air condition AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 11 of 72

11

Fan control

The control unit for radiator fan V293 regulates

the output of the radiator fan and controls the

continued coolant circulation. The induced-air

fan V7 and the forced-air fan V177 are

activated simultaneously.

Forced-air fan V177 is located upstream of the

condenser, water cooler and visco fan. It

assists the visco fan.

The electronic power control

The various fan settings are executed by an

electronic power control.

The fan motors are operated periodically, the

length of the operating cycle depending on the

fan setting selected. Fan output level is

controlled via pulse-width-modulated outputs.

Should a fan fail, the radiator fan control unit

increases the speed of the fan motor still

available.

Advantages of the power control:

•

The series resistors previously used for

power control are no longer required.

•

Lower power consumption in lower fan

settings.

•

Safety functions.

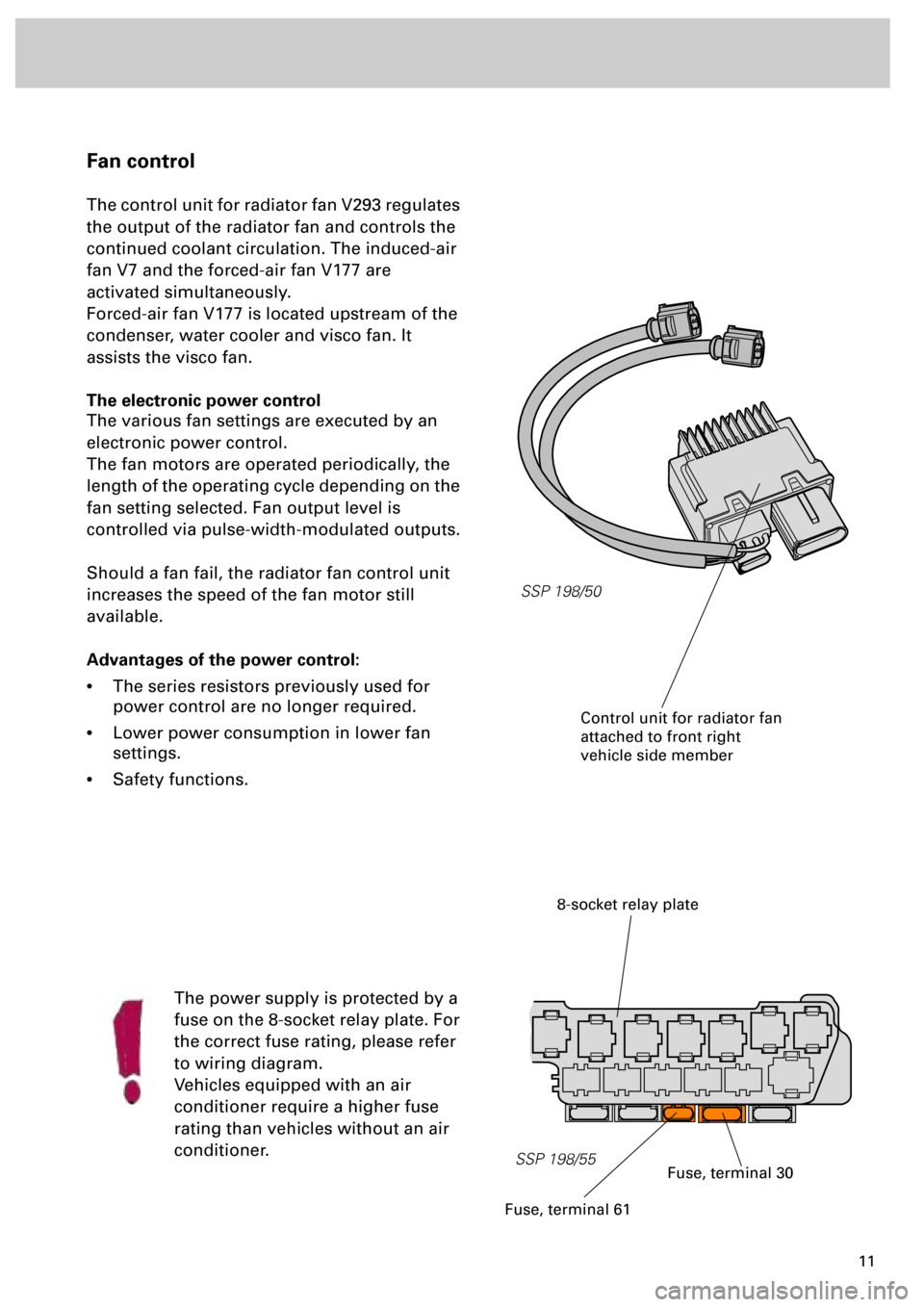

The power supply is protected by a

fuse on the 8-socket relay plate. For

the correct fuse rating, please refer

to wiring diagram.

Vehicles equipped with an air

conditioner require a higher fuse

rating than vehicles without an air

conditioner.

SSP 198/50

8-socket relay plate

SSP 198/55

Control unit for radiator fan

attached to front right

vehicle side member

Fuse, terminal 30

Fuse, terminal 61

Page 12 of 72

12

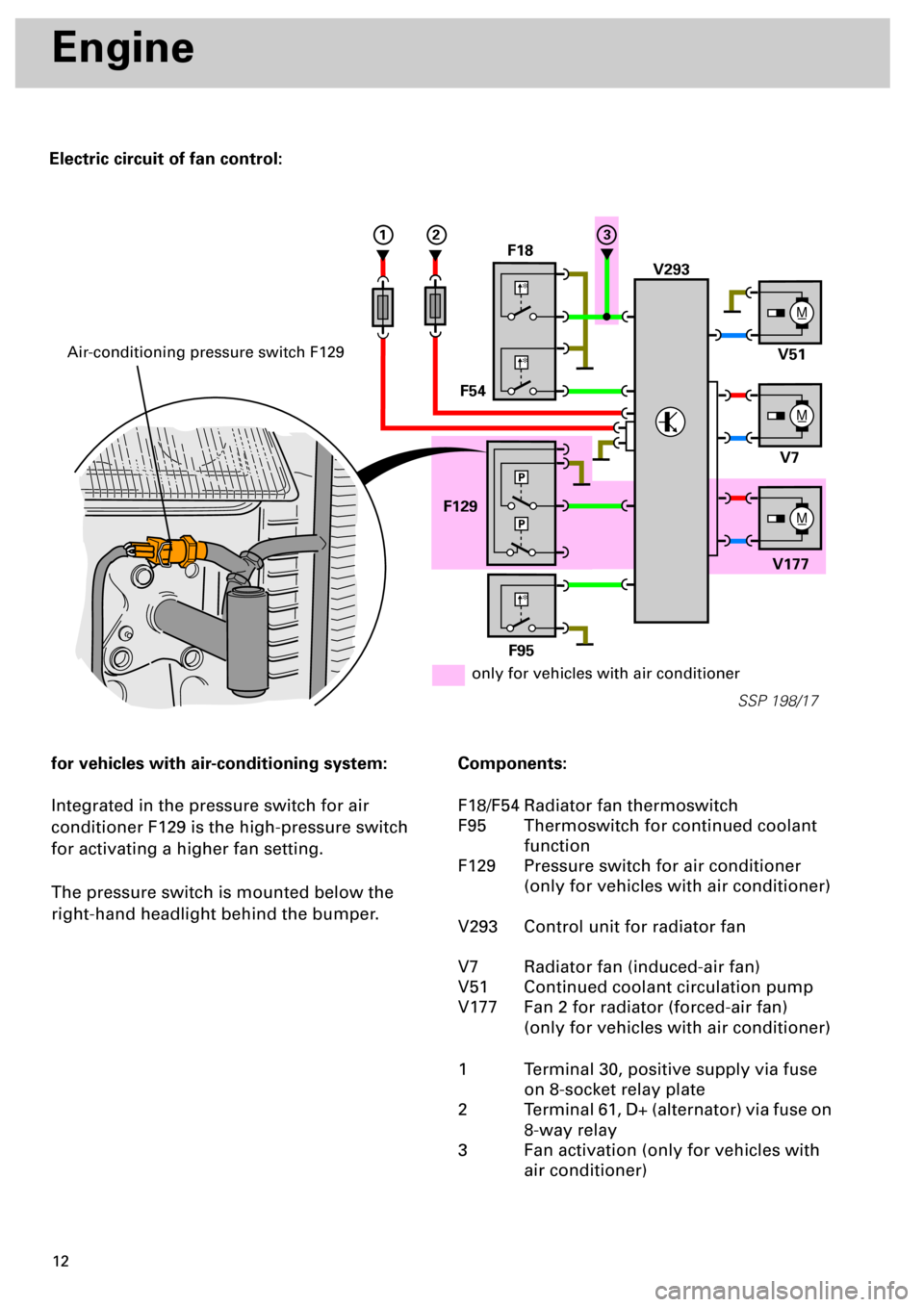

Electric circuit of fan control:

Engine

for vehicles with air-conditioning system:

Integrated in the pressure switch for air

conditioner F129 is the high-pressure switch

for activating a higher fan setting.

The pressure switch is mounted below the

right-hand headlight behind the bumper.

Components:

F18/F54 Radiator fan thermoswitch

F95 Thermoswitch for continued coolant

function

F129 Pressure switch for air conditioner

(only for vehicles with air conditioner)

V293 Control unit for radiator fan

V7 Radiator fan (induced-air fan)

V51 Continued coolant circulation pump

V177 Fan 2 for radiator (forced-air fan)

(only for vehicles with air conditioner)

1 Terminal 30, positive supply via fuse

on 8-socket relay plate

2 Terminal 61, D+ (alternator) via fuse on

8-way relay

3 Fan activation (only for vehicles with

air conditioner)

M_

V293 F18

F54

F129

V177V7 V51

M_

M_

SSP 198/17

*

*

F95

*

P

P

123

only for vehicles with air conditioner

Air-conditioning pressure switch F129

Page 13 of 72

13

Function of fan circuit

(for vehicles with air-conditioning

system)

4 fan settings are possible:

is activated by coolant pump thermoswitch

F95.

The fan motors and continued coolant

circulation pump V51 are activated.

The fan motors run at min. output (40%).

is requested by radiator fan thermoswitch F18

or by the air-conditioning control panel.

The fan motors run at 50% output.

is activated by air-conditioning system

pressure switch F129.

The fan motors run at 85 % output.

is activated by radiator fan thermoswitch F54.

The fan motors run at full output.

Fan speeds 1, 2 and 3 are only

activated if the “engine running“

signal is picked up at terminal 61.

The electrical coolant function.....

The continued coolant function is

only activated if the “engine not

running“ signal is picked up at

terminal 61. The continued coolant

function period is limited to 10

minutes.

Fan speed 1......

Fan speed 2......

Fan speed 3......

Page 48 of 72

49

Sensors

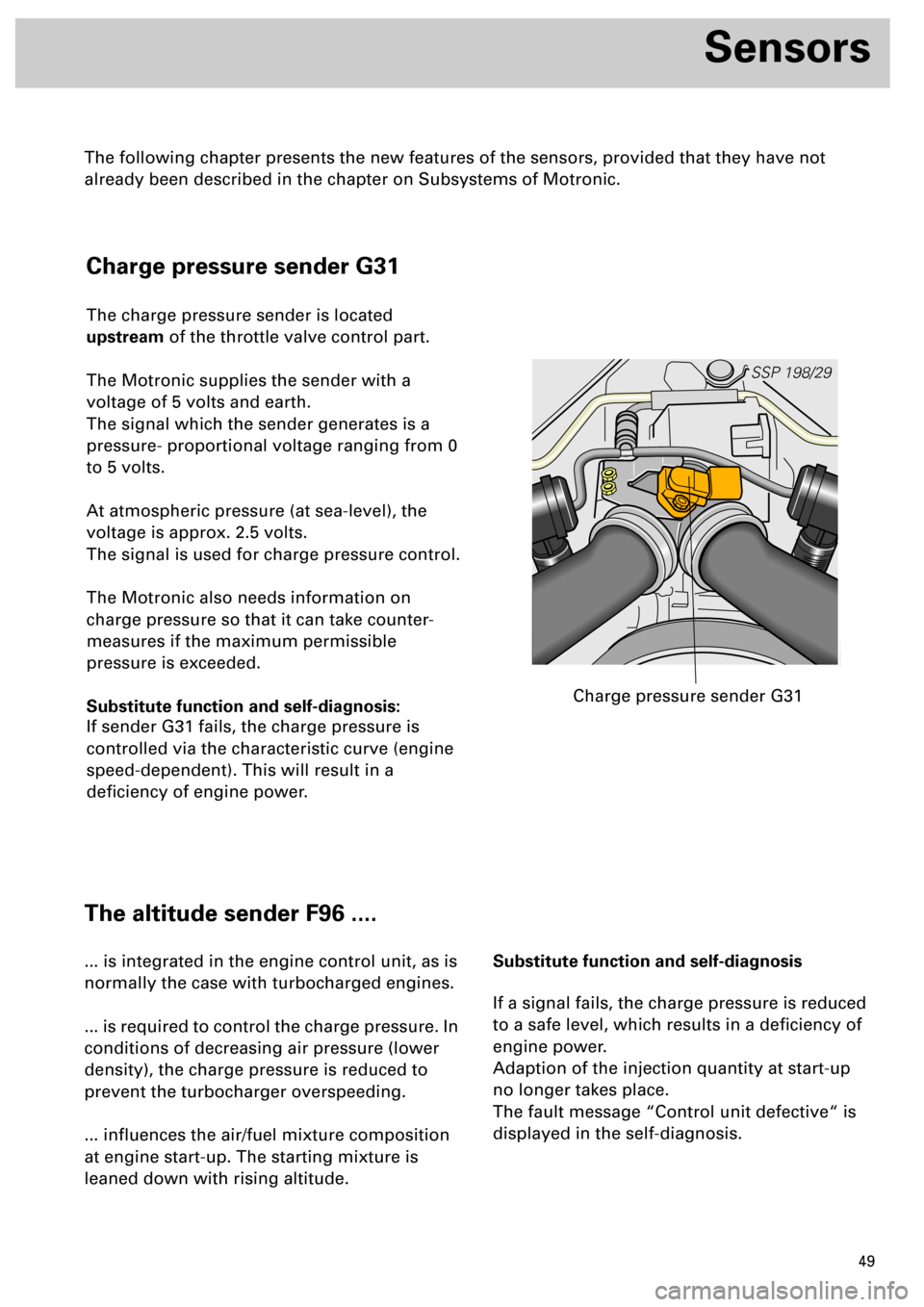

Charge pressure sender G31

The charge pressure sender is located

upstream of the throttle valve control part.

The Motronic supplies the sender with a

voltage of 5 volts and earth.

The signal which the sender generates is a

pressure- proportional voltage ranging from 0

to 5 volts.

At atmospheric pressure (at sea-level), the

voltage is approx. 2.5 volts.

The signal is used for charge pressure control.

The Motronic also needs information on

charge pressure so that it can take counter-

measures if the maximum permissible

pressure is exceeded.

Substitute function and self-diagnosis:

If sender G31 fails, the charge pressure is

controlled via the characteristic curve (engine

speed-dependent). This will result in a

deficiency of engine power.

SSP 198/29

Charge pressure sender G31

The altitude sender F96 ....

... is integrated in the engine control unit, as is

normally the case with turbocharged engines.

... is required to control the charge pressure. In

conditions of decreasing air pressure (lower

density), the charge pressure is reduced to

prevent the turbocharger overspeeding.

... influences the air/fuel mixture composition

at engine start-up. The starting mixture is

leaned down with rising altitude.Substitute function and self-diagnosis

If a signal fails, the charge pressure is reduced

to a safe level, which results in a deficiency of

engine power.

Adaption of the injection quantity at start-up

no longer takes place.

The fault message “Control unit defective“ is

displayed in the self-diagnosis.

The following chapter presents the new features of the sensors, provided that they have not

already been described in the chapter on Subsystems of Motronic.

Page 56 of 72

57

Additional signals/interfaces

Additional signals/interfaces to

Motronic ME 7.1

The Motronic receives a large number of

additional signals.

The following overview shows the signal

direction and meaning referred to the Motronic

control unit

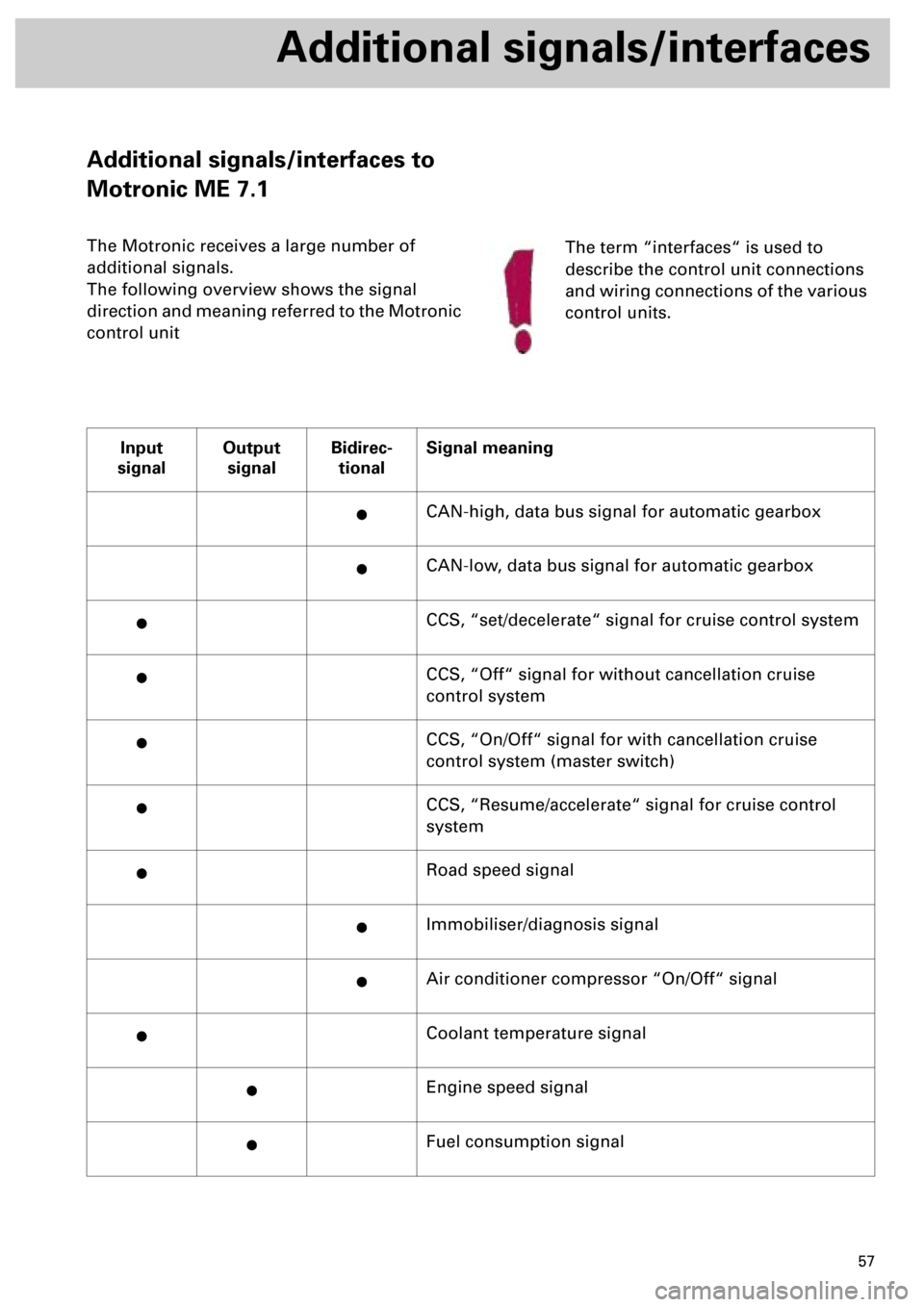

Input

signalOutput

signalBidirec-

tionalSignal meaning

·CAN-high, data bus signal for automatic gearbox

·CAN-low, data bus signal for automatic gearbox

·CCS, “set/decelerate“ signal for cruise control system

·CCS, “Off“ signal for without cancellation cruise

control system

·CCS, “On/Off“ signal for with cancellation cruise

control system (master switch)

·CCS, “Resume/accelerate“ signal for cruise control

system

·Road speed signal

·Immobiliser/diagnosis signal

·Air conditioner compressor “On/Off“ signal

·Coolant temperature signal

·Engine speed signal

·Fuel consumption signal

The term “interfaces“ is used to

describe the control unit connections

and wiring connections of the various

control units.

Page 57 of 72

58

Additional signals/interfaces

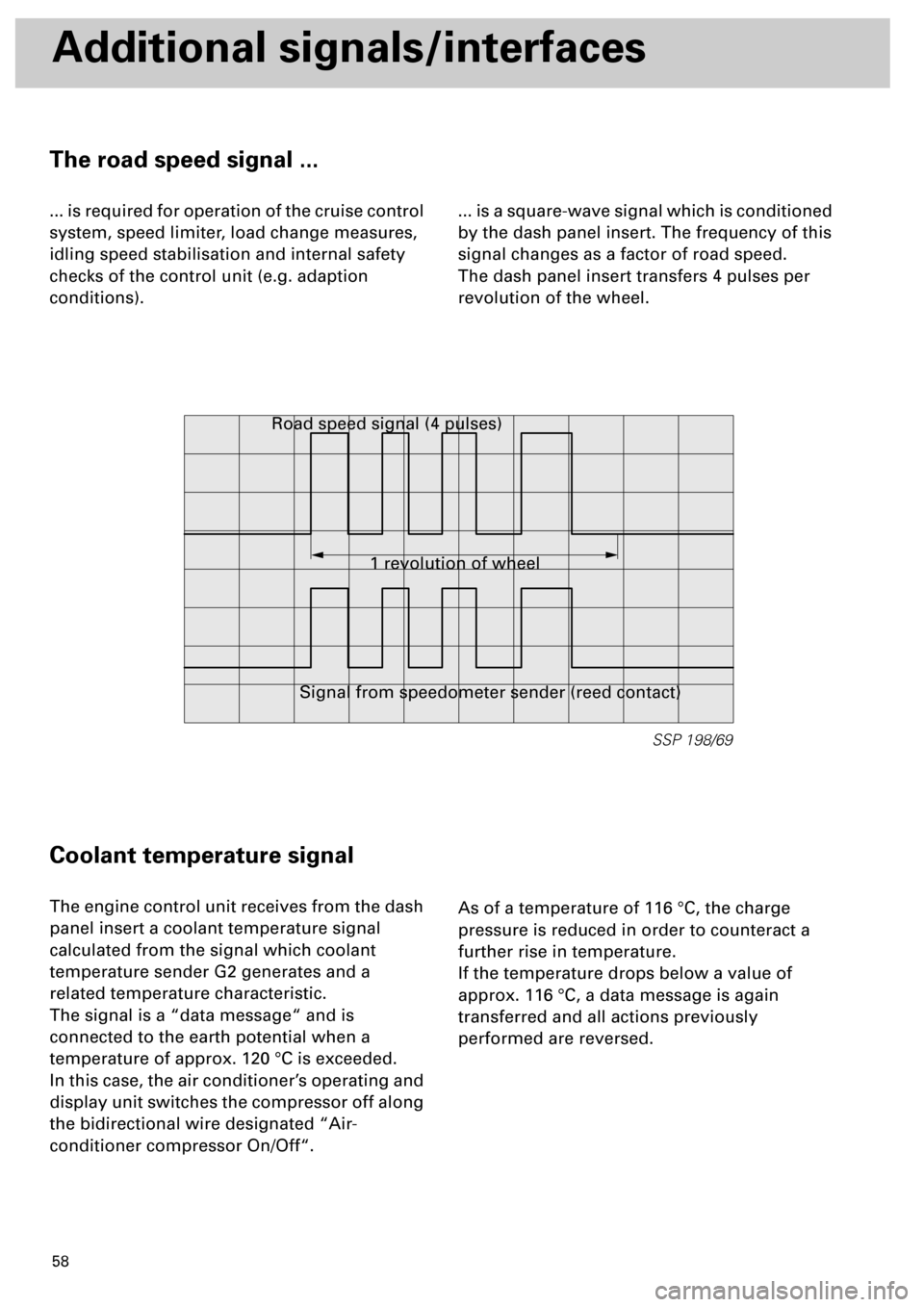

The road speed signal ...

... is required for operation of the cruise control

system, speed limiter, load change measures,

idling speed stabilisation and internal safety

checks of the control unit (e.g. adaption

conditions).... is a square-wave signal which is conditioned

by the dash panel insert. The frequency of this

signal changes as a factor of road speed.

The dash panel insert transfers 4 pulses per

revolution of the wheel.

Coolant temperature signal

The engine control unit receives from the dash

panel insert a coolant temperature signal

calculated from the signal which coolant

temperature sender G2 generates and a

related temperature characteristic.

The signal is a “data message“ and is

connected to the earth potential when a

temperature of approx. 120 °C is exceeded.

In this case, the air conditioner’s operating and

display unit switches the compressor off along

the bidirectional wire designated “Air-

conditioner compressor On/Off“.As of a temperature of 116 °C, the charge

pressure is reduced in order to counteract a

further rise in temperature.

If the temperature drops below a value of

approx. 116 °C, a data message is again

transferred and all actions previously

performed are reversed.

SSP 198/69

1 revolution of wheel Road speed signal (4 pulses)

Signal from speedometer sender (reed contact)

Page 58 of 72

59

The “Compressor On/Off“ interface ...

... serves to provide the engine control unit

with information on the circuit state of the

compressor.

... enables the engine control unit to switch off

the compressor or inhibit start-up.

... provides a link to the air conditioner’s

operating and display unit.

The interface as a signal input:

Shortly before switching on the magnetic

coupling, the air conditioner’s operating and

display unit applies voltage to the interface.

The engine control unit then increases the

idling speed to compensate for the higher

engine load.The interface as a signal output:

If the engine control unit applies an earth

potential to the interface, the compressor is

switched off for a defined period of time as

required.

The engine control unit switches the

compressor off in the following situations:

- After initiating basic setting (function 04)

- In certain emergency running programs

within a defined engine speed range

The immobiliser/diagnosis interface ...

... is the communication link between the

engine control unit and the immobiliser in the

dash panel insert.... also serves as the diagnosis wire (K-wire) for

the diagnosis tester. Dialogue takes place via:

diagnosis plug Û dash panel insert interface Û

immobiliser/diagnosis interface Û engine

control unit

Page 59 of 72

60

Additional signals/interface

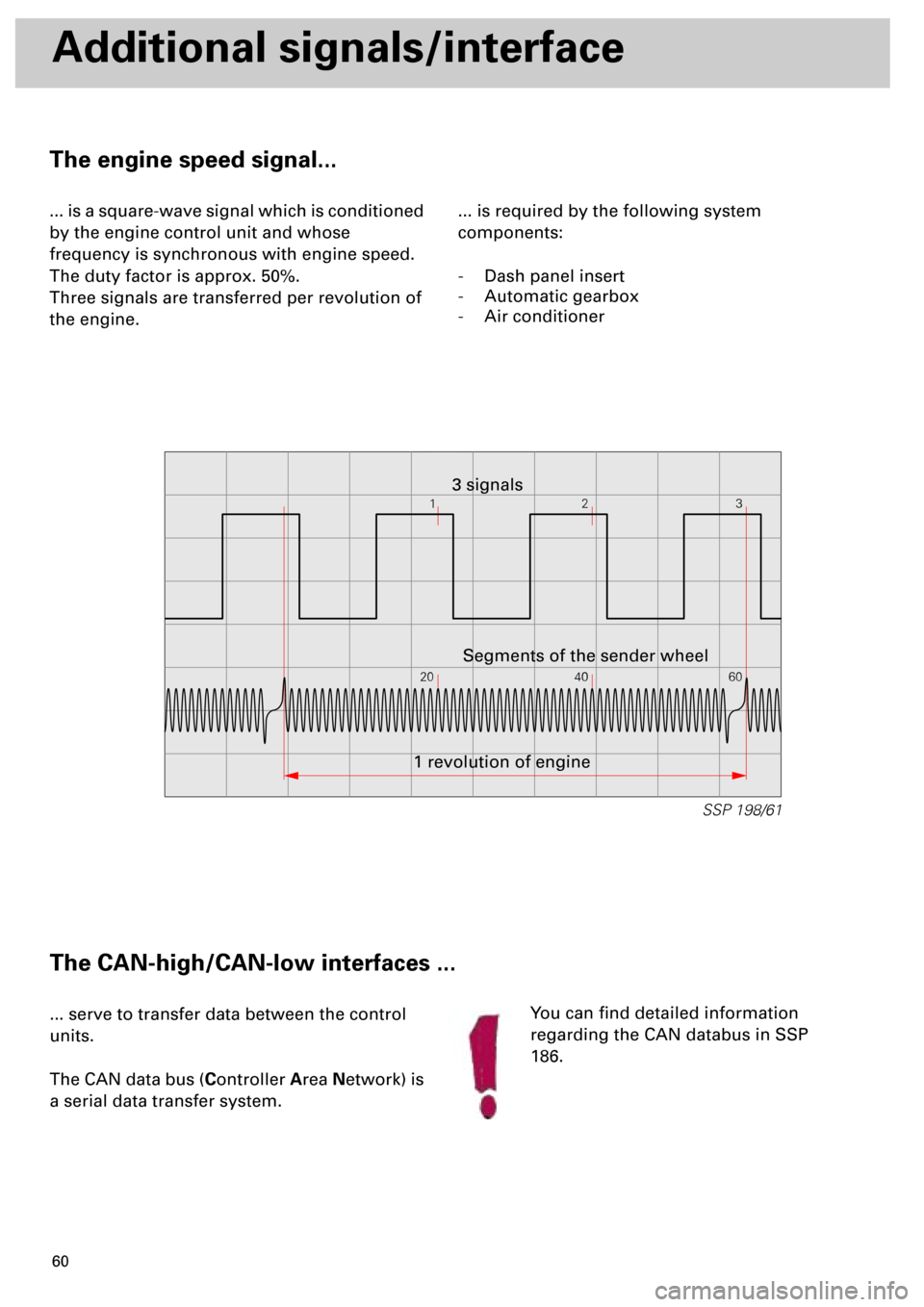

The engine speed signal...

... is a square-wave signal which is conditioned

by the engine control unit and whose

frequency is synchronous with engine speed.

The duty factor is approx. 50%.

Three signals are transferred per revolution of

the engine.... is required by the following system

components:

- Dash panel insert

- Automatic gearbox

- Air conditioner

The CAN-high/CAN-low interfaces ...

... serve to transfer data between the control

units.

The CAN data bus (Controller Area Network) is

a serial data transfer system.You can find detailed information

regarding the CAN databus in SSP

186.

12

20 40 603

SSP 198/61

1 revolution of engineSegments of the sender wheel 3 signals

Page 61 of 72

62

Functional diagram

Components:

F Brake light switch

F36 Clutch pedal switch

F47 Brake pedal switch

F96 Altitude sender (integrated in engine

control unit)

G2 Coolant temperature sender

G6 Fuel pump

G28 Engine speed sender

G31 Charge pressure sender

G39 Lambda probe (cylinder bank 1)

G40 Hall sender (cylinder bank 2)

G42 Intake air temperature sender

G 61 Knock sensor (cylinder bank 1)

G62 Coolant temperature sender

G66 Knock sensor (cylinder bank 2)

G70 Air mass meter

G79 Accelerator position sender 1

G108 Lambda probe (cylinder bank 2)

G163 Hall sender (cylinder bank 1)

G185 Accelerator position sender 2

G186 Throttle valve drive (electric throttle

control)

G187 Angle sender 1 for throttle valve drive

G188 Angle sender 2 for throttle valve drive

G235 Sender 1 for exhaust gas temperature

G236 Sender 2 for exhaust gas temperature

J17 Fuel pump relay

J220 Motronic control unit

J338 throttle valve control part

K132 Warning lamp for electric throttle

control

N Ignition coil, cylinder 1

N30 Injector, cylinder 1

N31 Injector, cylinder 2

N32 Injector, cylinder 3

N33 Injector , cylinder 4

N75 Solenoid valve for charge pressure

control

N80 Solenoid valve for activated charcoal

canister

N83 Injector, cylinder 5

N84 Injector, cylinder 6

N122 Output stage (cylinder bank 1)

N128 Ignition coil, cylinder 2

N158 Ignition coil, cylinder 3

N163 Ignition coil, cylinder 4

N164 Ignition coil, cylinder 5N189 Ignition coil, cylinder 6

N192 Output stage (cylinder bank 2)

N205 Camshaft adjustment valve 1 (cylinder

bank 1)

N208 Camshaft adjustment valve 2

(cylinder bank 2)

N249 Divert air valve for turbocharger

Z19 Heater for lambda probe

Z28 Heater for lambda probe 2

I To dash panel insert

II To dash panel insert (warning lamp)

Additional signals

1 CAN-high (automatic gearbox)

2 CAN-low (automatic gearbox)

3 „Set/decelerate“ signal for cruise

control system

4 “Off“ signal without cancellation for

cruise control system

5 “On/Off“ signal with cancellation for

cruise control system

6 Resume/accelerate“ signal for cruise

control system

7 Road speed signal

8 Immobiliser/diagnosis signal

9 Air conditioner compressor “On/Off“

signal

10 Coolant temperature signal

11 Engine speed signal

12 Fuel consumption signal

Colour codes:

Input signal

Output signal

Positive

Earth

Bidirectional