maintenance AUDI S4 2008 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 225 of 342

Intelligent technology223

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Note

•

To ensure that the ASR works properly, all four wheels must be

fitted with identical tyres. Any differences in the rolling radius of the

tyres can cause the system to reduce engine power when this is not

desired.

•

Should a malfunction occur in the ABS or EDL, both the ABS

warning lamp

and the ESP warning lamp

⇒ page 19 will light

up.

•

In the event of a malfunction in the ESP system, the warning

lamp ⇒ page 17 will light up.

•

If a malfunction should occur in the ABS, the ESP, EDL and ASR

will also be out of action.

•

The systems can make noises when they intervene.

Switching on and off

The ESP is switched on automatically when the engine is

started.

Switching off the traction control system (ASR)

In particular circumstances, it may be advisable to switch off the

traction control system (ASR) to allow a certain amount of wheel

slip. For example:•

Rocking the car backwards and forwards to free it

•

Driving in deep snow or on loose surfaces

•

Driving with snow chains

Press the button briefly ⇒fig. 232 or ⇒fig. 233. The

warning lamp

will light up and the message ASR off will appear

in the driver information system display.

The traction control system (ASR) can only be switched off at speeds

below 50 km/h on vehicles with front-wheel drive. At 70 km/h it will

switch on again automatically. The ASR can be deactivated at any

speed on vehicles with four-wheel drive.

Switching off the ESP

Press the button for longer than 3 seconds. The ESP

warning lamp will light up and the message ESP switched off will

appear in the display. The ASR is also deactivated when the ESP is

switched off.

Switching on

Press the button again. The message ESP/ASR on will

appear briefly on the display.

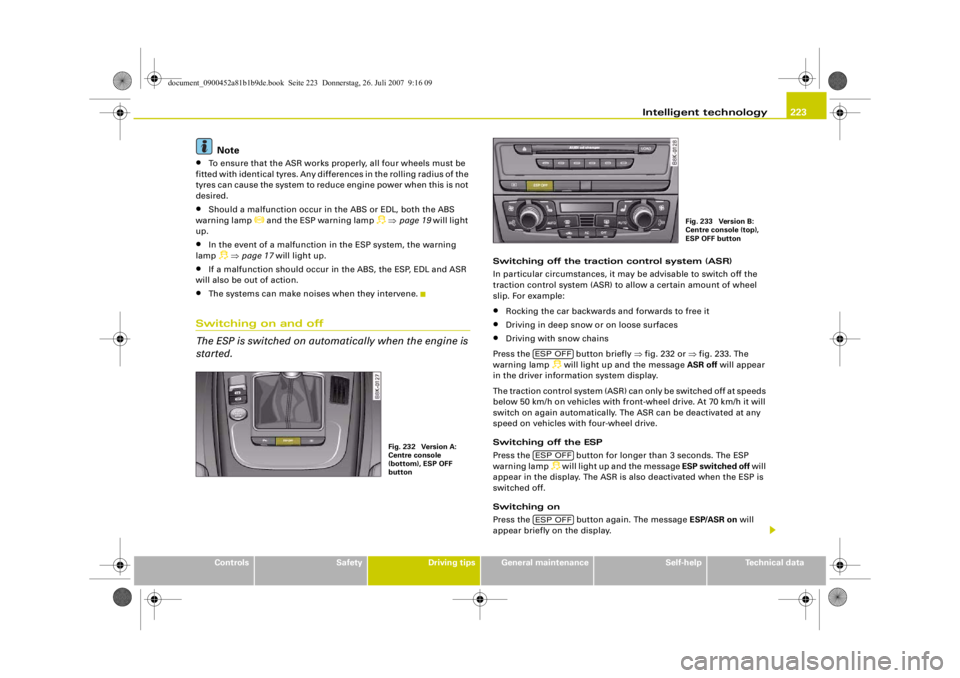

Fig. 232 Version A:

Centre console

(bottom), ESP OFF

button

Fig. 233 Version B:

Centre console (top),

ESP OFF button

ESP OFFESP OFFESP OFF

document_0900452a81b1b9de.book Seite 223 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-

(I]

T

•

-+

I I

+-

I I

I I

Page 227 of 342

Intelligent technology225

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

WARNING

•

When applying the brakes to clean off deposits on the pads and

discs, select a clear, dry road. Be sure not to inconvenience or

endanger other road users; do not risk an accident.

•

Never let the car coast with the engine switched off (this can

cause accidents).Caution

•

Never let the brakes “drag” by leaving your foot on the pedal

when you do not really intend to brake. This overheats the brakes,

resulting in longer stopping distances and greater wear.

•

Before driving down a long, steep gradient, it is advisable to

reduce speed and move the selector lever to a lower gear. In this

way you will make use of the engine braking effect and relieve the

load on the brakes. If you still have to use the brakes, it is better to

brake firmly at intervals than to apply the brakes continuously.Note

•

If the brake servo is out of action due to a malfunction, or if the

car has to be towed, you will have to press the brake pedal consid-

erably harder to make up for the lack of servo assistance.

•

If you wish to equip the car with accessories such as a front

spoiler or wheel covers, it is impo rtant that the flow of air to the

front wheels is not obstructed, otherwise the brakes can overheat.

Power steering (servotronic)The power steering assists th e driver when turning the

steering wheel (with the engine running).The power steering assists the driver by reducing the force needed

to turn the steering wheel. The degree of power assistance is

adapted electronically , depending on the speed. If a fault should occur in the

servotronic system the power steering

will still operate. The degree of power assistance will, however, no

longer adapt to different speeds. If the electronic regulating system

is not working properly, this is most noticeable when turning the

steering wheel at low speeds (for instance when parking) – more

effort will be required than usual. The fault should be corrected by

a qualified workshop as soon as possible.

The power steering does not function when the engine is switched

off. In this case the steering wheel is very hard to turn.

If the steering is held at its turning limit when the car is stationary,

this will place an excessive load on the power steering system. In

this case, the power steering system will make noises. It will also

reduce the idling speed of the engine.

Caution

Do not keep the steering in the full-lock position for longer than

15 seconds when the engine is running – this could cause damage

to the power steering system.

Note

•

If the power steering should fail at any time or the engine is

switched off (for instance when being towed), the car can still be

steered. However, more effort will be required to turn the steering

wheel.

•

If the system is leaking or malfunctioning, please take the car to

a qualified workshop as soon as possible.

•

The power steering requires a special hydraulic fluid. The fluid

reservoir is located at the front of the engine compartment on the

left ⇒page 256 . The correct fluid level in the reservoir is important

for the power steering to function properly. The hydraulic fluid level

is checked at the Inspection Service.

document_0900452a81b1b9de.book Seite 225 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

CD

-+

CD

[I]

[I]

+-

•

•

Page 229 of 342

Intelligent technology227

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

current even when the ignition is off. In some cases there may not

be enough power available to start the engine.

Your vehicle is equipped with an intelligent power management

system to control the distribution of electrical energy. This signifi-

cantly improves reliability when starting the engine, and also

prolongs the life of the battery.

The main functions incorporated in the power management system

are

battery diagnosis , residual current management and dynamic

power management .

Battery diagnosis

The battery diagnosis function constantly registers the condition of

the battery. Sensors detect the ba ttery voltage, battery current and

battery temperature. This enables the system to calculate the

current power level and charge condition of the battery.

Residual current management

The residual current management reduces power consumption

while the vehicle is parked. It controls the supply of power to the

various electrical components while the ignition is switched off. The

system takes the battery diagnosis data into consideration.

Depending on the power level of the battery, the individual electrical

components are switched off one after the other to prevent the

battery from losing too much charge and to ensure that the engine

can be started reliably.

Dynamic power management

While the vehicle is moving, this function distributes the available

power to the various electrical components and systems according

to their requirements. The power management ensures that on-

board systems do not consume more electrical power than the

alternator can supply, and thus maintains the maximum possible

battery power level.

Note

•

The power management system is not able to overcome the

given physical limits. Please remember that the power and life of

the battery are limited.

•

A warning message will appear ⇒page 228, “Driver message in

the instrument cluster display” if the battery power has dropped to

a level where reliable starting is impaired.

Points to remember

Starting ability has first priority.Short trips, city traffic and low te mperatures all place a heavy load

on the battery. In these conditions a large amount of power is

consumed, but only a small amount is supplied. The situation is also

critical if electrical equipment is in use when the engine is not

running. In this case power is consumed when none is being gener-

ated.

In these situations you will be aware that the power management

system is intervening to control the distribution of electrical power.

When the vehicle is parked for long periods

If you do not drive your vehicle for a period of several days or weeks,

the power management will gr adually shut off the on-board

systems one by one, or reduce the amount of current they are using.

This limits the amount of power consumed and helps to ensure reli-

able starting even after a long period.

Please note that certain convenience features, such as the Audi

advanced key*, the remote control key or the electrical seat adjust-

ment may not be available when yo u unlock the vehicle. These func-

tions will be restored when you switch on the ignition and start the

engine.

document_0900452a81b1b9de.book Seite 227 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-

[I]

T

•

-+ +-

Page 231 of 342

Your vehicle and the environment229

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Your vehicle and the environmentRunning inA new vehicle should be run in over a distance of 1,500 km. For the

first 1,000 km the engine speed should not exceed 2/3 of the

maximum permissible engine speed – do not use full throttle and do

not tow a trailer or caravan. From 1,000 to 1,500 km you can gradu-

ally increase the engine rpm and road speed.

During its first few hours of running, the internal friction in the

engine is greater than later on when all the moving parts have

bedded down.

How the vehicle is driven for the first 1,500 km also influences the

engine quality. After the first 1,500 km you should continue driving

at moderate engine speeds, in particular when the engine is cold.

This helps to reduce wear and tear on the engine and increases the

potential mileage which can be covered by the engine.

You should also avoid driving with the engine speed too low.

Change down to a lower gear when the engine no longer runs

“smoothly”. Excessively high engine speeds are prevented by an

automatic rev limiter.Emission control systemsCatalytic converter

Applies to vehicles with petrol engine: The vehicle must only be

used with unleaded petrol, otherwise the catalytic converter will be

destroyed.

Never run the tank completely dry. The irregular fuel supply can

cause misfiring, which would allow unburnt fuel to enter the

exhaust system, which could cause overheating and damage the

catalytic converter. Diesel particulate filter

Applies to vehicles

with diesel engine: The diesel particulate filter

can filter out almost all soot particles contained in the exhaust gas.

In normal driving conditions the filter is self-cleaning. Should the

self-cleaning function of the filter not be able to operate, e.g. when

the vehicle is continuously used only for short trips, the filter

becomes obstructed with soot and the symbol

for the diesel

particulate filter lights up ⇒page 38 .

WARNING

•

Because of the high temperatures which can occur in the emis-

sion control system (catalytic converter or diesel particulate

filter), do not park the vehicle where the exhaust can come into

contact with flammable materials under the car (e.g. on grass or

at the forest edge). - Fire hazard!

•

Do not apply any underseal agen ts in the area around the

exhaust system - fire hazard!

How to improve economy and minimise pollutionFuel economy, environmental impact and wear on the engine,

brakes and tyres depend largely on the way you drive the vehicle. By

adopting an economical driving style and anticipating the traffic

situation ahead, you can reduce fuel consumption by 10-15%. The

following section gives you some ti ps on lessening the impact on

the environment and reducing your operating costs at the same

time.

document_0900452a81b1b9de.book Seite 229 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

•

Page 233 of 342

Your vehicle and the environment231

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Save electrical energy

The engine drives the alternator to generate electricity. This means

that fuel consumption rises when more power is required for elec-

trical equipment. Switch off electrical equipment when it is not

needed. Electrical equipment which uses a lot of electricity includes

the blower (at a high se

tting), the rear window heating and the seat

heating*.

Environmental compatibilityEnvironmental protection is a top priority in the design, choice of

materials and production of your new Audi.

Design measures for economical recycling•

Joints and connections designed for ease of dismantling

•

Modular construction to facilitate dismantling

•

Increased use of single-grade materials

•

Plastic parts and elastomers are labelled in accordance with ISO

1043, ISO 11469 and ISO 1629

Choice of materials

•

Nearly all materials used can be recycled

•

Similar types of plastics grouped together for easy recycling

•

Recycled materials used in manufacture

•

Reduced vapour emissions from plastics

•

CFC-free refrigerant in air conditioner

Compliance with the laws prohibiting the use of : Cadmium,

asbestos, lead, mercury and chrome VI.

Manufacturing methods

•

Using recycling material for manufacturing plastic parts

•

Solvent-free cavity sealing

•

Solvent-free wax for protecting the vehicles in transit

•

Solvent-free adhesives

•

No CFCs used in production

•

Surplus materials used extensively for energy conversion and

building materials

•

Overall water consumption reduced

•

Heat recovery systems

•

Water-soluble paint

document_0900452a81b1b9de.book Seite 231 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

•

-+ +-

Page 235 of 342

Towing a trailer233

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

additional mirrors fitted. Both exterior mirrors should be mounted

on hinged extension brackets. Adjust the mirrors to give sufficient

vision to the rear.

Headlights

Before starting a journey, check

the headlight beam settings with

the trailer hitched up. If necessary, alter the height of the headlight

beams by means of the headlight range control ⇒page 60 .

Power supply

When you remove the ignition key the power supply to the trailer is

interrupted.

Removable ball joint coupling

Vehicles with a factory-fitted towing bracket are equipped with a

removable ball joint coupling. It is carried under the floor panel on

the left-hand side of the luggage compartment and is secured by a

strap.

Note

We recommend having the car serviced between the normal inspec-

tion intervals if it used frequently for towing a trailer.Applies to vehicles: with towing bracketTrailer stabilisation system

Trailer stabilisation helps to reduce the risk of the vehicle

skidding when towing a trailer.The trailer stabilisation system is operational only when the ESP is

switched on and there is no malfunction in the ESP ⇒page 17 .

When is the trailer stab ilisation system activated?

Trailer stabilisation is active when the following requirements are

met:•

The ESP must NOT be switched off ⇒page 222 ,

•

The trailer connector must be properly secured in the vehicle

socket.

•

Vehicle speed must be higher than approx. 60 km/h.

How trailer stabilisation works:

In many cases, the driver can stabilise a swaying trailer by manually

braking the vehicle.

However, if the ESP detects that th e trailer is swaying and this is

affecting the towing vehicle, it will automatically brake the vehicle

to stabilise the trailer by slowing it down. The warning lamp

will

light up in the instrument cluste r. If possible, do not turn the

steering wheel at this stage.

In order to warn traffic behind you, the brake lights will come on

during this automatic braking operation.

A trailer weighing less than 70% of the kerb weight of the towing

vehicle may sway quite considerably without the trailer stabilisation

system intervening. This can happen when the swaying movements

of the light-weight trailer are not or hardly passed on to the towing

vehicle and are therefore not detected by the ESP.

If the system for activating the trai ler brake lights is defective, this

will be indicated in the instrument cluster display ⇒page 37, “Bulb

monitor ”.

Requirements for correct functioning of the trailer

stabilisation system

If these conditions are not met in full, the trailer stabilisation system

will only intervene to a limited extent or not at all ⇒.

•

The electrical connection between the towing vehicle and the

trailer must be functioning correctly, without any defects.

•

The load on the trailer must be properly secured.

•

The tyre pressures on both the vehicle and the trailer must be

adapted to the load that is being carried.

•

Where possible, operate the trai ler with the maximum permitted

draw bar weight.

document_0900452a81b1b9de.book Seite 233 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ [[

+-

•

Page 237 of 342

Towing a trailer235

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

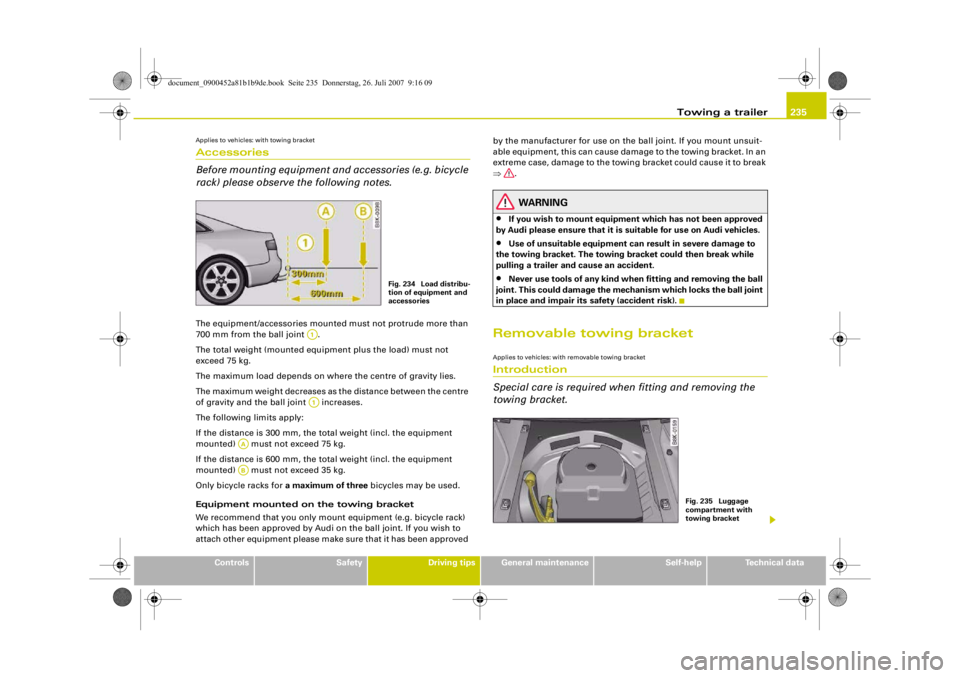

Applies to vehicles: with towing bracketAccessories

Before mounting equipment an d accessories (e.g. bicycle

rack) please observe the following notes.The equipment/accessories mounted must not protrude more than

700 mm from the ball joint .

The total weight (mounted equipment plus the load) must not

exceed 75 kg.

The maximum load depends on where the centre of gravity lies.

The maximum weight decreases as the distance between the centre

of gravity and the ball joint increases.

The following limits apply:

If the distance is 300 mm, the total weight (incl. the equipment

mounted) must not exceed 75 kg.

If the distance is 600 mm, the total weight (incl. the equipment

mounted) must not exceed 35 kg.

Only bicycle racks for a maximum of three bicycles may be used.

Equipment mounted on the towing bracket

We recommend that you only mount equipment (e.g. bicycle rack)

which has been approved by Audi on the ball joint. If you wish to

attach other equipment please make sure that it has been approved by the manufacturer for use on the

ball joint. If you mount unsuit-

able equipment, this can cause dama ge to the towing bracket. In an

extreme case, damage to the towing bracket could cause it to break

⇒ .

WARNING

•

If you wish to mount equipmen t which has not been approved

by Audi please ensure that it is suitable for use on Audi vehicles.

•

Use of unsuitable equipment can result in severe damage to

the towing bracket. The towing bracket could then break while

pulling a trailer and cause an accident.

•

Never use tools of any kind when fitting and removing the ball

joint. This coul d damage the mechanism wh ich locks the ball joint

in place and impair it s safety (accident risk).

Removable towing bracketApplies to vehicles: with removable towing bracketIntroduction

Special care is required when fitting and removing the

towing bracket.

Fig. 234 Load distribu-

tion of equipment and

accessories

A1A1

AAAB

Fig. 235 Luggage

compartment with

towing bracket

document_0900452a81b1b9de.book Seite 235 Donnerstag, 26. Juli 2007 9:16 09

-+

~

®! I

OJ

: G) : I t'I------J t)!Jf!Jlfl

I :

' I +

"(1111

I

I ,Ill

!Jv,JJIJUI

I,. I

--4 -

-T

•

+-

Page 239 of 342

Towing a trailer237

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Also check the shaft section of the ball joint and its asso-

ciated mechanical parts to make sure they are clean and

undamaged.Continued ⇒page 237, “Fitting the ball joint (step 2)”.

WARNING

It is important to keep the mounti ng fixture clean. Otherwise the

ball joint may fail to engage securely (accident risk).Applies to vehicles: with removable towing bracketFitting the ball joint (step 2)The spring mechanism inside the ball joint must

be in the "ready" position.

– Check that the red marking ⇒fig. 238 on the knob is

inside the green zone on the ball joint.

– Check that the locking ball is inside the hole in the shaft section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that there is a clear gap between the knob and the

ball joint.

The ball joint can only be installed if the internal spring mechanism

is in the ready position.

Continued ⇒page 237, “Fitting the ball joint (step 3)”.Applies to vehicles: with removable towing bracketFitting the ball joint (step 3)Setting the spring mechanism to the "ready"

position (if required)

– Insert the key ⇒fig. 239 for locking the ball joint into

the lock on the knob and turn it clockwise.

Fig. 238 Removable

towing bracket: Ball

joint

A2A1A3

Fig. 239 Removable

towing bracket:

Setting the spring

mechanism to the

"ready" positionFig. 240 Removable

towing bracket:

Inserting the ball joint

A4

document_0900452a81b1b9de.book Seite 237 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

Page 241 of 342

Towing a trailer239

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check that the ball joint fits tightly in the mounting

fixture (try moving it about to check).

Electrical socket for trailer

– The cable of the towing bracket can be connected to the socket ⇒page 238, fig. 242.If the safety check is not satisfactory, the ball joint must be fitted

again properly.

WARNING

To avoid accidents, the ball joint must meet all the safety require-

ments listed in the safety check. The towing bracket must not be

used if any one of these requirements is not met. If this is the case,

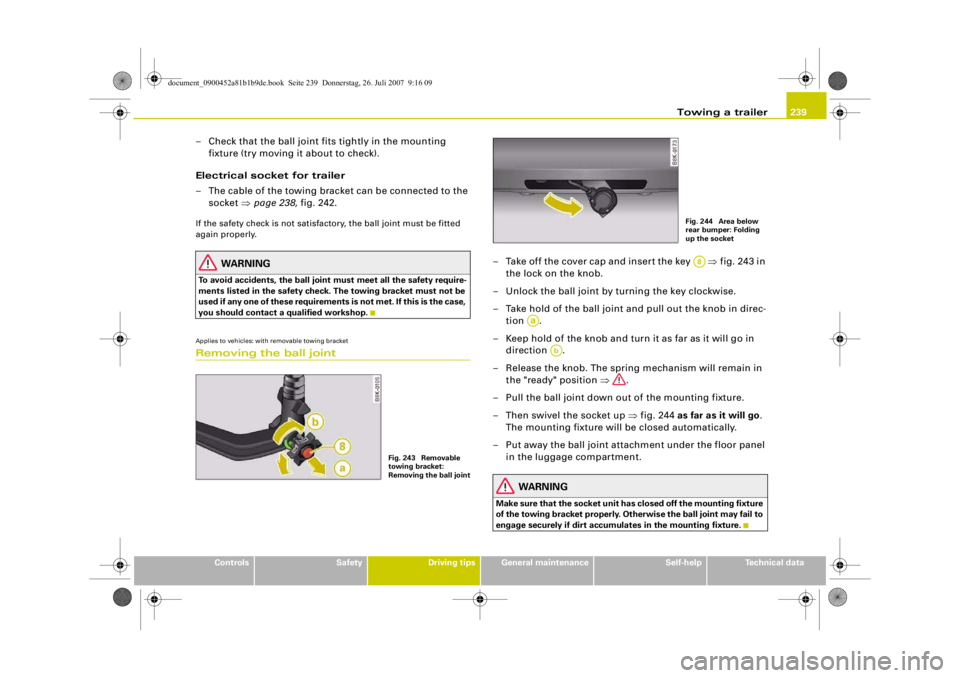

you should contact a qualified workshop.Applies to vehicles: with removable towing bracketRemoving the ball joint

– Take off the cover cap and insert the key ⇒fig. 243 in

the lock on the knob.

– Unlock the ball joint by turning the key clockwise.

– Take hold of the ball joint and pull out the knob in direc- tion .

– Keep hold of the knob and turn it as far as it will go in direction .

– Release the knob. The spring mechanism will remain in the "ready" position ⇒.

– Pull the ball joint down out of the mounting fixture.

– Then swivel the socket up ⇒fig. 244 as far as it will go .

The mounting fixture will be closed automatically.

– Put away the ball joint attachment under the floor panel in the luggage compartment.

WARNING

Make sure that the socket unit has closed off the mounting fixture

of the towing bracket properly. Other wise the ball joint may fail to

engage securely if dirt accumu lates in the mounting fixture.

Fig. 243 Removable

towing bracket:

Removing the ball joint

Fig. 244 Area below

rear bumper: Folding

up the socketA8

Aa

Ab

document_0900452a81b1b9de.book Seite 239 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

. I

Page 243 of 342

Towing a trailer241

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

document_0900452a81b1b9de.book Seite 241 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-