warning AUDI Q7 2014 Owner´s Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2014, Model line: Q7, Model: AUDI Q7 2014Pages: 340, PDF Size: 85.02 MB

Page 301 of 340

Loosening

• Install the wheel bolt wrench over the

whee l bolt and push it down as far as it wi ll

go.

• Take tight hold of th e

end of the wrench

handle and turn the whee l bolts

counter

clockwise

abou t one single turn in the di rec·

tion of arrow

c::> fig. 262 .

Tightening

• Install the wheel bolt wrench over the

wheel bolt and push it down as far as it will

go .

• Take tight hold of the

end of the wrench

handle and turn each wheel bolt

clockwise

until it is seated .

& WARNING

-Do not use force or hurry when changi ng

a whee l· you can cause the vehicle to slip

off the jac k and cause serious personal

injuries .

-Do not loosen the wheel bolts more than

one turn

before you raise the veh icle with

the jack. -You risk an injury.

(j) Tips

If a wheel bolt is very tight, you may find it

easie r to loosen by carefully pushing down

on the end of the wheel bolt wrench with

one foot only. As you do so, hold on to the

car to keep yo ur balance and take care not

to slip.

Raising the vehicle

The vehicle must be lifted with th e jack first

before the wheel can be removed .

Fig. 263 Sill pane ls: m arkin gs

What do I do now? 299

Fig. 264 Sill: p ositioning the jack

• Activate the vehicle jack mode* (only

veh icles with Adaptive Air Suspension)

c::> page 159 .

• Engage the parking brake to prevent your

vehicle from rolling unintentionally

• Move the

selector lever to position P .

• Find the marking (imprint) on the sill that is

nea rest the whee l that will be changed

c::>fig. 263. Behind the marking, there is a

lifting point on the sill for the jack.

• Turn the

jack located under the lifting point

on the sill to raise the jack until its arm@

c::> fig. 264 is located under the designated

plastic mount

c::> .&. c::> Q) .

• Align the jack so that its arm@ c::> fig. 264

engages in the designated lifting point in

the door s ill and the movable base® lies

flat on the ground. The base@ must be

ver

tical

under the lifting point@.

• Wind the jack up further until the flat tire

comes off the ground

c::> .,& .

Position the jack only under the designated

lifting points on the sill

c::> fig. 263. There is

exactly

one locat ion for each whe el. The jack

must not be positioned at any other location

c::> .&. c::> Q).

An unstable surface under the jack ca n cause

the vehicle to slip off the jack. Always provide

a firm base for the jack on the ground . If nec

essary place a sturdy board or similar support

under the jack . On

hard, slippery surfaces

(such as tiles) use a rubber mat or similar to

prevent the jack from slipping

c::> ,&.. .,,.

Page 302 of 340

300 What do I do now?

& WARNING

-You or your passengers could be injured

while changing a wheel if you do not

follow these safety precautions:

- Position the jack only at the designated

lifting points and align the jack. Other

wise, the jack could slip and cause an injury if it does not have sufficient hold

on the vehicle.

- A soft or unstable surface under the

jack may cause the vehicle to slip off the jack. Always provide a firm base for

the jack on the ground . If necessary,

use a sturdy board under the jack.

- On hard, slippery surface (such as tiles)

use a rubber mat or similar to prevent

the jack from slipping.

- To help prevent injury to yourself and

your passengers:

- Do not raise the vehicle until you are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up.

- Make sure that passengers wait in a

safe place away from the vehicle and

well away from the road and traffic.

- Make sure jack position is correct, ad

just as necessary and then continue to

raise the jack.

(D Note

Do not lift the vehicle by the sill. Position

the jack only at the designated lifting

points on the sill. Otherwise , your vehicle

will be damaged.

Taking the wheel off /installing the

inflatable spare tire

Follow these instructions step-by-step for

changing the wheel

Fig. 265 Changing a wheel: alignment pin inside the

top hole

After you have loosened all wheel bolts and raised the vehicle off the ground, remove and

replace the wheel as follows:

Removing the wheel

.,. Remove the topmost wheel bolt completely

and set it aside on a

clean surface.

.,. Screw the threaded end of the

alignment

pin

from the tool kit hand-tight into the

empty bolt hole

¢ fig . 265.

.,. Then remove the other wheel bolts as de

scribed above.

.,. Take off the wheel leaving the alignment pin

in the bolt hole ¢(D.

Putting on the inflatable spare tire

.,. Inflate the inflatable spare tire ¢ page 296

and push the wheel over the alignment pin.

"Screw in and tighten all wheel bolts

slightly.

.,. Remove the alignment pin and insert and

tighten the remaining wheel bolt slightly

like the rest .

.,. Turn the jack handle counter-clockwise to

lower the vehicle until the jack is fully re

leased .

" Use the wheel bolt wrench to tighten all

wheel bolts firmly ¢

page 298 . Tighten

them

crosswise, from one bolt to the (ap

proximately) opposite one, to keep the

wheel centered.

Page 303 of 340

(D Note

When removing or installing the wheel,

the rim could hit the bra ke rotor and dam

age the rotor . Wor k carefully and have a

second person help you.

- W hen mounting tires with

unidirectional

tread design

ma ke s ure the tread pat

tern is pointed the r ight way

<=> page 301.

-The wheel bolts should be clea n and easy

to tu rn . Check for d irt and corrosio n on

t h e mat ing su rfaces of both the whee l

and the hub. Remove a ll dirt from these

su rfaces before remo untin g t he wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design must be

mounted with their tr ead pattern point ed in

the right dire ction.

Using a spare tire with a tread pattern

intended for use in a specific direction

W hen using a spa re tire w ith a t read patte rn

in te nded fo r use in a specific direction, p lease

n ot e t he followi ng:

- The direction of rotation is marked by an ar

row on the side of the tire .

- If the spare t ire has to be installed in the in

correct di rection, use the spa re tire only

tem porarily si nce th e tir e will not be able to

a ch ieve i ts op timum pe rfo rm ance chara cter

is tics with reg ard to aq uaplani ng, noise and

wea r.

- W e recommend that you p ay pa rticular at

tent io n t o this fact du ring wet weathe r and

t h at you adjus t your spee d to matc h roa d

con dit ions .

- Re place the fla t tire w ith a new one and

have it installed on your vehicle as soon as

poss ible to restore the hand ling advantages

of a unid irect iona l tire.

What do I do now?

Notes on wheel changing

P lease read t he i nfo rmat ion c:> page 284, New

t ires and replacing tires and wheels

if y ou a r e

go ing to use a sp are tire w hich is different

from the ti res on yo ur vehicle.

After yo u cha nge a tire:

- Check the tire pressure on the spare imme

diately after installation .

- Have the wheel bolt tightening torque

che cked with a torque wrench as soon as

possible by your authorized Audi dealer or

a qualified workshop.

- With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of 120 ft lb (160 Nm) .

- If you notice that the wheel bolts are cor

roded and difficult to turn while changing

a tire, they should be replaced before you

check the tightening torque.

- Repla ce the flat tire with a new one and

have it installed on your vehicle as s oon as

possible. Remount the wheel cover.

Until then, drive with extra care and at re

duced speeds .

&_ WARNING

-

- If yo u are goi ng to e quip yo u r ve hicl e

wit h tires o r rims whi ch di ffer from those

which were fac to ry installed, t hen be

sure to rea d the information

c:> page 284,

New tires and replacing tires and

wheels.

- Always make s ure the damaged wheel o r

even a flat tire and the jack and t ool kit

are prope rly secured in the luggage com

pa rtme nt and are not loose in the pas

senge r compartment .

- In an accident or sudden maneuver they

could fly forwa rd, inj uri ng a nyo ne in the

veh icle.

- Always sto re damaged wheel , jack a nd

too ls sec urely in the luggage compa rt

men t. Othe rwise, in a n accide nt o r sud

de n m aneuver they could fly forwa rd,

c a u sing i nju ry to passenger s in th e ve hi

cle.

301

•

•

Page 304 of 340

302 Fuses and bulbs

Fuses and bulbs

Electrical fuses

Replacing fuses

Fuses that have blown will have metal strips

that have burned through.

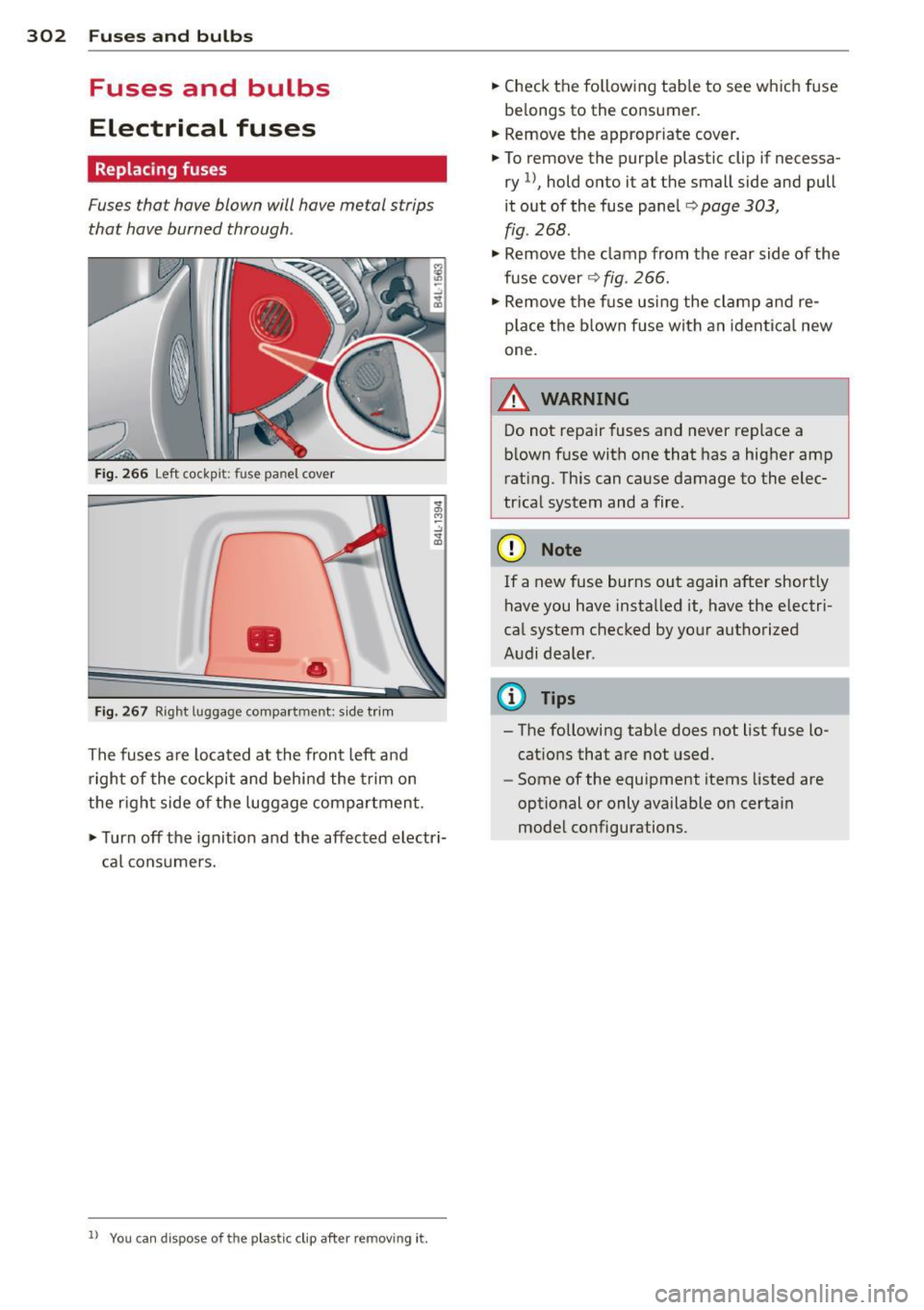

Fig . 266 Left cockp it: fuse panel cover

•

•

F ig . 267 Right luggage compa rtment: s ide t rim

The fuses are located at the fron t left and

right of the cockpit and behi nd the trim on

the r ight side of the luggage compartmen t.

.,. Turn off the ignit ion and the affected electri

cal consumers.

ll You ca n dispose of the plastic clip after remov ing it.

.. Check the following tab le to see wh ich fuse

be longs to the consumer.

.. Remove t he appropriate cover .

.. To remove the purp le plastic clip if necessa

ry

1) , hold onto it at the small side and pull

it out of the fuse pane l

c:> page 303,

fig.

268 .

• Remove the clamp from the rear side of the

fuse cover

c:> fig. 266.

• Remove the f use us ing the clamp and re

p lace t he bl own f use with an iden tica l new

one.

A WARNING

--

Do not repair fuses and never replace a

b lown fuse with one that has a hig her amp

rat ing. Th is can ca use damage to the elec

tr ica l system and a fire .

(D Note

If a new fuse burns out again after shortly

have you have installed it, have the e lectri

ca l system checked by yo ur authorized

Audi dealer .

{!) Tips

-The following table does not list fuse lo

cat ions that are not used.

- Some of the equipment items listed are

optional or only available on certa in

mode l configurations .

Page 308 of 340

306 Fuses and bulbs

must be co rrectly taken apart and then prop

erly put back together to help prevent break

age of parts and long term damage from wa

te r that can enter housings that have not been

properly resealed.

F or your safety, we recommend that you have

your author ized Audi deale r replace any bulbs

for you, since your dealer has the proper tools,

the correct bulbs and the expertise.

Gas discharge lamps (Xenon lights)*:

Due to the high electrical vo ltage, have the

bu lbs rep laced by a qualified technician.

Headlights with Xenon light can be identified

by the high voltage sticker.

A WARNING

Contact with high-voltage components of

the electrical system and improper re placement of gas discharge (Xenon) head

light bulbs can cause serious personal in

jury and death .

- Xenon bulbs are pressurized and can ex

plode when be ing changed .

-Chang ing Xenon lamps requires the spe

cial train ing, instructions and equip

ment .

- Only an authorized Audi dealer or other

qualified workshop should change the

bulbs in gas d ischarge lamps.

A WARNING

There are parts with sharp edges on the

openings and on the bulb holders that can

cause serious cuts.

- If you are uncertain about what to do,

have the work performed by an author

ized Audi dea le r or other qualified work

shop. Serious personal injury may result

from improperly performed work .

(j) Tips

-If you must replace the light bu lbs your

se lf, always remembe r that the engine

compartment of any vehicle is a hazard

ous area to work in . Always read and

heed all WARNINGS

c::> page 257 ¢ _& .

-

- It is best to ask your authorized Audi

dealer whenever you need to change a

bulb .

Page 309 of 340

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who have the necessary tools and equipment to

perform these operations.

Starting by pushing or

towing

(D Note

Your v ehicl e is e quipped w ith an automatic

tra nsm iss io n. Cons eque ntly, the e ngine

cann ot be started by pus hing o r tow ing.

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If th e engine shou ld fail to start because of a

d ischarged o r weak battery, the battery can be

connected to the battery of

another veh icle,

usi ng a

pair of jumper cables to start the en

gine .

Jumper c ables

Use only jumper cab les of sufficiently large

cross section to carry the starter cur rent safe

l y. Refer to the man ufacturer's specifications.

Use only jumper cables with

insulated te rm i

na l clamps w hich are d istinctly mar ked:

plus(+ ) cable in mos t ca ses co lore d red

minus(-) cable

i n most cases colored black .

A WARNING

Batteries con tai n elec trici ty, a cid, and gas.

Any o f these c an caus e ve ry ser ious or f atal

injury . Follow the instruc tions below fo r

safe han dling of your veh icle's battery .

- Alw ays s hield y our eyes and a void le an

ing over the batte ry w henever possib le .

Emergency situations 307

- A discharged battery can freeze at tem

pe rat ures just below 32 °F (0 °C). Before

connecting a jumpe r cable, you must

thaw the frozen battery c omp lete ly, ot h

e rwise it could explode.

- Do not allow battery acid to co ntact eyes

or skin . Fl ush any con tacted area wi th

wat er immediately .

- Imp roper use of a booster battery to

s tart a vehicle may cause an ex plosion.

- Vehicle batter ies generate expl osive gas

es. Keep sparks, flame and lighted c iga

rettes away from ba tte ries.

- Do not t ry to jump start a ny ve hicle w it h

a low ac id leve l in the battery.

- The voltage of the booste r battery m ust

also have a 12-Vo lt rat ing. T he capac ity

(Ah) of the booste r batt ery sho uld not b e

lowe r than that of th e discharged bat

t ery. Use o f batt eries of d iffe ren t vol tage

or su bstan tia lly differen t "Ah" rat ing

may cause an exp losion and pers onal in

jury .

- N ever ch arge a fr ozen batt ery. Gas t ra p

pe d in the ice may c ause an ex plosion .

- N ev e r ch arge o r use a batt ery th at h as

been fro zen . Th e batte ry case may have

be weake ned.

- U se o f batter ies of di ffere nt vol tage or

substantially differen t ca pa city (Ah) rat

i ng may cause an exp losion and injury .

T he ca pa c ity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compa rtment, always read an d heed a ll

WARNINGS

c::;,page 257.

(D Note

-App lyi ng a hi gher vo ltage booste r ba t

t ery wi ll cause expens ive damage to sen

sit ive e lectronic components, such as

cont ro l units, relays, rad io , etc.

- There must be no electrical c ontact be

tween the vehicles as otherw ise current

co uld already start to f low as soon as t he

posi tive(+) terminals a re con nect ed. ..,. •

•

Page 310 of 340

308 Emergen cy si tuation s

@ Tips

- The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump starting or charging the

battery, never connect the negative

ground cable to the battery negative post because the battery manager sys

tem must be ab le to detect the battery 's

state of cha rge. A lways connect the neg

at ive g round c able to the neg ative

ground post o f the battery manager co n

trol uni t.

Use of jumper cables

Make sure to connect the jumper coble

clomps in exactly the order described below!

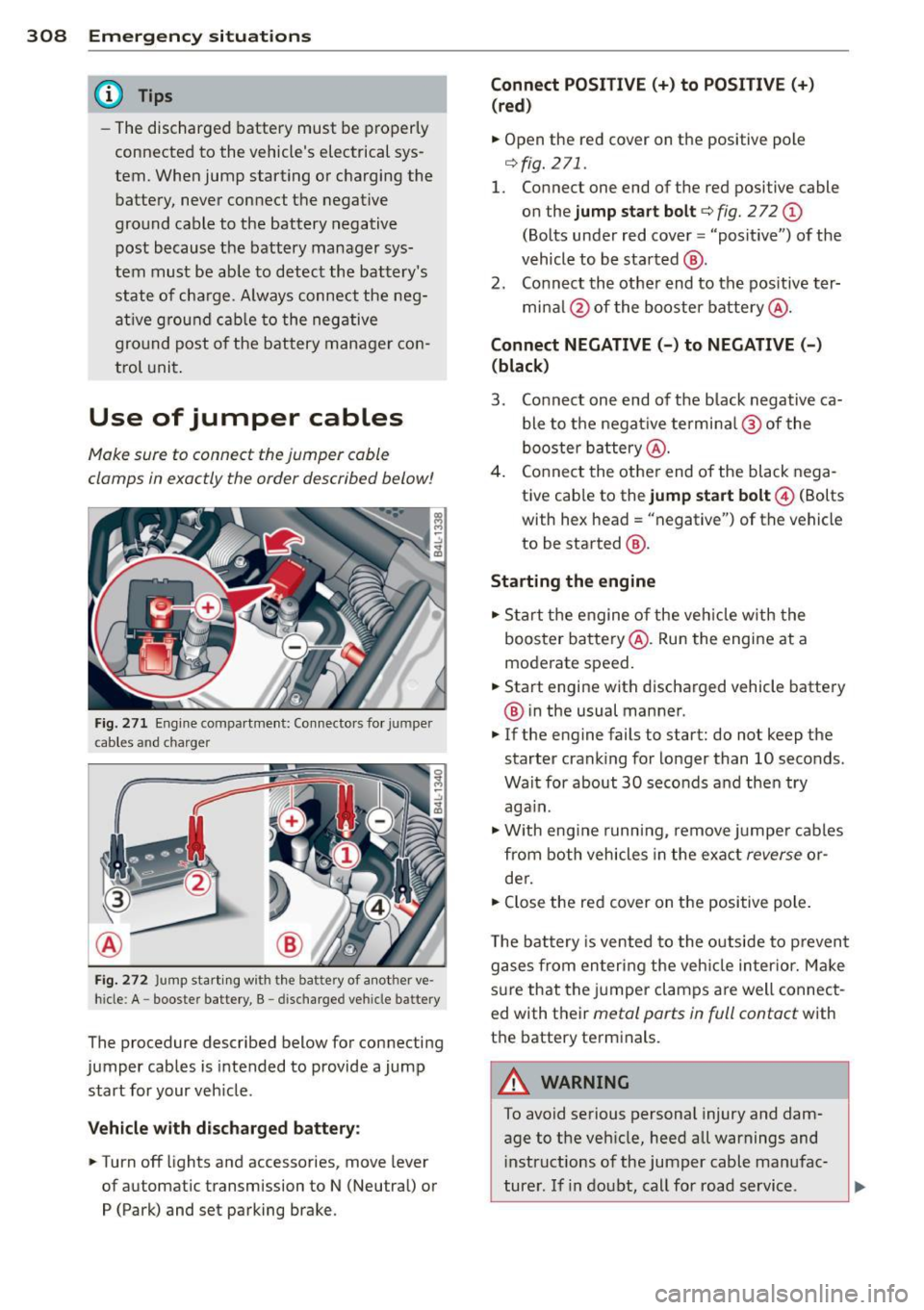

Fig. 271 Eng ine compartme nt: Co nnecto rs fo r jumper

cab les and c harger

®

Fi g. 272 Jump starting with the battery of another ve

hicle: A - booste r battery, B - discha rged vehicle battery

The procedure described below for connecting

jumper cables is intended to provide a jump

start for your veh icle.

Vehicle with discharged b attery :

.. Turn

off lights and accessories, move lever

of automatic transmission to N (Neutral) or

P (Park) and set parking brake. Connect POSITIVE(+) to POSITIVE(+

)

(red )

.. Open the red cover on the positive pole

¢fig. 271.

1. Connect one end of the red positive cable

on the

jump start bolt c::;, fig. 2 72 @

(Bolts under red cover = "positive") of the

vehicle to be started @.

2. Connect th e othe r end to the positive ter-

mi na l@ of the booster batte ry @ .

Connect NEGATIVE (-) to NEGATIVE (-)

(black )

3. Connect one end of the b lack negative ca

ble to the negat ive termi na l@ of the

booster ba ttery @.

4 . Connect the othe r end of the black nega

tive cab le to the

jump start bolt@ (Bolts

with hex head= "negative") of the vehicle

to be started @.

Sta rting the engine

.. Start t he engine o f the veh icle w ith the

booste r ba ttery @. Run the engine at a

moderate speed .

.. Start engine with discharged vehicle battery

@ in the usual manner.

.. If the engine fails to start: do not keep the

starter crank ing for lo nger than 10 seconds.

Wait for about 30 seconds an d the n try

again.

"" With engine running, remove j umpe r cab les

from both vehicles in the exact

reverse o r·

de r .

.. Close the red cover on the positive pole .

T he battery is vente d to the outside to p reven t

gases from entering the veh icle inter ior. M ake

s u re that the j umper clamps are well connec t

ed with their

metal ports in full contact with

the battery term inals.

A WARNING

-

To avoid serious persona l injury and dam-

age to the veh icle, h eed all warnings and

i nstructions of the jumper cable ma nufac-

turer. If in doubt , call for road service. ,..

Page 311 of 340

-Jumper cables must be long enough so

that the vehicles do not t ouch.

- W hen connecting jumper ca bles, make

sure that they cannot get caught in any

moving parts in the eng ine compart

ment.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

Q page 257.

(D Note

Improper hook-up of jumper cables can ru

in the generator.

- Always connect POSITIVE( +) to POSI

TIVE(+), and NEGATIVE(-) to NEGATIVE

( - ) ground post of the battery manager

control unit.

- Check that all screw plugs on the battery

cells are screwed in firmly. If not, tighten plugs prior to connecting clamp on nega

tive battery terminal.

- Please note that the procedure for con

nect ing a jumper cable as described

above applies spec ifically to the case of

your vehicle be ing jump started . When

you are giving a jump start to another ve

hi cle, do

not connec t the negat ive (-) ca

ble to the negat ive( -) term inal on the

discharged battery ©¢

fig. 2 72. In

stead, securely connect the negative( -)

cable to e ither a solid metal component

that is firmly bolted to the engine block

or to the engine block itse lf. If the bat

tery that is being charged does not vent

to the outside, escaping battery gas

could ignite and exp lode!

Em erg en cy si tuation s 309

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing.

T he following information is to be used by

commercial tow t ruck operators who know

how to operate their equipment safely.

- Never tow your Audi , towing will cause

damage to the engine a nd transmi ssion.

- Never wrap th e safet y chain s or winch c a

ble s around th e brak e lin es.

- To prevent unne ce ss ary dam age, your Aud i

mu st be t ransp orted with a flat bed truck .

- To load th e vehi cle on to the fl at bed, us e

the t owing loop found in the vehicle t ool s

and atta ch to the front or rear anch o rage

¢ page 310 and Qpage 310 .

A WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyone to ride in a

vehicle be ing towed, for any reason.

-

•

•

Page 312 of 340

310 Emergency situations

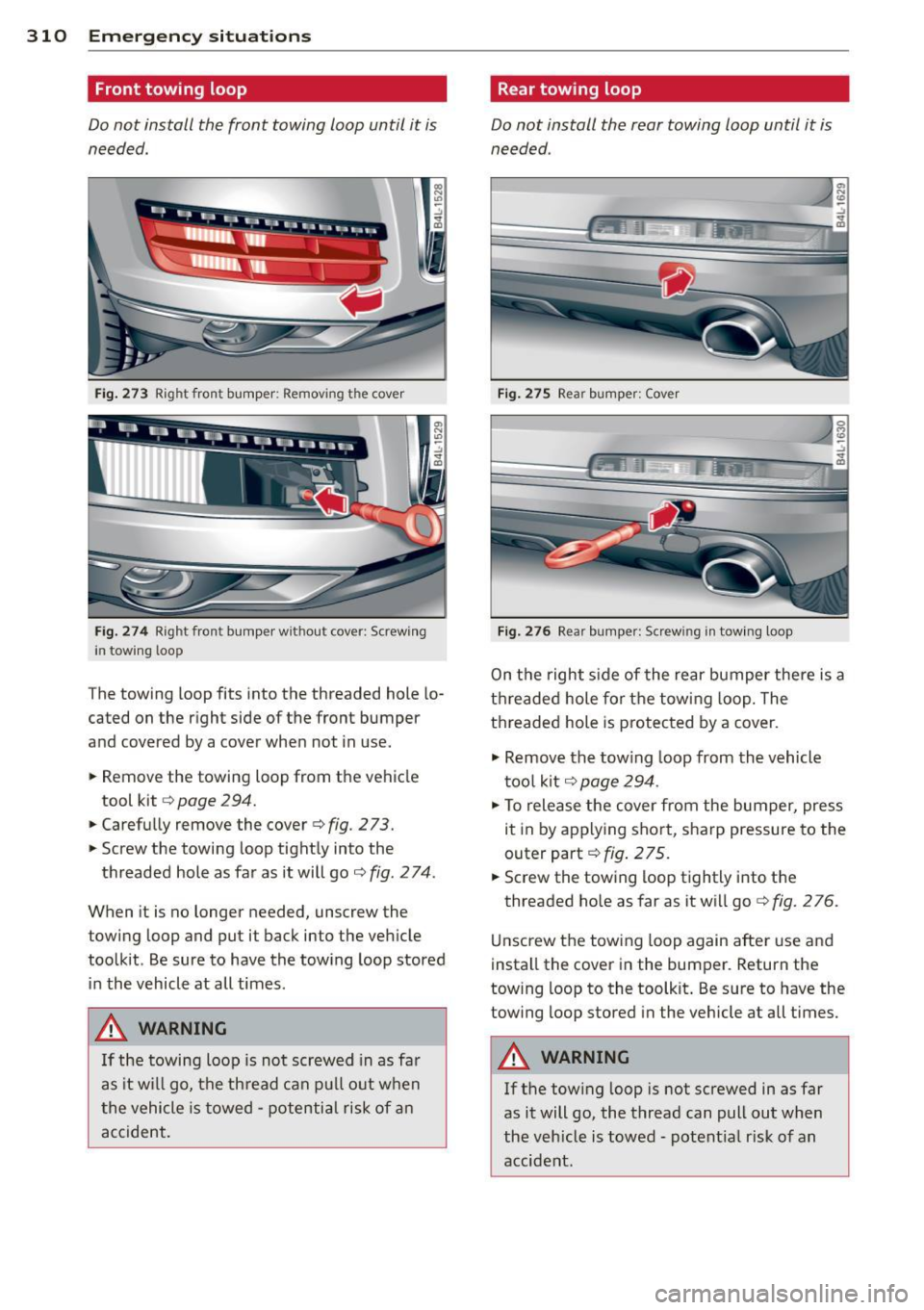

Front towing loop

Do not install the front towing loop until it is

needed.

Fig. 273 Right fron t bu mpe r: Remov ing t he cove r

Fig. 27 4 Righ t fron t bumpe r w it h out cove r: Screw ing

i n tow ing loo p

The towing loop fits into the threaded hole lo

cated on the r ight side of the front bumper

a nd covered by a cover whe n not in use.

• Remove the towing loop from the vehicle

tool kit

Q page 294.

• Carefully remove the cover q fig. 273.

• Screw the towi ng loop tightly into the

threaded hole as fa r as it will go

q fig . 274 .

When it is no longer needed , unscrew the

towing loop and put it back into the vehicle

too lkit. Be sure to have the tow ing loop stored

i n the vehicle at all times .

A WARNING

If the towing loop is not scr ewed in as far

as it w ill go, the th read ca n pul l o ut w hen

t he vehicle is towed -potenti al risk of an

a cc ide nt.

Rear towing loop

Do not install the rear towing loop until it is

needed .

Fig . 275 Rea r bu mper: Cove r

Fig. 27 6 Rear bumpe r: Sc rew ing in tow ing loop

On t he right s ide of the rear bumper there is a

t hr eaded hole for t he towing loop. The

t h readed hole is protec ted by a cover.

• Remove th e tow ing loop from th e vehicl e

t oo l kit

q page 294 .

• To release the cover from the bumper, press

it in by app ly ing short, sharp pressure to the

outer part

q fig . 2 75.

• Screw the tow ing loop t ightly i nto the

threaded ho le as far as it wi ll go

q fig. 2 76.

U nscrew t he towing loop again afte r use and

insta ll the cover in the bumper. Return the

tow ing loop to the toolkit . Be su re to have the

towing loop stored in the vehicle at a ll times.

A WARNING

If the tow ing lo op is not screwed in as far

as it will go, the thread can pull ou t when

the veh icle is towed -potent ial ris k of an

accident.

Page 313 of 340

Loading the vehicle onto a flat bed truck

Fig. 277 Veh icle on flat bed truck

Front hook up

.. Align the vehicle with the centerline of the

car carrier ramp.

.. Attach the winch hook to the front towline

eye previously installed .

Rear hook up

.. Align the vehicle with the centerline of the

car carrier ramp.

.. Attach the winch hook to the rear towline

eye previously installed.

(D} Tips

Check carefully to make sure the hook-up

is secure before moving the car up the flat

bed truck ramp.

Lifting vehicle

Lifting with workshop hoist and with

floor jack

The vehicle may only be li~ed at the lifting

points illustrated .

Fig. 278 Front l ifting po int

Emergency situations 311

Fig . 279 Rea r lift ing po int

.,. Read and heed WARNING c::> .&, .

.,. Locate lifting points c::> fig. 2 78 and

¢ fig. 279 .

.,. Adju st lifting arms of workshop hoist or

floor jack to match veh icle lifting points.

.. Insert a rubber pad between the floor jack/

workshop hoist and the lift ing points.

If you must lift your vehicle with a floor jack

to work underneath, be sure the vehicle is

safely supported on stands intended for this

purpose .

Front lifting point

T he lifti ng point is loca ted on the floo r pan re

info rcemen t about at the same level as the

jack mounting point

c::>fig. 278. Do not lift

the vehicle at the vertical sill reinforcement.

Rear lifting point

The lifting point is located o n the vert ica l rein

forcement of the lower sill for the on board

jack

c::> fig. 2 79 .

Lifting with vehicle jack

Refer to c:;, page 299.

A WARNING

-To reduce the risk of ser ious injury and

vehicle damage.

- Always lift the vehicle only at the spe

cia l workshop hoist and floor jack lift

points illustrated

c:;, fig. 278 and

¢fig. 279.

- Fail ure to lift the veh icle at these

-

points could cause the vehicle to tilt or ..,.