack is securely engaged.

- Passengers must not rema in in the vehicle

when it is jacked up.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic . .,_

Page 219 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

-Make sure jack posit ion is correct , adjust

as necessary and then cont inue to raise

the jack.

- If work has to be done under the vehicle,

ensure that it is safely supported on su ita

ble stands -risk of injury!

- Never start the engine when the vehicle is

on the jack -risk of accident!

CD Note

Do not lift the vehicle by the sill. Position the

vehicle jack on ly at the designated lifting

points on the sill. Otherwise, your vehicle will

be damaged.

Taking the wheel off/installing the spare

tire

F ollow these instructions step-by-step for chang

ing the wheel .

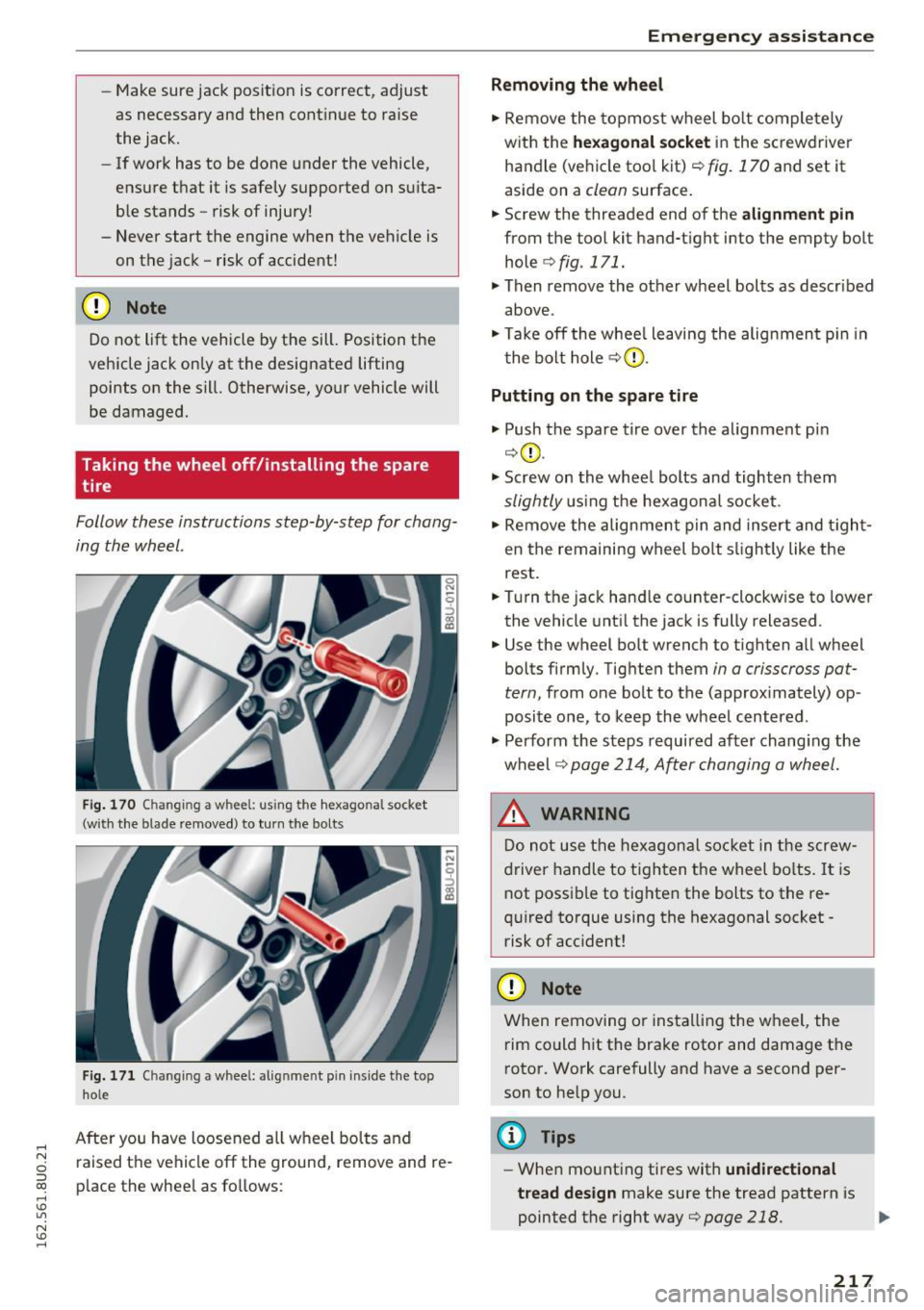

Fig. 170 C hangin g a w heel: using th e hexagonal s oc ket

(w it h the blade removed ) to turn t he bolt s

Fig. 171 Chan gin g a w hee l: a lig nm ent pin in side the to p

h ol e

After you have loosened all wheel bolts and

raised the vehicle off the ground, remove and re

p lace the whee l as follows:

Em ergen cy a ssis tanc e

Removing the whe el

"' Remove the topmost wheel bolt completely

with the

he xagona l s oc ket in the screwdriver

handle (vehicle too l kit)

c::> fig. 170 and set it

aside on a

clean surface.

.. Screw the threaded end of the

alignment pin

from the tool kit hand-tight into the empty bolt

hole

c::> fig . 171.

"' Then remove the other wheel bolts as described

above .

"' Take off the whee l leaving the alignment p in in

the bolt hole

c::> G) .

Putting on the spare tire

"' Push the spare tire over the alignment pi n

c::>(D .

"' Screw on the whee l bolts and tighten them

slightly u sing the hexagona l socket .

"' Remove the alignment pin and insert and t ight

en the remaining wheel bo lt s lightly like the

rest .

.. Turn the jack hand le count er-clockw ise to lower

the vehicle unti l the jack is fully released .

.. Use the wheel bo lt wrench to tighten all wheel

bolts firmly . Tighten them

in a crisscross pa t

tern,

from one bolt to the (approx imately) op

posite one, to keep the wheel centered .

"' Perform the steps required after chang ing the

wheel

c::> page 214, A~er changing a wheel.

_& WARNING

Do not use the hexagon al soc ket in the screw

driver handle to tighten the wheel bo lts. It is

not possible to tighten the bolts to the re

qu ired torque using the hexagonal socket -

risk of acc ident!

CD Note

When removing or installing the wheel, the

rim could h it the brake rotor and damage t he

rotor. Work carefully and have a second per

son to he lp you.

@ Tips

- When mounting tires with un idirectional

tread de sign

make sure the tread pattern is

pointed the right way

c::> page 218 . 1JJ,,

217

Page 222 of 252

Fuses and bulbs

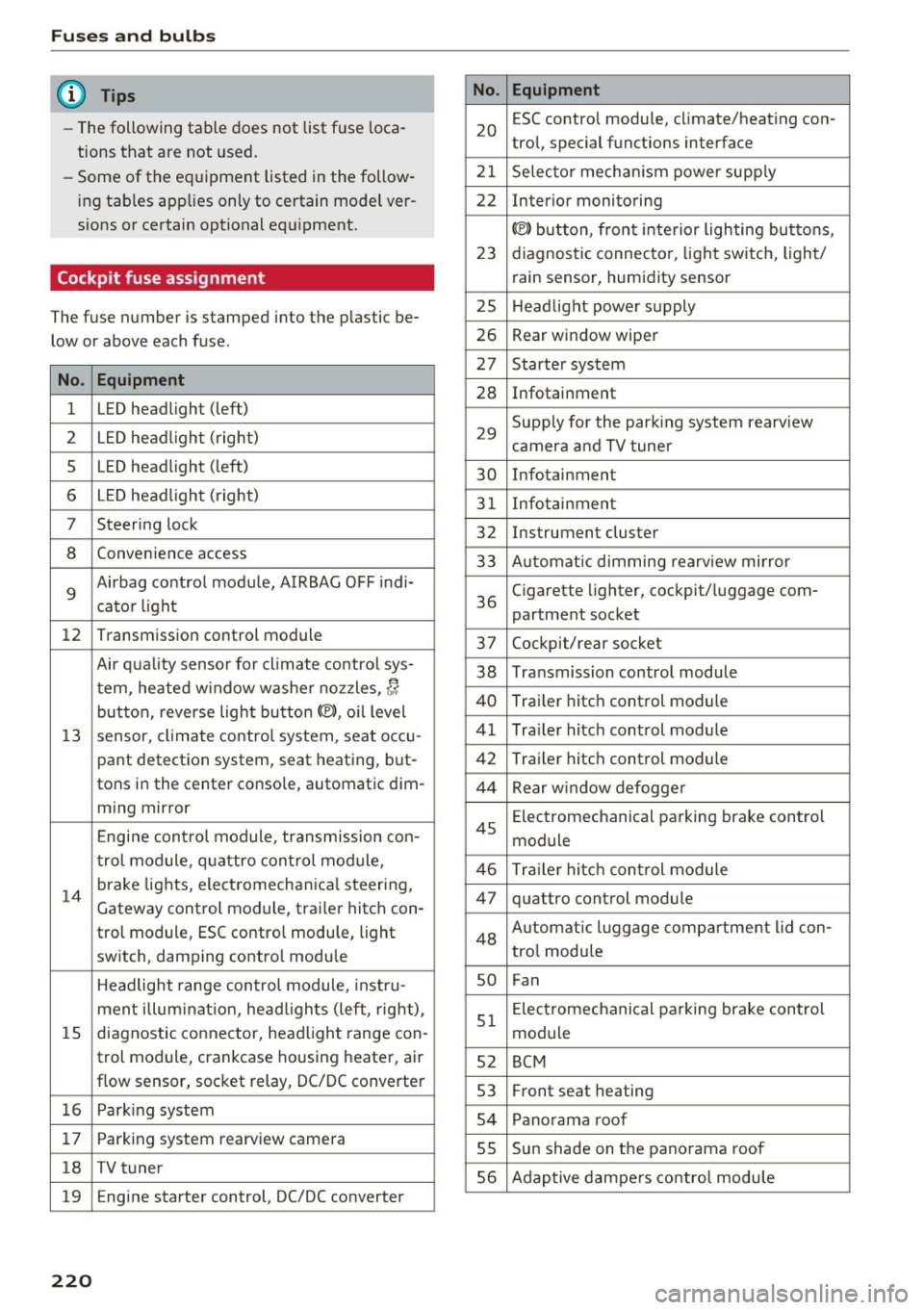

(D Tips

- The following table does not list fuse loca

tions that are not used.

- Some of the equipment listed in the follow

ing tables applies only to certain model ver

sions or certain optional equipment.

Cockpit fuse assignment

The fuse number is stamped into the plastic be

low or above each fuse.

No. Equipment

1 LED headlight (left)

2 LED headlight ( right)

5 LED headlight (left)

6 LED headlight (right)

7 Steering lock

8 Convenience access

9

Airbag control module, AIRBAG OFF indi-

cator light

12 Transmission control module

Air quality sensor for climate contro l sys-

tern, heated w indow washer nozzles,~

button, reverse light button<®>, oil level

13 sensor, climate control system, seat occu-

pant detection system, seat heating , but-

tons in the center console, automatic dim-

ming mirror

Engine control module, transmission con-

trol module, quattro control module,

14

brake lights, electromechanica l steering,

Gateway cont rol module, trailer hitch con-

trol module, ESC contro l module, light

switch, damping control module

Headlight range control module, instru-

ment illuminat ion, headl ights (left, right),

15 diagnostic connector, headlight range con-

trol module, crankcase housing heater, air

flow sensor, socket relay, DC/DC converter

16 Park ing system

17 Parking system rearview camera

18 TV tuner

19 E ngine starter control, DC/DC converter

220

No . Equipment

20

ESC contro l module, climate/heating con-

tro l, special functions interface

21 Selecto r mechanism power supply

22 Interior monitoring

© button, front interior lighting buttons,

23 diagnostic connector, light switch, light/

rain sensor, humidity sensor

25 Headlight power supply

26 Rear window wiper

27 Starter system

28 Infotainment

29

Supply for the park ing system rearv iew

camera and TV tuner

30 Infotainment

31 Infotainment

32 Instrument cluster

33 A utomat ic dimming rearview mirror

36

Cigarette lighter, cockpit/ luggage com-

partment socket

37 Cockpit/rear socket

38 Transmission control module

40 Trailer hitch control module

41 Trailer hitch control module

42 Trailer hitch control module

44 Rear window defogger

45

Electromechanical parking brake control

module

46 Trailer hitch control module

47 quattro control module

48 Aut omat ic lu ggage compartment lid con-

tro l module

so Fan

51

Electromechanical parking brake control

module

52 BCM

53 Fr ont seat heating

54 Panorama roof

55 Sun shade on the panorama roof

56 Adaptive dampers control module

Page 223 of 252

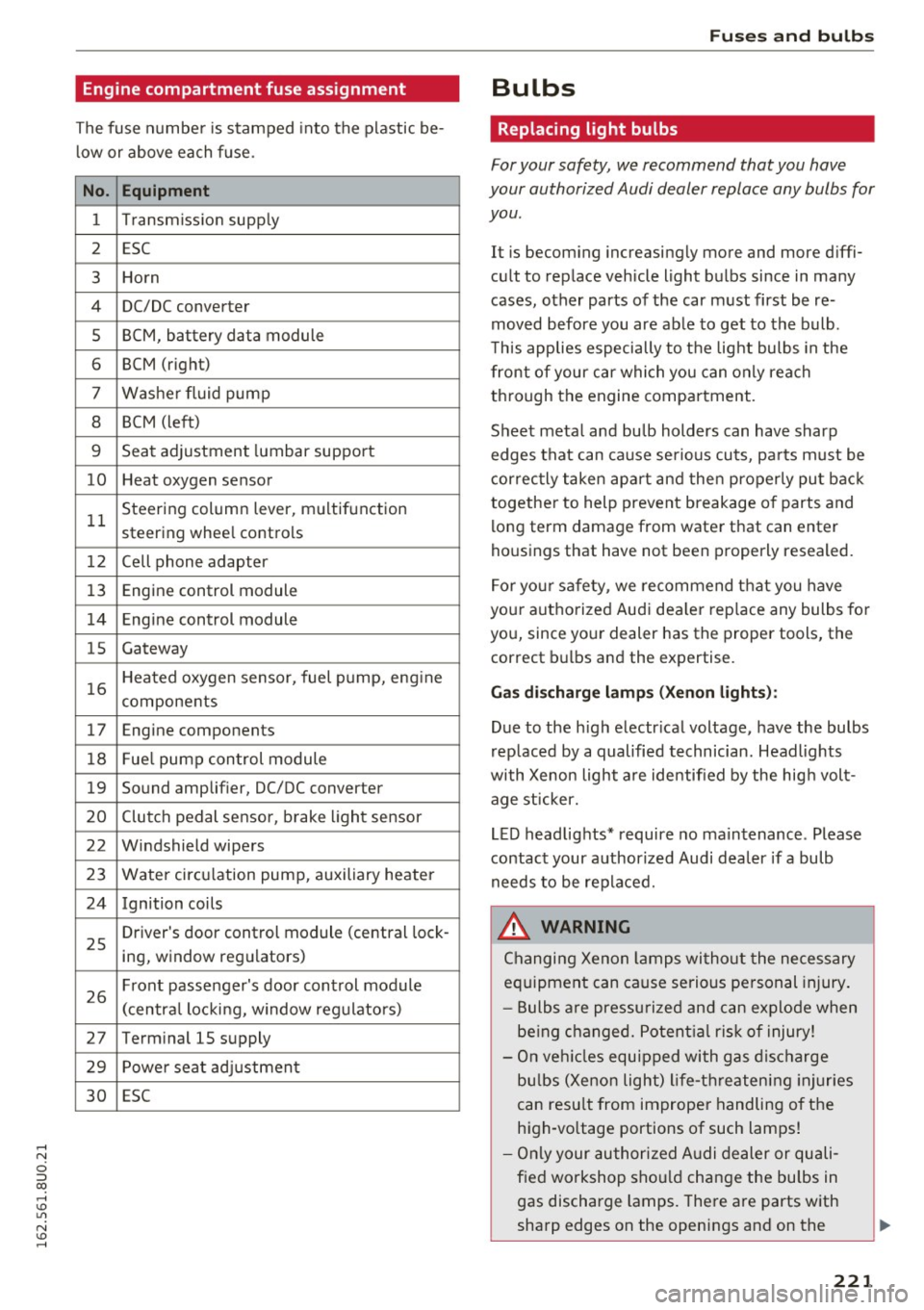

Engine compartment fuse assignment

The fuse number is stamped into the plastic be

low or above each fuse.

No. Equipment

1 Transmiss ion supply

2 ESC

3 Horn

4 DC/DC

converter

5 BCM, battery data module

6 BCM (right)

7 Washer fluid pump

8 BCM (left)

9 Seat adjustment lumbar support

10 Heat oxygen sensor

11 Steering

column lever, multifunction

steering wheel contro ls

1 2 Cell phone adapter

13 Engine control

module

14 Engine control module

15 Gateway

16 Heated oxygen sensor, fuel pump,

engine

components

17 Engine components

18 Fue l pump control module

19 Sound

amplifier, DC/DC converter

20 Clutch pedal sensor, brake light sensor

22 Windshield wipers

23 Water circu

lation pump, auxiliary heater

24 Ignition coils

25 Driver's door

control module (central lock-

ing, window regu lators)

26 Front

passenger's door control module

(centra l locki ng, window reg ulators)

27 Terminal 15 supply

29 Powe r seat adjustment

30 ESC

Fuses an d bulb s

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you .

It is becoming increasingly more and more diffi

cult to replace vehicle light bulbs since in many

cases, other parts of the car m ust first be re

moved before you are able to get to the bulb .

T his applies especially to the light bulbs in the

front of your car which you can only reach

through the engine compartment .

Sheet metal and bu lb holders can have sharp

edges that can cause serious cuts, pa rts must be

correctly taken apart and then properly put back

together to help prevent breakage o f parts and

long term damage from water that can enter

housings that have not been properly resealed.

For your safety, we recommend t hat you have

your authorized Aud i dea le r rep lace any bulbs fo r

you, since your dealer has the proper tools, the

correct bulbs and the expertise.

Gas di schar ge la mps (Xe no n light s):

Due to the high electr ical voltage, have the bulbs

rep laced by a qualified technician. Headlights

with Xenon light are identified by the hig h volt

age st icker.

LED headlights* require no maintenance . Please

contact your authorized Audi dea ler if a bulb

needs to be replaced.

_&. WARNING

Changing Xenon lamps wi thout the necessary

equipment can cause serious personal injury .

- Bulbs are pressu rized and can explode when

be ing changed. Potent ial ris k of injury!

- On veh icles equipped with gas disc harge

bu lbs (Xenon light) life-threatening injuries

can resu lt from improper handling of the

high-vo ltage portions of such lamps!

- Only your authorized A udi dealer or quali

fied workshop sho uld change the bulbs in

gas discharge lamps. There are parts with

sharp edges on the openings and on the

221

Page 226 of 252

Emergency situations

When jump starting or charging the bat

tery, never connect the negative ground ca

ble to the battery negative post because the

battery manager system must be able to de

tect the battery's state of charge. Always

connect the negative ground cable to the

negative ground post of the battery manag

er contro l unit.

Use of jumper cables

Make sure to connect the jumper cable clamps in

exactly the order described below!

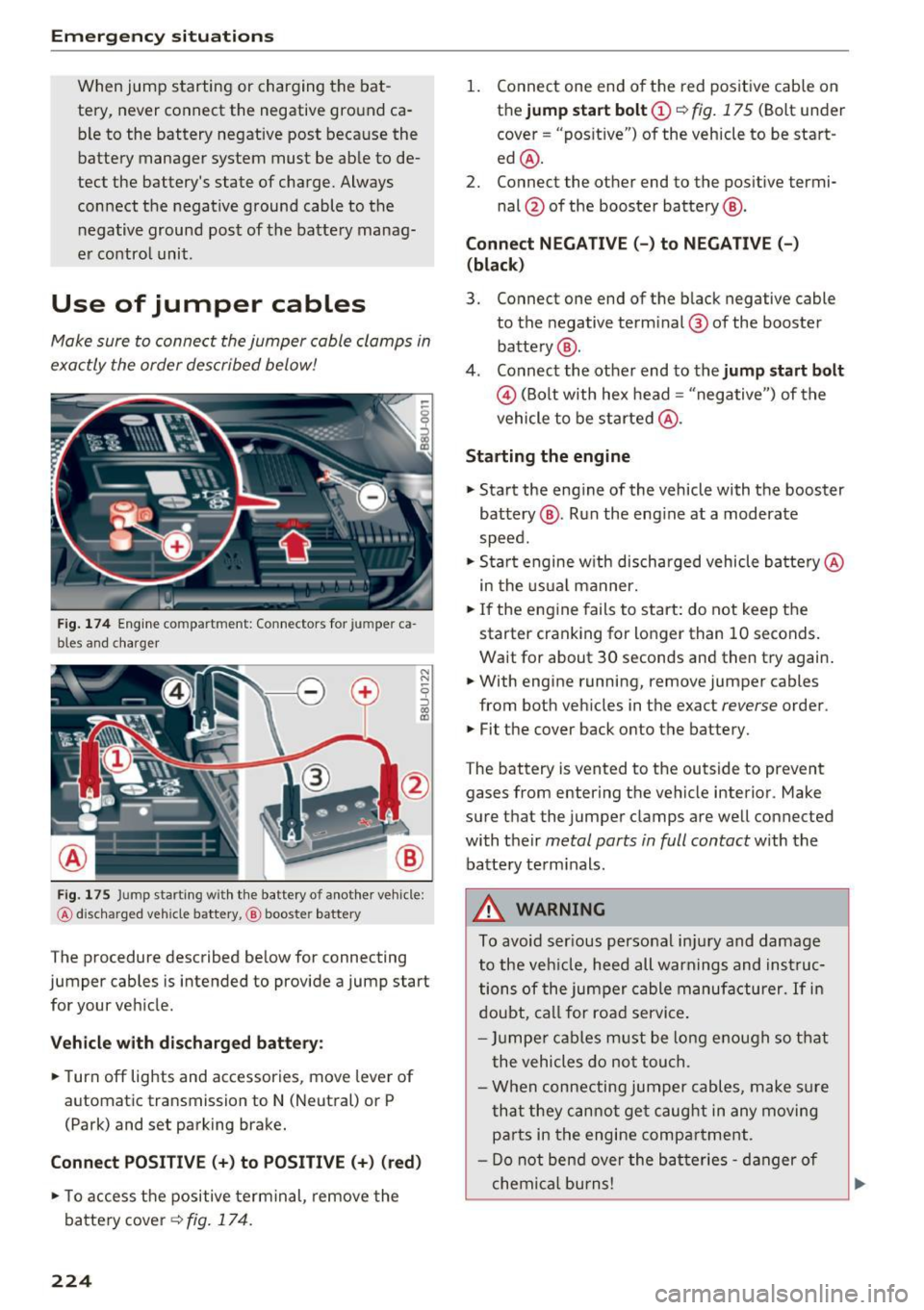

F ig . 1 74 Engine compar tment: Connectors for jumper ca

bles and charger

N N ~ 9 ::, 00 CXl

F ig. 175 Jump starti ng wit h the battery of another veh icle:

@ discharged vehicle battery,@booster battery

The procedure described below for connecting

jumper cables is intended to provide a jump start for your vehicle.

Vehicle with discharged battery:

• Turn off lights and accessories, move lever of

automatic transmission to N (Neutral) or P

(Park) and set parking brake.

Connect POSITIVE (+) to POSITIVE (+) (red)

• To access the positive terminal, remove the

battery cover

c::> fig. 17 4.

224

1. Connect one end of the red pos itive cable on

the

jump start bolt (D c::> fig. 175 (Bolt under

cover= "positive") of the vehicle to be start

ed @.

2. Connect the other end to the positive termi-

nal @ of the booster battery @.

Connect NEGATIVE (- ) to NEGATIVE (-)

(black)

3. Connect one end of the black negative cable

to the negative term inal @ of the booster

battery @.

4. Connect the other end to the

jump start bolt

@ (Bolt with hex head = "negative") of the

vehicle to be started @.

Starting the engine

• Start the eng ine of the vehicle with the booster

battery @. Run the eng ine at a moderate

speed.

• Sta rt engine w ith discharged vehicle ba ttery @

in the usual manner.

• If the engine fails to start: do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again.

• With engine running, remove jumper cables

from both vehicles in the exact

reverse order.

• Fit the cover back onto the battery.

The battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connected

with their

metal parts in full contact with the

battery terminals.

&_ WARNING

To avoid ser ious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch .

- When connecting jumper cables, make sure

that they cannot get caug ht in any moving

parts in the engine compartment.

- Do not bend over the batteries - danger of

chemical burns!

Page 227 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

-The battery cell lock ing screws must be

t ightened secure ly.

- Befo re yo u check anything in the en gine

compartment, a lways read and heed a ll

WARNINGS

¢ page 177.

(D Note

Imp ro per hook -u p of jum pe r cables can r uin

the gene rato r.

-Always con nect POSIT NE

(+ ) to POSITI VE

(+ ), and NEGATIVE( -) to NEGATIVE( -)

ground post of the battery manager contro l

u nit .

- Check that all sc rew p lugs on the batter y

ce lls are screwed in firmly . If not, t ighten

pl ugs prior to connecting clamp on negative

batte ry te rminal.

- Please note t hat the procedure fo r con nect

i ng a jumper cab le as desc ribed above ap

p lies specif ica lly to the case of yo ur vehicle

being jump start ed. Wh en you are giv ing a

ju mp sta rt to anothe r vehicle, do

not con

n ec t t he neg ative (-) ca b le to the negative

( -) t ermina l on the disch arged b attery @

¢

fig. 175. In ste ad , secure ly connec t the

negative( -) ca b le to either a solid me tal

com ponent th at is f irm ly bolted to the e n

gine block o r to t he engine block i tsel f. If

the battery that is be ing c ha rged does not

vent to the outs ide, escap ing batte ry ga s

could ignite and exp lode!

Towing with a tow truck

General hints

Your Audi requires s pecial handling for towing .

The following informa tion is to be used by com

mercia l tow tr uck operators who know how to op

e ra te the ir equip men t safely.

- Ne ver tow your Audi, towing will cause dam

age to the engine and transmission .

- Never wrap the safety chains or winch cables

around the brake lines.

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck .

Emergency situations

-To load the vehicle on to the flat bed , use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

¢ page 225 and ¢ page 226.

A WARNING

A veh icle being towed is not safe for passen

ge rs. Neve r allow a nyo ne to ride in a vehicle

b eing towed, for any reason .

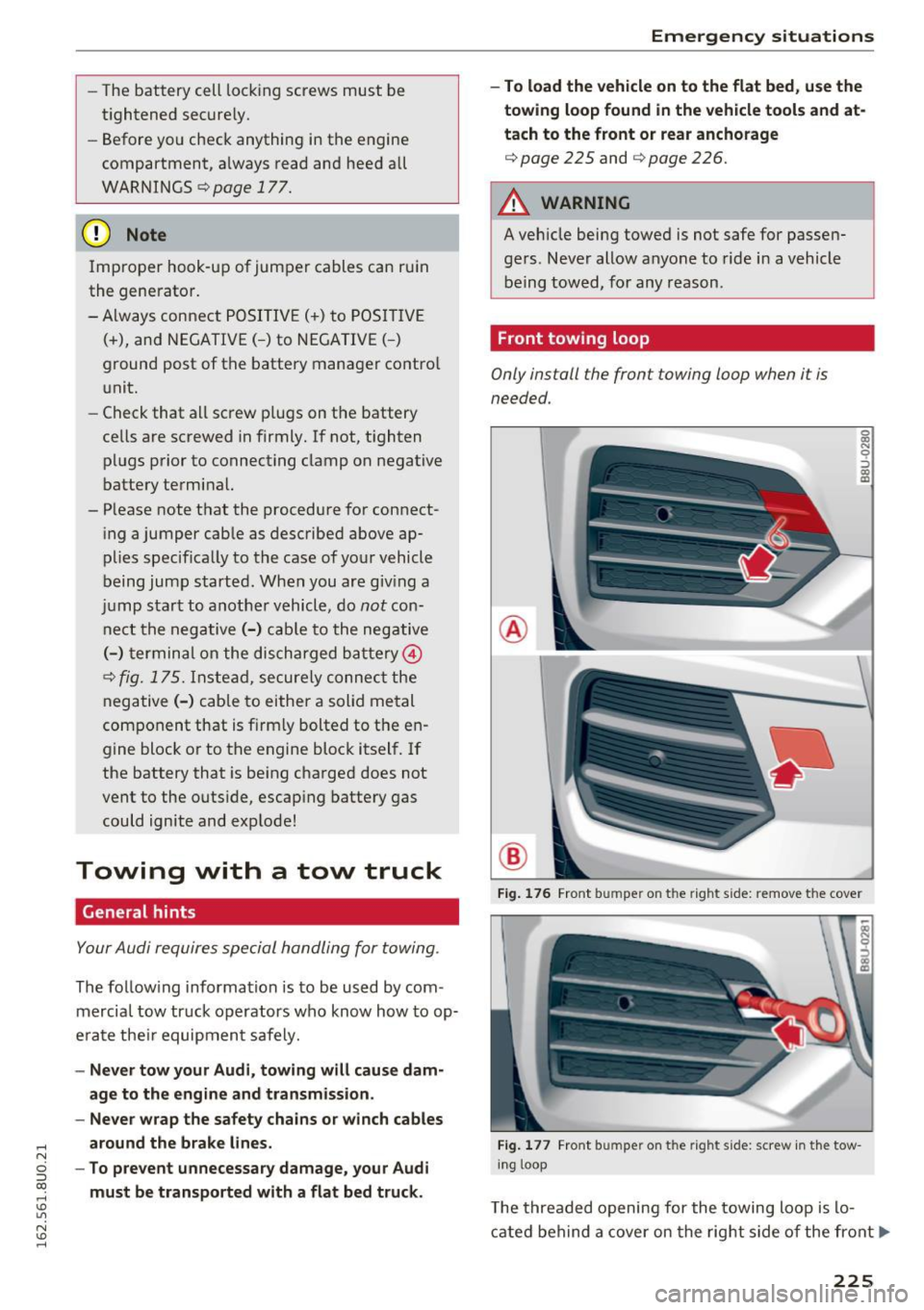

Front towing loop

Only ins tall the front towing loop when i t is

needed .

®

®

-

0 0) N 9 ::>

gi

Fig. 176 Front bum pe r o n th e rig "h t side : remove t he co ver

Fi g. 177 Fron t bum per o n th e right sid e: screw in t he tow

in g loop

The threaded opening for the towing loop i s lo

cate d be hind a cove r on t he rig ht side of the front .,.

225