lock AUDI S4 2008 Manual PDF

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S4, Model: AUDI S4 2008Pages: 342, PDF Size: 15.01 MB

Page 263 of 342

Checking and topping up fluids261

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

•

The coolant additive G12++ can be mixed only with additives

G12+ and G12.

Checking coolant level

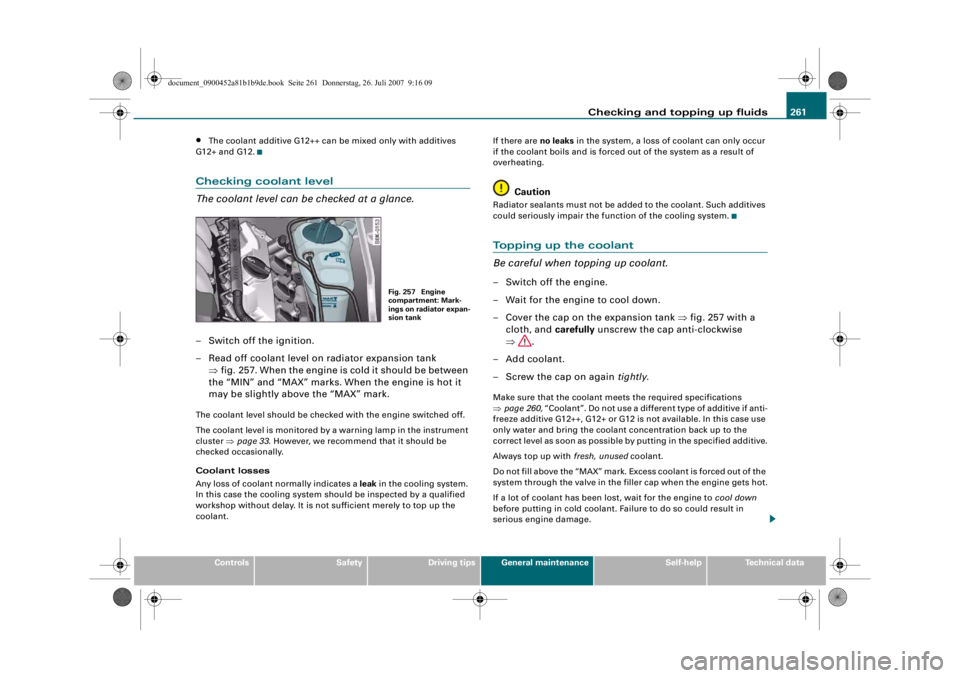

The coolant level can be checked at a glance.– Switch off the ignition.

– Read off coolant level on radiator expansion tank ⇒fig. 257. When the engine is cold it should be between

the “MIN” and “MAX” marks. When the engine is hot it

may be slightly above the “MAX” mark.The coolant level should be checke d with the engine switched off.

The coolant level is monitored by a warning lamp in the instrument

cluster ⇒page 33 . However, we recommend that it should be

checked occasionally.

Coolant losses

Any loss of coolant normally indicates a leak in the cooling system.

In this case the cooling system should be inspected by a qualified

workshop without delay. It is not sufficient merely to top up the

coolant. If there are

no leaks in the system, a loss of coolant can only occur

if the coolant boils and is forced out of the system as a result of

overheating.

Caution

Radiator sealants must not be added to the coolant. Such additives

could seriously impair the function of the cooling system.Topping up the coolant

Be careful when topping up coolant.– Switch off the engine.

– Wait for the engine to cool down.

– Cover the cap on the expansion tank ⇒fig. 257 with a

cloth, and carefully unscrew the cap anti-clockwise

⇒ .

– Add coolant.

– Screw the cap on again tightly.Make sure that the coolant meets the required specifications

⇒page 260, “Coolant”. Do not use a different type of additive if anti-

freeze additive G12++, G12+ or G12 is not available. In this case use

only water and bring the coolant concentration back up to the

correct level as soon as possible by putting in the specified additive.

Always top up with fresh, unused coolant.

Do not fill above the “MAX” mark. Ex cess coolant is forced out of the

system through the valve in the filler cap when the engine gets hot.

If a lot of coolant has been lost, wait for the engine to cool down

before putting in cold coolant. Failure to do so could result in

serious engine damage.

Fig. 257 Engine

compartment: Mark-

ings on radiator expan-

sion tank

document_0900452a81b1b9de.book Seite 261 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

---- 0

•

-+ +-

Page 265 of 342

Checking and topping up fluids263

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Changing brake fluid

When required, the brake fluid should be changed by a

competent mechanic with the proper equipment.Brake fluid gradually absorbs moisture from the atmosphere. If the

water content in the brake fluid is too high, this may cause corrosion

in the brake system over time. In addition, the boiling point of the

brake fluid will be considerably reduced. This could adversely affect

the braking ability in certain circumstances.

For this reason the brake fluid must be changed periodically.

Your vehicle's Service Schedule will tell you when the brake fluid has

to be changed.

It is advisable to have the brake fluid changed as part of a regular

Inspection Service at your Audi workshop. They are familiar with the

procedure and have the necessary special tools and spare parts as

well as the proper facilities for disposing of the old fluid.

Use only the genuine brake fluid specified by the factory Qualified

workshops know that the brake fluid “DOT 4” is approved by Audi.

The brake fluid must be fresh and unused.

WARNING

•

Brake fluid is poisonous; store it in the sealed original container

in a safe place out of reach of children.

•

Heavy use of the brakes may caus e a vapour lock if the brake

fluid is left in the system for too long. This would seriously affect

the efficiency of the brakes and th e safety of the car – risk of acci-

dent.Caution

Please note that brake fluid will attack the paintwork on contact.

For the sake of the environment

If the fluid has to be drained out of the brake system, use an appro-

priate container to catch the used brake fluid and dispose of it in the

proper manner.BatteryGeneral notes

All work on batteries requires specialist knowledge.The battery is virtually maintenance-free. It is checked as part of the

Inspection Service.

We recommend that you replace a ba ttery once it is older than 5

years.

When an airbag is triggered, the battery will, under certain circum-

stances, be disconnected from the on-board power supply for

safety reasons ⇒ in “General notes on airbag system” on

page 201 .

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will

become inoperative (e.g. electric windows). These functions will

require resetting after the battery is reconnected. For this reason,

the battery should only be disconnected from the vehicle's electrical

system when absolutely necessary.

If the vehicle is not used for long periods

If you do not drive your vehicle for a period of several days or weeks,

the power management will gr adually shut off the on-board

systems one by one, or reduce the amount of current they are using.

This limits the amount of power consumed and helps to ensure reli-

able starting even after a long period ⇒page 226 .

document_0900452a81b1b9de.book Seite 263 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

-+ +-

CD

Page 266 of 342

Checking and topping up fluids

264Please note that certain convenience features, such as the Audi

advanced key*, the remote control ke y or the electrical seat adjust-

ment may not be available when you unlock the vehicle. These func-

tions will be restored when you swit ch on the ignition and start the

engine.

Winter conditions

At low temperatures the battery has to work very hard. It also

provides only a fraction of the starting power it has at normal

temperatures.

For this reason, we recommend having the battery checked and

charged if necessary before the start of winter ⇒page 265 .

WARNING

•

All work on batteries requires s pecialist knowledge. For queries

regarding the vehicle battery please contact an Audi dealership or

other qualified workshop (risk of chemical burns / risk of explo-

sion).

•

The battery must not be opened. Do not attempt to make any

changes to the electrolyte level of the battery. Otherwise, there is

a risk that a mixture of oxygen and hydrogen gas can accumulate

and cause an explosion.Note

If the vehicle is to be left standing for a period of several weeks at

extremely low temperatures, the battery should be removed from

the vehicle. This ensures that it cannot “freeze up” and be

damaged.

Important safety warnings for handling a car battery

All work on batteries requires specialist knowledge.The vehicle battery is located unde r the floor panel in the luggage

compartment.

WARNING

Always be aware of the danger of injury and chemical burns as

well as the risk of accident or fire when working on the battery and

the electrical system.•

Wear safety glasses. Do not allow acid or lead particles to come

into contact with eyes, skin or clothing.

•

Battery acid is extremely corrosi ve. Wear protective gloves and

safety glasses. Do not tilt the ba ttery - acid can leak out of the

vapour vent. If electrolyte should splash into the eyes rinse at once

for several minutes using clear wa ter. Then seek medical care

immediately. Neutralize any acid splashes on the skin or clothing

with soap solution, and rinse off with plenty of water. If acid is

swallowed by mistake, cons ult a doctor immediately.

•

Keep open flames, sparks, uncovered lights and lit cigarettes

away from battery. Avoid sparks (including those from static

Wear safety glasses!

Battery acid is extremely corrosive. Wear protec-

tive gloves and safety glasses.

Keep open flames, sparks, uncovered lights and

lit cigarettes away from battery!

A highly explosive mixture of gases is given off

when the battery is under charge!

Keep children away from the battery and battery

acid.

document_0900452a81b1b9de.book Seite 264 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

[I]

•

Page 286 of 342

Self-help

284If you need the tools, the Tyre Mobili ty System or the jack*, you will

have to open the floor panel and take out the spare wheel*

⇒ page 284 .

The tool kit includes:•

A hook for removing hub caps

•

Pin for mounting a wheel

•

Screwdriver with reversible blade

•

Tool for changing bulbs

•

Interchangeable socket (Torx socket for changing bulbs)

•

Crank handle for jack

•

Adapter for anti-theft wheel bolts*

•

Jack*

•

Box spanner for wheel bolts

•

Towline anchorage

Some of the parts listed are only fitted on certain models or are

optional extras.

Before stowing the jack* again, wind down the arm of the jack as far

as it will go.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to

tighten the wheel bolts. It is not po ssible to tighten the bolts with

the required torque – risk of accident.

•

The jack supplied by the factor y is only designed for changing

wheels on this model. On no account attempt to use it for lifting

heavier vehicles or other loads – risk of injury.

•

Never start the engine when the vehicle is on the jack - risk of

accident.

•

If work has to be done under the ve h i cl e , e n su re t h a t i t is sa fe l y

supported on stands designed for th e purpose, otherwise there is

a risk of injury.

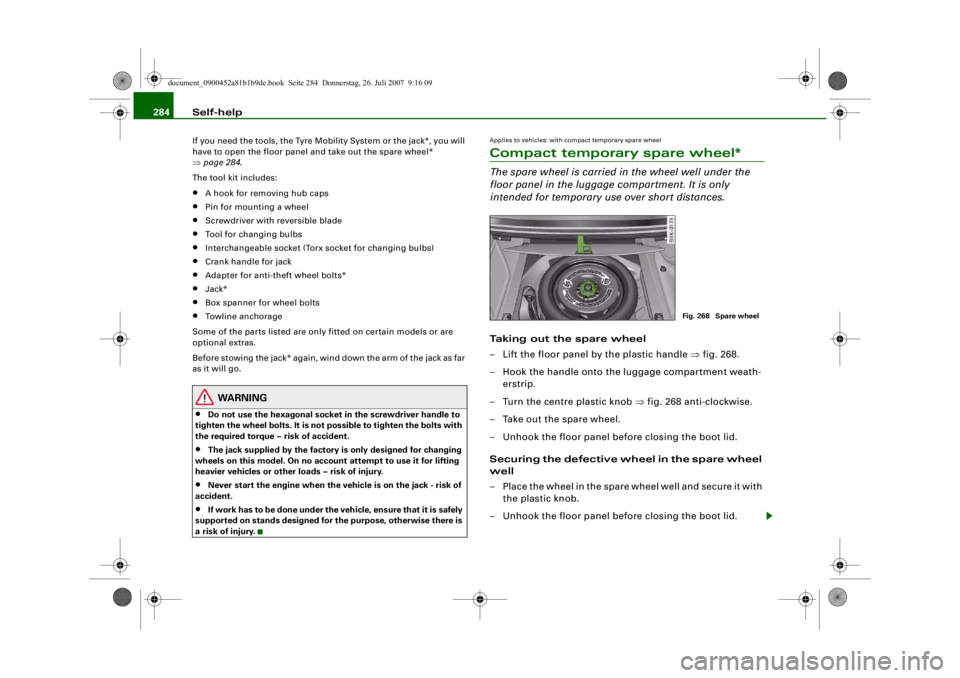

Applies to vehicles: with compact temporary spare wheelCompact temporary spare wheel*The spare wheel is carried in the wheel well under the

floor panel in the luggage compartment. It is only

intended for temporary use over short distances.Taking out the spare wheel

– Lift the floor panel by the plastic handle ⇒fig. 268.

– Hook the handle onto the luggage compartment weath- erstrip.

– Turn the centre plastic knob ⇒ fig. 268 anti-clockwise.

– Take out the spare wheel.

– Unhook the floor panel before closing the boot lid.

Securing the defective wheel in the spare wheel

well

– Place the wheel in the spare wheel well and secure it with the plastic knob.

– Unhook the floor panel before closing the boot lid.

Fig. 268 Spare wheel

document_0900452a81b1b9de.book Seite 284 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 290 of 342

Self-help

288•

Seek professional assistance if th e repair of a tyre puncture is

not possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10

minutes, the tyre is too badly damaged. Do not drive on. You

should obtain professional assistance.Caution

Take special care if you have to repair a tyre on a gradient.

Note

•

Do not use the compressor for longer than 6 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

•

After carrying out a tyre repair remember to buy a new tyre

sealant can at a qualified workshop. This will ensure that the Tyre

Mobility System is operative again.

•

Please observe the relevant regulations.

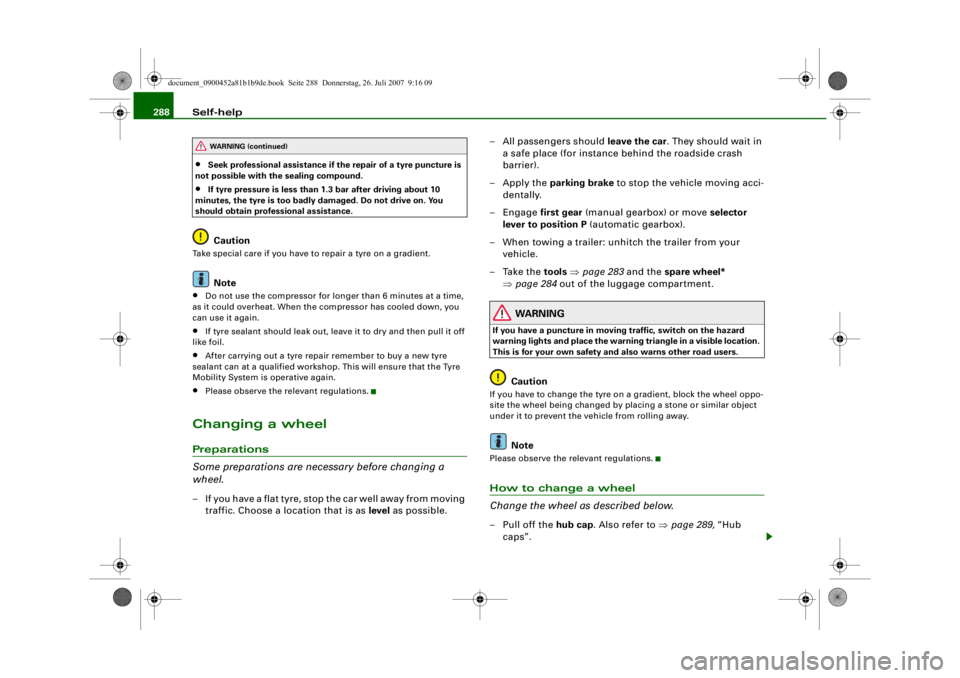

Changing a wheelPreparations

Some preparations are necessary before changing a

wheel.– If you have a flat tyre, stop the car well away from moving traffic. Choose a location that is as level as possible.– All passengers should

leave the car. They should wait in

a safe place (for instance behind the roadside crash

barrier).

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).

– When towing a trailer: unhitch the trailer from your vehicle.

– Take the tools ⇒ page 283 and the spare wheel*

⇒ page 284 out of the luggage compartment.

WARNING

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel oppo-

site the wheel being changed by placing a stone or similar object

under it to prevent the vehicle from rolling away.

Note

Please observe the relevant regulations.How to change a wheel

Change the wheel as described below.–Pull off the hub cap . Also refer to ⇒page 289, “Hub

caps”.

WARNING (continued)

document_0900452a81b1b9de.book Seite 288 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

0 [I)

-+

I&

+-

0

•

•

Page 292 of 342

Self-help

290

Loosening

–Fit the box spanner as far as it will go over the wheel bolt

5).

– Grip the box spanner as close to the end as possible and

turn the wheel bolts about one turn anti-clockwise

⇒ page 289, fig. 272 -arrow-.

Tightening

– Fit the box spanner as far as it will go over the wheel bolt5).

– Grip the box spanner as close to the end as possible and

tighten the bolt firmly by turning clockwise.

WARNING

To avoid accidents, the wheel bolts should only be loosened

slightly (about one turn) before ra ising the vehicle with the jack*.

Note

•

Do not use the hexagonal socket in the screwdriver handle to

loosen or tighten the wheel bolts.

•

If the wheel bolt is very tight, it may be possible to loosen it by

pushing down the end of the spanner carefully with your foot. Hold

on to the car for support and take care not to slip.

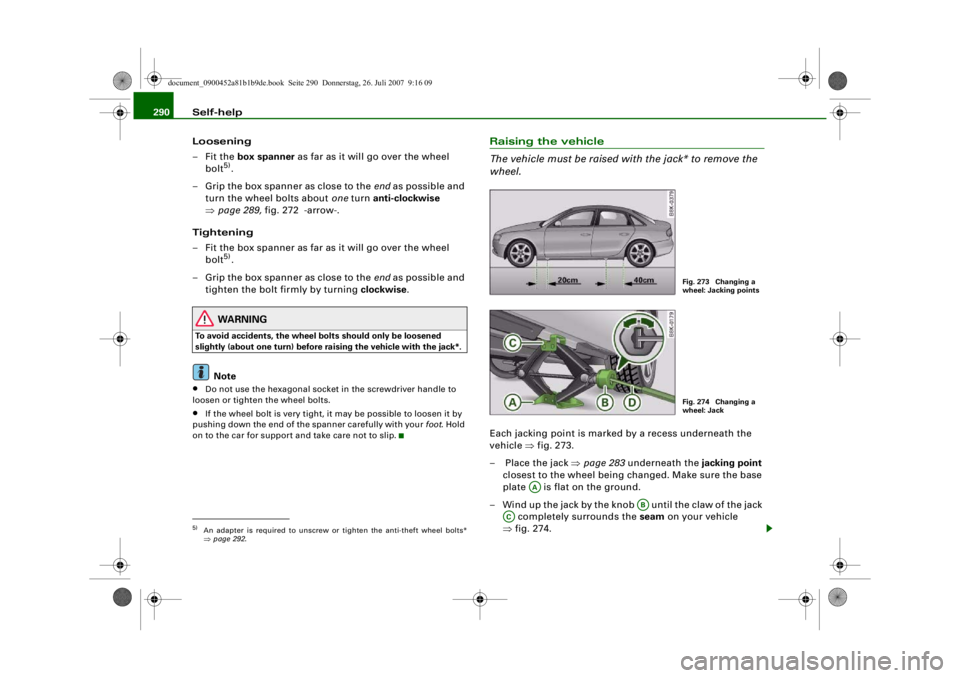

Raising the vehicle

The vehicle must be raised with the jack* to remove the

wheel.Each jacking point is marked by a recess underneath the

vehicle ⇒fig. 273.

– Place the jack ⇒page 283 underneath the jacking point

closest to the wheel being changed. Make sure the base

plate is flat on the ground.

– Wind up the jack by the knob until the claw of the jack completely surrounds the seam on your vehicle

⇒ fig. 274.

5)An adapter is required to unscrew or tighten the anti-theft wheel bolts*

⇒page 292 .

Fig. 273 Changing a

wheel: Jacking pointsFig. 274 Changing a

wheel: Jack

AA

AB

AC

document_0900452a81b1b9de.book Seite 290 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+

[I)

+-

•

Page 293 of 342

Self-help291

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Now fit the crank handle onto the jack by inserting it

in the opening on the knob ⇒page 290, fig. 274. Turn the

crank handle clockwise or anti-clockwise to secure it in

place.

– Raise the vehicle by windin g the crank handle until the

defective wheel is clear of the ground.Recesses at the front and rear of the door sills mark the jacking

points ⇒page 290, fig. 273. There is one jacking point for each

wheel. The distance from the jacking points to the wheel arches is

approximately 20 cm at the front an d 40 cm at the rear. The jack may

only be applied at the seam of the jacking points shown.

An unstable surface under the jack may cause the vehicle to slip off

the jack. Always provide a firm base for the jack on the ground. If

necessary use a large, strong board or similar support. On a hard,

slippery surface (such as tiles) use a rubber mat or similar to prevent

the jack from slipping.

WARNING

•

Prevent the base of the jack fr om slipping – risk of injury.

•

The car can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip

off suddenly if it is not properly engaged.

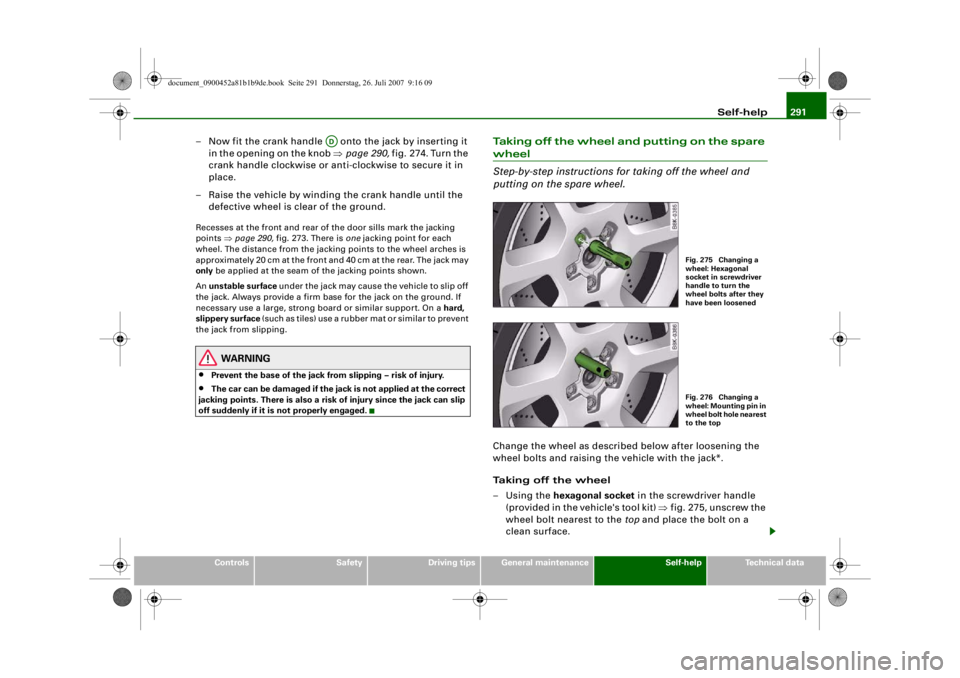

Taking off the wheel and putting on the spare wheel

Step-by-step instructions for taking off the wheel and

putting on the spare wheel.Change the wheel as described below after loosening the

wheel bolts and raising the vehicle with the jack*.

Taking off the wheel

–Using the hexagonal socket in the screwdriver handle

(provided in the vehicle's tool kit) ⇒fig. 275, unscrew the

wheel bolt nearest to the top and place the bolt on a

clean surface.

AD

Fig. 275 Changing a

wheel: Hexagonal

socket in screwdriver

handle to turn the

wheel bolts after they

have been loosenedFig. 276 Changing a

wheel: Mounting pin in

wheel bolt hole nearest

to the top

document_0900452a81b1b9de.book Seite 291 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

-+ +-

•

Page 297 of 342

Self-help295

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

terminal must not touch metal parts of the vehicle: this can cause

short circuiting.

•

Do not bend over the batteries – risk of acid burns.

•

The screw plugs on the battery ce

lls must be screwed in firmly.

•

Keep sparks, flame and lighted cigarettes away from batteries:

the gases given off can cause an explosion.

•

If jump-starting another vehicle, position the jump leads in

such a way that they cannot come into contact with any moving

parts in the engine compart ment of the other vehicle.Caution

Please note that the above method of connecting the leads is meant

for jump-starting your vehicle. If jump-starting another vehicle, you

should not connect the negative lead (–) to the negative terminal of

the discharged battery, but directly to the engine block or a solid

metal part bolted to the engine bl ock. If the battery of the other

vehicle does not have a gas vent, there is a risk that a mixture of

oxygen and hydrogen gas can accumulate and cause an

explosion.Tow-starting and towing awayGeneral notes

Points to observe when tow-starting or towing awayIf you use a towrope:

Notes for the driver of the towing vehicle

– The towrope must be taut before driving off. – Engage the clutch very gently when starting to move; on

vehicles with automatic gearbox press the accelerator

slowly.

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the turn signals, horn, windscreen wipers and washers can be

used. Please ensure that the steering wheel is unlocked

when you switch on the ignition, and that it moves freely.

–Put gear lever in neutral (manual gearbox) or move

selector lever to position N (automatic gearbox).

– The brake servo and power steering only work when the engine is running. Considerably more effort is required

on the brake pedal and steering wheel when the engine

is switched off.

– Ensure that the towrope remains taut at all times when towing.

Towrope or towbar

It is easier and safer to tow a vehicle with a tow bar. You should only

use a tow rope if you do not have a towbar.

A towrope should be slightly elasti c to reduce the loading on both

vehicles. It is advisable to use a towrope made of synthetic fibre or

similar material.

Attach the tow-rope or tow-bar only to the towing anchorages

intended for this purpose ⇒page 296 or ⇒page 297 .

Driving technique

Towing requires some experience – especially when using a

tow rope . Both drivers should be familiar with the technique required

for towing. Inexperienced drivers sh ould not attempt to tow-start or

tow away another vehicle.

WARNING (continued)

document_0900452a81b1b9de.book Seite 295 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

CD

-+ +-

•

Page 304 of 342

Fuses and bulbs

302Fuses on the passenger's sideSome of the items listed are only fitted on certain models or are

optional extras.

Please note that the following li st, while correct at the time of

printing, is subject to alterations. If discrepancies should occur,

please refer to the sticker on the inside of the fuse cover for the

correct information for your vehicle.

The seats with electrical adjustment are protected by circuit

breakers . These reset automatically after a few seconds when the

overload has been corrected.

Fuse list Fuse listNo.

Electrical equipment

amps

Fuse carrier (black)1

Vacant

2

Vacant

3

Vacant

4

Vacant

5

Steering column switch module

5

6

Electronic Stabilisation Program

5

Fig. 285 Diagram of

fuse box (left-hand

drive vehicle)

7

Diagnostic connector

5

8

Gateway (diagnostic in

terface for data bus)

5

9

Vacant

10

Vacant

11

Vacant

12

Vacant

No.

Electrical equipment

amps

Fuse carrier (brown)1

CD drive

5

2

Switch module for Audi drive select

5

3

MMI/Radio

10/20

4

Light switch

5

5

Control unit for instrument cluster

5

6

Ignition lock

5

7

Vacant

8

Air conditioner blower

40

9

Steering column lock

5

10

Air conditioner

10

11

Diagnostic connector

10

12

Steering column switch module

5

No.

Electrical equipment

amps

document_0900452a81b1b9de.book Seite 302 Donnerstag, 26. Juli 2007 9:16 09

-+ ~

--11-

..

-

..

-

..

-

..

-

..

..

..

..

..

..

..

..

..

..

..

--4 -

-

-

T

-

-

-

-

-

+-

-

-

-

-

-

•

4-

---r

Page 307 of 342

Fuses and bulbs305

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

WARNING

•

Take particular care when working on components in the

engine compartment if the engine is warm - risk of burns!

•

Bulbs are sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

•

Incorrect handling of the high-voltage element of xenon gas-

discharge bulbs* can have potentially fatal consequences.

•

When changing bulbs, please take care not to injure yourself on

sharp edges, in particular on the headlight housing.Caution

•

Always remove the ignition key before carrying out any work on

the electrical system - danger of short circuiting!

•

Switch off the lights or parking lights before you change a bulb.

•

Take good care to avoid damaging any components.

•

Removing the lights in particular can lead to the paintwork

becoming damaged. This is another reason why we recommend

having the bulbs changed by a qualified workshop.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in

the proper manner.

Note

Place the parts you have removed on a soft cloth so that they do not

become scratched.•

Please check at regular intervals that all lighting (especially the

exterior lighting) on your vehicle is functioning properly. This is not

only in the interest of your own safe ty, but also in that of all other

road users.

•

Before changing a bulb, make sure you have the correct new

bulb.

•

Do not touch the glass part of the bulb with your bare hands, use

a cloth or paper towel instead. Otherwise, the fingerprints left on

the glass will vaporise as a result of the heat generated by the bulb,

be deposited on the reflector and impair its surface.

Bulbs with a bayonet fastenerBulbs with a bayonet fastener must be changed as follows:

Removing the bulb

– Lightly press the defective bulb into the bulb holder, then turn it anti-clockwise and remove it.

– Do not touch the glass part of the new bulb with your bare hands, use a cloth or paper towel instead.

Fitting the bulb

– Fit the new bulb, pressing it into the bulb holder, and turn it clockwise as far as it will go.

– If necessary, use a cloth to remove any fingerprints from the glass part of the bulb.

document_0900452a81b1b9de.book Seite 305 Donnerstag, 26. Juli 2007 9:16 09

--4 -

-T

•

CD

-+ +-

•

[I]