lights AUDI S5 2008 8T / 1.G Workshop Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2008, Model line: S5, Model: AUDI S5 2008 8T / 1.GPages: 294, PDF Size: 12.13 MB

Page 213 of 294

Downloaded from www.Manualslib.com manuals search engine Care of vehicle and cleaning211

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

WARNING

•

Do not wash the vehicle with the ignition switched on – risk of

accident.

•

Do not clean the underside of the car or inside the wheel arches

without protecting your hands and arms. You may cut yourself on

sharp metal parts.

•

Take care when washing the car during the winter: moisture

and ice on the brakes may affect braking efficiency – this could

cause an accident.Caution

•

Do not wash the vehicle in direct sunlight – otherwise the paint

can be damaged.

•

Do not use insect sponges, or abrasive household sponges, etc.

– they can damage the surfaces.

•

The headlights should only be washed with water – do not wipe

them with a dry cloth or sponge. It is best to use soapy water.

•

Never wash tyres with a jet that sprays the water out in a direct

stream. This could damage the tyres – even if the spray is kept at a

distance and only used for a very short time.For the sake of the environment

The car should only be washed in special wash bays. This prevents

oily water from getting into the public drains. In some districts,

washing vehicles anywhere else may be prohibited.Waxing and polishingWaxing

Waxing protects the paintwork. It is time to apply a good coat of wax

when water no longer forms droplets and rolls off the clean paint-

work.Even if a wax solution is used regularly in the car wash, it is advis-

able to protect the paint with a coat of wax at least twice a year.

In the summer, you will find it is much easier to remove dead insects

(which accumulate on the bumper and the front of the bonnet) if the

car has been waxed recently.

Polishing

Polishing is only necessary if the paint has lost its shine, and the

gloss cannot be brought back by putting on wax.

The car must be waxed after polishing if the polish used does not

contain wax compounds to seal the paint.

Caution

Matt painted and plastic parts must not be treated with wax or

polish.Ornamental trim and mouldingsThe metal brightwork on the body is made of aluminium rather than

chrome (for environmental reasons).

Dirt or marks on the trim mouldings should be removed with an

acid-free cleaning agent (do not use a chrome cleaner). Body polish

is also unsuitable for use on trim mouldings. The intensive cleaning

fluids often used before the car goes into a car wash may contain

alkaline substances, which can cause dull or milky patches when

they dry out.

Audi dealers carry stocks of cleaning products which have been

tested for use on your vehicle and are not harmful to the

environment.

document_0900452a81793dcc.book Seite 211 Mittwoch, 21. März 2007 5:42 17

Page 231 of 294

Downloaded from www.Manualslib.com manuals search engine Checking and topping up fluids229

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

Important safety warnings for handling a car battery

All work on batteries requires specialist knowledge.The vehicle battery is located under the floor panel in the luggage

compartment.

WARNING

Always be aware of the danger of injury and chemical burns as

well as the risk of accident or fire when working on the battery and

the electrical system.•

Wear safety glasses. Do not allow acid or lead particles to come

into contact with eyes, skin or clothing.

•

Battery acid is extremely corrosive. Wear protective gloves and

safety glasses. Do not tilt the battery - acid can leak out of the

vapour vent. If electrolyte should splash into the eyes rinse at once

for several minutes using clear water. Then seek medical care

immediately. Neutralize any acid splashes on the skin or clothing

with soap solution, and rinse off with plenty of water. If acid is

swallowed by mistake, consult a doctor immediately.

•

Keep open flames, sparks, uncovered lights and lit cigarettes

away from battery. Avoid sparks (including those from static charges) when handling cables and electrical equipment. Never

cross the battery poles. The resulting high-energy sparks can

cause injury.

•

A highly explosive mixture of gases is given off when the

battery is under charge. Only charge battery in a well ventilated

area.

•

Keep children away from the battery and battery acid.

•

Switch off all electrical equipment before starting any work on

the vehicle electrical system. Remove the ignition key. The minus

cable of the battery must be disconnected. When changing a light

bulb, it is sufficient to only turn off the light.

•

Before disconnecting the battery, turn off the anti-theft

system! Otherwise, the alarm will sound.

•

When disconnecting the battery from the vehicle's electrical

system, first disconnect the minus cable and then the plus cable.

•

Before reconnecting the battery, turn off all electrical equip-

ment. First connect the plus cable, then the minus cable. The

battery cables must not be connected to the wrong battery poles

- serious risk of cable fire.

•

Never charge a frozen or thawed out battery - risk of explosion

and chemical burns! A battery must be replaced once it has been

frozen. When it is discharged the battery can freeze at tempera-

tures around 0°C.

•

Make sure that the vapour hose is always attached to the

battery.

•

Never use a damaged battery - risk of explosion! Replace a

damaged battery immediately.Caution

•

Never disconnect the car's battery with the engine running or

with the ignition turned on, otherwise the electrical system or elec-

trical components will be damaged.

Wear safety glasses!

Battery acid is extremely corrosive. Wear protec-

tive gloves and safety glasses.

Keep open flames, sparks, uncovered lights and

lit cigarettes away from battery!

A highly explosive mixture of gases is given off

when the battery is under charge!

Keep children away from the battery and battery

acid.

WARNING (continued)

document_0900452a81793dcc.book Seite 229 Mittwoch, 21. März 2007 5:42 17

Page 251 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help249

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

– Ensure that all passengers leave the vehicle and move

away from the danger area ⇒.

– Take the tyre sealant can and the electric compressor out

of the luggage compartment ⇒page 245.

– Fix the sticker “max. 80 km/h”, which is included with the

tyre sealant can, onto the instrument cluster where the

driver will see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as

far as it will go. This will automatically pierce the foil

sealing the can.

– Take the valve cap off the tyre valve and use the enclosed

valve insert tool to unscrew the valve insert ⇒page 248,

fig. 228.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert

the hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the

complete contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert

firmly back into the tyre valve.

Inflating the tyre

– Screw the filling hose of the electric compressor onto the

tyre valve and plug the connector into the cigarette

lighter.– Pump the tyre up to 2.0 to 2.5 bar and monitor the pres-

sure shown on the pressure gauge.

– If the tyre pressure remains lower than the value speci-

fied above drive the vehicle approx. 10 metres forwards

or backwards, so that the sealant can spread evenly in

the tyre. If the pressure is still lower than the specifica-

tion the tyre is too badly damaged and cannot be

repaired using the tyre sealant.

Final checks

– After about 10 minutes stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly

damaged. Do not drive on. You should obtain profes-

sional assistance.

WARNING

•

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

•

Make sure your passengers wait in a safe place (for instance

behind the roadside crash barrier).

•

Please observe the manufacturers' safety notes on the

compressor and the instructions supplied with the tyre sealant

can.

•

If it was not possible to build up a tyre pressure of 2.0 bar

within 6 minutes this means that the tyre is too badly damaged.

Do not drive on.

•

Seek professional assistance if the repair of a tyre puncture is

not possible with the sealing compound.

•

If tyre pressure is less than 1.3 bar after driving about 10

minutes, the tyre is too badly damaged. Do not drive on. You

should obtain professional assistance.

document_0900452a81793dcc.book Seite 249 Mittwoch, 21. März 2007 5:42 17

Page 252 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help 250

CautionTake special care if you have to repair a tyre on a gradient.

Note

•

Do not use the compressor for longer than 6 minutes at a time,

as it could overheat. When the compressor has cooled down, you

can use it again.

•

If tyre sealant should leak out, leave it to dry and then pull it off

like foil.

•

After carrying out a tyre repair remember to buy a new tyre

sealant can at a qualified workshop. This will ensure that the Tyre

Mobility System is operative again.

•

Please observe the relevant regulations.

Changing a wheelPreparations

Some preparations are necessary before changing a

wheel.– If you have a flat tyre, stop the car well away from moving

traffic. Choose a location that is as level as possible.

– All passengers should leave the car. They should wait in

a safe place (for instance behind the roadside crash

barrier).

– Apply the parking brake to stop the vehicle moving acci-

dentally.

–Engage first gear (manual gearbox) or move selector

lever to position P (automatic gearbox).– When towing a trailer: unhitch the trailer from your

vehicle.

– Take the tools ⇒page 245 and the spare wheel*

⇒page 246 out of the luggage compartment.

WARNING

If you have a puncture in moving traffic, switch on the hazard

warning lights and place the warning triangle in a visible location.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel oppo-

site the wheel being changed by placing a stone or similar object

under it to prevent the vehicle from rolling away.

Note

Please observe the relevant regulations.How to change a wheel

Change the wheel as described below.–Pull off the hub cap. Also refer to ⇒page 251, “Hub

caps”.

–Loosen the wheel bolts ⇒page 251.

–Raise the car with the jack* ⇒page 252.

–Ta k e o f f the wheel with the flat tyre and then put on the

spare wheel* ⇒page 253.

–Lower the vehicle to the ground.

document_0900452a81793dcc.book Seite 250 Mittwoch, 21. März 2007 5:42 17

Page 260 of 294

Downloaded from www.Manualslib.com manuals search engine Self-help 258Do not pull too hard with the towing vehicle and take care to avoid

jerking the towrope. When towing on a loose surface there is always

a risk of overloading and damaging the anchorage points.

Caution

If there is no oil in the gearbox or no lubricant in the automatic

transmission the car may only be towed with the driven wheels

lifted clear of the road, or transported on a special car transporter

or trailer.

Note

•

Note the regulations concerning towing.

•

The hazard warning lights of both vehicles must normally be

switched on. However, observe any regulations to the contrary.

•

Make sure that the towrope is not twisted, as otherwise the front

towline anchorage on your vehicle could work itself loose.

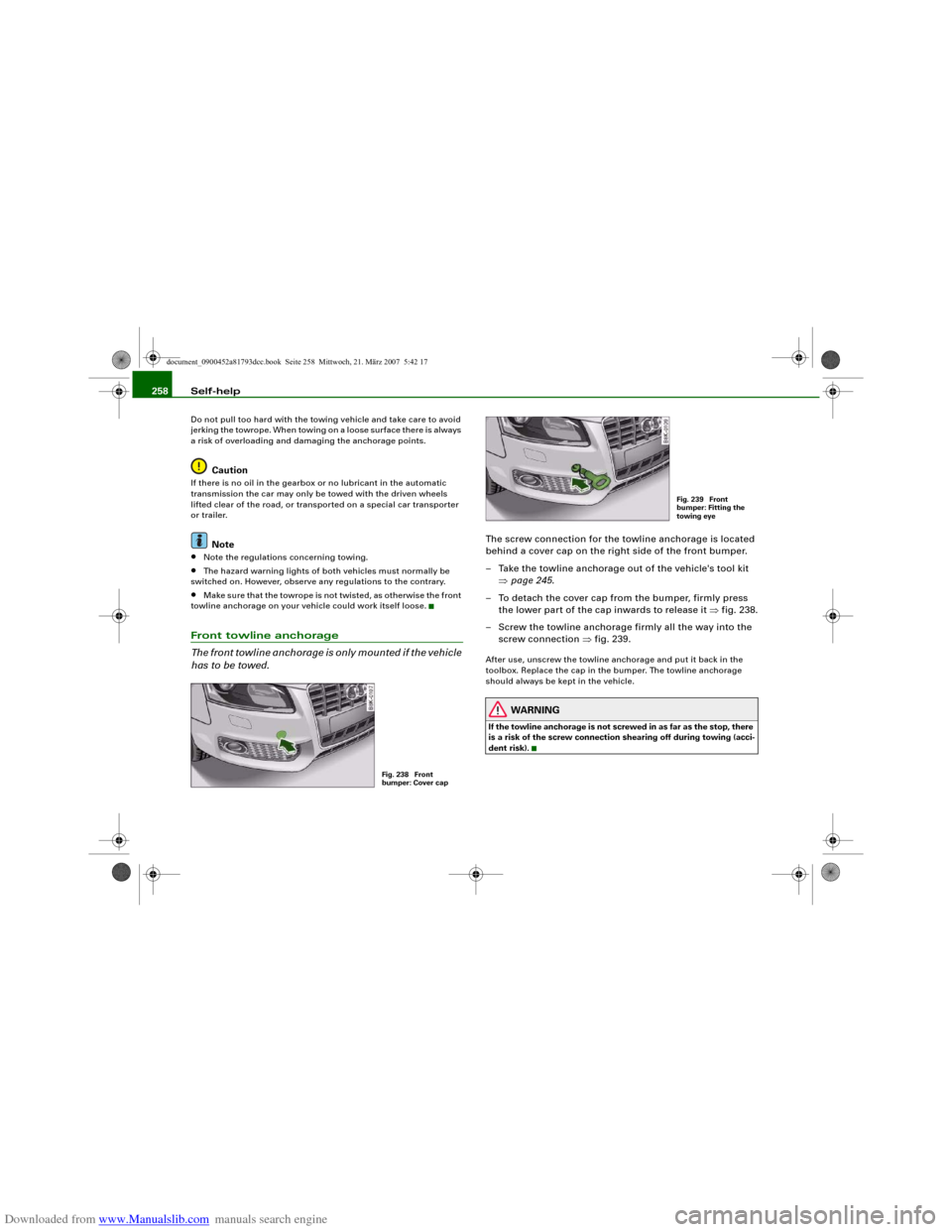

Front towline anchorage

The front towline anchorage is only mounted if the vehicle

has to be towed.

The screw connection for the towline anchorage is located

behind a cover cap on the right side of the front bumper.

– Take the towline anchorage out of the vehicle's tool kit

⇒page 245.

– To detach the cover cap from the bumper, firmly press

the lower part of the cap inwards to release it ⇒fig. 238.

– Screw the towline anchorage firmly all the way into the

screw connection ⇒fig. 239.After use, unscrew the towline anchorage and put it back in the

toolbox. Replace the cap in the bumper. The towline anchorage

should always be kept in the vehicle.

WARNING

If the towline anchorage is not screwed in as far as the stop, there

is a risk of the screw connection shearing off during towing (acci-

dent risk).

Fig. 238 Front

bumper: Cover cap

Fig. 239 Front

bumper: Fitting the

towing eye

document_0900452a81793dcc.book Seite 258 Mittwoch, 21. März 2007 5:42 17

Page 267 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs265

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

BulbsChanging bulbs

Changing bulbs requires a certain degree of practical

skill.You can change the following bulbs for exterior lights yourself:•

Bulb for turn signals

•

Bulb for fog light

•

Bulbs for rear lights in boot lid

•

Bulbs for rear lights in side panel

•

Bulbs for number plate light

The following bulbs should only be changed by a qualified work-

shop:

•

Xenon headlights: Light source for daytime running

lights/parking lights

•

Bulb for headlights: Bi-xenon lights ⇒

•

Light source for turn signal in exterior mirror housing

•

Light source for high-level brake light

As a rule, you require a certain degree of practical skill to change

defective bulbs. This applies in particular to those bulbs which are

only accessible from the engine compartment.

If in doubt, we recommend that you have defective bulbs changed

by a qualified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment your-

self, be aware of the safety risks involved ⇒page 221 ⇒.

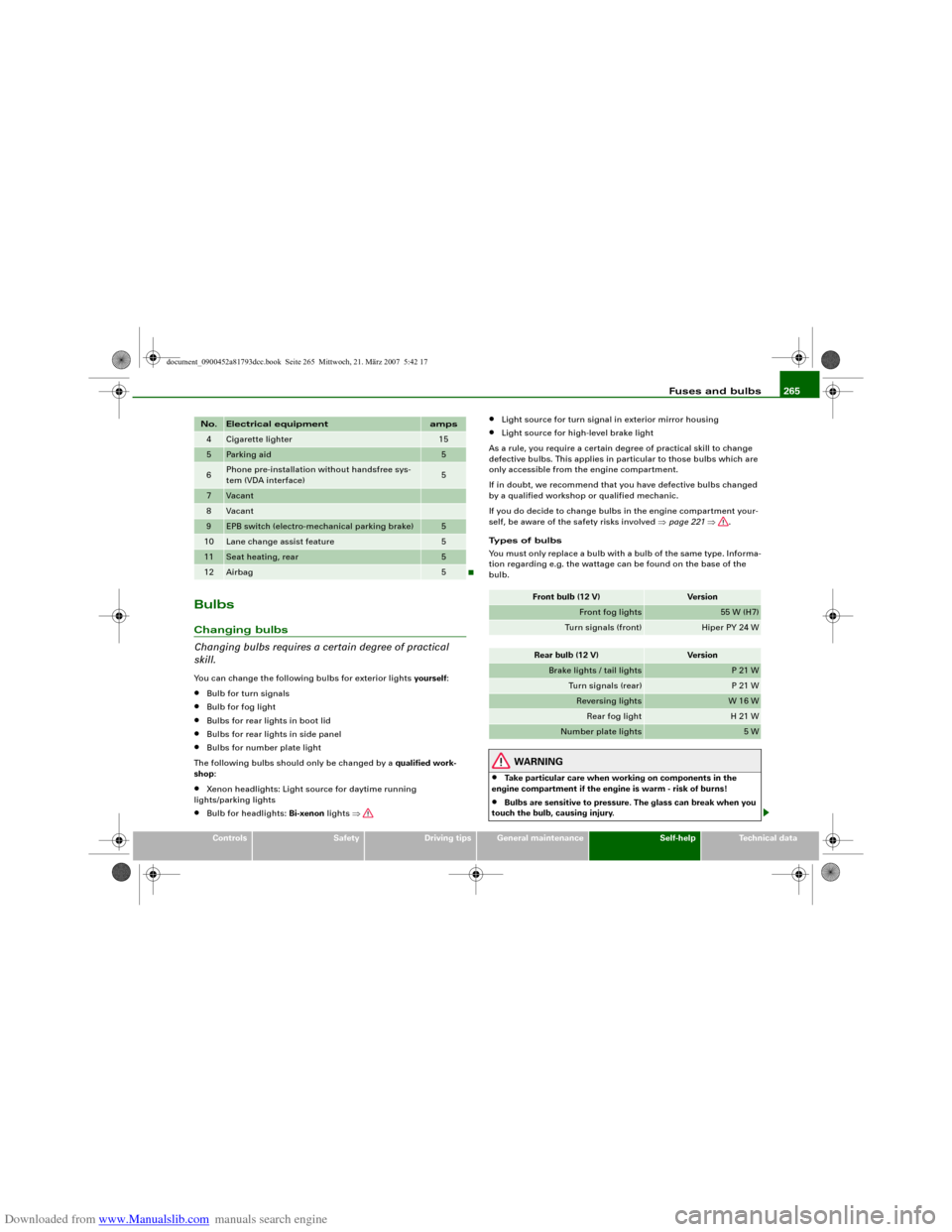

Types of bulbs

You must only replace a bulb with a bulb of the same type. Informa-

tion regarding e.g. the wattage can be found on the base of the

bulb.

WARNING

•

Take particular care when working on components in the

engine compartment if the engine is warm - risk of burns!

•

Bulbs are sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

4

Cigarette lighter

15

5

Parking aid

5

6

Phone pre-installation without handsfree sys-

tem (VDA interface)

5

7

Vacant

8

Vacant

9

EPB switch (electro-mechanical parking brake)

5

10

Lane change assist feature

5

11

Seat heating, rear

5

12

Airbag

5

No.

Electrical equipment

amps

Front bulb (12 V)

Version

Front fog lights

55 W (H7)

Turn signals (front)

Hiper PY 24 W

Rear bulb (12 V)

Version

Brake lights / tail lights

P 21 W

Turn signals (rear)

P 21 W

Reversing lights

W 16 W

Rear fog light

H 21 W

Number plate lights

5 W

document_0900452a81793dcc.book Seite 265 Mittwoch, 21. März 2007 5:42 17

Page 268 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs 266•

Incorrect handling of the high-voltage element of xenon gas-

discharge bulbs* can have potentially fatal consequences.

•

When changing bulbs, please take care not to injure yourself on

sharp edges, in particular on the headlight housing.Caution

•

Always remove the ignition key before carrying out any work on

the electrical system - danger of short circuiting!

•

Switch off the lights or parking lights before you change a bulb.

•

Take good care to avoid damaging any components.

•

Removing the lights in particular can lead to the paintwork

becoming damaged. This is another reason why we recommend

having the bulbs changed by a qualified workshop.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in

the proper manner.

Note

Place the parts you have removed on a soft cloth so that they do not

become scratched.•

Please check at regular intervals that all lighting (especially the

exterior lighting) on your vehicle is functioning properly. This is not

only in the interest of your own safety, but also in that of all other

road users.

•

Before changing a bulb, make sure you have the correct new

bulb.

•

Do not touch the glass part of the bulb with your bare hands, use

a cloth or paper towel instead. Otherwise, the fingerprints left on

the glass will vaporise as a result of the heat generated by the bulb,

be deposited on the reflector and impair its surface.

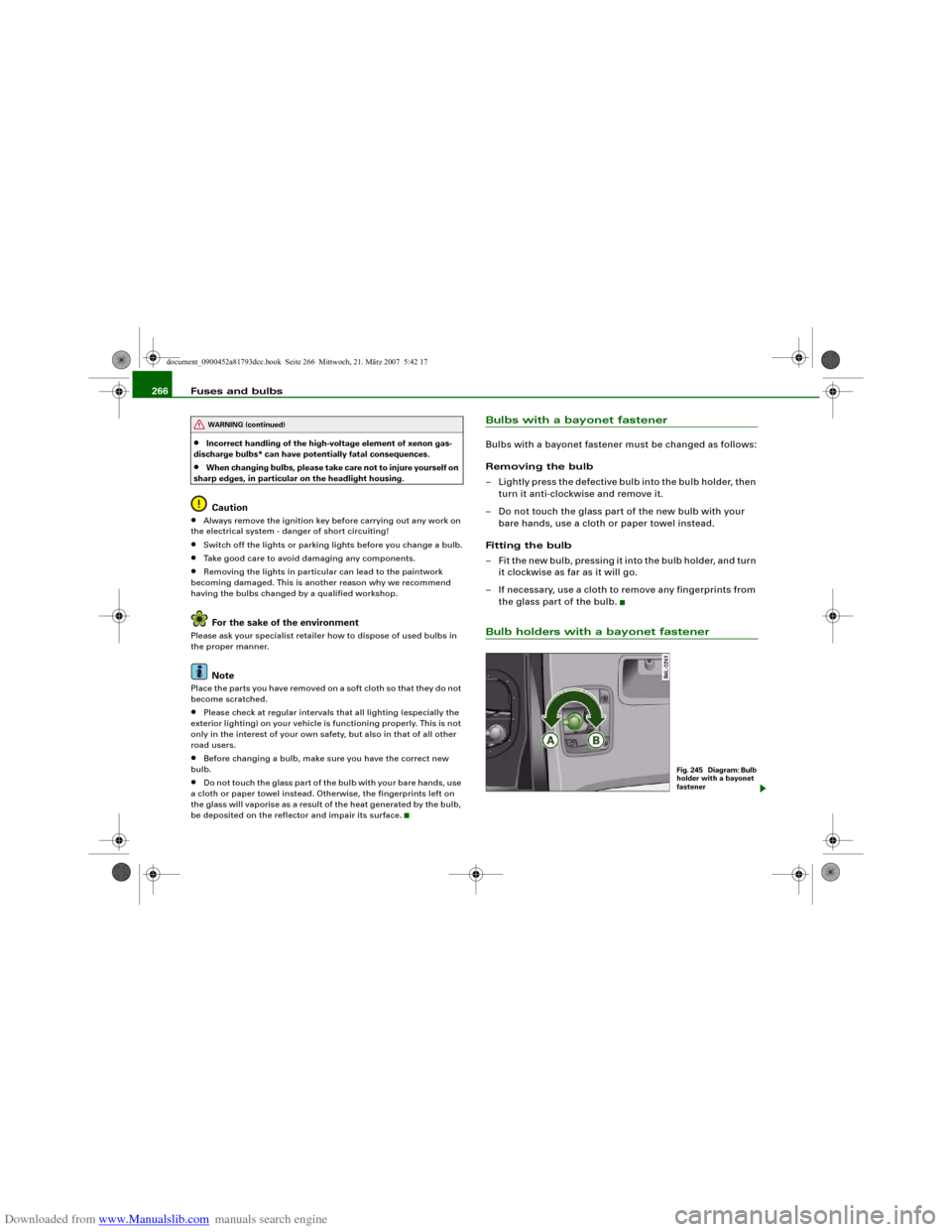

Bulbs with a bayonet fastenerBulbs with a bayonet fastener must be changed as follows:

Removing the bulb

– Lightly press the defective bulb into the bulb holder, then

turn it anti-clockwise and remove it.

– Do not touch the glass part of the new bulb with your

bare hands, use a cloth or paper towel instead.

Fitting the bulb

– Fit the new bulb, pressing it into the bulb holder, and turn

it clockwise as far as it will go.

– If necessary, use a cloth to remove any fingerprints from

the glass part of the bulb.Bulb holders with a bayonet fastener

WARNING (continued)

Fig. 245 Diagram: Bulb

holder with a bayonet

fastener

document_0900452a81793dcc.book Seite 266 Mittwoch, 21. März 2007 5:42 17

Page 269 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs267

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

In the case of bulb holders with a bayonet fastener please

proceed as follows:

Removing the bulb holder

– Turn the bulb holder in the direction of the arrow

⇒page 266, fig. 245 as far as it will go and then take the

bulb holder out of the light unit.

Fitting the bulb holder

– Insert the bulb holder into the light unit, making sure you

keep the bulb holder straight, i.e. the rubber seal makes

even contact all around.

– Turn the bulb holder in the direction indicated by the

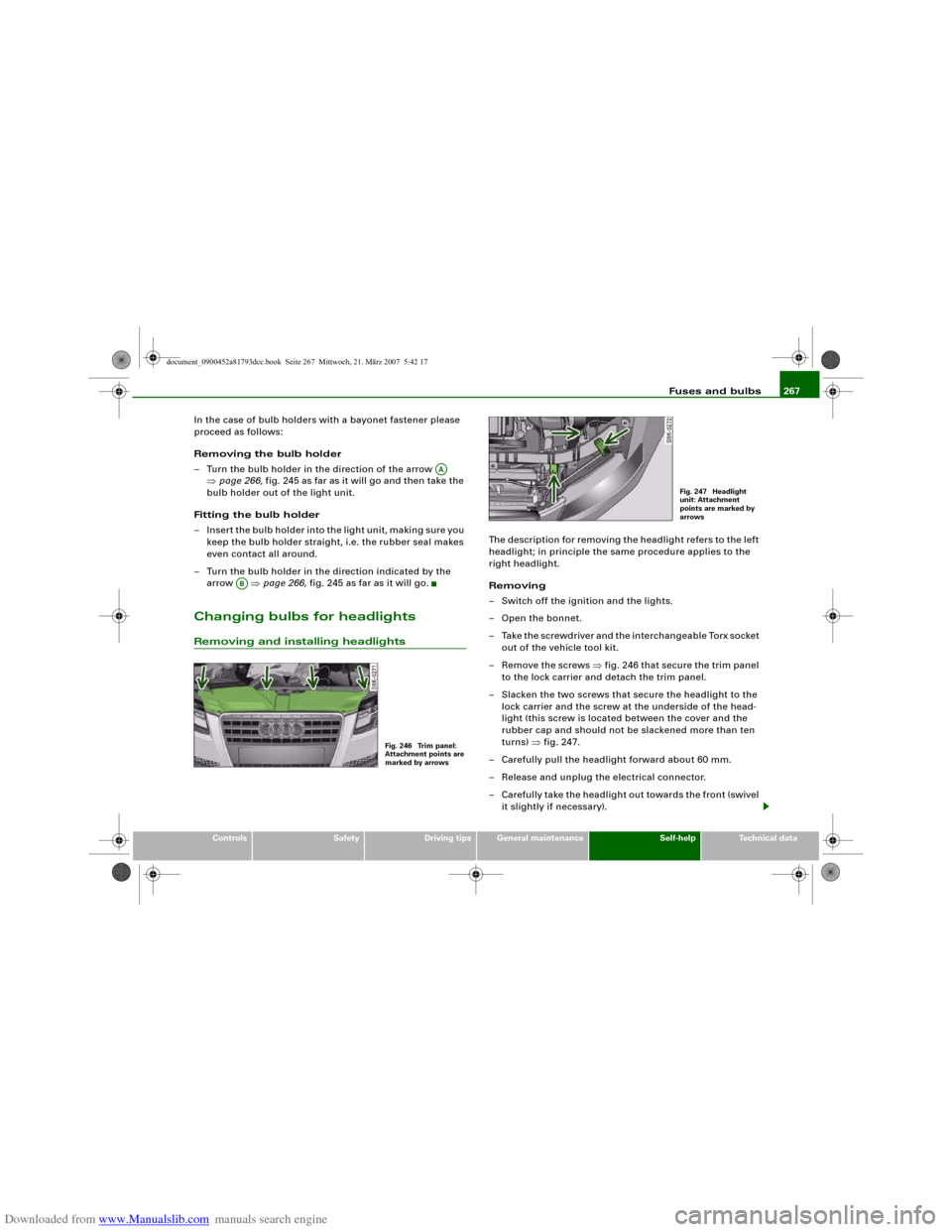

arrow ⇒page 266, fig. 245 as far as it will go.Changing bulbs for headlightsRemoving and installing headlights

The description for removing the headlight refers to the left

headlight; in principle the same procedure applies to the

right headlight.

Removing

– Switch off the ignition and the lights.

– Open the bonnet.

– Take the screwdriver and the interchangeable Torx socket

out of the vehicle tool kit.

– Remove the screws ⇒fig. 246 that secure the trim panel

to the lock carrier and detach the trim panel.

– Slacken the two screws that secure the headlight to the

lock carrier and the screw at the underside of the head-

light (this screw is located between the cover and the

rubber cap and should not be slackened more than ten

turns) ⇒fig. 247.

– Carefully pull the headlight forward about 60 mm.

– Release and unplug the electrical connector.

– Carefully take the headlight out towards the front (swivel

it slightly if necessary).

AA

AB

Fig. 246 Trim panel:

Attachment points are

marked by arrows

Fig. 247 Headlight

unit: Attachment

points are marked by

arrows

document_0900452a81793dcc.book Seite 267 Mittwoch, 21. März 2007 5:42 17

Page 270 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs 268

Installing

– Perform all of the above steps in reverse sequence.The headlight must be inserted in two guides (on the underside of

the headlight). This is the only way to ensure that the headlight is

installed in the correct position. To determine whether the headlight

is correctly installed, check that it is aligned flush with adjacent

body parts (such as the wing panel).

Do not interchange the securing screws.

Caution

Please take particular care not to damage or scratch the adjacent

parts of the body when removing or installing the headlights.Applies to vehicles: with xenon headlight bulbsChanging bulb for turn signalsThe bulb is secured in the bulb carrier with a bayonet

fastener.

– Remove the headlight ⇒page 267.

– Take off the rubber cap (small cover) and remove the bulb

carrier.

– Lightly press the defective bulb into the bulb carrier, then

turn it anti-clockwise and remove it.

– Do not touch the glass part of the new bulb with your

bare hands, use a cloth or paper towel instead.

– Fit the new bulb, pressing it into the bulb carrier, and turn

it clockwise as far as it will go.

– If necessary, use a cloth to remove any fingerprints from

the glass part of the bulb.– Insert the bulb carrier into the headlight.

Note

Ensure that the rubber cap is seated correctly so that no water can

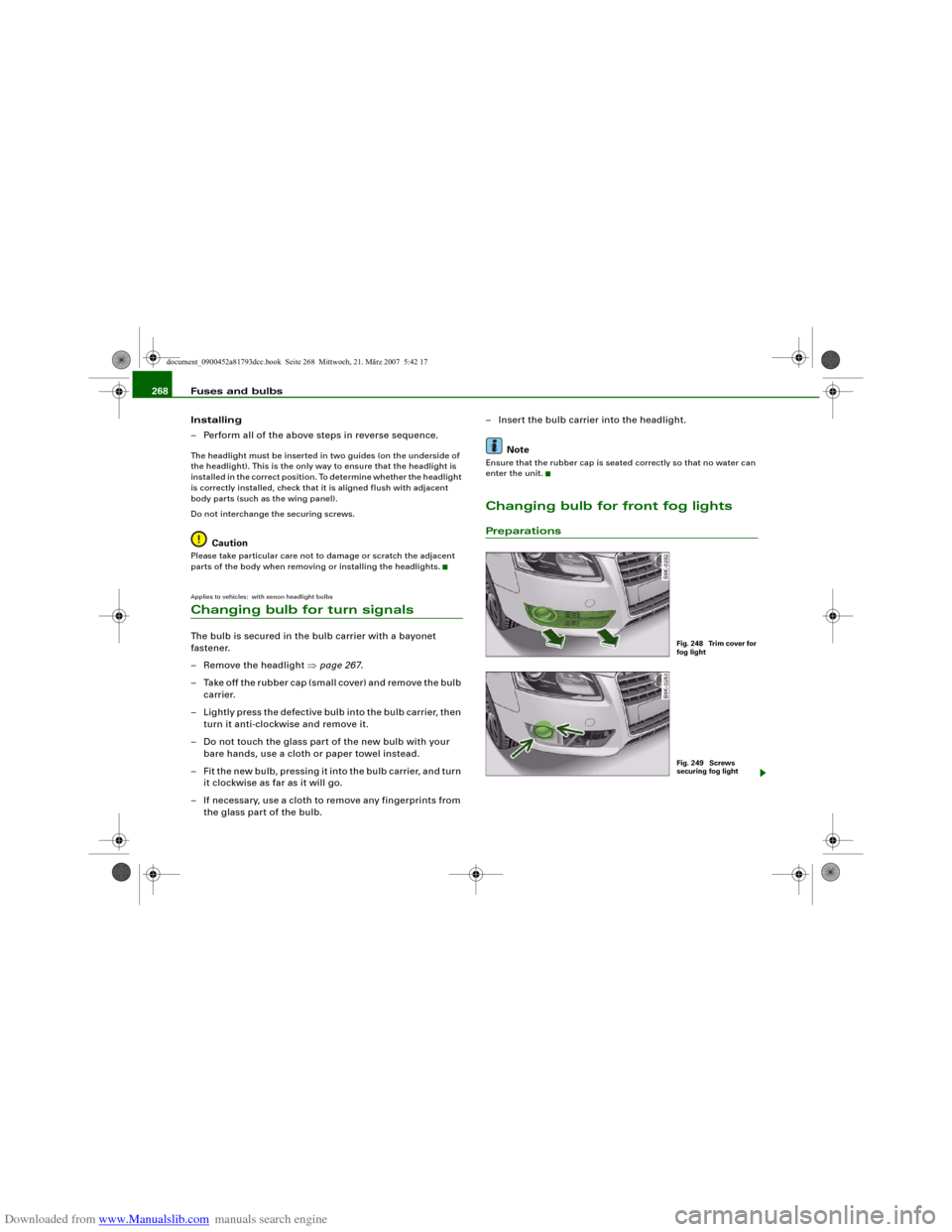

enter the unit.Changing bulb for front fog lightsPreparations

Fig. 248 Trim cover for

fog lightFig. 249 Screws

securing fog light

document_0900452a81793dcc.book Seite 268 Mittwoch, 21. März 2007 5:42 17

Page 271 of 294

Downloaded from www.Manualslib.com manuals search engine Fuses and bulbs269

Controls

Safety

Driving tips

General maintenance

Self-help

Technical data

The description for changing the bulb refers to the left fog

light; in principle the same procedure applies to the right

fog light.

– Switch off the ignition and the lights.

– Detach the trim cover ⇒page 268, fig. 248 (pull it care-

fully in the direction of the arrow).

– Remove the two securing screws ⇒page 268, fig. 249

and pull the fog light unit out of the bumper.

– Unplug the electrical connector.

CautionThe trim cover is secured to the bumper by several retaining hooks.

Do not use force when removing the trim cover to avoid damaging

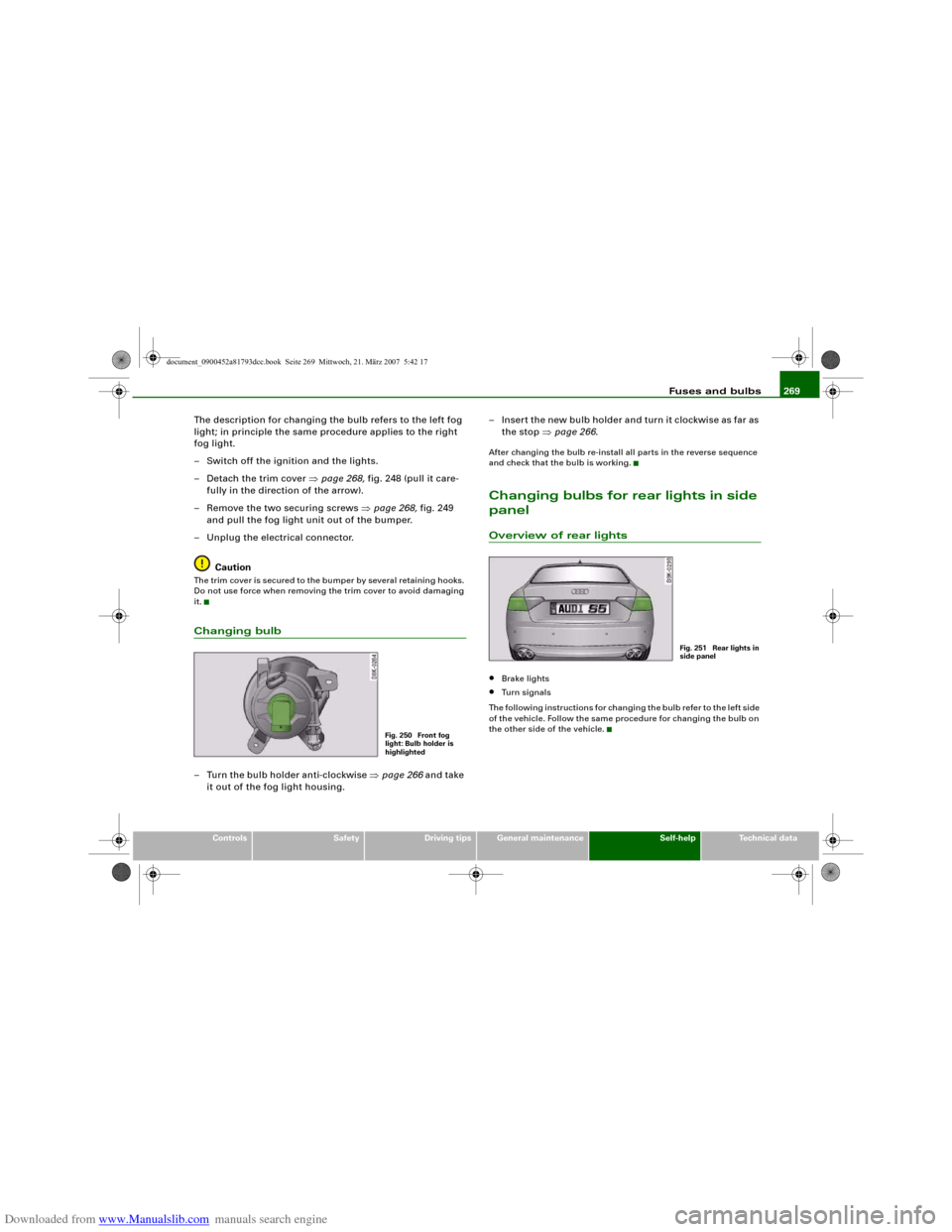

it.Changing bulb– Turn the bulb holder anti-clockwise ⇒page 266 and take

it out of the fog light housing.– Insert the new bulb holder and turn it clockwise as far as

the stop ⇒page 266.

After changing the bulb re-install all parts in the reverse sequence

and check that the bulb is working.Changing bulbs for rear lights in side

panelOverview of rear lights•

Brake lights

•

Turn signals

The following instructions for changing the bulb refer to the left side

of the vehicle. Follow the same procedure for changing the bulb on

the other side of the vehicle.

Fig. 250 Front fog

light: Bulb holder is

highlighted

Fig. 251 Rear lights in

side panel

document_0900452a81793dcc.book Seite 269 Mittwoch, 21. März 2007 5:42 17