AUDI Q5 2016 Owners Manual

Manufacturer: AUDI, Model Year: 2016, Model line: Q5, Model: AUDI Q5 2016Pages: 300, PDF Size: 75.02 MB

Page 271 of 300

,....,

N

co

er::

co

,....,

whenever you need to change a bulb.

Fuses and bulbs

269

Page 272 of 300

Emergency situations

Emergency situations

General

This chapter is intended for trained emergency crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

CD Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engin e con be started by con

necting it to the battery of another vehicle.

If the engine should fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumper cables to start the engine.

Jumper cables

Use only jumper cables of sufficiently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated terminal

clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for

safe

handling of your vehicle's battery.

-Always shield your eyes and avoid leaning

over the battery whenever possible.

-A discharged battery can freeze at tempera

tures just below 32 °F (0 °C). Before con

necting a jumper cable, you must thaw the

270

frozen battery completely, otherwise it could explode.

- Do not allow battery acid to contact eyes or

skin. Flush any contacted area with water immediately.

- Improper use of a booster battery to start a

vehicle may cause an explosion.

- Vehicle batteries generate explosive gases.

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery.

- The voltage of the booster battery must also

have a 12-Volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batteries of different voltage or substantial

ly different "Ah" rating may cause an explo

sion and personal injury.

- Never charge a frozen battery. Gas trapped in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen . The battery

case may have be weak

ened .

- Use of batteries of different voltage or sub

stantially different capacity (Ah) rating may

cause an explosion and injury. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

~page 220.

CD Note

-Applying a higher voltage booster battery

will cause expensive damage to sensitive

electronic components, such as control

units, relays, radio, etc.

- There must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

(+) terminals are connected.

@ Tips

- The discharged battery must be properly

connected to the vehicle's electrical system. .,..

Page 273 of 300

..... N

co ~ CX)

..... I.Cl U"I

..... I.Cl .....

When jump starting or charging the bat

tery, never connect the negative ground ca

ble to tbe battery negat ive post because the

battery manager system must be ab le to de

tect the battery's state of charge. Always

connect the negative ground cable to the

negative ground post of the battery manag

er contro l unit .

Use of jumper cables

Make sure to connect the jumper coble clomps in

exactly the order described below!

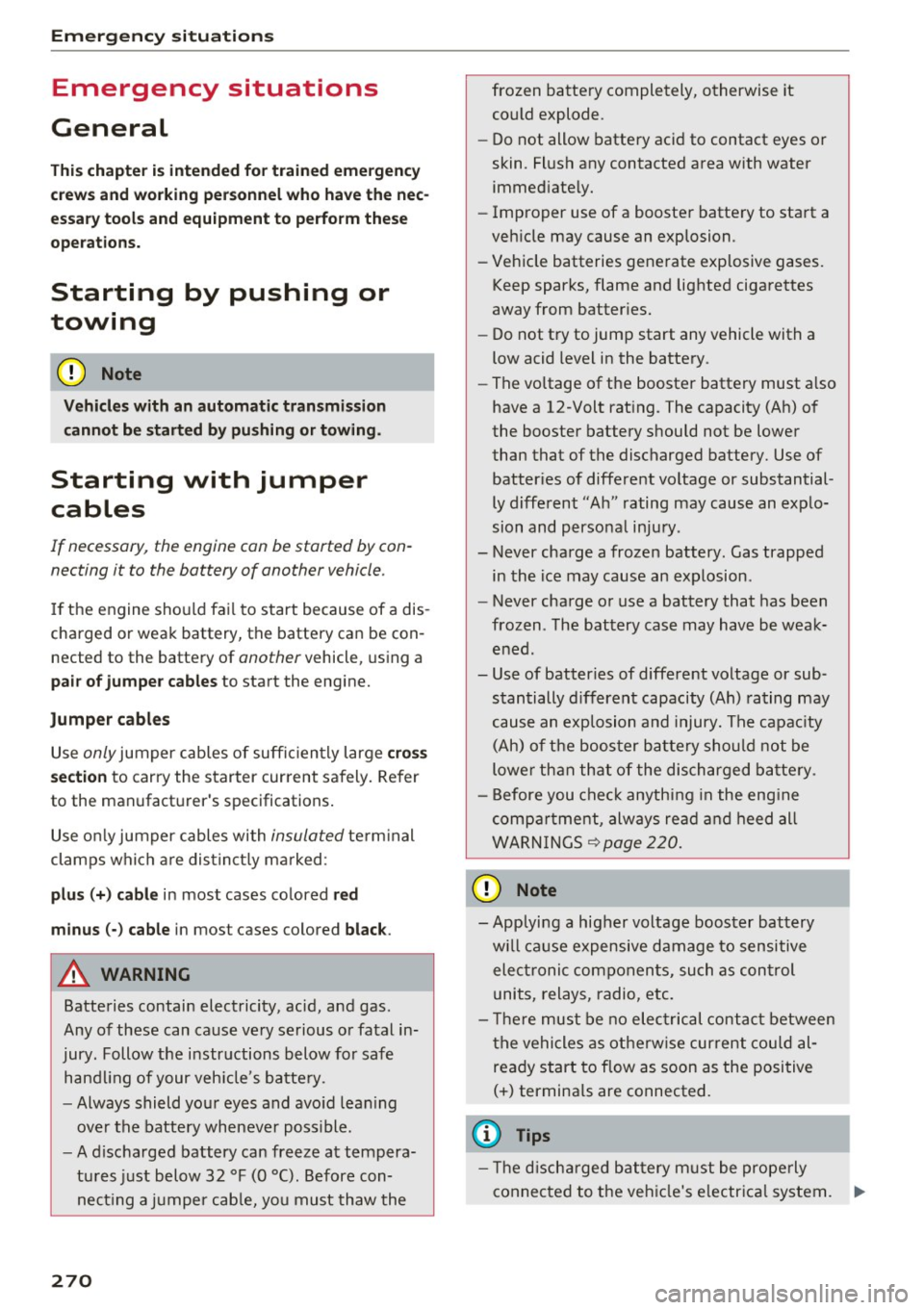

Fig. 227 Engine co mpartment: Connectors for jumper ca

b les and charger

Fig. 228 Jump starting w ith the bat tery of a nother vehicle:

@ booste r battery, @ discha rged veh icle battery

The procedure described below for connecting

jumper cables is intended to provide a jump start for your vehicle.

Hybrid drive*: read the important information

concerning a dead high voltage battery under

c;;,poge 104.

Vehicle with discharged battery:

.. Turn off lights and accessories, move lever of

automatic transmission to N (Neutral) or P

(Park) and set parking brake .

Emergency situations

Connect POSITIVE(+) to POSITIVE (+) (red)

.. Remove the cover@ by pressing on the arrow

¢fig. 227.

.. Open the cover @on the positive terminal.

1. Connect one end of the red positive cab le on

the

jump start bolt r=;;, fig. 228 @ (Bolts un

der cover= "positive") of the vehicle to be

started @.

2. Connect the other end to the positive termi-

nal @ of the booster battery @.

Connect NEGATIVE(-) to NEGATIVE(-)

(black)

3. Connect one end of the black negative cable

to the negative te rm i nal @of the booster

battery @.

4. Connect the other end of the bla ck negative

cable to the

jump start bolt@ (Bolts wi th

hex head = "negative") of the vehicle to be

started @.

Starting the engine

.. Start the engine of the vehicle with the booster

battery @. Run the eng ine at a moderate

speed .

.. Start engine w ith discharged vehicle battery®

in the usual manner .

.. If the engine fails to start: do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again .

.. With eng ine running,

remove jumper cables

from both veh icles in the exact

reverse order .

.. Close the

cover @on the positive terminal and

re-install the cover (!)¢

fig. 227.

T he battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connected

with their

metal ports in full contact with the

battery term inals.

& WARNING ~

To avoid serious personal injury and damage

to the veh icle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road

service.

-Jumper cables must be long enough so that

the vehicles do not touch.

~

271

Page 274 of 300

Emergency situations

-When connecting jumper cables, make sure

that they cannot get caught in any moving

parts in the engine compartment.

- Do not bend over the batteries -danger of

chemical burns!

- The battery cell locking screws must be

tightened securely.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

c> page 220.

(D Note

Improper hook-up of jumper cables can ruin

the generator .

- Always connect POSITIVE(+) to POSITIVE

(+), and NEGATIVE(-) to NEGATIVE(-)

ground post of the battery manager control

unit.

- Check that all screw p lugs on the battery

cells are screwed in firmly. If not, tighten

plugs prior to connect ing clamp on negative

battery terminal.

- Please note that the procedure for connect

i ng a jumper cable as described above ap

plies specifically to the case of your vehicle

being jump started . When you are giving a

ju mp start to another vehicle , do

not con

nect the negative (-) cable to the negative

(-) terminal on the discharged batte ry @

c> fig. 228. Instead, securely connect the

negative( -) cab le to either a solid metal

component that is firm ly bolted to the en

gine block or to the engine block itself. If

the battery that is being charged does not

vent to the outside, escap ing battery gas

could ignite and explode !

Towing with a tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by com

mercial tow truck operators who know how to op

erate the ir equipment safely.

-Never tow your Audi, towing will cause dam

age to the engine and transmission.

272

-Never wrap the safety chains or winch cables

around the brake lines .

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck .

- To load the vehicle on to the flat bed, use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

i:>pag e 272 and i:> page 273.

A WARNING

A vehicle being towed is not safe for passen

gers . Never allow anyone to ride in a vehicle

being towed, for any reason.

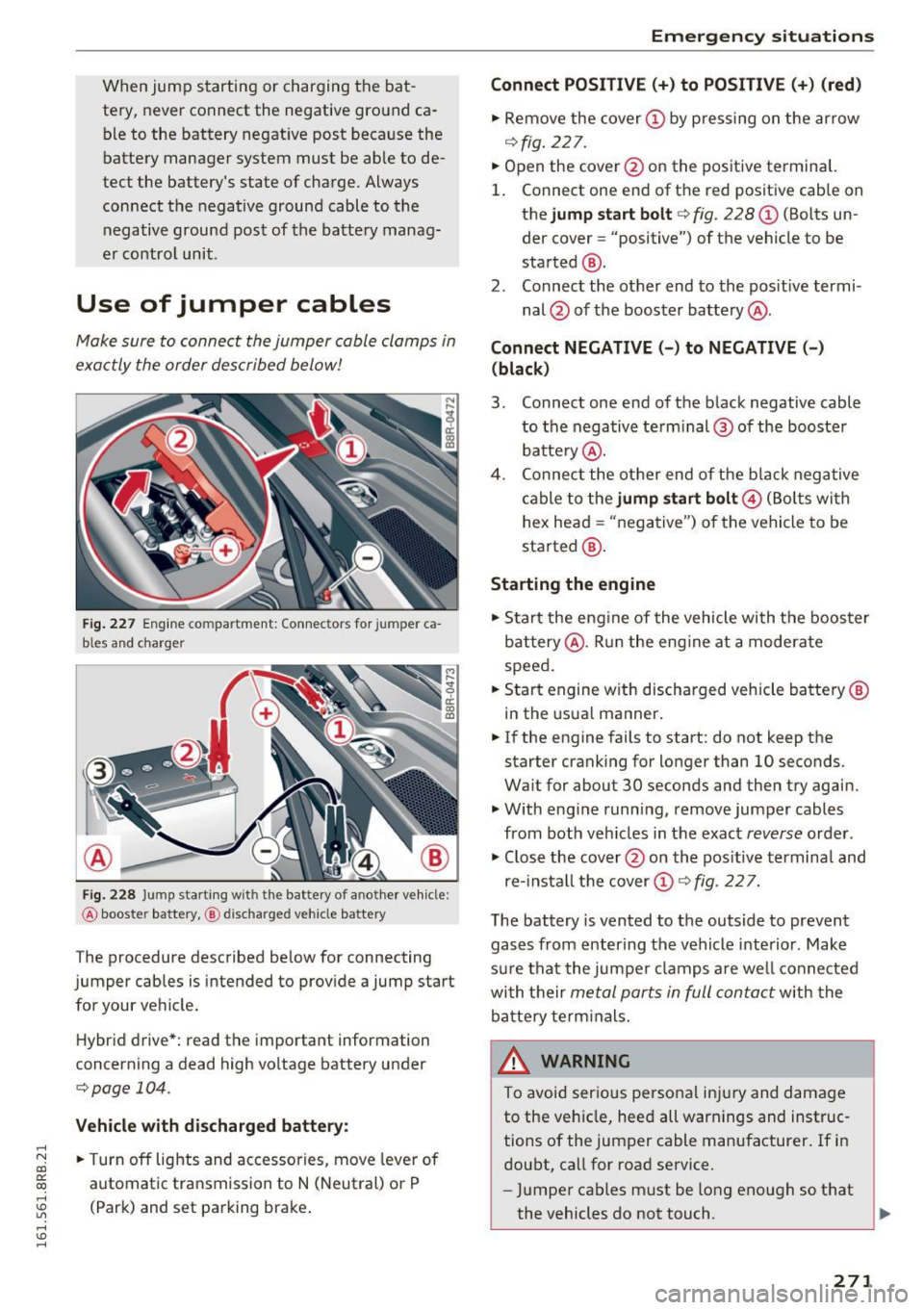

Front towing loop

Do not install the front towing loop until it is

needed.

Fig. 229 Front bumper : remov ing the cover cap

Fig. 230 Front bumper: s crew ing in t he towing loop

The towing loop fits into the threaded hole locat

ed on the right side o f the front bumper and cov

ered by a cover when not in use.

.,. Remove the towing loop from the vehicle tool

kit

c> page 254 .

.,. Carefully remove the cove r c> fig. 229.

.,. Screw the towing loop tightly into the threaded

hole as far as it will go

c> fig. 230. Ill>

Page 275 of 300

..... N

co ~ CX)

..... I.Cl U"I

..... I.Cl .....

When it is no longer needed, unscrew the towing

loop and put it back into the vehicle toolkit. Be

sure to have the towing loop stored in the vehicle

at all times.

When r e-installing the cover be sure to first in

sert the tabs on the cover into the retainers near

the radiator grille. Then install the other side of

the cover and push it into the retainers

¢fig. 229.

The appearance of the cover varies from the i llus

tration for some model vers ions.

.&_ WARNING

If the towing loop is not screwed in as far as it

will go, the thread can pull out when the vehi

cle is towed -potential risk of an accident.

(D Note

The cover is attached to the bumper with sev

eral hooks. Do not use excessive force when

removing the cover to avoid damag ing it.

Rear towing loop

On vehicles without a factory-installed trailer

hitch*, the threaded hole for the towing loop is

on the right side of the rear bumper.

Fig. 231 Rear bumper: Cover

Emergency situations

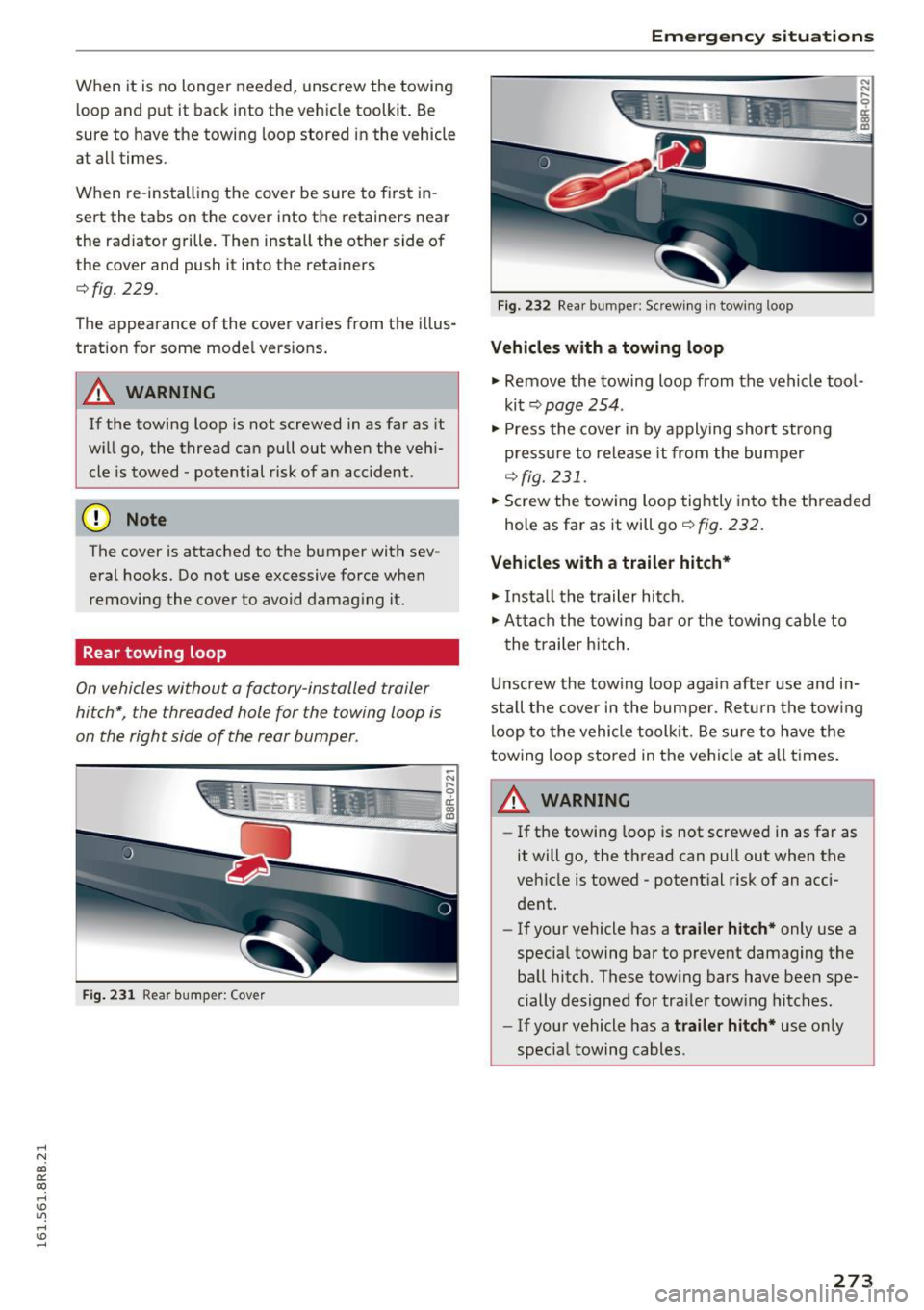

Fig. 232 Rear bumper: Screw ing in towing loop

Vehicles with a towing loop

.,. Remove the towing loop from the vehicle tool

kit

c;, page 254.

.,. Press the cover in by applying short stro ng

press ure to release it from the bumper

¢fig. 231 .

.,. Screw the towing loop tightly into the threaded

hole as far as it will go

c;, fig. 232.

Vehicles with a trailer hitch*

.,. Insta ll the trailer hitch.

.,. Atta ch the towing bar or the towing cable to

the trailer hitch.

Unscrew the towing loop again after use and in

stall the cover in the bumper . Ret urn the towing

loop to the vehicle toolkit. Be sure to have the

towing loop stored in the vehicle at all times.

A WARNING

-If the towing loop is not screwed in as far as

it will go, the thread can pull out when the

vehicle is towed - potential risk of an acci

dent.

- If your vehicle has a

trailer hitch* only use a

special towing bar to prevent damaging the

ball hitch. These tow ing bars have been spe

cially designed for trailer tow ing hitches.

- If your vehicle has a

trailer hitch* use only

special towing cables .

273

Page 276 of 300

Emergency situations

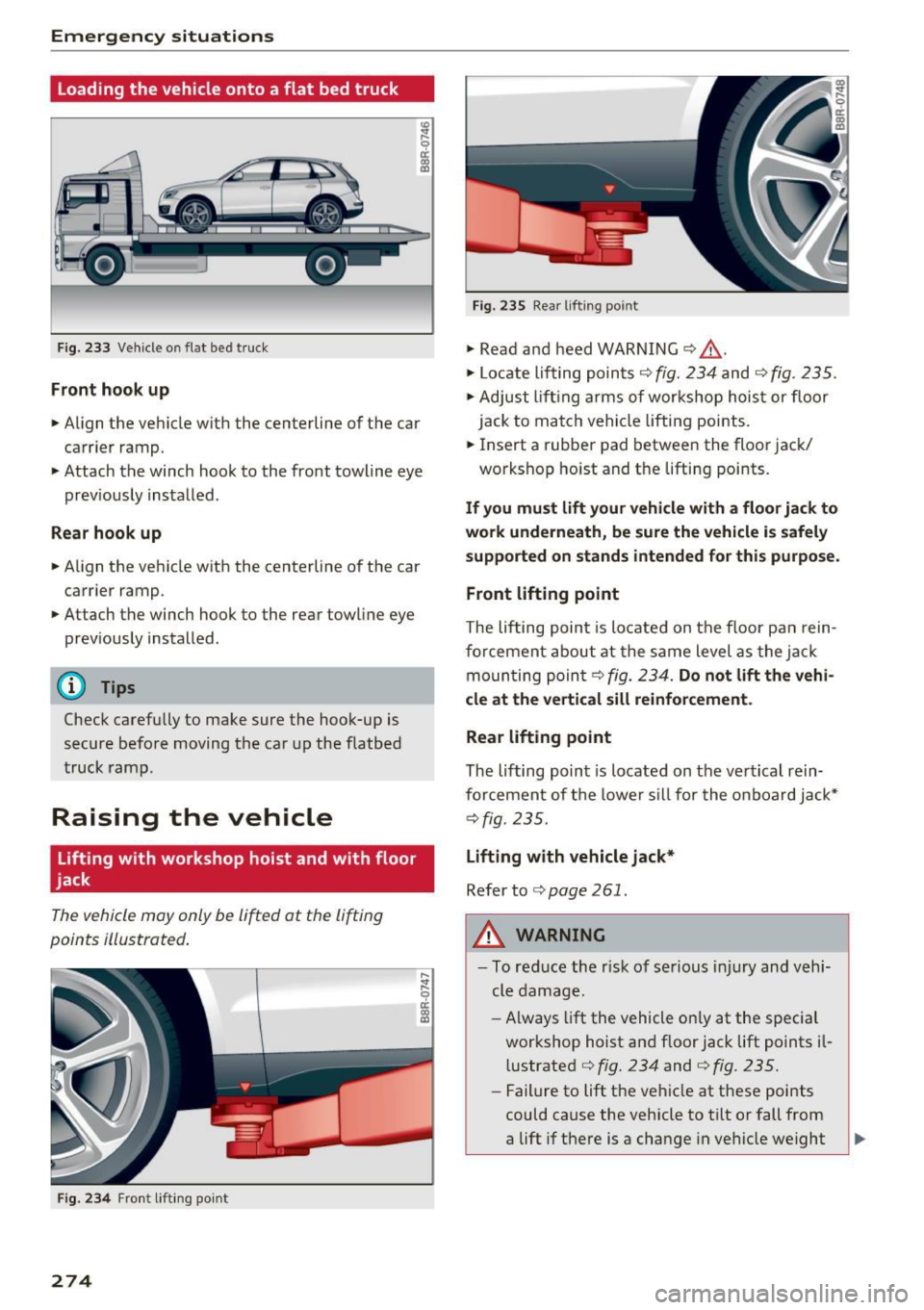

Loading the vehicle onto a flat bed truck

Fig. 233 Veh icle o n flat bed truck

Front hook up

.. Align the vehicle with the centerline of the car

carr ier ramp.

.. Attach the winch hook to the front towline eye

prev iously installed.

Rear hook up

.. Align the vehicle with the centerline of the car

carrier ramp.

.. Attach the winch hook to the rear towline eye

previously installed .

@ Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp.

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be lifted at the lifting

points illustrated.

Fig. 234 Front lifting point

274

Fig. 235 Rear lifting point

.. Read and heed WARNING ¢ f1..

.. Locate lifting points r;!) fig. 234 and c;!) fig. 235.

.. Adjust lifting arms of workshop hoist or floor

jack to match vehicle lifting points .

.. Insert a rubber pad between the floor jack/

workshop hoist and the lifting points .

If you must lift your vehicle with a floor jack to

work underneath, be sure the vehicle is safely

supported on stands intended for this purpose .

Front lifting point

The lifting point is located on the floor pan rein

forcement about at the same level as the jack

moun ting poin t¢

fig. 234. Do not lift the vehi

cle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located on the vertical rein

forcement of the lower sill for the on board jack*

¢fig. 235.

Lifting with vehicle jack*

Refer to<=> page 261.

,&. WARNING

-To reduce the r isk of serious injury and vehi

cle damage.

- Always lift the vehicle on ly at the special

workshop hoist and floor jack lift points il

l ustrated <=>

fig. 234 and ¢ fig. 235.

-Failure to lift the vehicle at these points

could cause the vehicle to tilt or fall from

a lift if there is a change in vehicle weight

Page 277 of 300

,....,

N

co

er::

co

,....,

pen, for exam ple, when heavy compo

nents such as the engine b lock or trans

miss io n are removed.

- When removing heavy components like

th ese, anc hor vehicle t o hoist o r add corr e

sponding weights to maintain the center of

grav ity. Oth erwise, the ve hicle might ti lt or

s li p off the hois t, causing s erious person al

lnJUry.

(D Note

- Be awar e of the fo llowing poi nts before lift

i ng t he vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine oil pan , the transmission housing, the front

or rear axle or the body side members .

This could lead to serious damage.

- To avoid damage to the unde rbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points.

- Before driv ing over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist .

- Before driving over a workshop hoist, en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve

hicle.

Emergency situations

275

Page 278 of 300

Technical data

Technical data

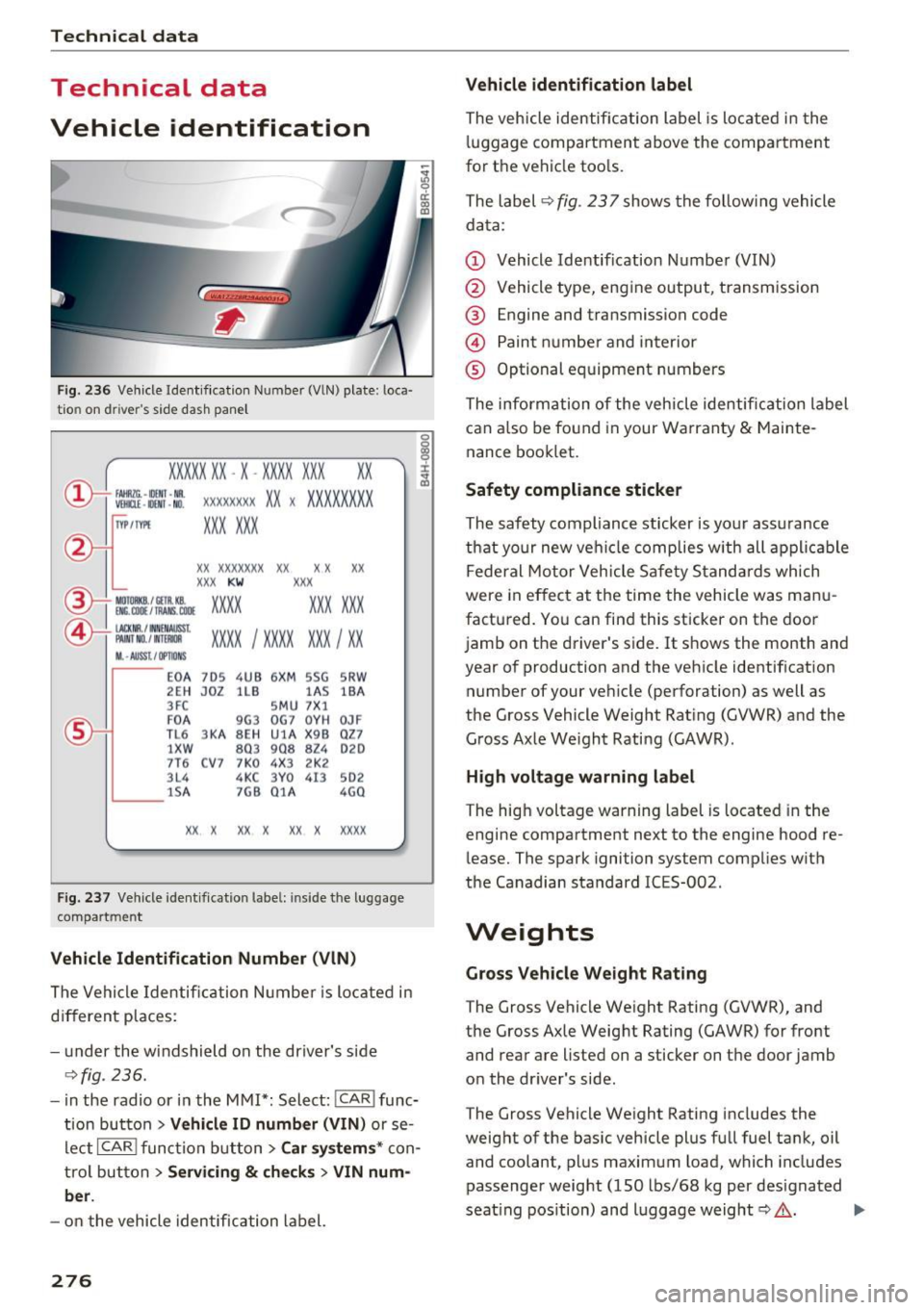

Vehicle identification

Fig. 236 Vehicle Ident if ication Numbe r (VlN) plate : loca·

tio n on d river 's side dash panel

XXXXX XX -X -XX XX XXX XX

@-+ ~J:~t::1 ::: xxxxxxxx xx x xxxx xxx x

IYP lf'VPE XXX X XX

xx xxxxxxx xx xx xx

XXX KW

XXX

EM:. COil / fAANS , COOE xxxx XXX XXX ®i MOIOlll

©-+ IAC KIIR . / tN NEN AIJSSt

XXXX I XXXX XXX I XX PAI NT NO./ WT£Jldl

II. -AUSST . / OPTIO NS

E0 A 7D5 4UB 6X

M SSG SR W

2EH JOZ lLB lAS

lBA

3FC SM U 7 X1

F0 A

9G3 0

G7 0Y H

0JF

TL 6 3 KA 8EH UlA X 9B Q

Z7

1 XW

803 908

824 020

7T6 C V7 7 K0 4X3 2K2

3L4 4KC 3Y0 413

502

lS A 7GB 01A

4G0

XX X XX X

XX X xxxx

Fig. 237 Vehicle identificat ion labe l: in side the luggage

compart ment

Vehicle Identification Number (VlN)

The Vehicle Identification Number is located in

different places :

- under the windshield on the driver's side

¢fig . 236.

- in the radio or in the MMI*: Select: !CAR i func·

tion button

> Vehicle ID number (VIN) or se·

Leet

I CAR ! function button > Car systems* con·

trol button

> Servicing & checks > VIN num

ber .

-on the vehicle identification label.

276

Vehicle identification label

The vehicle identification label is located in the

luggage compartment above the compartment

for the vehicle tools.

The label ¢

fig. 237 shows the following vehicle

data:

(D Vehicle Identification Number (VIN)

@ Vehicle type, engine output, transmission

® Engine and transmission code

@ Paint number and interior

® Optional equipment numbers

The information of the vehicle identification label

can also be found in your Warranty

& Mainte·

nance booklet.

Safety compliance sticker

The safety compliance sticker is yo ur ass urance

that your new vehicle complies with all applicable

Federal Motor Vehicle Safety Standards which

were in effect at the time the vehicle was manu

factured. You can find this sticker on the door

jamb on the driver's side. It shows the month and

year of production and the vehicle identification

number of your vehicle (perforation) as well as

the Gross Vehicle Weight Rating (GVWR) and the

Gross Axle We ight Rating (GAWR).

High voltage warning label

The high voltage warning label is located in the

engine compartment next to the engine hood re·

lease. The spark ignition system complies w ith

the Canadian standard ICES-002 .

Weights

Gross Vehicle Weight Rating

The Gross Vehicle Weight Rating (GVWR), and

the Gross Axle Weight Rating (GAWR) for front

and rear are listed on a sticker on the door jamb

on the dr iver's side .

The Gross Vehicle Weight Rating includes the

weight of the basic vehicle plus full fuel tank, oil

and coolant, plus maximum load, which includes

passenger weight (150 lbs/68 kg per designated

seat ing position) and luggage weight¢,&. .

Page 279 of 300

,....,

N

co

er::

co

,....,

The G ross Axle We igh t Rating is the max imum

l oad that can be applied at each axle of the vehi

cle ~.& .

Vehicle capacity weight

The vehicle capac ity we ight (max. load) is listed

on the drive r's side 8-p illar.

_& WARNING

- T he ac tual Gross Ax le Weight Ra ting a t the

front and rear axles sho uld not exceed the

permissible weights, and their combination

must not exceed the Gross Ve hicle We ight

Rating.

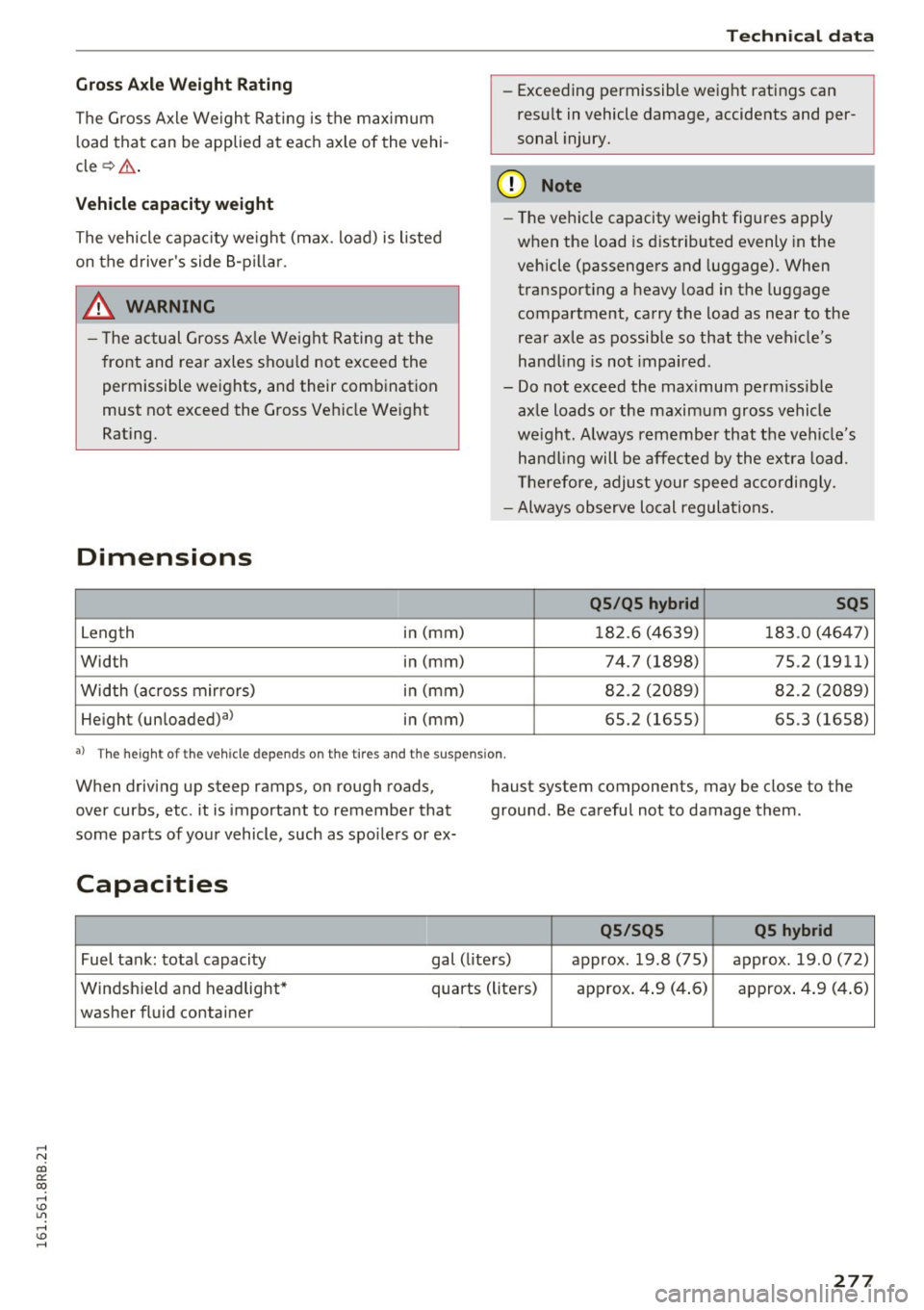

Dimensions

Leng th i

n (mm)

Width in (mm)

Width (a cross mirro rs) in (mm)

He ight (un loaded)al in (mm)

Technical data

- Exceeding permissible weight ratings can

res ult in vehicle damage, accidents and per

sonal injury.

(D Note

- The vehi cle capacity weig ht figures apply

when the load is d istributed evenly in the

vehicle (passengers and luggage) . When

transport ing a heavy load in the luggage

compartment, carry the load as near to the

rear axle as possib le so that the veh icle's

hand ling is not impaired .

- Do not exceed the maximum perm iss ible

ax le loads or the maximum gross vehicle

we igh t. Always remember that the veh icle's

han dling will be affe cted by the extra load.

Th erefore, adjust your spee d accordingly.

- Always observe local regulations.

QS /QS hybrid SQS

18 2.6 (4639) 183 .0 (464 7)

74.7 (1898) 75.2 (1911)

8 2.2 ( 2089) 82 .2 (2089)

65.2 (1655) 65 .3 (1658)

a ) T he heig h t of t he ve hicl e de pe nds on th e tir es and the suspen sio n.

When driving up steep ramps, on rough roads,

over curbs, etc . it is important to remember that

some pa rts of your vehicle, such as spo ile rs or ex- haust system components, may be close to the

ground. Be carefu

l not to damage them.

Capacities

QS /SQS QS hybrid

Fuel tank: tota l capacity gal (liters) approx. 19.8 (75) approx . 19 .0 (72)

Windsh ield and h eadlight* quarts (liters) approx . 4 .9 (4 .6) approx . 4 .9 (4 .6)

washer fluid container

277

Page 280 of 300

Tech nical data

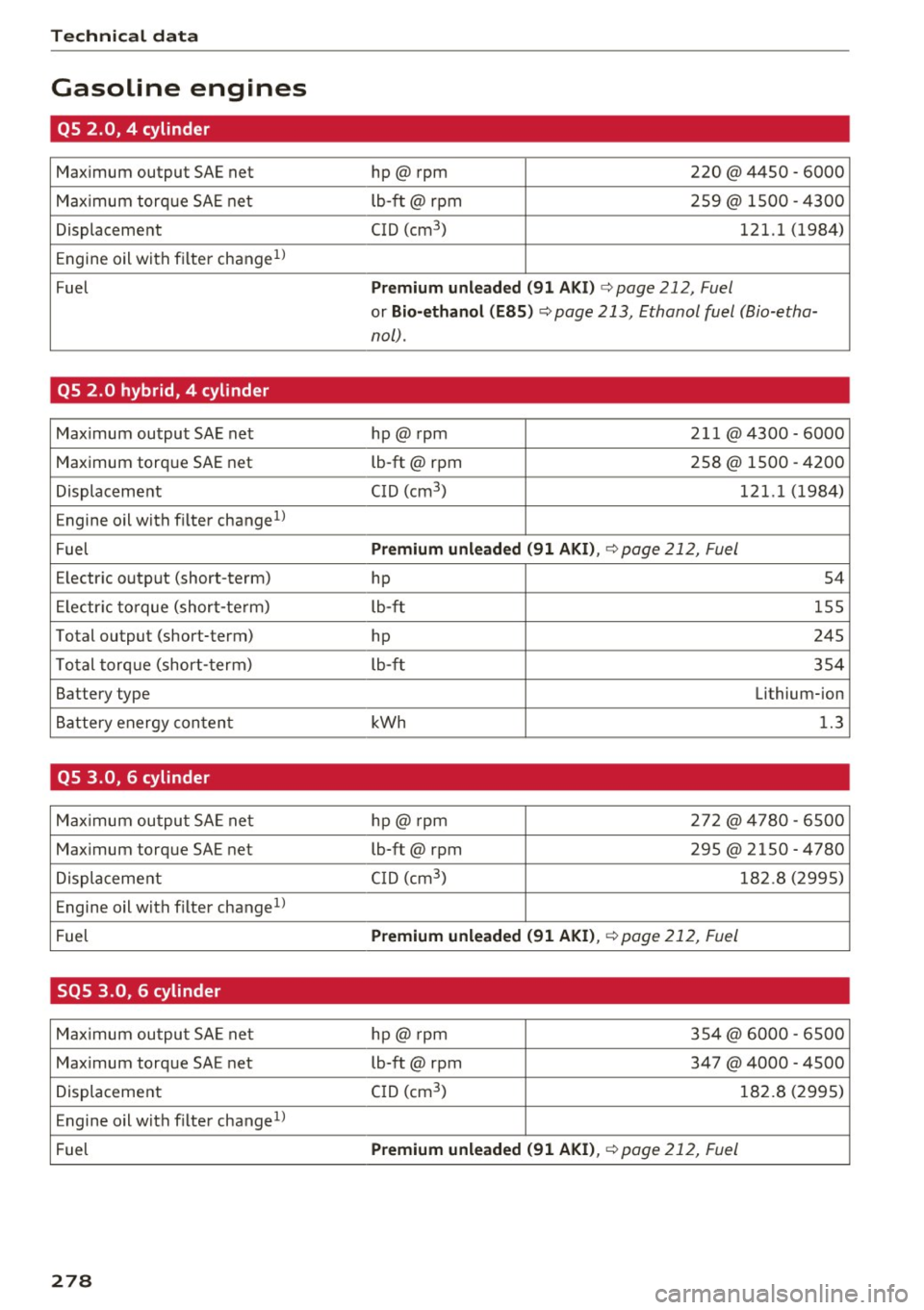

Gasoline engines

QS 2.0, 4 cylinder

Maximum output SAE net hp@ rpm 220 @ 4450 -6000

Max imum torq ue SAE net lb-ft@ rpm 259@ 1500 - 4300

Displacement CID (cm

3

) 121.1 (1984)

Engine oil with filter change

1>

Fuel Premium unl ead ed (9 1 A KI) c;, page 212, Fuel

or Bio-ethanol (E85 ) ¢ page 213, Ethanol fuel (Bio-etha-

no[) .

QS 2.0 hybrid, 4 cylinder

Maximum output SAE net hp@ rpm 211 @4300 -6000

Maximum torque SAE net lb-ft@ rpm 258 @ 1500 - 4200

Displacement C

ID (cm

3

) 1 21.1 (1984)

Engine oil with filter change

1

)

Fuel Premium unleaded (91 AKI) , ¢ page 212, Fuel

Electr ic output (short-term)

hp 54

El ectr ic to rque (short-te rm) lb-ft

155

Total output (short-term) hp 245

T otal torq ue (short-term)

lb-ft 354

Battery type Lithium-ion

Battery energy conten t kWh 1.3

QS 3.0, 6 cylinder

Max imum ou tput SA E net hp@ rpm 2

72@ 4780 -6500

Maximum torque SAE net lb-ft@ rpm 295 @2150 -4780

Displacement C

ID (cm

3

) 1 82 .8 (2995)

Engine oil with filter change

1l

Fuel Premium unleaded

(91 AKI) ,

c;, page 212, Fuel

SQS 3.0, 6 cylinder

Maximum ou tpu t SA E ne t hp@ rpm 354@ 6000

-6500

Max imum torq ue SA E net lb-ft@ rpm 347 @4000 -4500

Displacement C

ID (cm

3

) 1 82.8 (2995)

E ngine o il w ith f ilter change

1l

Fuel Premium unleaded

(91 AKI) ,

c;, page 212, Fuel

278