towing AUDI S4 2008 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 235 of 342

Towing a trailer233

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

additional mirrors fitted. Both exterior mirrors should be mounted

on hinged extension brackets. Adjust the mirrors to give sufficient

vision to the rear.

Headlights

Before starting a journey, check

the headlight beam settings with

the trailer hitched up. If necessary, alter the height of the headlight

beams by means of the headlight range control ⇒page 60 .

Power supply

When you remove the ignition key the power supply to the trailer is

interrupted.

Removable ball joint coupling

Vehicles with a factory-fitted towing bracket are equipped with a

removable ball joint coupling. It is carried under the floor panel on

the left-hand side of the luggage compartment and is secured by a

strap.

Note

We recommend having the car serviced between the normal inspec-

tion intervals if it used frequently for towing a trailer.Applies to vehicles: with towing bracketTrailer stabilisation system

Trailer stabilisation helps to reduce the risk of the vehicle

skidding when towing a trailer.The trailer stabilisation system is operational only when the ESP is

switched on and there is no malfunction in the ESP ⇒page 17 .

When is the trailer stab ilisation system activated?

Trailer stabilisation is active when the following requirements are

met:•

The ESP must NOT be switched off ⇒page 222 ,

•

The trailer connector must be properly secured in the vehicle

socket.

•

Vehicle speed must be higher than approx. 60 km/h.

How trailer stabilisation works:

In many cases, the driver can stabilise a swaying trailer by manually

braking the vehicle.

However, if the ESP detects that th e trailer is swaying and this is

affecting the towing vehicle, it will automatically brake the vehicle

to stabilise the trailer by slowing it down. The warning lamp

will

light up in the instrument cluste r. If possible, do not turn the

steering wheel at this stage.

In order to warn traffic behind you, the brake lights will come on

during this automatic braking operation.

A trailer weighing less than 70% of the kerb weight of the towing

vehicle may sway quite considerably without the trailer stabilisation

system intervening. This can happen when the swaying movements

of the light-weight trailer are not or hardly passed on to the towing

vehicle and are therefore not detected by the ESP.

If the system for activating the trai ler brake lights is defective, this

will be indicated in the instrument cluster display ⇒page 37, “Bulb

monitor ”.

Requirements for correct functioning of the trailer

stabilisation system

If these conditions are not met in full, the trailer stabilisation system

will only intervene to a limited extent or not at all ⇒.

•

The electrical connection between the towing vehicle and the

trailer must be functioning correctly, without any defects.

•

The load on the trailer must be properly secured.

•

The tyre pressures on both the vehicle and the trailer must be

adapted to the load that is being carried.

•

Where possible, operate the trai ler with the maximum permitted

draw bar weight.

document_0900452a81b1b9de.book Seite 233 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ [[

+-

•

Page 236 of 342

Towing a trailer

234•

The trailer overrun brake must be set correctly. This is important

to ensure that the trailer can be br aked correctly, to avoid the vehicle

and trailer “jack-knifing” and to pr event excess braking of the trailer.

•

At low outside temperatures, both the towing vehicle and the

trailer should be fitted with winter tyres.

WARNING

It is essential that you adjust your speed to suit the weather, road

and traffic conditions. Do not let the trailer stabilisation system

tempt you into taking any risks wh en driving – this can cause acci-

dents.•

The ESP and trailer stabilisatio n system cannot defy the laws

of physics. This should be kept in mind, particularly on slippery

and wet roads and when towing a trailer with a light load.

•

The trailer stabilisation system is functional, regardless of

whether the trailer has a mechanical overrun brake or not.

•

The trailer stabilisation system is not always able to detect

swaying of trailers with a light load and will therefore not inter-

vene.

•

A trailer can still “jack-knife” on slippery roads with little grip,

even if the towing vehicle is eq uipped with the trailer stabilisation

system.

•

Trailers with a high centre of gravity may even tip over before

they start to sway sideways.

•

If you are not towing a trailer, but the trailer socket is being

used (e.g. for an illuminated bicycl e rack), the trailer stabilisation

system may be activated in extreme driving conditions.

•

Please note the additional information and warnings

⇒ page 234 .

Notes on towing

Driving with a trailer always requires extra care.Weight distribution

Try to avoid towing a loaded trailer with an unladen vehicle. If this

cannot be avoided, drive extra slowly to allow for the unbalanced

weight distribution.

Speed

The stability of the car and trailer is reduced with increasing speed.

For this reason it is advisable not to drive at the maximum permis-

sible top speed in unfavourable road, weather or wind conditions.

This applies especially on a downhill gradient.

You should always reduce speed immediately if the trailer shows

the slightest sign of swaying. Never try to stop the swaying by accel-

erating further.

Always brake in good time. If the trailer has an overrun brake, apply

the brakes gently at first and then firmly. This will prevent the jerking

that can be caused by the trailer wheels locking. Change down in

good time before going down a steep hill so that you can use the

engine braking effect to slow down the vehicle.

Swaying and pitching can be reduced by stabiliser aids. We recom-

mend having stabiliser aids installed when towing trailers with a

high trailer weight. They can be purchased and installed at an Audi

dealer.

Overheating

When climbing long hills in hot weather with the engine running

fast in low gear, you should keep an eye on the coolant temperature

gauge ⇒page 11 . Reduce speed immediately if the needle moves to

the top end of the scale. If the temperature warning lamp

in the

instrument cluster should start flashing, stop the car and let the

engine cool down by running it at idling speed for a few minutes.

document_0900452a81b1b9de.book Seite 234 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

•

Page 237 of 342

Towing a trailer235

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

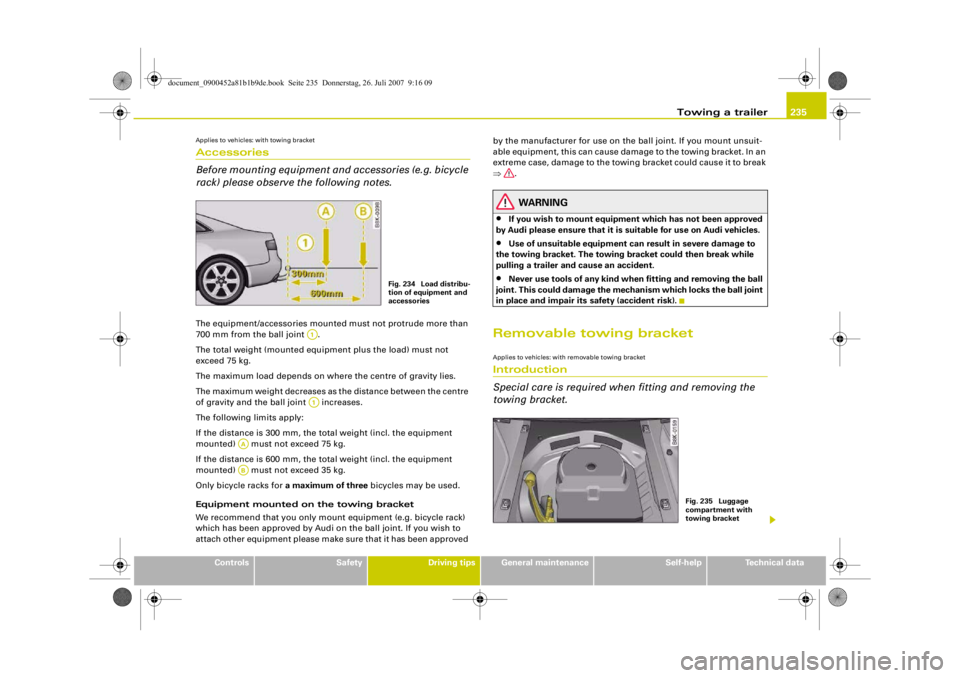

Applies to vehicles: with towing bracketAccessories

Before mounting equipment an d accessories (e.g. bicycle

rack) please observe the following notes.The equipment/accessories mounted must not protrude more than

700 mm from the ball joint .

The total weight (mounted equipment plus the load) must not

exceed 75 kg.

The maximum load depends on where the centre of gravity lies.

The maximum weight decreases as the distance between the centre

of gravity and the ball joint increases.

The following limits apply:

If the distance is 300 mm, the total weight (incl. the equipment

mounted) must not exceed 75 kg.

If the distance is 600 mm, the total weight (incl. the equipment

mounted) must not exceed 35 kg.

Only bicycle racks for a maximum of three bicycles may be used.

Equipment mounted on the towing bracket

We recommend that you only mount equipment (e.g. bicycle rack)

which has been approved by Audi on the ball joint. If you wish to

attach other equipment please make sure that it has been approved by the manufacturer for use on the

ball joint. If you mount unsuit-

able equipment, this can cause dama ge to the towing bracket. In an

extreme case, damage to the towing bracket could cause it to break

⇒ .

WARNING

•

If you wish to mount equipmen t which has not been approved

by Audi please ensure that it is suitable for use on Audi vehicles.

•

Use of unsuitable equipment can result in severe damage to

the towing bracket. The towing bracket could then break while

pulling a trailer and cause an accident.

•

Never use tools of any kind when fitting and removing the ball

joint. This coul d damage the mechanism wh ich locks the ball joint

in place and impair it s safety (accident risk).

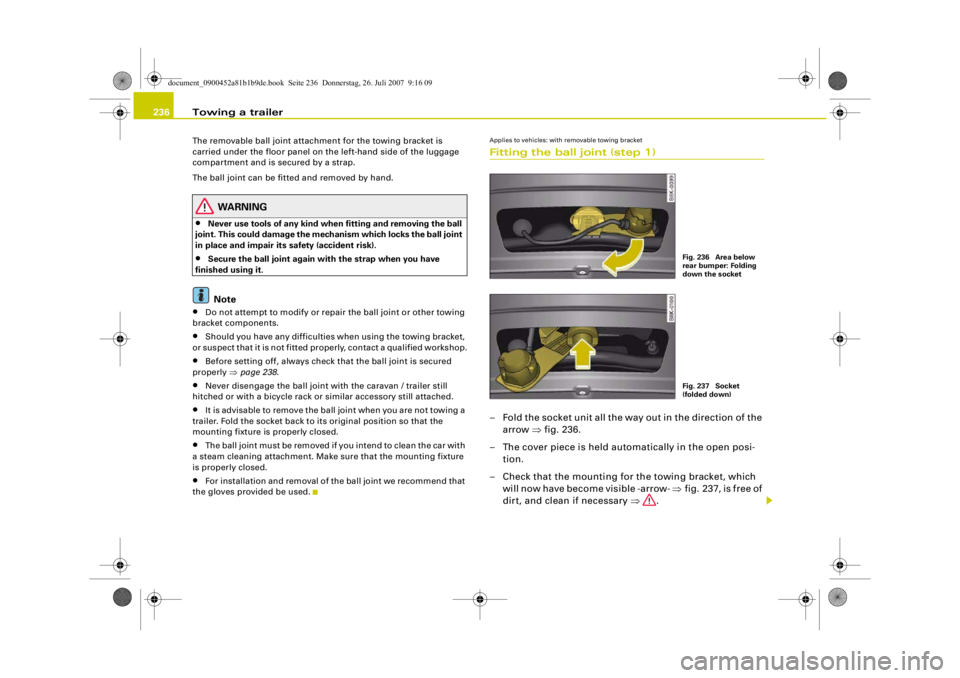

Removable towing bracketApplies to vehicles: with removable towing bracketIntroduction

Special care is required when fitting and removing the

towing bracket.

Fig. 234 Load distribu-

tion of equipment and

accessories

A1A1

AAAB

Fig. 235 Luggage

compartment with

towing bracket

document_0900452a81b1b9de.book Seite 235 Donnerstag, 26. Juli 2007 9:16 09

-+

~

®! I

OJ

: G) : I t'I------J t)!Jf!Jlfl

I :

' I +

"(1111

I

I ,Ill

!Jv,JJIJUI

I,. I

--4 -

-T

•

+-

Page 238 of 342

Towing a trailer

236The removable ball joint attachment for the towing bracket is

carried under the floor panel on the left-hand side of the luggage

compartment and is secured by a strap.

The ball joint can be fitted and removed by hand.

WARNING

•

Never use tools of any kind when fitting and removing the ball

joint. This coul d damage the mechanism wh ich locks the ball joint

in place and impair it s safety (accident risk).

•

Secure the ball joint again wi th the strap when you have

finished using it.Note

•

Do not attempt to modify or repair the ball joint or other towing

bracket components.

•

Should you have any difficulties when using the towing bracket,

or suspect that it is not fitted properly, contact a qualified workshop.

•

Before setting off, always check that the ball joint is secured

properly ⇒page 238 .

•

Never disengage the ball joint with the caravan / trailer still

hitched or with a bicycle rack or similar accessory still attached.

•

It is advisable to remove the ball joint when you are not towing a

trailer. Fold the socket back to its original position so that the

mounting fixture is properly closed.

•

The ball joint must be removed if you intend to clean the car with

a steam cleaning attachment. Make sure that the mounting fixture

is properly closed.

•

For installation and removal of the ball joint we recommend that

the gloves provided be used.

Applies to vehicles: with removable towing bracketFitting the ball joint (step 1)– Fold the socket unit all the way out in the direction of the arrow ⇒fig. 236.

– The cover piece is held automatically in the open posi- tion.

– Check that the mounting for the towing bracket, which will now have become visible -arrow- ⇒fig. 237, is free of

dirt, and clean if necessary ⇒.

Fig. 236 Area below

rear bumper: Folding

down the socketFig. 237 Socket

(folded down)

document_0900452a81b1b9de.book Seite 236 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

[I]

-+ +-

•

Page 239 of 342

Towing a trailer237

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Also check the shaft section of the ball joint and its asso-

ciated mechanical parts to make sure they are clean and

undamaged.Continued ⇒page 237, “Fitting the ball joint (step 2)”.

WARNING

It is important to keep the mounti ng fixture clean. Otherwise the

ball joint may fail to engage securely (accident risk).Applies to vehicles: with removable towing bracketFitting the ball joint (step 2)The spring mechanism inside the ball joint must

be in the "ready" position.

– Check that the red marking ⇒fig. 238 on the knob is

inside the green zone on the ball joint.

– Check that the locking ball is inside the hole in the shaft section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that there is a clear gap between the knob and the

ball joint.

The ball joint can only be installed if the internal spring mechanism

is in the ready position.

Continued ⇒page 237, “Fitting the ball joint (step 3)”.Applies to vehicles: with removable towing bracketFitting the ball joint (step 3)Setting the spring mechanism to the "ready"

position (if required)

– Insert the key ⇒fig. 239 for locking the ball joint into

the lock on the knob and turn it clockwise.

Fig. 238 Removable

towing bracket: Ball

joint

A2A1A3

Fig. 239 Removable

towing bracket:

Setting the spring

mechanism to the

"ready" positionFig. 240 Removable

towing bracket:

Inserting the ball joint

A4

document_0900452a81b1b9de.book Seite 237 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

Page 240 of 342

Towing a trailer

238

– Pull out the knob in direction , hold and turn in direc-tion until the locking ball engages ⇒.

Inserting the ball joint

– With the spring mechanism in the “ready” position, insert the ball joint into the mounting fixture and push it

upwards ⇒page 237, fig. 240 in the direction indicated

(arrow) ⇒. The spring mechanism should then

engage automatically wi th an audible click.

– Lock the ball joint by turn ing the key anti-clockwise.

– Take out the key and press the cover cap provided onto the lock.Continued ⇒page 238, “Fitting the ball joint (step 4)”.

WARNING

•

If it is not possible to set th e spring mechanism to the "ready"

position as described abov e, do not use the ball joint. Please take

your vehicle to a qualified workshop.

•

To avoid injury, keep your hand s away from the knob and the

cover piece when inserting the ball joint into the mounting fixture.Note

Make sure that the knob can turn freely when the ball joint is

inserted.

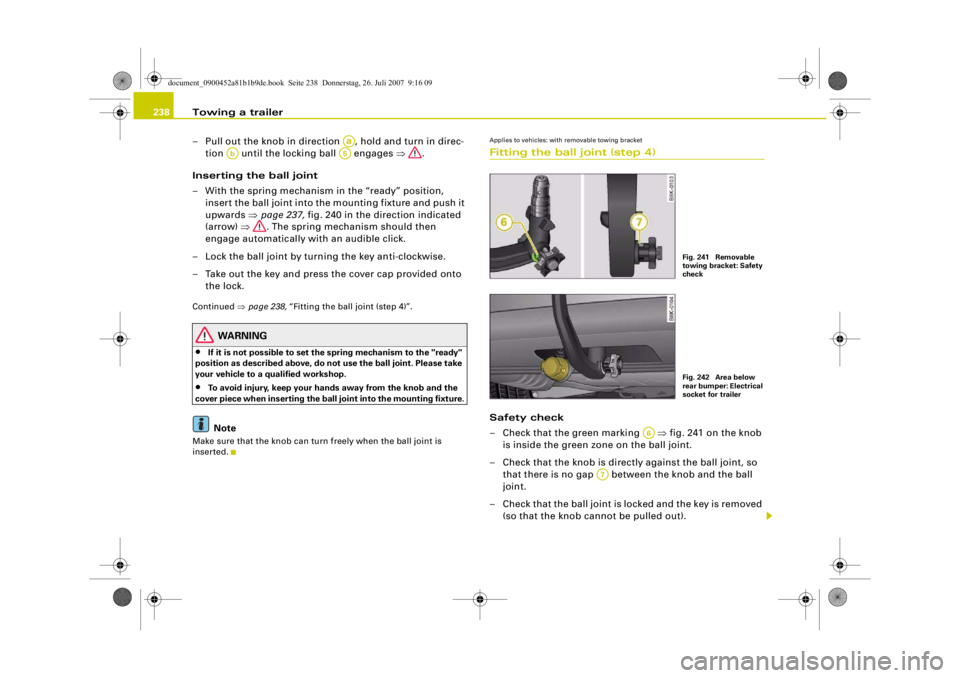

Applies to vehicles: with removable towing bracketFitting the ball joint (step 4)Safety check

– Check that the green marking ⇒fig. 241 on the knob

is inside the green zone on the ball joint.

– Check that the knob is directly against the ball joint, so that there is no gap between the knob and the ball

joint.

– Check that the ball joint is locked and the key is removed (so that the knob cannot be pulled out).

Aa

Ab

A5

Fig. 241 Removable

towing bracket: Safety

checkFig. 242 Area below

rear bumper: Electrical

socket for trailer

A6

A7

document_0900452a81b1b9de.book Seite 238 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

r-----6

-----------j

+-

[I]

•

Page 241 of 342

Towing a trailer239

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Check that the ball joint fits tightly in the mounting

fixture (try moving it about to check).

Electrical socket for trailer

– The cable of the towing bracket can be connected to the socket ⇒page 238, fig. 242.If the safety check is not satisfactory, the ball joint must be fitted

again properly.

WARNING

To avoid accidents, the ball joint must meet all the safety require-

ments listed in the safety check. The towing bracket must not be

used if any one of these requirements is not met. If this is the case,

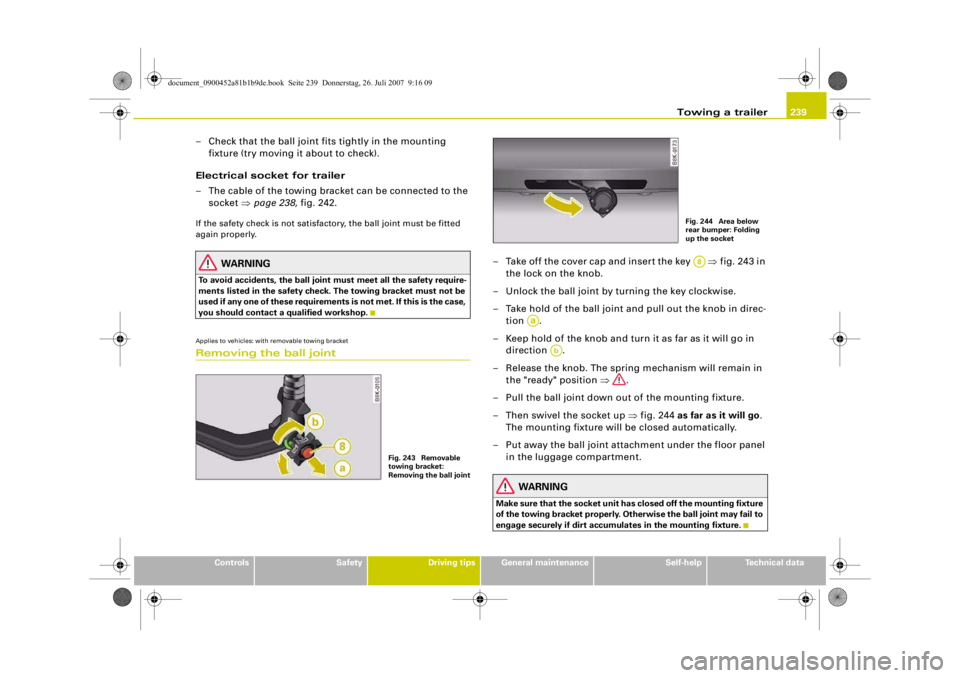

you should contact a qualified workshop.Applies to vehicles: with removable towing bracketRemoving the ball joint

– Take off the cover cap and insert the key ⇒fig. 243 in

the lock on the knob.

– Unlock the ball joint by turning the key clockwise.

– Take hold of the ball joint and pull out the knob in direc- tion .

– Keep hold of the knob and turn it as far as it will go in direction .

– Release the knob. The spring mechanism will remain in the "ready" position ⇒.

– Pull the ball joint down out of the mounting fixture.

– Then swivel the socket up ⇒fig. 244 as far as it will go .

The mounting fixture will be closed automatically.

– Put away the ball joint attachment under the floor panel in the luggage compartment.

WARNING

Make sure that the socket unit has closed off the mounting fixture

of the towing bracket properly. Other wise the ball joint may fail to

engage securely if dirt accumu lates in the mounting fixture.

Fig. 243 Removable

towing bracket:

Removing the ball joint

Fig. 244 Area below

rear bumper: Folding

up the socketA8

Aa

Ab

document_0900452a81b1b9de.book Seite 239 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

•

+-

. I

Page 242 of 342

Towing a trailer

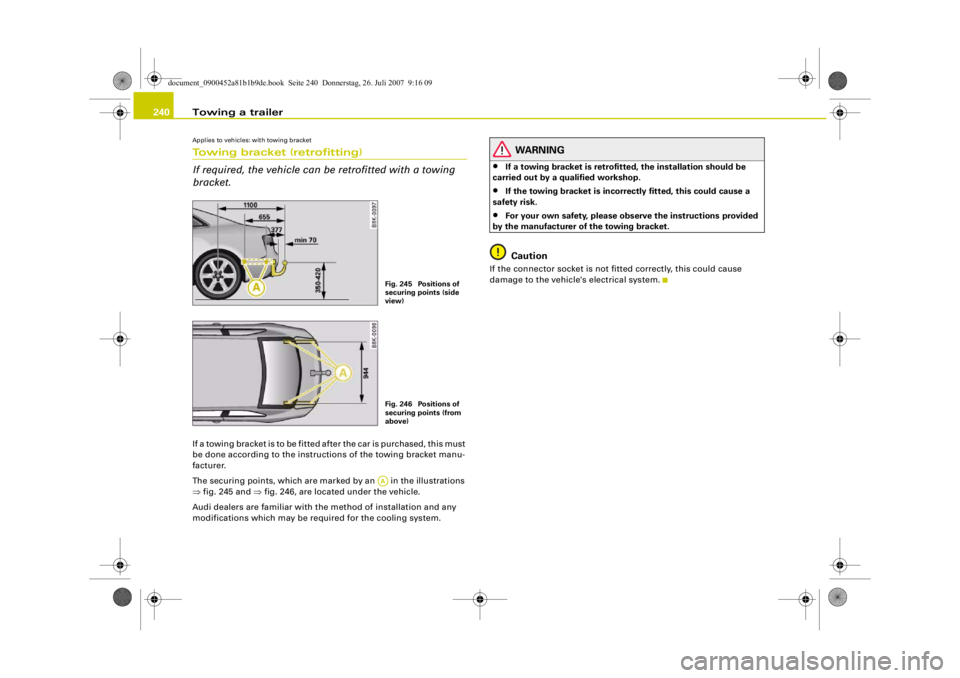

240Applies to vehicles: with towing bracketTowing bracket (retrofitting)

If required, the vehicle can be retrofitted with a towing

bracket.If a towing bracket is to be fitted after the car is purchased, this must

be done according to the instructions of the towing bracket manu-

facturer.

The securing points, which are marked by an in the illustrations

⇒ fig. 245 and ⇒ fig. 246, are located under the vehicle.

Audi dealers are familiar with th e method of installation and any

modifications which may be required for the cooling system.

WARNING

•

If a towing bracket is retrofitted, the installation should be

carried out by a qualified workshop.

•

If the towing bracket is incorrectly fitted, this could cause a

safety risk.

•

For your own safety, please ob serve the instructions provided

by the manufacturer of the towing bracket.Caution

If the connector socket is not fi tted correctly, this could cause

damage to the vehicle's electrical system.

Fig. 245 Positions of

securing points (side

view)Fig. 246 Positions of

securing points (from

above)AA

document_0900452a81b1b9de.book Seite 240 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

! "'

CD

•

-+

-

~

-

='-..

'"

~

I

1

...,~

l +

I

i

+-

A

,

I

j

- "'

~

-

_-:,_/

-

Page 243 of 342

Towing a trailer241

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

document_0900452a81b1b9de.book Seite 241 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

Page 286 of 342

Self-help

284If you need the tools, the Tyre Mobili ty System or the jack*, you will

have to open the floor panel and take out the spare wheel*

⇒ page 284 .

The tool kit includes:•

A hook for removing hub caps

•

Pin for mounting a wheel

•

Screwdriver with reversible blade

•

Tool for changing bulbs

•

Interchangeable socket (Torx socket for changing bulbs)

•

Crank handle for jack

•

Adapter for anti-theft wheel bolts*

•

Jack*

•

Box spanner for wheel bolts

•

Towline anchorage

Some of the parts listed are only fitted on certain models or are

optional extras.

Before stowing the jack* again, wind down the arm of the jack as far

as it will go.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to

tighten the wheel bolts. It is not po ssible to tighten the bolts with

the required torque – risk of accident.

•

The jack supplied by the factor y is only designed for changing

wheels on this model. On no account attempt to use it for lifting

heavier vehicles or other loads – risk of injury.

•

Never start the engine when the vehicle is on the jack - risk of

accident.

•

If work has to be done under the ve h i cl e , e n su re t h a t i t is sa fe l y

supported on stands designed for th e purpose, otherwise there is

a risk of injury.

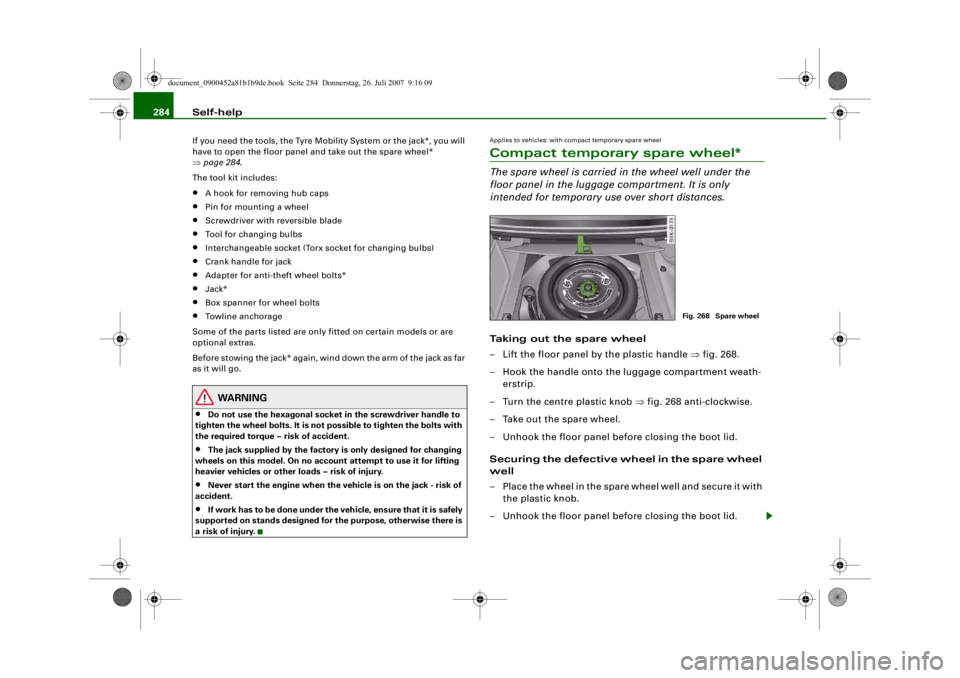

Applies to vehicles: with compact temporary spare wheelCompact temporary spare wheel*The spare wheel is carried in the wheel well under the

floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

– Lift the floor panel by the plastic handle ⇒fig. 268.

– Hook the handle onto the luggage compartment weath- erstrip.

– Turn the centre plastic knob ⇒ fig. 268 anti-clockwise.

– Take out the spare wheel.

– Unhook the floor panel before closing the boot lid.

Securing the defective wheel in the spare wheel

well

– Place the wheel in the spare wheel well and secure it with the plastic knob.

– Unhook the floor panel before closing the boot lid.

Fig. 268 Spare wheel

document_0900452a81b1b9de.book Seite 284 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•