AUDI Q7 2017 Owner´s Manual

Manufacturer: AUDI, Model Year: 2017, Model line: Q7, Model: AUDI Q7 2017Pages: 402, PDF Size: 100.39 MB

Page 371 of 402

u co ...... N r-... N ...... 0

0

:E: '

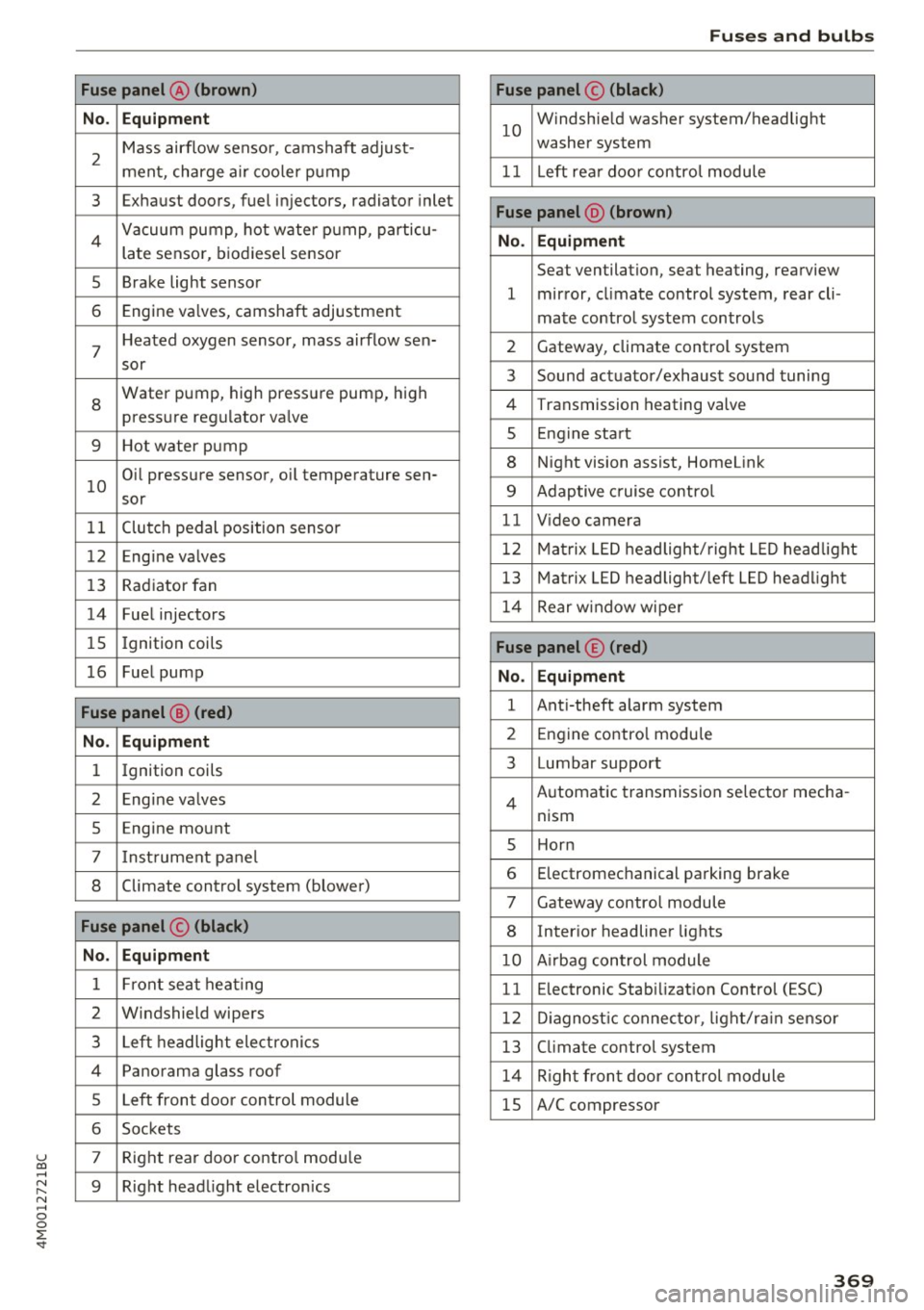

No . Equipment

2

Mass airflow sensor, camshaft adjust-

ment, charge air cooler pump

3 Exhaust doors, fuel injectors, radiator inlet

4 Vacuum pump, hot water pump, particu-

late sensor, biodiesel sensor

5 Brake light sensor

6 Engine va lves, camshaft adjustment

7

Heated oxygen sensor, mass airflow sen-

sor

8

Water pump, high pressure pump, high

pressure regulator va lve

9 Hot water pump

10

Oil pressure sensor, oil temperature sen-

sor

11 Clutch pedal position sensor

12 Engine valves

13 Radiator fan

14 Fuel injectors

15 Ignition coils

16 Fuel pump

Fuse panel @ (red)

No . Equipment

1 Ignition coils

2 Eng ine va lves

5 Engine mount

7 I nstrument pane l

8 Climate control system (blower)

Fuse panel © (black)

No. Equipment

1 Front seat heating

2 Windshield wipers

3 Left headlight electronics

4 Panorama glass roof

5 Left front door control module

6 Sockets

7 Right rear door contro l module

9 Right headlight electronics

Fuses and bulbs

Fuse panel© (black)

10

Windshie ld washer system/headlight

washer system

11 Left rear doo r contro l module

Fuse panel @ (brown)

No . Equipment

Seat ventilation, seat heating, rearview

1 mirror, cl imate control system, rear cli-

mate control system controls

2 Gateway, climate control system

3 Sound actuator/exhaust sound tuning

4 Transmission heating valve

s Engine start

8 Night vision assist, HomeLink

9 Adaptive cruise contro l

11 Video camera

12 Matrix LED headlight/right LED headlight

13 Matrix LED headlight/left LED headlight

14 Rear window wipe r

Fuse panel© (red)

No. Equipment

1 Anti-theft alarm system

2 Engine control module

3 Lumbar support

Automatic transmission selector mecha-

4

nism

s Horn

6 Electromechanical parking brake

7 Gateway control module

8 Inter ior headliner lights

10 A irbag control module

11 Electronic Stabilization Control (ESC)

12 Diagnostic connector, light/ra in sensor

13 Climate control system

14 Right front door control module

15 A/C compressor

369

Page 372 of 402

Fuses and bulbs

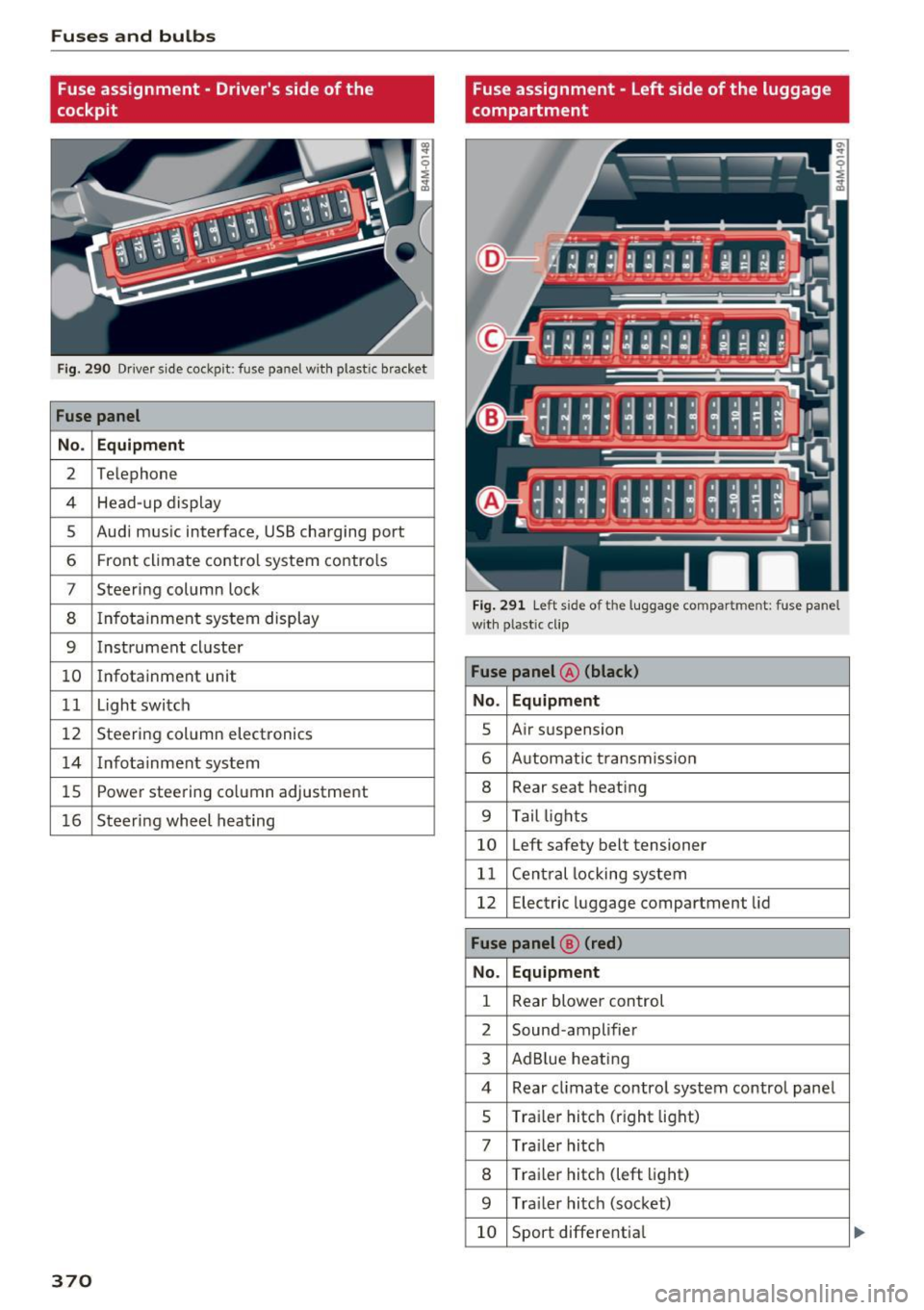

Fuse assignment - Driver's side of the

cockpit

Fig . 290 D river side cockpit: fuse panel wit h plastic bracket

Fuse panel

No . Equipment

2 Te lep hone

4 Head-up display

5 Audi mus ic interface, USB charging port

6 Front climate contro l system contro ls

7 Steering column lock

8 Infotainment system display

9 Instrument cl uster

10 Infotainment unit

11 Light switch

12 Steer ing column electronics

14 Infotainment system

lS Powe

r steering co lumn adjustme nt

1 6 Steer ing wheel heating

370

Fuse assignment - Left side of the luggage

compartment

Fig. 291 L eft side of the lu ggage compartment: fuse panel

wi th plastic cl ip

Fuse panel @ (black)

No. Equipment

5 Air suspension

6 Automat ic t ransmiss ion

8 Rear seat heating

9 Tail lights

10 Left safety belt tensioner

11 Central locking system

12 Electric luggage compartment lid

Fuse panel@ (red)

No . Equipment

1 Rear blower control

2 Sound-amplifier

3 AdBlue heating

4 Rear cl imate contro l system control panel

5 Traile r hitch (right light)

7 Tra iler hitch

8 Trai le r hitch (left light)

9 Trailer hitch (socket)

10 Sport differential

Page 373 of 402

u co .... N r-... N .... 0

0

:E: '

11 AdBlue heating

12 Third row seats

Fuse panel © (brown)

No . Equipment

2 Telephone

3 Lumbar support

4 Audi side assist

8 Smart module (tank)

9 CD /DVD player

12 Homelink

13 Rearview camera, peripheral cameras

14 Right tail lights

16 Right safety belt tensioner

Fuse panel @ (red)

No .

I Equipment

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you.

It is becoming increasingly more and more diffi

cult to replace vehicle light bulbs since in many

cases, other parts of the car must first be re

moved before you are able to get to the bulb.

This applies especially to the light bulbs in the

front of your car wh ich you can only reach

through the eng ine compartment.

Sheet metal and bulb ho lders can have sharp

edges that can cause serious cuts, parts must be

correctly taken apart and then properly put back

together to help prevent breakage of parts and long term damage from water that can enter

housings that have not been properly resea led.

For your safety, we recommend that you have

your author ized Audi dealer replace any bulbs for

you, s ince your dealer has the proper tools, the

correct bulbs and the expert ise.

Gas discharge lamps (Xenon lights):

Fuses and bulbs

Due to the high e lectrica l voltage, have the bulbs

rep laced by a qualified technician. Headlights

with Xenon light are identified by the high volt

age sticker.

LED headlights*

LED headlights require no maintenance. Please

contact your authorized Audi dealer if a bulb

needs to be replaced.

& WARNING ~ -

Changing Xenon lamps without the necessary

equipment can cause serious personal injury.

- Bulbs are pressurized and can explode when

being changed . Potential risk of injury!

- On veh icles equipped with gas discharge

bu lbs (Xenon light) life-threatening injuries

can resu lt from improper handling of the

h igh-vo ltage portions of such lamps!

- Only your authorized Audi dealer or quali

fied workshop shou ld change the bulbs in

gas discharge lamps. There are parts with

sharp edges on the openings and on the bulb holders that can cause serious cuts. If

you are uncerta in about what to do, have

the work performed by an authorized Audi deale r or qualified workshop. Ser ious per

sonal injury may result from improperly per

formed work.

(D Tips

-If you st ill prefer to replace the light bulbs

yourself, be awa re that the engine compa rt

ment is a hazardous area to work in~.&..

in

Working in the engine compartment on

page 322.

-It is best to ask your authorized Audi dealer

whenever you want to change a bulb.

371

Page 374 of 402

Emergency situations

Emergency situations

General

This chapter is intended for trained emergency crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine con be started by con

necting it to the battery of another vehicle.

If the engine should fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumper cables to start the engine.

Jumper cables

Use only jumper cables of sufficiently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated terminal

clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus(-) cable

in most cases colored black.

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for

safe

handling of your vehicle's battery.

-Always shield your eyes and avoid leaning

over the battery whenever possible.

-A dead battery can freeze at temperatures

around 32 °F (0 °C) . If the vehicle battery is

frozen, you must thaw it before connecting

the jump start cables.

If you do not, this in-

372

creases the risk of an explosion and chemi

cal burns. After jump starting the vehicle,

drive to an authorized Audi dealer or author

ized Audi Service Facility immediately to

have the vehicle battery checked.

- Do not allow battery acid to contact eyes or

skin . Flush any contacted area with water

immediately.

- Improper use of a booster battery to start a

vehicle may cause an explosion .

- Vehicle batteries generate explosive gases.

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery.

- The voltage of the booster battery must also

have a 12-Volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batteries of different voltage or substantial

ly different "Ah" rating may cause an explo

sion and personal injury.

- Never charge a frozen battery. Gas trapped

in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen. The battery case may have be weak

ened.

- Use of batteries of different voltage or sub

stantially different capacity (Ah) rating may

cause an explosion and injury. The capacity (Ah) of the booster battery should not be

lower than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

r=:> poge 322.

([) Note

-Applying a higher voltage booster battery

will cause expensive damage to sensitive electronic components, such as control

units, relays, radio, etc.

- There must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

(+) terminals are connected.

Page 375 of 402

u (0 ...... N r--. N ...... 0

0

:E

The discharged battery must be properly con

nected to the vehicle's electrical system .

When jump starting or charg ing the battery,

never connect the negative ground cable to

the battery negative post because the battery

manager system must be able to detect the

battery's state of charge. Always connect the

negative ground cable to the negative ground

post of the battery manager control unit.

Using the jump start

cable

Both jump start cables must be connected in the

correct order!

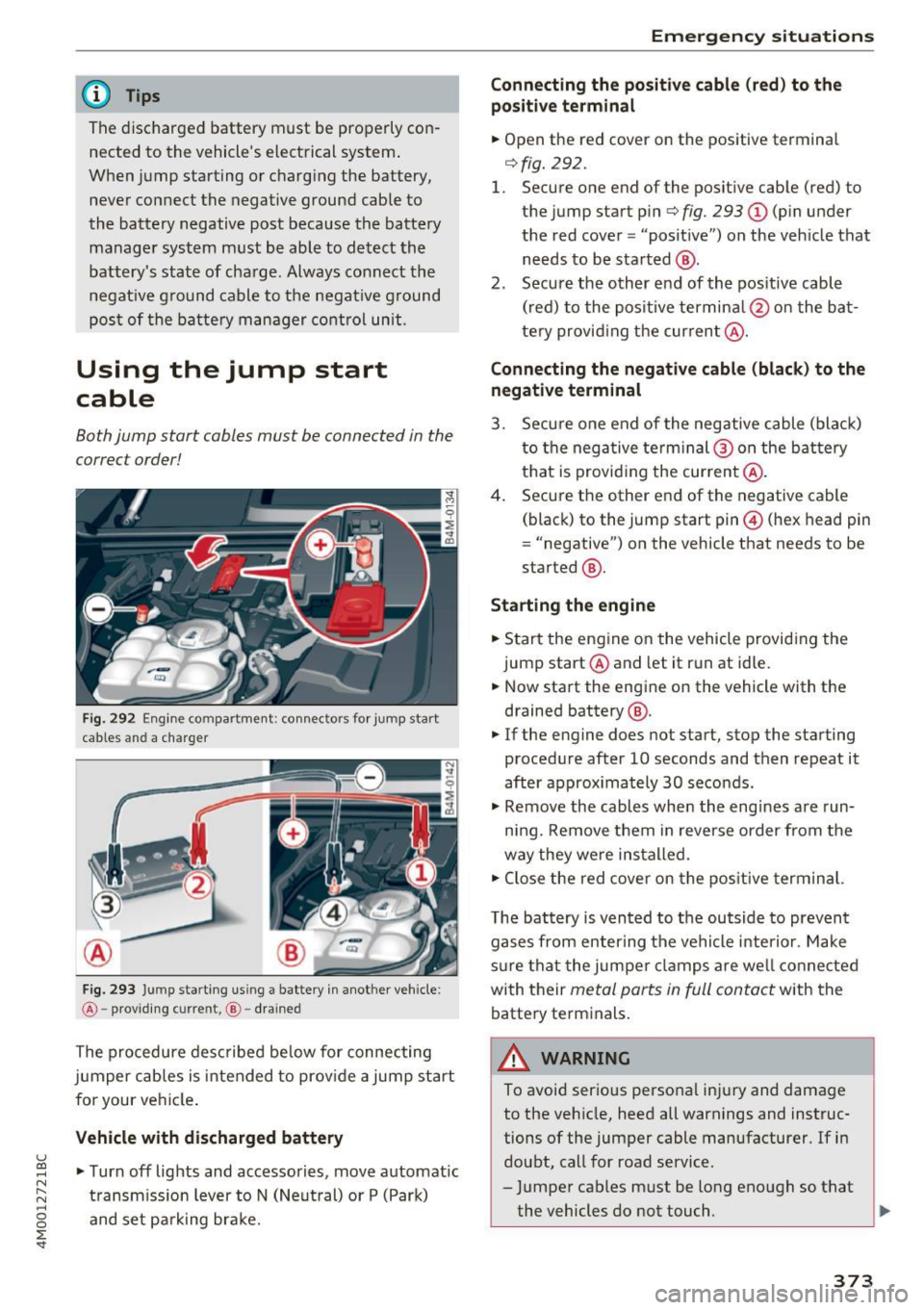

Fig. 292 Engine compartment: connect ors for jump start

cables and a charger

Fig. 293 Ju mp starting us ing a battery in another vehicle:

@ -providing current, @-drained

The procedure described below for connecting

jumper cables is intended to prov ide a jump start

for your vehicle .

Vehicle with discharged battery

•Turnoff lights and accessories, move automatic

transmission lever to N (Neutral) or P (Park)

and set parking brake.

Emergency situations

Connecting the positive cable (red) to the

positive terminal

• Open the red cover on the positive terminal

r=>fig. 292 .

1. Secure one end of the positive cable (red) to

the jump start pin

r=> fig. 293 (D (pin under

the red cover = "posit ive") on the vehicle that

needs to be started @.

2. Secure the other end of the positive cable

(red) to the positive termina l@ on the bat

tery provid ing the current @.

Connecting the negative cable (black) to the

negative terminal

3. Secure one end of the negative cable (black)

to the nega tive term inal @ on the battery

that is providing the current @.

4. Secure the other end of the negative cable

(black) to the jump start pin@ (hex head pin

= "negative") on the vehicle that needs to be

started @.

Starting the engine

• Start the engine on the vehicle providing the

jump start @and let it run at idle.

• Now start the engine on the vehicle with the

drained battery @.

• If the engine does not start, stop the starting

procedure after 10 seconds and then repeat it

after approx imately 30 seconds.

• Remove the cables when the engines are run

ning. Remove them in reverse order from the

way they were installed.

• Close the red cover on the positive terminal.

T he battery is vented to the outside to prevent

gases from enter ing the vehicle interior . Make

sure that the jumper clamps are well connected

with their

metal parts in full contact with the

battery terminals.

_& WARNING

-To avoid serious personal injury and damage to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch . ..,_

373

Page 376 of 402

Emergency situations

-When connecting jumper cables, make sure

that they cannot get caught in any moving

parts in the engine compartment.

- Do not bend over the batteries -danger of

chemical burns!

- The battery cell locking screws must be

tightened securely.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

i=> page 322.

(D Note

Improper hook-up of jumper cables can ruin

the generator.

- Always connect POSITIVE(+) to POSITIVE

(+), and NEGATIVE(-) to NEGATIVE(-)

ground post of the battery manager control

unit.

- Check that all screw p lugs on the battery

cells are screwed in firmly. If not, tighten

plugs prior to connect ing clamp on negative

battery terminal.

- Please note that the procedure for connect

i ng a jumper cable as described above ap

plies specifically to the case of your vehicle

being jump started . When you are giving a

ju mp start to another vehicle, do

not con

nect the negative (-) cable to the negative

(-) terminal on the discharged batte ry @

c> fig. 293. Instead, securely connect the

negative( -) cab le to either a solid metal

component that is firm ly bolted to the en

gine block or to the engine block itself. If

the battery that is being charged does not

vent to the outside, escap ing battery gas

could ignite and explode!

Towing with a tow truck

General hints

Your Audi requires special handling for towing.

The following information is to be used by com

mercial tow truck operators who know how to op

erate the ir equipment safely.

-Never tow your Audi, towing will cause dam

age to the engine and transmission.

374

-Never wrap the safety chains or winch cables

around the brake lines .

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck .

- To load the vehicle on to the flat bed, use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

i=>page 374 and i=>page 375.

A WARNING

A vehicle being towed is not safe for passen

gers. Never allow anyone to ride in a vehicle

being towed, for any reason.

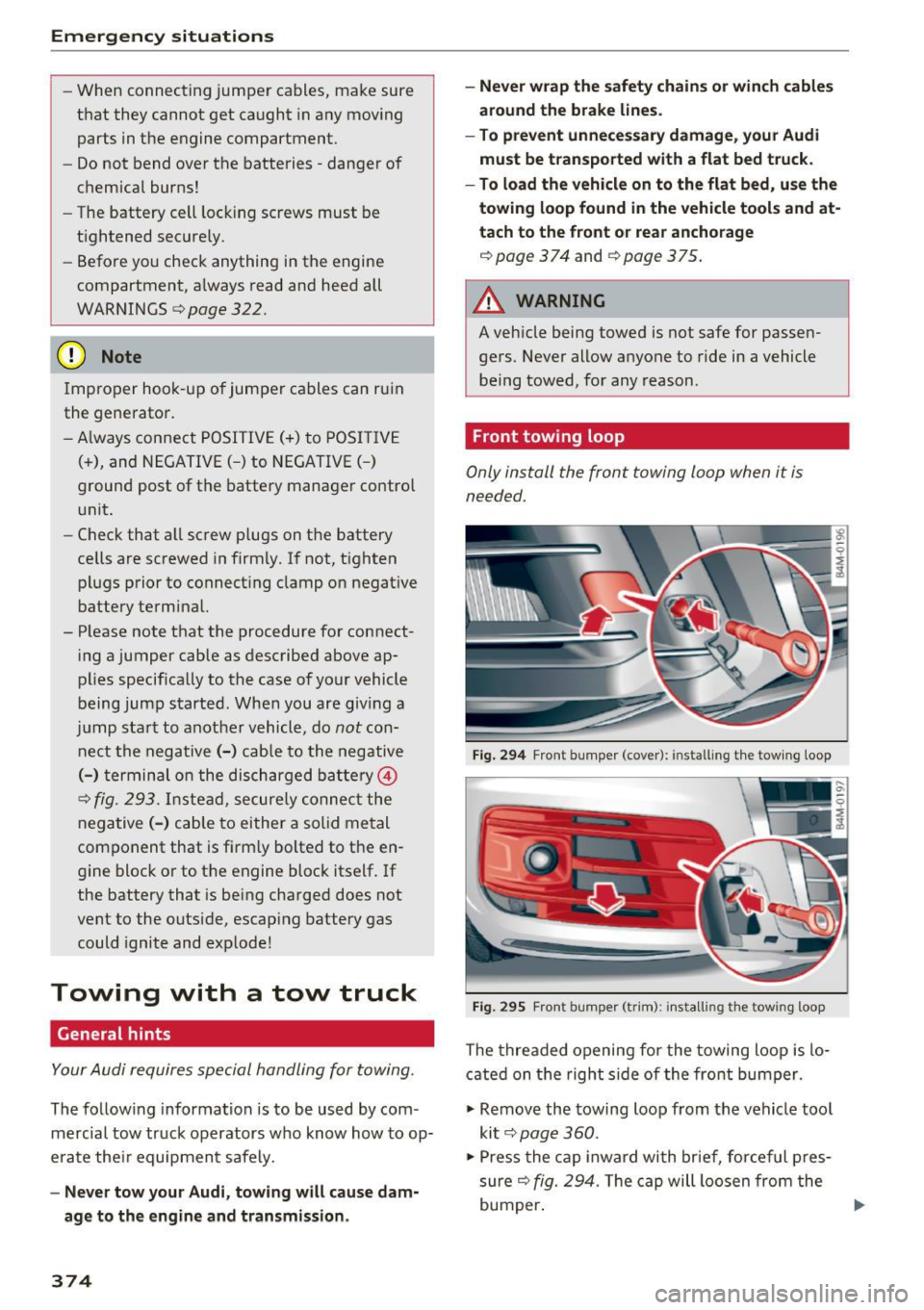

Front towing loop

Only install the front towing loop when it is

needed.

Fig. 294 Front bumper (cover): installing t he tow ing loop

Fig. 29S Front bumper (trim): install ing t he towing loo p

The threaded opening for the towing loop is lo

cated on the right side of the front bumper.

"' Remove the towing loop from the vehicle tool

kit

i=> page 360.

"'Press the cap inward with brief, forceful pres

sure

c> fig. 294. The cap will loosen from the

bumper. ""

Page 377 of 402

u (0 ...... N r--. N ...... 0

0

:E

the arrow to remove

c:> fig. 295.

.. Insert the towing loop all the way into the

threaded opening and tighten it with a wheel

wrench .

.. After using, place the towing loop back in the

vehicle tool kit.

_& WARNING

If the towing loop is not tightened unti l it

stops when installing, the threads may be

pulled o ut when towing the vehicle and that

cou ld cause an acc ident .

(D Note

The trim is attached to the bumper with sev

eral hooks. To reduce the risk of damage, do

no t use any force when remov ing and instal

ling .

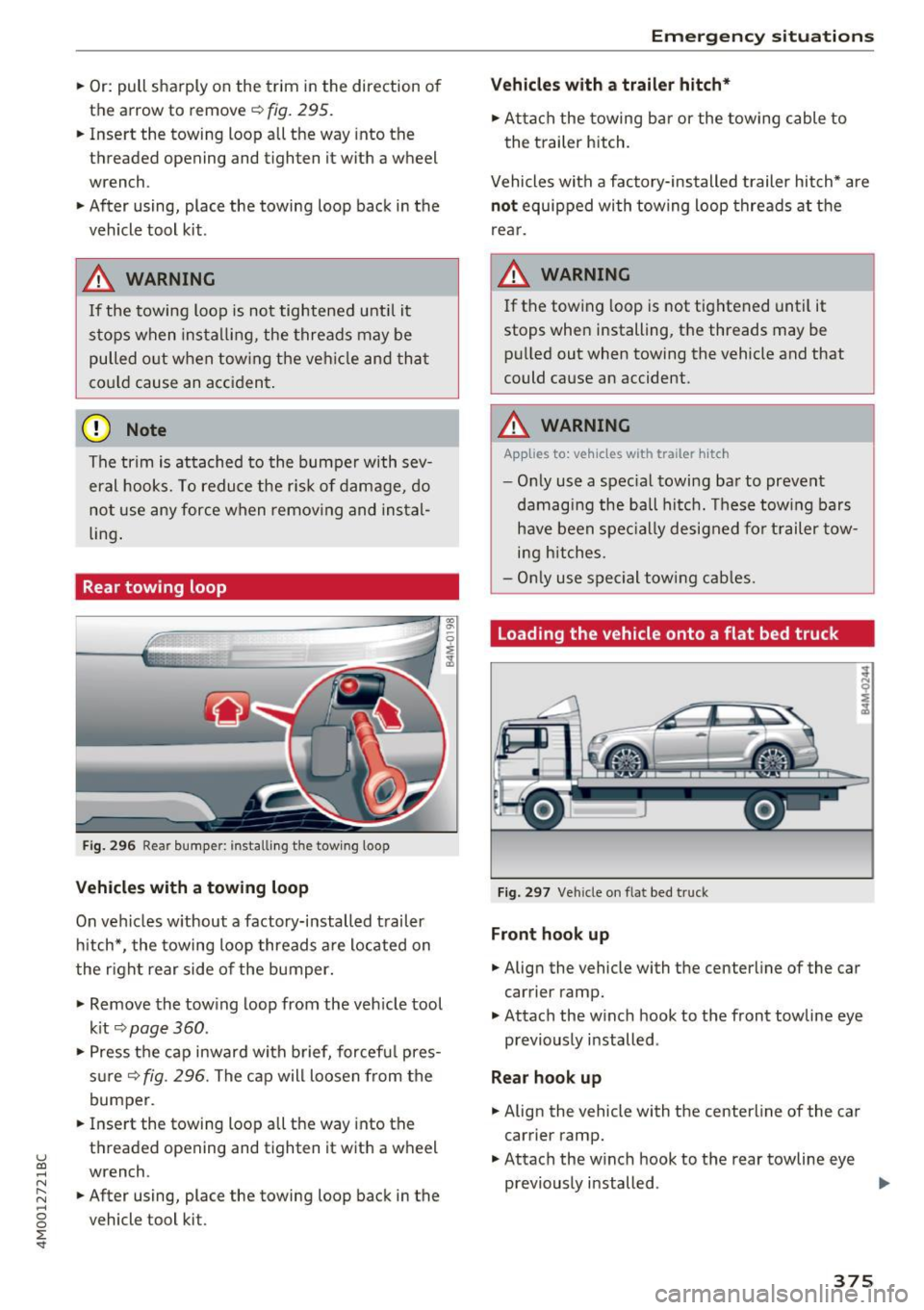

Rear towing loop

Fig. 296 Rear bumper: installi ng the tow ing loop

Vehicles with a towing loop

On vehicles w ithout a factory-installed trailer

hitch*, the towing loop threads a re located on

the right rear side of the bumper.

-

.,. Remove the tow ing loop from the veh icle tool

k it

c:> page 360 .

.. Press the cap inward wi th brief, forcef ul pres

s ur e

c:>fig. 296. The cap will loosen from the

bumper.

.. Inse rt the towing loop all the way into the

threaded opening and tighten it with a wheel

wrench .

.. After using, place the towing loop back in the

vehicle tool kit.

Emergency situations

Vehicles with a trailer hitch*

.. Attach the towing bar or the towing cable to

the trailer hitch.

Vehicles with a facto ry -installed trailer hitch* are

not equipped with towing loop threads at the

rear.

_& WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be pulled out when towing the vehicle and that

could cause an accident.

_& WARNING

-Applies to: vehicles with trailer hitch

- Only use a spec ial towing bar to prevent

damaging the ball hitch. These towing bars

have been specially designed for trailer tow

i ng hitches.

- Only use special towing cables.

Loading the vehicle onto a flat bed truck

Fig. 297 Vehicle on flat bed truck

Front hook up

.. Align the vehicle with the centerline of the car

carrier ramp .

.,. Attach the w inch hook to the front towline eye

previously installed .

Rear hook up

.. Align the vehicle with the centerline of the car

carrier ramp.

.. Attach the w inch hook to the rear towline eye

previously installed . .,.

375

Page 378 of 402

Emergency situations

@ Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

truck ramp.

Raising the vehicle

Lifting with workshop hoist and with floor

jack

The vehicle may only be li~ed at the lifting

poin ts illus trated .

Fig . 298 Front lift ing point

Fig . 299 Rear lifti ng po int

• Read and heed WARNING c::> .&_ .

• Locate lifting po ints c::> fig . 298 and ¢ fig. 299.

• Adjus t lifting arms of workshop ho ist o r floo r

ja ck to match veh icle lif ting poin ts.

• Inse rt a rubber pa d between t he f loor jack/

w ork shop hoist and the lifting poin ts.

If you must lift your vehicle with a floor jack to

work underneath , be sure the vehicle is safely

s upported on stands intended for this purpo se.

Front lifting point

The lift ing po int is located on the floor pan re in

forcement about at the same level as the jack

376

moun ting poin t c::> fig. 298 . Do not lift the vehi

cle at the ve rtical sill reinfo rcement.

Rear lifting point

The lifting poin t is lo cated on t he ve rti cal rein

fo rcemen t of t he lower s ill for the onboard j ack

¢fig. 2 99 .

Lifting with vehicle jack

Refer to c::> page 363.

A WARNING

-To r educe th e risk of s erious inju ry an d vehi

cle damage.

- Always lift the vehicle o nly at the special

workshop hoist and f loor jack lift points i l

l ustrated

c::> fig. 298 and c::> fig. 299.

- Failure to lift the ve hicle a t these points

could ca use the vehicle to tilt o r fall from

a lift if there is a change in ve hicle weight

dist ribution and balance . This might hap

pen, fo r example, whe n heavy compo

nen ts su ch as the eng in e b lock o r trans

mi ssion are removed.

- Whe n removing heavy co mponen ts lik e

these, anchor vehicle to hois t or ad d c orre

s p ondin g weights to maintai n the ce nt er of

g ra vity. Oth erw ise, the vehicle mig ht tilt or

slip off the hoist, ca using serio us persona l

in jur y.

(D Note

-Be aw are of the fo ll ow ing poi nts bef ore lift

ing the vehicle:

- The vehicle should never be lifted or

jacked up from underneath the engine oil pan, the transmission hous ing, the front

or rear axle or the body side members.

This could lead to serious damage .

- To avoid damage to the underbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points.

- Before driving over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist. ..,.

Page 379 of 402

u co ...... N r-... N ...... 0

0

:E: '

sure that there is sufficient clearance be

tween the hoist and low parts of the ve

hicle.

Vehicle transport

A ppl ies to: ve hicles with a ir susp en sio n

The following contains information you should

know about transporting your vehicle.

Wh en transporting the vehicle on a ca r ca rri

er, tra in, sh ip or by ot her means , only t ie the

ve hicle down at t he r unnin g surface of the

tires, w hich i s t he outer circumference. Secur

ing the vehicle at the axle components, sus

p ens io n struts or tow ing eyes is no t per mitted

b ecause the pressure in the air suspens io n

str uts ca n cha nge dur in g tra ns port. Th e vehi

cle may no t be se cu red su ffici entl y if this ha p

pe ns.

Emergency situations

377

Page 380 of 402

Technical data

Technical data

Vehicle specifications

Fig. 300 Windsh iel d (fro nt left) : Ve hicl e Iden tific ation

N um ber ( VIN )

XXXXX XX -X -XXXX XXX XX

@-+ ~J:~t::1 ::: xxxxxxxx xx x xxxxxxxx

I YP lf'VPE XXX XXX

XX XXXXXXX XX X X XX

XXX

KW XXX

15\_L I MOIOlll

@-+ ~~

1

:tr:~i XXXX I XXXX XXX I XX

II. -AUSST . / OPTIONS

.__ __

E0A 7D5 4UB

2EH JOZ lLB

3FC

F0 A 9G3

TL6 3 KA 8EH

lXW 803

7T6 CV7 7KO

3L4 4KC

lS A 7GB

6XM SSG

lAS

SMU 7Xl

0G7 0YH

UlA X9B

908 8Z4

4X3 2K2

3Y0 413

01A

SRW

1BA

OJF

027

020

502

4G0

XX X XX X XX X XXXX

Fig . 301 Vehicle identificat ion lab el

Vehicle Identification Number (VIN) in the

Infotainment system

~ Select in the Infotainment system: the I MENU I

button > Vehicle > left contro l button > Service

& checks> Vehicle information.

Vehicle Identification Number (VIN)

The VIN can be found in the Infotainment sys

tem, on the vehicle data label, and under the

windshield on the front left side* <=:>

fig. 300 . The

VIN is also in the right side of the luggage com

partment (the fende r) under a cover.

378

Vehicle identification label

The vehicle identification label <=:> fig. 301 is locat

ed in the luggage compartment under the cargo

floor cover.

The information of the vehicle identification label

can also be found in your Warranty

& Mainte

nance booklet.

The st icker contains the follow ing vehicle data:

(D Vehicle Iden tifica tion Number (VIN)

@ Vehicle type, eng ine output, transmission

® Engine and transmission cod es

@ Paint and interior codes

® Optional equipment numbers

Safety compliance sticker

The safety compliance sticker is your assurance

that your new veh icle complies with all applicable

Federal Motor Vehicle Safety Standards which

were in effect at the time the vehicle was manu

factured. You can find this sticker on the driver's

s id e B-pillar .

It shows the month and year of pro

duction and the vehicl e identification number of

your vehicle (perfo ration) as well as the Gross Ve

hicle Weight Rating (GVWR) and the Gro ss Axle

Weight Rating (GAWR).

H igh voltage warning label

The high voltage warn ing label is located in the

e ngine compartment next to the engine hood re

lease. The spark ignit ion system complies w ith

the Canadian s tand ard IC ES-002.

Notes about technical

data

The values may vary based on special equipment

as well as market-specific equipment and meas

u ring methods.

Please note that the specifications listed in the

vehicle documentation a lways take precedence .

(D Tips

Missing technical data was not available at

the time of printing .