change wheel AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 26 of 72

27

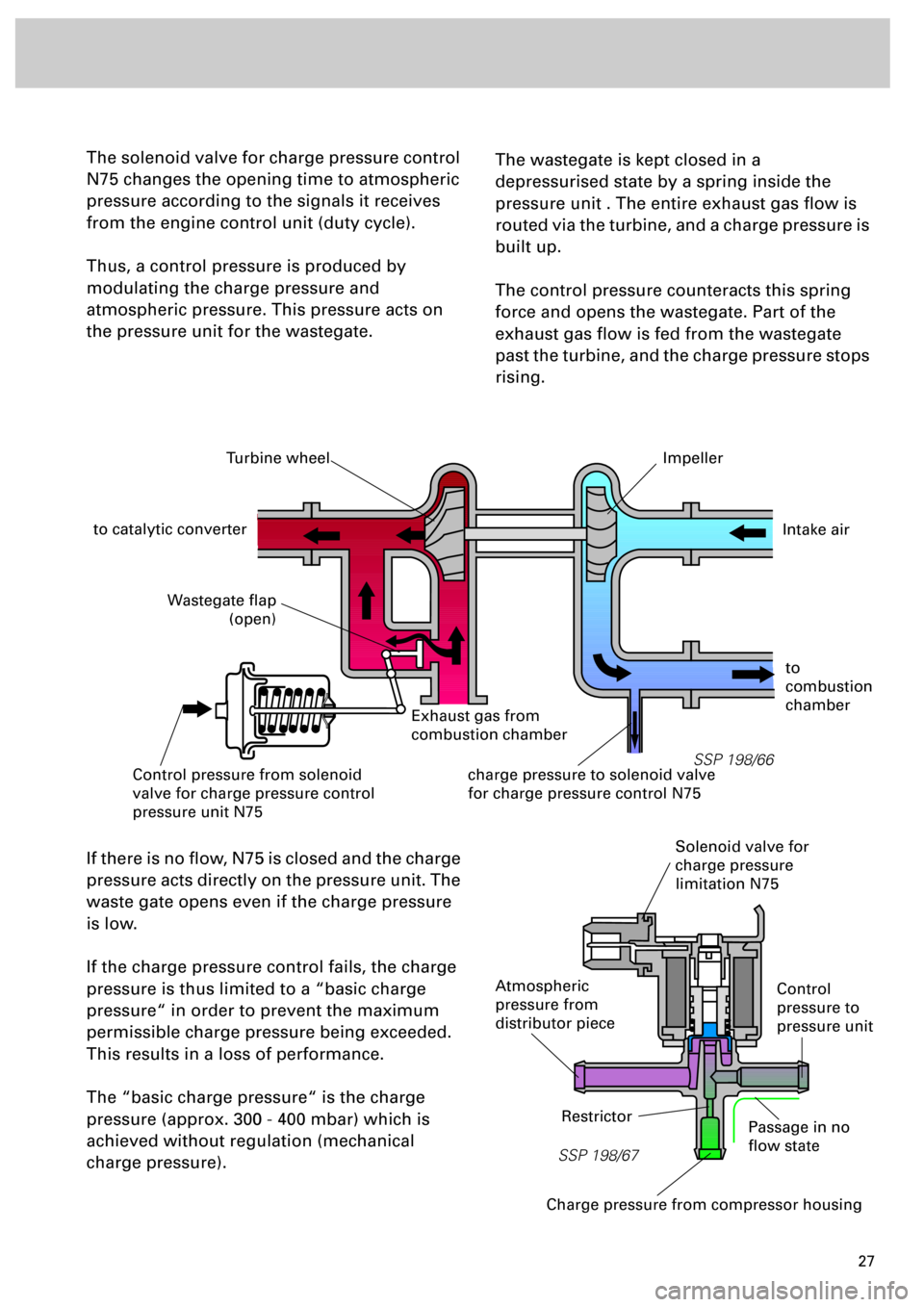

The solenoid valve for charge pressure control

N75 changes the opening time to atmospheric

pressure according to the signals it receives

from the engine control unit (duty cycle).

Thus, a control pressure is produced by

modulating the charge pressure and

atmospheric pressure. This pressure acts on

the pressure unit for the wastegate.

The wastegate is kept closed in a

depressurised state by a spring inside the

pressure unit . The entire exhaust gas flow is

routed via the turbine, and a charge pressure is

built up.

The control pressure counteracts this spring

force and opens the wastegate. Part of the

exhaust gas flow is fed from the wastegate

past the turbine, and the charge pressure stops

rising.

If there is no flow, N75 is closed and the charge

pressure acts directly on the pressure unit. The

waste gate opens even if the charge pressure

is low.

If the charge pressure control fails, the charge

pressure is thus limited to a “basic charge

pressure“ in order to prevent the maximum

permissible charge pressure being exceeded.

This results in a loss of performance.

The “basic charge pressure“ is the charge

pressure (approx. 300 - 400 mbar) which is

achieved without regulation (mechanical

charge pressure).

SSP 198/66

Turbine wheel

to catalytic converter

Impeller

Exhaust gas from

combustion chamber

Wastegate flap

(open)

Control pressure from solenoid

valve for charge pressure control

pressure unit N75charge pressure to solenoid valve

for charge pressure control N75

Intake air

to

combustion

chamber

SSP 198/67

Atmospheric

pressure from

distributor piece

Solenoid valve for

charge pressure

limitation N75

Charge pressure from compressor housing

RestrictorPassage in no

flow state

Control

pressure to

pressure unit

Page 27 of 72

28

SSP 198/05

Engine

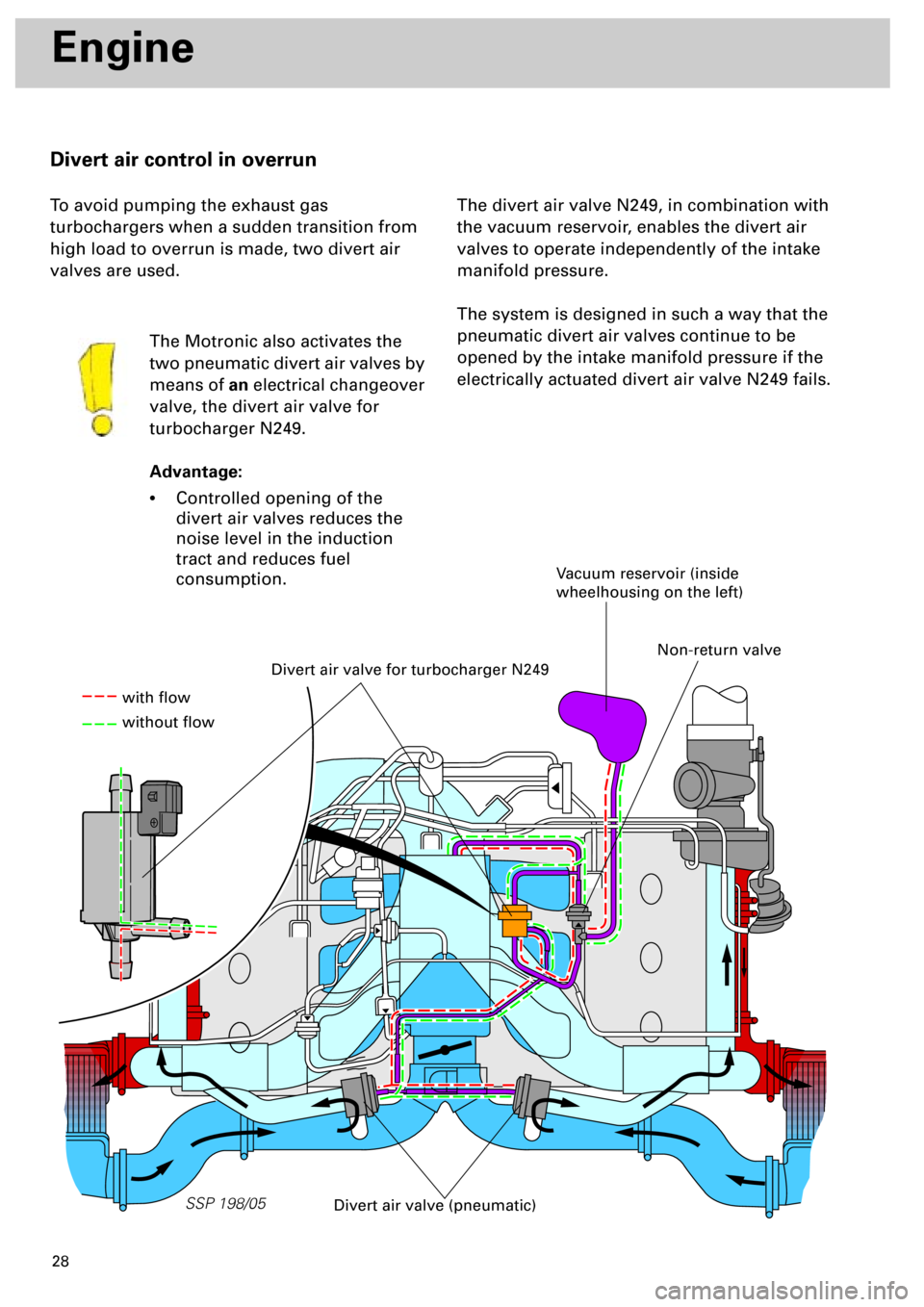

Divert air control in overrun

To avoid pumping the exhaust gas

turbochargers when a sudden transition from

high load to overrun is made, two divert air

valves are used.

The Motronic also activates the

two pneumatic divert air valves by

means of

an

electrical changeover

valve, the divert air valve for

turbocharger N249.

Advantage:

•

Controlled opening of the

divert air valves reduces the

noise level in the induction

tract and reduces fuel

consumption.

The divert air valve N249, in combination with

the vacuum reservoir, enables the divert air

valves to operate independently of the intake

manifold pressure.

The system is designed in such a way that the

pneumatic divert air valves continue to be

opened by the intake manifold pressure if the

electrically actuated divert air valve N249 fails.

Divert air valve for turbocharger N249

Vacuum reservoir (inside

wheelhousing on the left)

Divert air valve (pneumatic)

with flow

without flow

Non-return valve

Page 53 of 72

54

Sensors

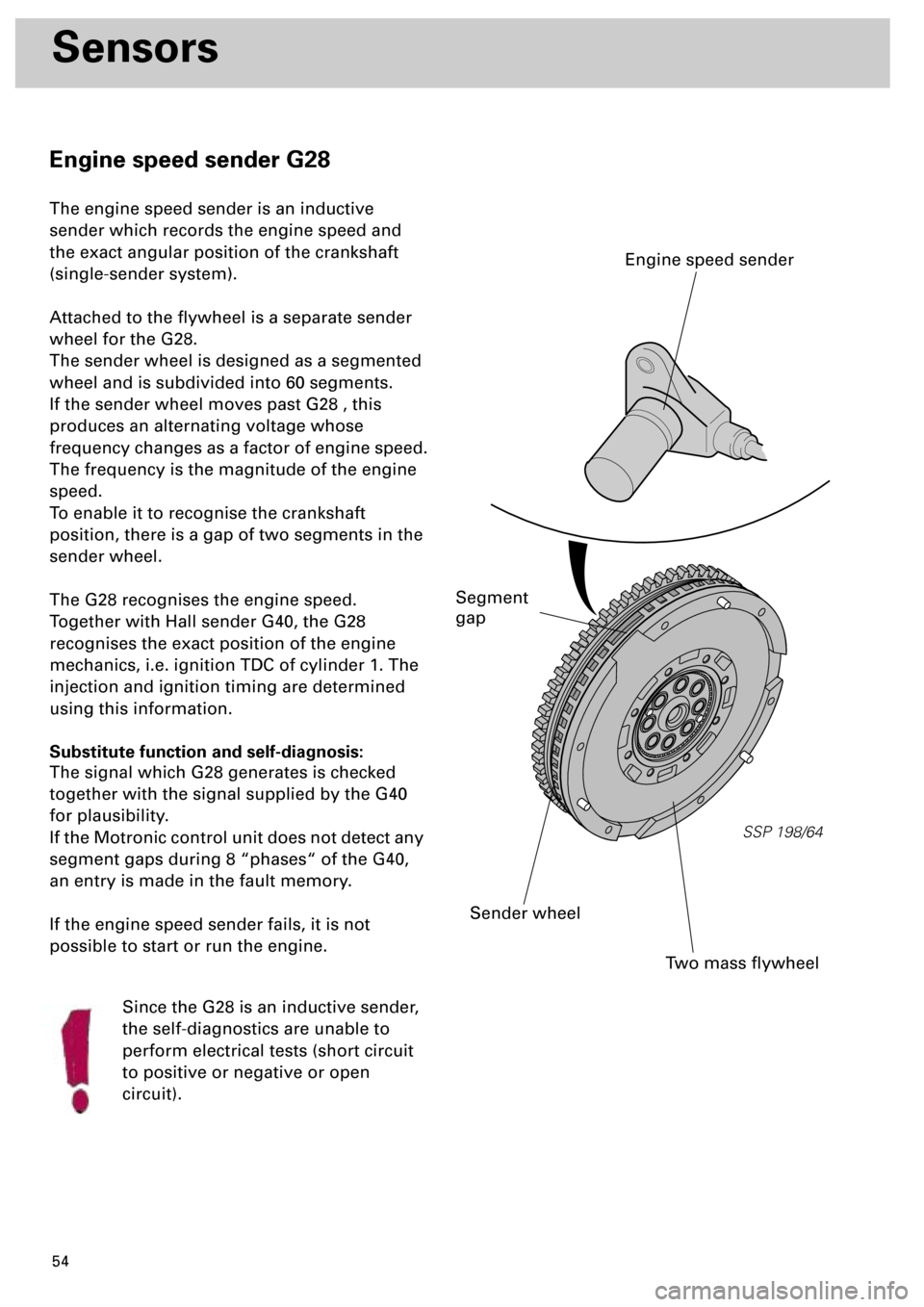

Engine speed sender G28

The engine speed sender is an inductive

sender which records the engine speed and

the exact angular position of the crankshaft

(single-sender system).

Attached to the flywheel is a separate sender

wheel for the G28.

The sender wheel is designed as a segmented

wheel and is subdivided into 60 segments.

If the sender wheel moves past G28 , this

produces an alternating voltage whose

frequency changes as a factor of engine speed.

The frequency is the magnitude of the engine

speed.

To enable it to recognise the crankshaft

position, there is a gap of two segments in the

sender wheel.

The G28 recognises the engine speed.

Together with Hall sender G40, the G28

recognises the exact position of the engine

mechanics, i.e. ignition TDC of cylinder 1. The

injection and ignition timing are determined

using this information.

Substitute function and self-diagnosis:

The signal which G28 generates is checked

together with the signal supplied by the G40

for plausibility.

If the Motronic control unit does not detect any

segment gaps during 8 “phases“ of the G40,

an entry is made in the fault memory.

If the engine speed sender fails, it is not

possible to start or run the engine.

Since the G28 is an inductive sender,

the self-diagnostics are unable to

perform electrical tests (short circuit

to positive or negative or open

circuit).

SSP 198/64

Two mass flywheel

Sender wheel

Engine speed sender

Segment

gap

Page 57 of 72

58

Additional signals/interfaces

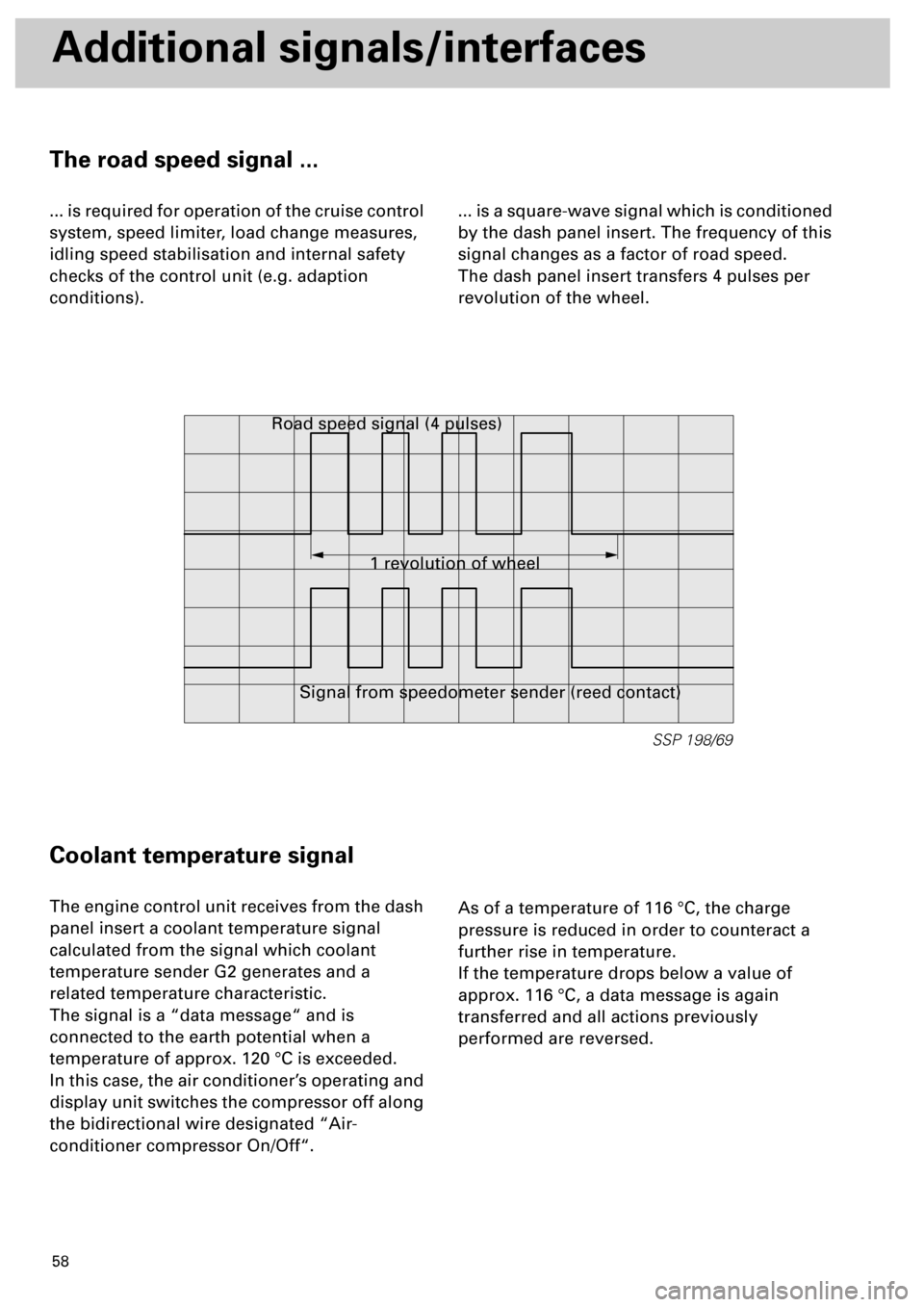

The road speed signal ...

... is required for operation of the cruise control

system, speed limiter, load change measures,

idling speed stabilisation and internal safety

checks of the control unit (e.g. adaption

conditions).... is a square-wave signal which is conditioned

by the dash panel insert. The frequency of this

signal changes as a factor of road speed.

The dash panel insert transfers 4 pulses per

revolution of the wheel.

Coolant temperature signal

The engine control unit receives from the dash

panel insert a coolant temperature signal

calculated from the signal which coolant

temperature sender G2 generates and a

related temperature characteristic.

The signal is a “data message“ and is

connected to the earth potential when a

temperature of approx. 120 °C is exceeded.

In this case, the air conditioner’s operating and

display unit switches the compressor off along

the bidirectional wire designated “Air-

conditioner compressor On/Off“.As of a temperature of 116 °C, the charge

pressure is reduced in order to counteract a

further rise in temperature.

If the temperature drops below a value of

approx. 116 °C, a data message is again

transferred and all actions previously

performed are reversed.

SSP 198/69

1 revolution of wheel Road speed signal (4 pulses)

Signal from speedometer sender (reed contact)