oil AUDI S4 2008 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 259 of 342

Checking and topping up fluids257

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

The positions of the engine oil filler cap and the engine oil dipstick

⇒

page 256, fig. 252 (items and ) may be different on some

engine versions.

Engine oilGeneral notesWe recommend that you have the oil change carried out by an Audi

dealership / qualified workshop according to the intervals stated in

the Service Schedule or according to the service interval display in

the instrument cluster.

Whether your vehicle is serviced at flexible service intervals or fixed

service intervals is shown in the Service Schedule.

The correct oil specifications for your engine are listed in the Te c h -

nical data section ⇒page 323, “Performance, weights and dimen-

sions”.

Check that the specifications quoted (VW standards) appear on the

container either singly or in combination with other specifications.

Flexible service intervals (Audi LongLife Service*)

Special engine oils ⇒page 323, “Performance, weights and dimen-

sions” have been developed as part of the Audi LongLife Service

( ⇒ “Service Schedule”).

This type of oil must be used if you intend to take advantage of the

extended maintenance intervals allowed by the Audi LongLife

Service.•

Do not mix the LongLife oil with oil intended for fixed service

intervals, as the requirements for the extended service intervals are

then no longer guaranteed.

•

In exceptional circumstances, if the engine oil level is too low

⇒ page 258 and you cannot obtain the specified LongLife oil, you

can put in a small quantity of oil for fixed service intervals -

⇒ page 323, “Performance, weights and dimensions”. This should not be done more than once and no more than 0.5 litres should be

used.

Fixed service intervals (Inspection Service)*

If you do not take advantage of th

e LongLife service for your car, you

can use the oils for fixed service intervals - ⇒ page 323, “Perform-

ance, weights and dimensions”. In this case, your car must be serv-

iced after a fixed interval of 1 year / 15,000 km (9,000 miles) – see

Service Schedule.

•

In exceptional circumstances, if the engine oil level is too low

⇒ page 258 and you cannot obtain the oil specified for your vehicle,

you can put in a small quantity of oil conforming to the specification

ACEA A2 or ACEA A3 (petrol engines) or ACEA B3 or ACEA B4 (diesel

engines). This should not be done more than once and no more than

0.5 litres should be used.

Vehicles with diesel particulate filter*

The Service Schedule states whether your vehicle is fitted with a

diesel particulate filter.

•

Vehicles with diesel particulate filter must only be filled with

engine oil VW 507 00. This oil can be used regardless of whether the

vehicle is serviced at flexible service intervals (Audi LongLife

Service) or fixed service intervals.

•

Avoid mixing this oil with other engine oils.

•

In exceptional circumstances, if the engine oil level is too low

⇒ page 258 and you cannot obtain the oil specified for your vehicle,

you can put in a small quantity of oil conforming to the specification

VW 506 00 / VW 506 01 or VW 505 00 / VW 505 01 or ACEA B3 /

ACEA B4. This should not be done more than once and no more than

0.5 litres should be used.

A3

A4

document_0900452a81b1b9de.book Seite 257 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

•

Page 260 of 342

Checking and topping up fluids

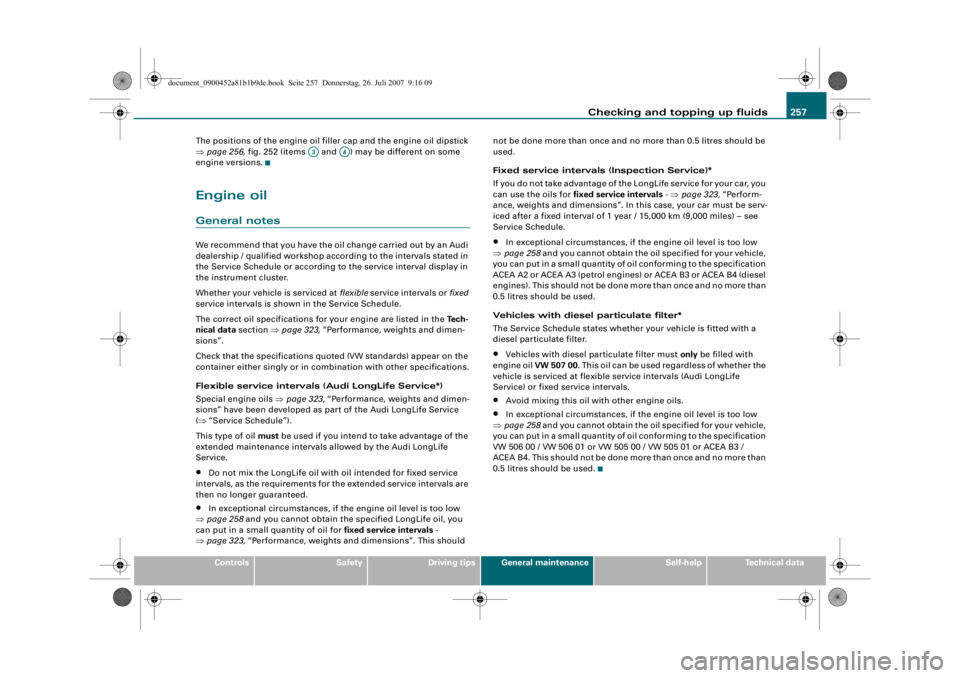

258Checking the oil level (with dipstick)Checking the oil level

– Park your vehicle on a level surface.

– Allow the warm engine to run briefly at idling speed and

then switch off the ignition.

– Wait approx. 2 minutes.

– Pull out the dipstick. Wipe the dipstick with a clean cloth and insert it again, pushing it in as far as it will go. – Then pull the dipstick out again and check the oil level

⇒fig. 253 or ⇒fig. 254. If the oil level is too low, add

more engine oil ⇒page 259 .

Oil level in area

–Do not top up oil.

Oil level in area

–Oil can be topped up. After topping up the oil level should

be in area .

Oil level in area

–Oil must be topped up. After topping up the oil level

should be in area .

Depending on how you drive and the conditions in which the car is

used, oil consumption can be up to 0.5 ltr./1000 km. Oil consump-

tion is likely to be higher for the first 5000 km. You should therefore

check the oil level at regular intervals, ideally every time you fill the

tank, and also before setting off on a long trip.

Fig. 253 Variant 1:

Markings on oil

dipstickFig. 254 Variant 2:

Markings on oil

dipstick

AaAb

Aa

AcAa

document_0900452a81b1b9de.book Seite 258 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

Page 261 of 342

Checking and topping up fluids259

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

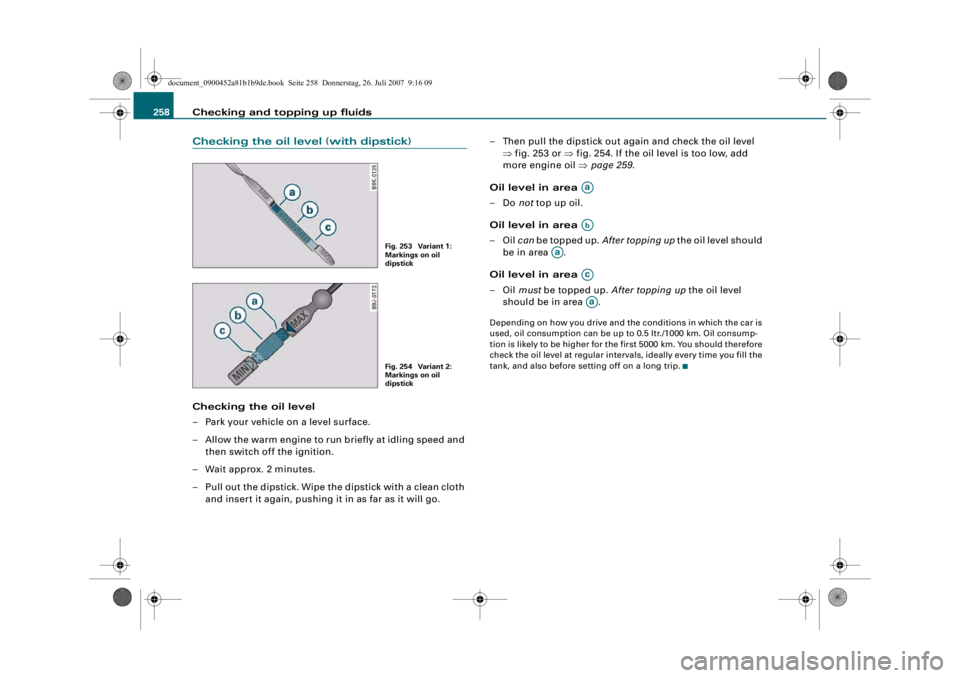

Applies to vehicles: without oil dipstickChecking the oil level (without dipstick)

You can check the engine oil level via the sound system or

MMI*.– Select: Function selector button > Oil level.

– Park your vehicle on a level surface.

– Allow the warm engine to run briefly at idling speed and then switch off the ignition.

– Wait approx. 2 minutes.

– Read off the oil level on the display ⇒fig. 255. Top up the

engine oil if the bar in the oil level display is near the

“min” mark ⇒ page 259.Depending on how you drive and the conditions in which the car is

used, oil consumption can be up to 0.5 ltr./1000 km. Oil consump-

tion is likely to be hi gher for the first 5000 km.

Note

The oil level display is intended solely for information purposes. An

oil level warning will appear in the instrument cluster if the oil level

is too low. Add more oil ⇒ page 259. If the bonnet has been opened, the current oil level will be shown in the instrument cluster the next

time the ignition is switched on.

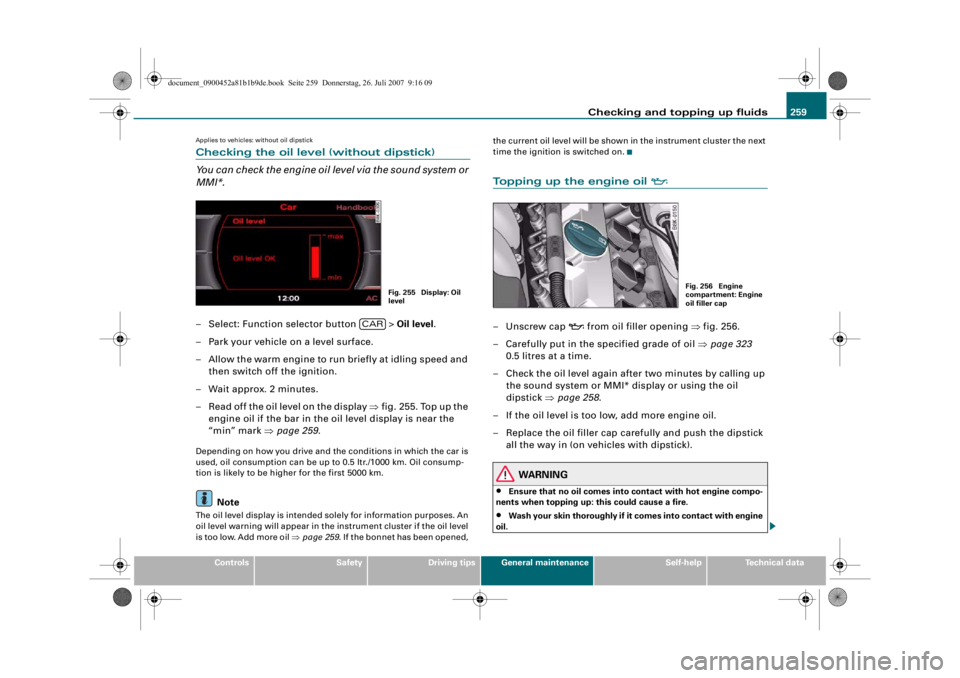

Topping up the engine oil

–Unscrew cap

from oil filler opening

⇒fig. 256.

– Carefully put in the specified grade of oil ⇒page 323

0.5 litres at a time.

– Check the oil level again after two minutes by calling up the sound system or MMI* display or using the oil

dipstick ⇒page 258 .

– If the oil level is too low, add more engine oil.

– Replace the oil filler cap carefully and push the dipstick all the way in (on vehicles with dipstick).

WARNING

•

Ensure that no oil comes into contact with hot engine compo-

nents when topping up: this could cause a fire.

•

Wash your skin thoroughly if it comes into contact with engine

oil.

Fig. 255 Display: Oil

level

CAR

Fig. 256 Engine

compartment: Engine

oil filler cap

document_0900452a81b1b9de.book Seite 259 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

[I]

Page 262 of 342

Checking and topping up fluids

260

Caution•

The oil level must never be above area ⇒page 258, fig. 254,

as this may result in damage to the catalytic converter or to the

engine. On vehicles without an oil dipstick, you can check the oil

level via the sound system or MMI*. Contact a qualified workshop to

extract the engine oil if necessary.

•

No additives should be used with engine oil. Any damage caused

by the use of such additives would not be covered by the factory

warranty.For the sake of the environment

•

Never pour oil down drains or into the ground.

•

Always observe statutory requirements when disposing of

empty oil canisters.

Cooling systemCoolant

The purpose of the coolant is to carry heat away from the

engine. The correct amount of anti-freeze is important to

prevent the cooling system from freezing in winter.The cooling system is filled for life at the factory, so the coolant does

not need to be changed. The coolant consists of a mixture of water

and anti-freeze additive G12++. This is a glycol-based anti-freeze

with anti-corrosion additives.

Anti-freeze additive

The amount of anti-freeze additive required depends on the temper-

atures to be expected in the winter season. If the anti-freeze concen-

tration is too low the coolant can freeze, resulting in failure of the

cooling system and heater. The cooling system is filled at the

factory with the correct amount of

anti-freeze for the country concerned.

In most cases the mixture consists of 60% water and 40% additive.

This mixture gives the required anti-freeze protection at tempera-

tures down to -25 °C and protects the alloy parts of the cooling

system against corrosion. It also prevents scaling and raises the

boiling point of the coolant.

Countries with warm climate

The coolant concentration must not be reduced by adding plain

water, even in the summer or in warm climates. The concentration

of the anti-freeze additive must always be at least 40%.

Countries with cold climate

If greater anti-freeze protection is required in very cold climates, the

proportion of the anti-freeze additive G12++ can be increased. A

concentration of 60% offers protection down to about - 40 °C. The

concentration of the anti -freeze additive must not be more than

60% , otherwise this would reduce the anti-freeze protection. In addi-

tion, the cooling effect wi ll be adversely affected.

Vehicles for export to countries wi th a cold climate (such as Sweden,

Norway and Finland) are supplied wi th antifreeze protection down

to about -35 °C. The concentration of the antifreeze additive for

these countries should always be at least 50%.

Caution

•

It is advisable to have the cooling system checked before the

winter season to make sure that the antifreeze concentration is

adequate for the conditions to be expected. This applies particularly

if you intend to take the car into a colder climate zone. If necessary,

have the anti-freeze concentration increased to 50 - 60% as required.

•

Use only anti-freeze additive G12++, an additive meeting the

specification “TL 774 G”. Other additives may give considerably

inferior corrosion protection. The resulting corrosion in the cooling

system can lead to a loss of coolant, causing serious damage to the

engine.

Aa

document_0900452a81b1b9de.book Seite 260 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-

0

T

-+

•

+-

0

Page 263 of 342

Checking and topping up fluids261

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

•

The coolant additive G12++ can be mixed only with additives

G12+ and G12.

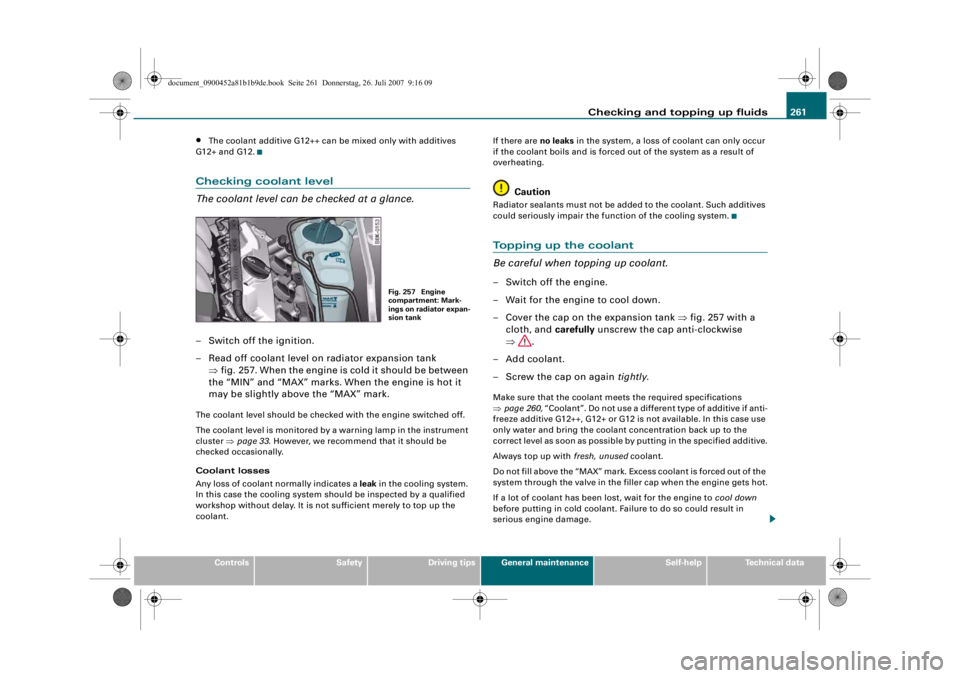

Checking coolant level

The coolant level can be checked at a glance.– Switch off the ignition.

– Read off coolant level on radiator expansion tank ⇒fig. 257. When the engine is cold it should be between

the “MIN” and “MAX” marks. When the engine is hot it

may be slightly above the “MAX” mark.The coolant level should be checke d with the engine switched off.

The coolant level is monitored by a warning lamp in the instrument

cluster ⇒page 33 . However, we recommend that it should be

checked occasionally.

Coolant losses

Any loss of coolant normally indicates a leak in the cooling system.

In this case the cooling system should be inspected by a qualified

workshop without delay. It is not sufficient merely to top up the

coolant. If there are

no leaks in the system, a loss of coolant can only occur

if the coolant boils and is forced out of the system as a result of

overheating.

Caution

Radiator sealants must not be added to the coolant. Such additives

could seriously impair the function of the cooling system.Topping up the coolant

Be careful when topping up coolant.– Switch off the engine.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒fig. 257 with a

cloth, and carefully unscrew the cap anti-clockwise

⇒ .

– Add coolant.

– Screw the cap on again tightly.Make sure that the coolant meets the required specifications

⇒page 260, “Coolant”. Do not use a different type of additive if anti-

freeze additive G12++, G12+ or G12 is not available. In this case use

only water and bring the coolant concentration back up to the

correct level as soon as possible by putting in the specified additive.

Always top up with fresh, unused coolant.

Do not fill above the “MAX” mark. Ex cess coolant is forced out of the

system through the valve in the filler cap when the engine gets hot.

If a lot of coolant has been lost, wait for the engine to cool down

before putting in cold coolant. Failure to do so could result in

serious engine damage.

Fig. 257 Engine

compartment: Mark-

ings on radiator expan-

sion tank

document_0900452a81b1b9de.book Seite 261 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

---- 0

•

-+ +-

Page 265 of 342

Checking and topping up fluids263

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Changing brake fluid

When required, the brake fluid should be changed by a

competent mechanic with the proper equipment.Brake fluid gradually absorbs moisture from the atmosphere. If the

water content in the brake fluid is too high, this may cause corrosion

in the brake system over time. In addition, the boiling point of the

brake fluid will be considerably reduced. This could adversely affect

the braking ability in certain circumstances.

For this reason the brake fluid must be changed periodically.

Your vehicle's Service Schedule will tell you when the brake fluid has

to be changed.

It is advisable to have the brake fluid changed as part of a regular

Inspection Service at your Audi workshop. They are familiar with the

procedure and have the necessary special tools and spare parts as

well as the proper facilities for disposing of the old fluid.

Use only the genuine brake fluid specified by the factory Qualified

workshops know that the brake fluid “DOT 4” is approved by Audi.

The brake fluid must be fresh and unused.

WARNING

•

Brake fluid is poisonous; store it in the sealed original container

in a safe place out of reach of children.

•

Heavy use of the brakes may caus e a vapour lock if the brake

fluid is left in the system for too long. This would seriously affect

the efficiency of the brakes and th e safety of the car – risk of acci-

dent.Caution

Please note that brake fluid will attack the paintwork on contact.

For the sake of the environment

If the fluid has to be drained out of the brake system, use an appro-

priate container to catch the used brake fluid and dispose of it in the

proper manner.BatteryGeneral notes

All work on batteries requires specialist knowledge.The battery is virtually maintenance-free. It is checked as part of the

Inspection Service.

We recommend that you replace a ba ttery once it is older than 5

years.

When an airbag is triggered, the battery will, under certain circum-

stances, be disconnected from the on-board power supply for

safety reasons ⇒ in “General notes on airbag system” on

page 201 .

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will

become inoperative (e.g. electric windows). These functions will

require resetting after the battery is reconnected. For this reason,

the battery should only be disconnected from the vehicle's electrical

system when absolutely necessary.

If the vehicle is not used for long periods

If you do not drive your vehicle for a period of several days or weeks,

the power management will gr adually shut off the on-board

systems one by one, or reduce the amount of current they are using.

This limits the amount of power consumed and helps to ensure reli-

able starting even after a long period ⇒page 226 .

document_0900452a81b1b9de.book Seite 263 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

CD

Page 270 of 342

Wheels and tyres

268Wheels and tyresWheelsGeneral notes–When driving with new tyres , be especially careful during

the first 500 km.

– If you have to drive over a kerb or similar obstacle, drive very slowly and as near as possible at a right angle to the

kerb.

– Inspect the tyres regularly for damage (cuts, cracks or blisters, etc.). Remove any foreign bodies embedded in

the treads.

– Damaged wheels and tyres must be replaced immedi- ately.

– Keep grease, oil and fuel off the tyres.

– Replace any missing valve caps as soon as possible.

– Mark the wheels before taking them off so that they rotate in the same direction when put back.

– When removed, the wheels or tyres should be stored in a cool, dry and preferably dark place.New tyres

New tyres do not give maximum grip straight away and should

therefore be “run in” by driving carefully and at moderate speeds for

about the first 500 km. This will also help to make the tyres last

longer.

The tread depth of new tyres may vary, according to the type and

make of tyre and the tread pattern. Concealed damage

Damage to tyres and rims is often

not readily visible. If you notice

unusual vibration or the car pulling to one side , this may indicate

that one of the tyres is damaged. Reduce speed immediately if there

is any reason to suspect that damage may have occurred. Inspect

the tyres for damage. If no external damage is visible, drive slowly

and carefully to the nearest qualified workshop and have the car

inspected.

Tyres with directional tread pattern

An arrow on the tyre sidewall indicates the direction of rotation on

tyres with directional tread. Always note the direction of rotation

indicated when mounting the wheel. This guarantees optimum grip

and helps to avoid aquaplaning, excessive noise and wear.

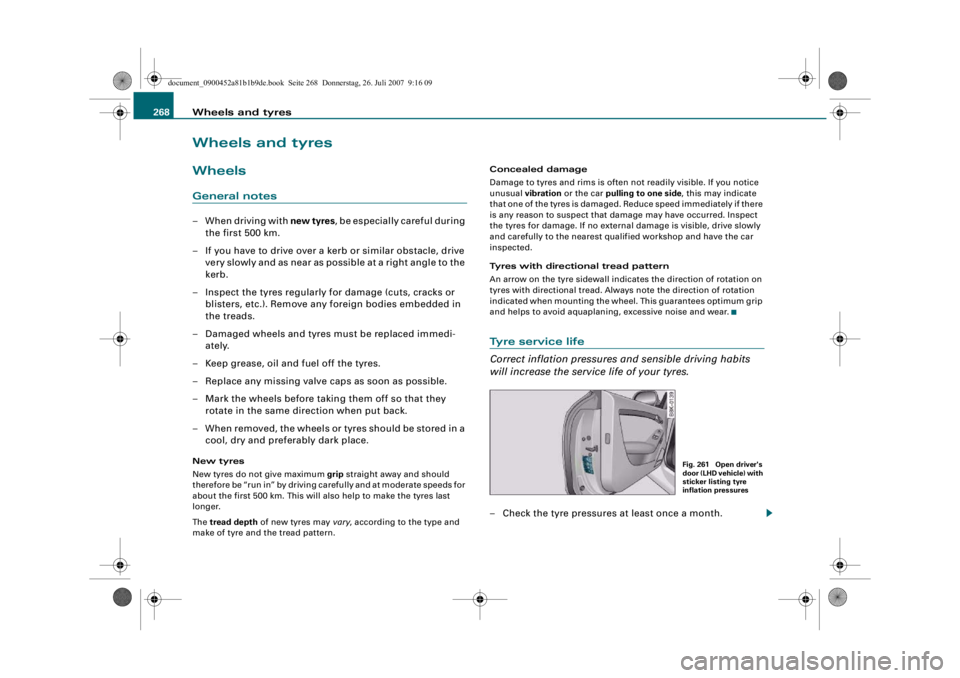

Tyre service life

Correct inflation pressures and sensible driving habits

will increase the service life of your tyres.– Check the tyre pressures at least once a month.

Fig. 261 Open driver's

door (LHD vehicle) with

sticker listing tyre

inflation pressures

document_0900452a81b1b9de.book Seite 268 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

Page 288 of 342

Self-help

286The TMS can be used at outside temperatures down to – 20 °C.

WARNING

After repairing a tyre please note the following points:•

Do not drive faster than 80 km/h.

•

Avoid heavy acceleration, hard braking and fast cornering.

•

Vehicle handling could be impaired.

•

Tyres which have been sealed using the TMS are only suitable

for temporary use. Damaged tyres must be renewed.

•

The TMS must NOT be used,

− on cuts and punctures larger than 4 mm

− if the wheel rim has been damaged

− if you have been driving with very low pressure or a

completely flat tyre

•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

Do not allow the sealant to come into contact with your eyes,

skin or clothing.

•

If you do come into contact wi th the sealant immediately rinse

the eyes or skin affected with clean water.

•

Change clothing immediately if it becomes soiled with the tyre

sealant.

•

Make sure you do not breathe in the fumes!

•

If any of the tyre sealant is a ccidentally ingested, immediately

rinse the mouth thoroughly and drink lots of water.

•

Do not induce vomiting. Immediately contact a doctor!

•

If any allergic reactions should occur get medical help immedi-

ately.

•

Keep the sealant away from children.

For the sake of the environment

Used bottles of sealing compound can be returned to an Audi dealer

for disposal.

Note

•

If sealant should leak out, leave it to dry. When it has dried, you

can pull it off like a piece of foil.

•

Observe the expiry date stated on the sealing compound can.

Have the sealing compound exchanged by a qualified workshop.

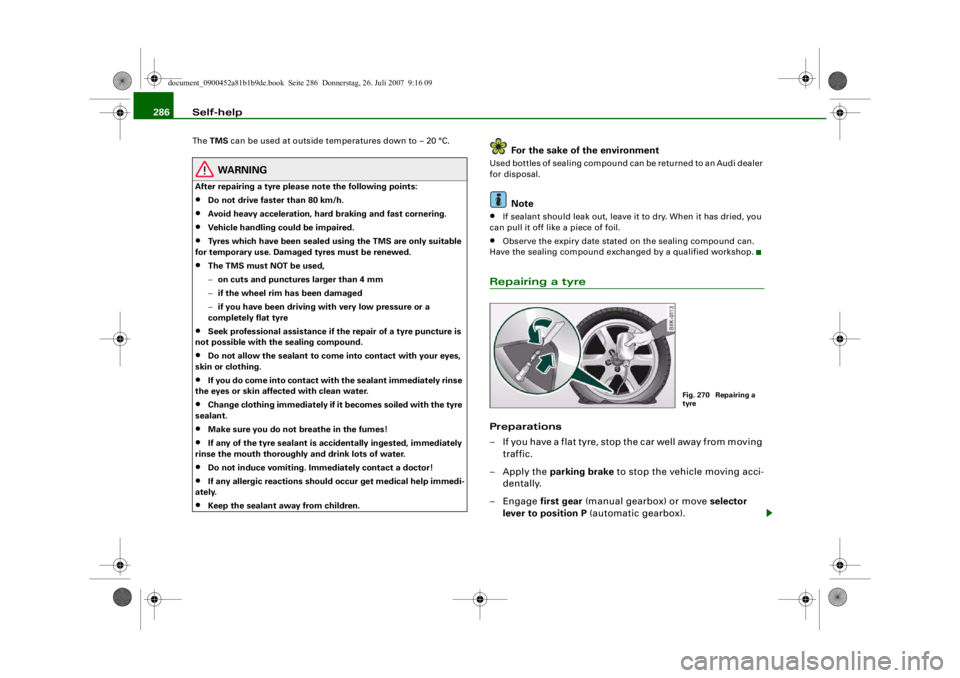

Repairing a tyrePreparations

– If you have a flat tyre, stop the car well away from moving traffic.

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

Fig. 270 Repairing a

tyre

document_0900452a81b1b9de.book Seite 286 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

[I]

•

-+ +-

Page 289 of 342

Self-help287

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check whether a repair is possible using the Tyre

Mobility System ⇒page 285.

– Ensure that all passengers leave the vehicle and move

away from the danger area ⇒.

– Take the tyre sealant can and the electric compressor out

of the luggage compartment ⇒page 283.

– Fix the sticker “max. 80 km/h”, which is included with the tyre sealant can, onto the instrument cluster where the

driver will see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it will go. This will automatically pierce the foil

sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve insert tool to unscrew the valve insert ⇒page 286,

fig. 270.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back into the tyre valve. Inflating the tyre

– Screw the filling hose of th

e electric compressor onto the

tyre valve and plug the connector into the cigarette

lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pres- sure shown on the pressure gauge.

– If the tyre pressure remains lower than the value speci- fied above drive the vehicle approx. 10 metres forwards

or backwards, so that the sealant can spread evenly in

the tyre. If the pressure is still lower than the specifica-

tion the tyre is too badly damaged and cannot be

repaired using the tyre sealant.

Final checks

– After about 10 minutes stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly damaged. Do not drive on. You should obtain profes-

sional assistance.

WARNING

•

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

•

Make sure your passengers wait in a safe place (for instance

behind the roadside crash barrier).

•

Please observe the manufacturers' safety notes on the

compressor and the instructions supplied with the tyre sealant

can.

•

If it was not possible to build up a tyre pressure of 2.0 bar

within 6 minutes this means that the tyre is too badly damaged.

Do not drive on.

document_0900452a81b1b9de.book Seite 287 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

Page 290 of 342

Self-help

288•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10

minutes, the tyre is too badly damaged. Do not drive on. You

should obtain professional assistance.Caution

Take special care if you have to repair a tyre on a gradient.

Note

•

Do not use the compressor for longer than 6 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

•

After carrying out a tyre repair remember to buy a new tyre

sealant can at a qualified workshop. This will ensure that the Tyre

Mobility System is operative again.

•

Please observe the relevant regulations.

Changing a wheelPreparations

Some preparations are necessary before changing a

wheel.– If you have a flat tyre, stop the car well away from moving traffic. Choose a location that is as level as possible.– All passengers should

leave the car. They should wait in

a safe place (for instance behind the roadside crash

barrier).

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

– When towing a trailer: unhitch the trailer from your vehicle.

– Take the tools ⇒ page 283 and the spare wheel*

⇒ page 284 out of the luggage compartment.

WARNING

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel oppo-

site the wheel being changed by placing a stone or similar object

under it to prevent the vehicle from rolling away.

Note

Please observe the relevant regulations.How to change a wheel

Change the wheel as described below.–Pull off the hub cap . Also refer to ⇒page 289, “Hub

caps”.

WARNING (continued)

document_0900452a81b1b9de.book Seite 288 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I)

-+

I&

+-

0

•

•