lock AUDI S4 1998 B5 / 1.G Engine Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 1998, Model line: S4, Model: AUDI S4 1998 B5 / 1.GPages: 72, PDF Size: 3.25 MB

Page 8 of 72

8

Engine

The variable valve timing

The camshaft timing has been modified

compared to the 2.8-litre V6 engine to meet the

demands of turbocharging technology.

Variable valve timing with an adjustment angle

of 22° is used here for the first time in

turbocharged engines

.

Advantage:

•

A torque increase of approx. 10% is

achieved at the bottom and top ends of the

engine speed range.

•

Better emission levels and fuel

consumption figures.

The variable valve timing is activated by the

Motronic by means of camshaft adjustment

valves N205 and N208.The design and function of the

variable valve timing are already

described in Self-study Programmes

182 and 192.

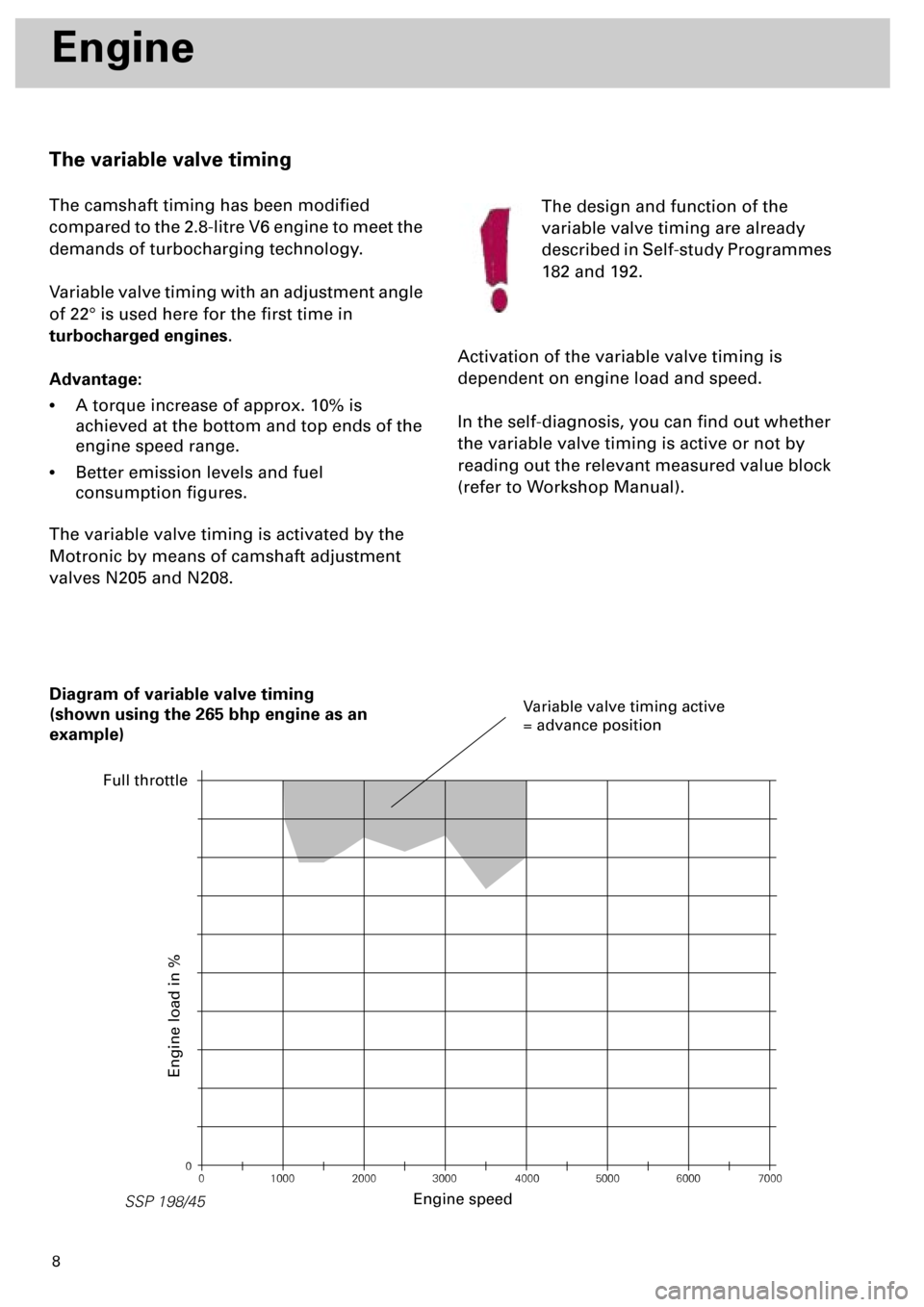

Activation of the variable valve timing is

dependent on engine load and speed.

In the self-diagnosis, you can find out whether

the variable valve timing is active or not by

reading out the relevant measured value block

(refer to Workshop Manual).

0

0 1000 2000 3000 4000 5000 6000 7000

SSP 198/45

Diagram of variable valve timing

(shown using the 265 bhp engine as an

example)

Engine speed

Engine load in %

Variable valve timing active

= advance position

Full throttle

Page 25 of 72

26

SSP 198/08

Engine

Charge pressure control

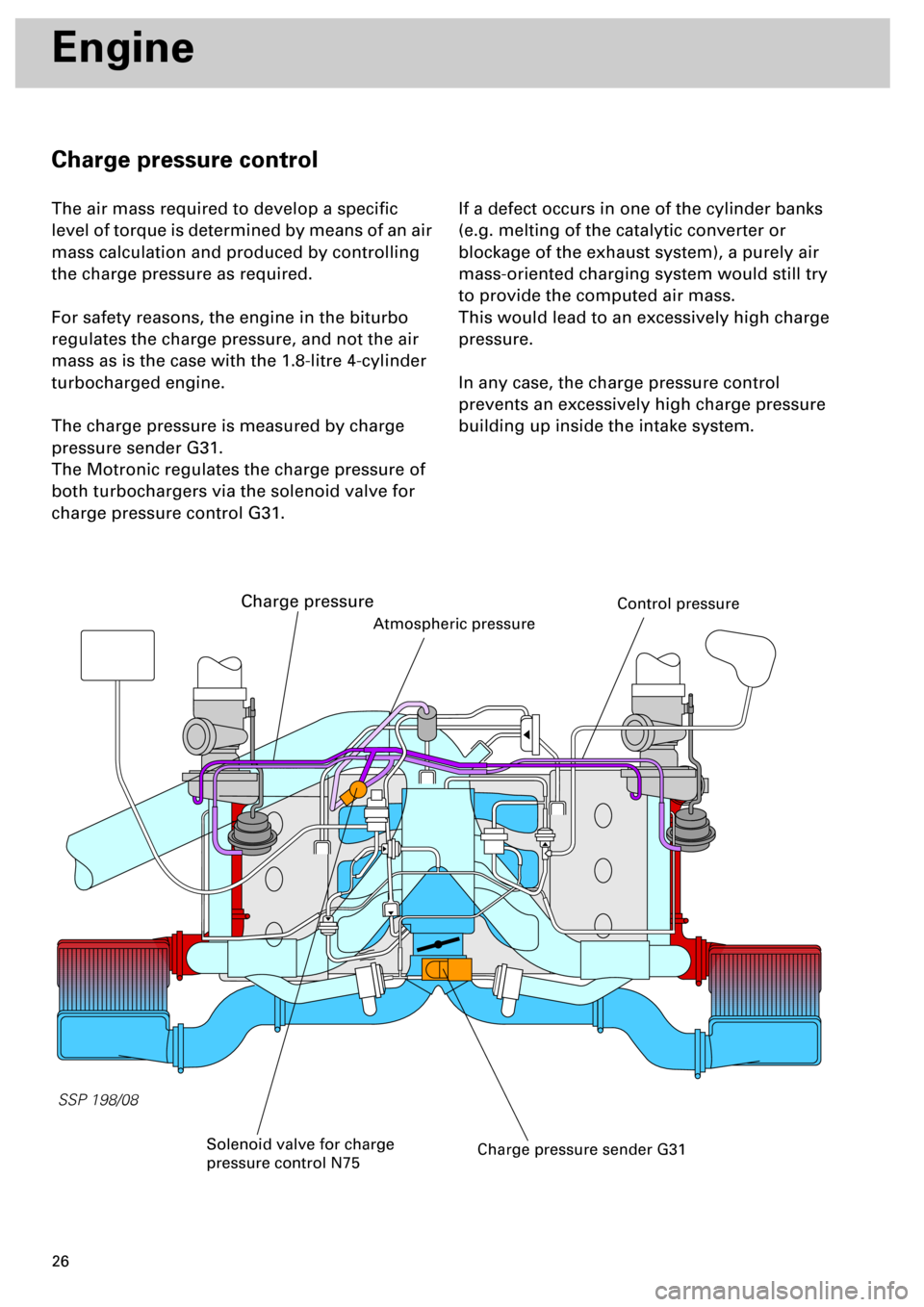

The air mass required to develop a specific

level of torque is determined by means of an air

mass calculation and produced by controlling

the charge pressure as required.

For safety reasons, the engine in the biturbo

regulates the charge pressure, and not the air

mass as is the case with the 1.8-litre 4-cylinder

turbocharged engine.

The charge pressure is measured by charge

pressure sender G31.

The Motronic regulates the charge pressure of

both turbochargers via the solenoid valve for

charge pressure control G31.

If a defect occurs in one of the cylinder banks

(e.g. melting of the catalytic converter or

blockage of the exhaust system), a purely air

mass-oriented charging system would still try

to provide the computed air mass.

This would lead to an excessively high charge

pressure.

In any case, the charge pressure control

prevents an excessively high charge pressure

building up inside the intake system.

Charge pressure sender G31

Atmospheric pressure

Solenoid valve for charge

pressure control N75

Charge pressure

Control pressure

Page 41 of 72

42

Subsystems of the Motronic

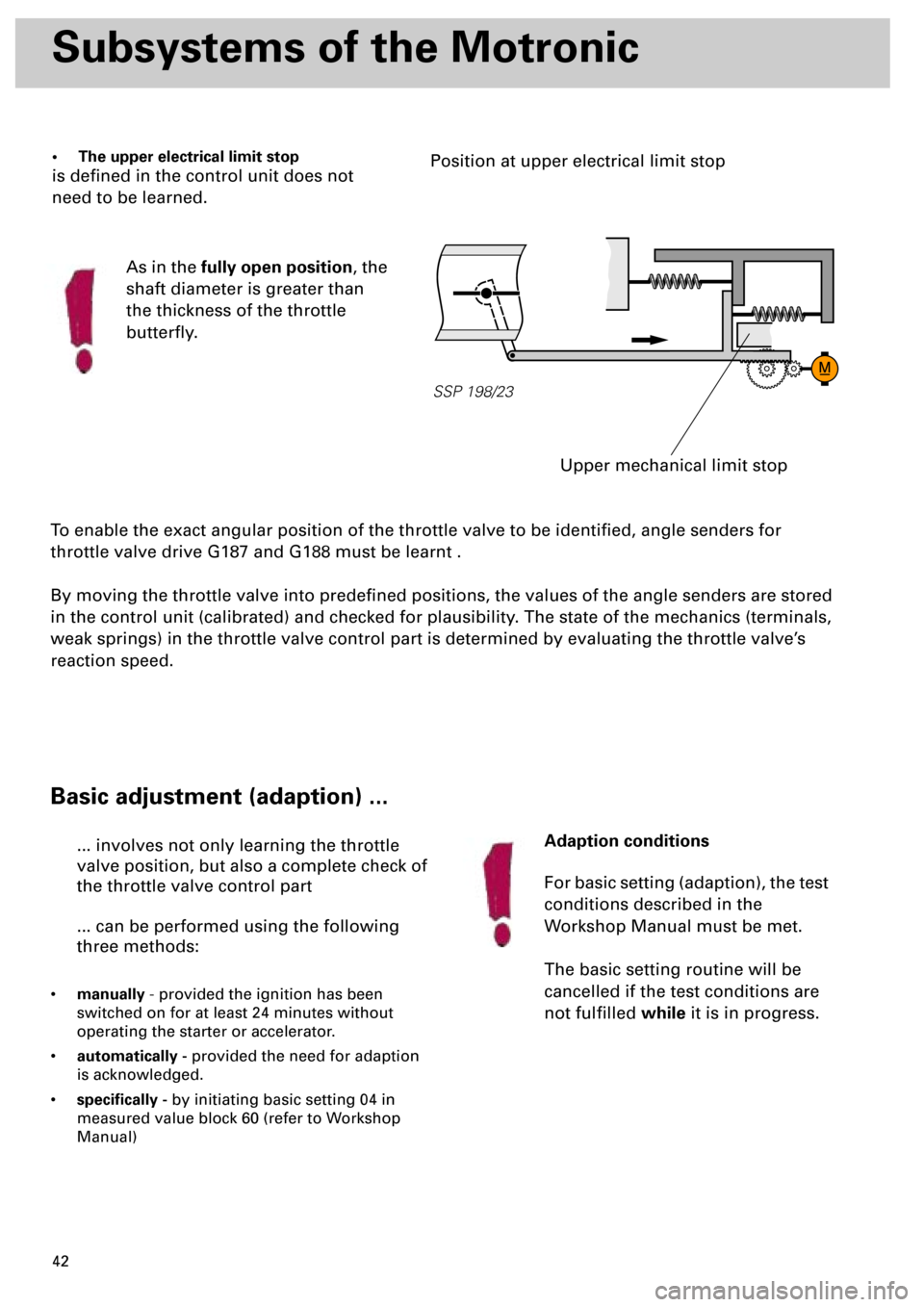

To enable the exact angular position of the throttle valve to be identified, angle senders for

throttle valve drive G187 and G188 must be learnt .

By moving the throttle valve into predefined positions, the values of the angle senders are stored

in the control unit (calibrated) and checked for plausibility. The state of the mechanics (terminals,

weak springs) in the throttle valve control part is determined by evaluating the throttle valve’s

reaction speed.

... involves not only learning the throttle

valve position, but also a complete check of

the throttle valve control part

... can be performed using the following

three methods:

•

manually

- provided the ignition has been

switched on for at least 24 minutes without

operating the starter or accelerator.

•

automatically -

provided the need for adaption

is acknowledged.

•

specifically -

by initiating basic setting 04 in

measured value block 60 (refer to Workshop

Manual)

• The upper electrical limit stop

is defined in the control unit does not

need to be learned.

As in the

fully open position

, the

shaft diameter is greater than

the thickness of the throttle

butterfly.

SSP 198/23

Upper mechanical limit stop

Position at upper electrical limit stop

Basic adjustment (adaption) ...

Adaption conditions

For basic setting (adaption), the test

conditions described in the

Workshop Manual must be met.

The basic setting routine will be

cancelled if the test conditions are

not fulfilled

while

it is in progress.

Page 62 of 72

63

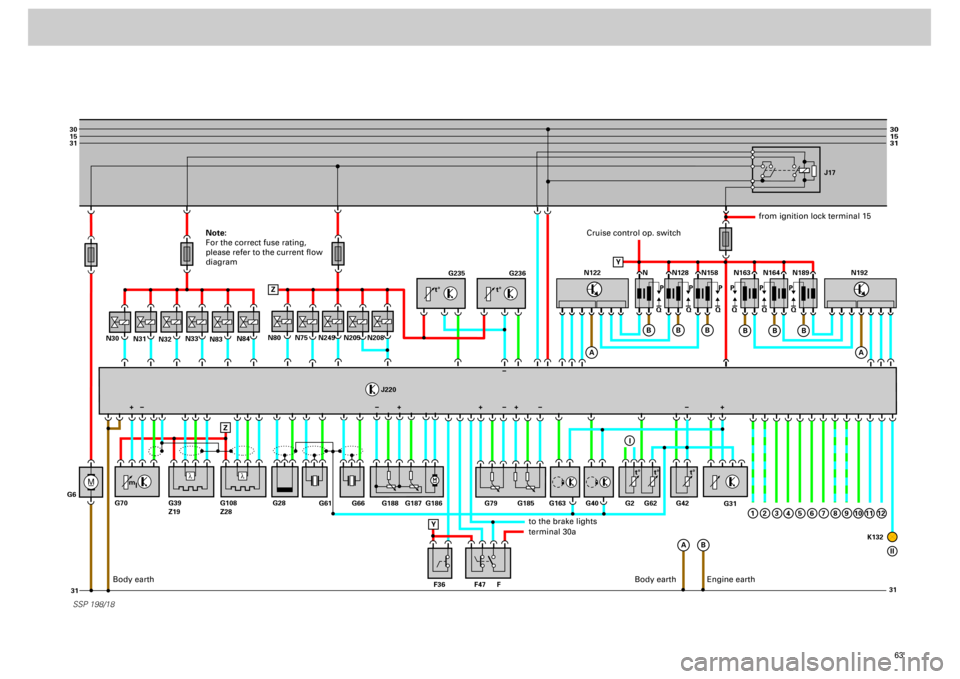

M

30

15

31

31 31

30

15

31

_

G6N31

N32N33N80

J220

N83N84

N30

N75

N249

N205

N208

SSP 198/18

G235

G236

G31

N N128J17

N158 N163 N164 N189

Q PPPPPP

QQ QQQ

A

A

B Z

ZB

B

B

N122

A

B

B

B

1

N192

G61

G66 G188 G187 G186 G79

F47 F36 FG163 G40 G62G2 G42

K132 G185

G28 G70 G39

Z19G108

Z28

Y

+

Y

I

2

3

4

5

6

7

8

9

10

11

12

II

l

l

t° t°

m

lt° t° t°

+++ +

Cruise control op. switch

from ignition lock terminal 15

to the brake lightsterminal 30a

Body earth

Engine earth

Note:

For the correct fuse rating,

please refer to the current flow

diagram

Body earth