brake AUDI S7 2013 Repair Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2013, Model line: S7, Model: AUDI S7 2013Pages: 310, PDF Size: 77.45 MB

Page 259 of 310

Unbalanced whee ls must be rebalanced to

avoid excessive wea r on steering, suspension

and tires. A wheel must a lso be rebalanced

when a new tire is installed .

Incorrect wheel alignment

Incorrect whee l alignment can cause exces

sive tire wear, impairing the safety o f the vehi

cle. If tires show excess ive wear, have the

wheel alignment checked by an authorized

Audi dealer or qualified workshop .

All-wheel d rive

Vehicles w ith quattro ® must always have tires

of the same size, construction and tread type .

F or detai ls see

r=!:> page 201 .

A WARNING

Sudden tire failure can lead to loss of con

trol, a crash and serious persona l injury!

- Never drive a veh icle when the tread on

any tire is worn down to the wear indica

tors.

- Worn tires are a safety hazard, they do not grip well on wet roads and increase

your risk of"hydrop lan ing" and loss of

co ntrol.

- Always keep chemicals that can cause

tire damage, such as grease, oil , gasoline

and brake fluid away from t ires.

- Tires age eve n if they are not be ing used

and can fail suddenly, especially at high

speeds. T ires that are more than 6 years

o ld can only be used in an emergency

and then with spe cial care a nd at lower

s peeds.

- Never mount used ti res on yo ur vehicle if

yo u a re not s ure of their "prev ious histo

ry." Old used ti res may have been dam

aged even though the damage cannot be

seen that can lead to s udden tire failure

and loss of vehicle control. Tires and wheels 25

7

New tires and replacing tires and wheels

New tires and wheels have to be broken in .

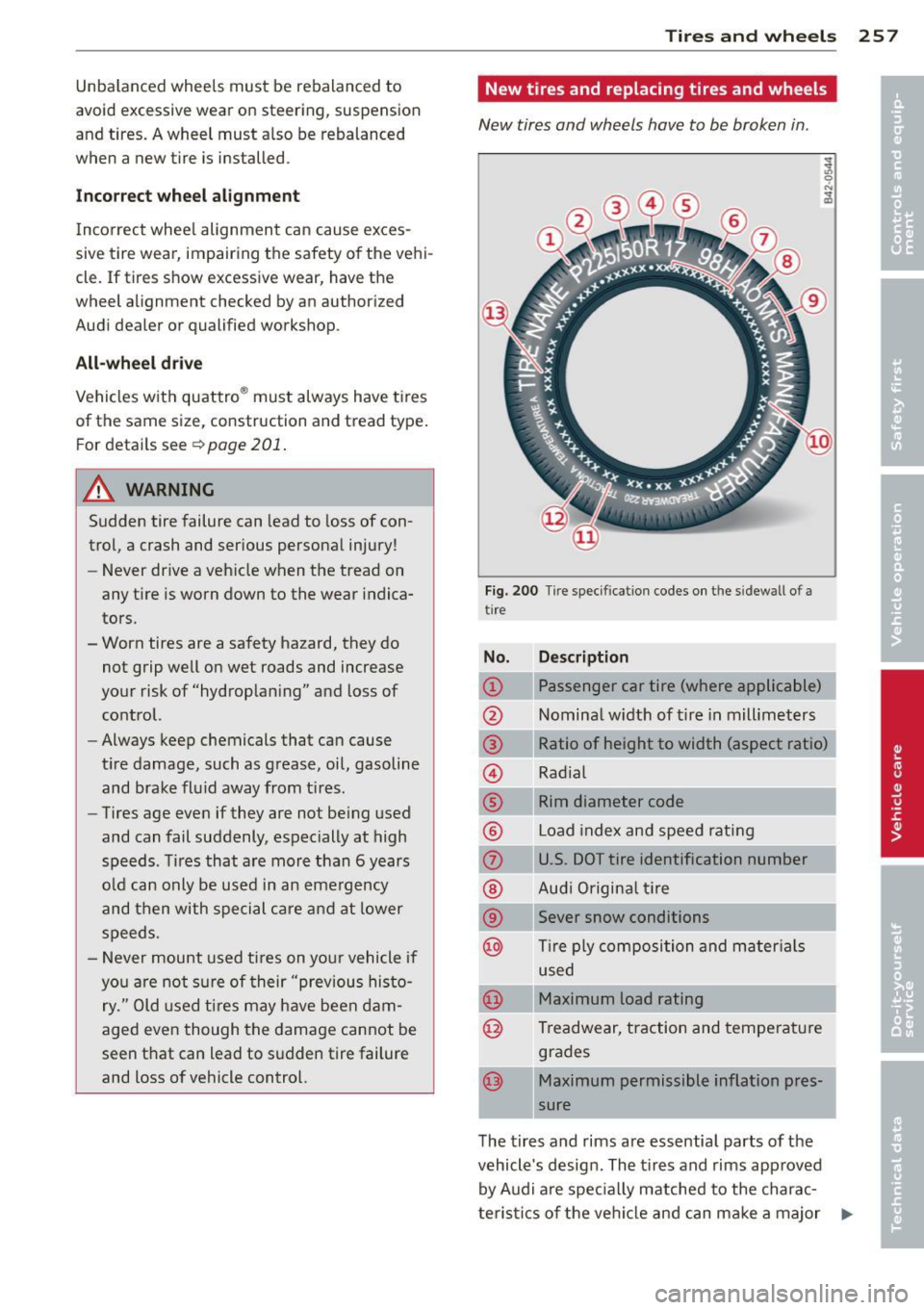

Fig. 20 0 Tir e spec ificat io n codes on t he s idewall o f a

tire

No. De sc ription

CD Passenger car tire (where applicable)

@ Nomina l w idth of t ire in mill imeters

® Ratio of height to width (aspect ratio)

© Rad ial

® Rim diameter code

® Load index and speed rating

(f) U.S. DOT tire identification number

® Aud i Origina l tire

® Sever snow conditions

@ T ire ply composition and mater ials

used

@ Maximum load rating

@ Treadwear, traction and temperat ure

grades

@ Maximum permissible inflation pres-

sure

T he tires and rims are essential parts o f the

vehicle's design . The ti res and rims app roved

by Audi a re spec ia lly matched to the charac

teris tic s of the ve hicl e and can m ake a major .,.

•

Page 262 of 310

260 Tires and wheels

-If the spare tire is not the same as the

tires that are mounted on the vehicle -

for example with winter tires - only use

the spare tire for a short period of time and drive with extra care. Refit the nor

mal road wheel as soon as safely possi

ble.

- Never drive faster than the maximum

speed for which the tires on your vehicle

are rated because tires that are driven

faster than their rated speed can fail

suddenly.

- Overloading tires cause heat build-up,

sudden tire failure, including a blowout

and sudden deflation and loss of control.

- Temperature grades apply to tires that

are properly inflated and not over or un

derinflated.

- For technical reasons it is not always

possible to use wheels from other

vehicles -in some cases not even wheels

from the same vehicle model.

- If you install wheel trim discs on the ve

hicle wheels, make sure that the air flow

to the brakes is not blocked. Reduced air

flow to the brakes can them to overheat,

increasing stopping distances and caus

ing a collision.

- Run flat tires may only be used on

vehicles that were equipped with them

at the factory. The vehicle must have a

chassis designed for run flat tires. Incor

rect use of run flat tires can lead to vehi

cle damage or accidents. Check with an

authorized Audi dealer or tire specialist

to see if your vehicle can be equipped

with run flat tires. If run flat tires are

used, they must be installed on all four

wheels. Mixing tire types is not permit

ted.

- For technical reasons, it is not generally

possible to use the wheel rims from oth

er vehicles. This can hold true for wheels

of the same vehicle type.

- If the spare tire is different from the

tires that you have mounted on your ve- hicle (for example winter tires or wide

profile tires), then use the spare tire for a

short period of time only and drive with

extra care. Replace

the flat tire with the

tire matching the others on your vehicle

as soon as possible.

- Never drive without the valve stem cap.

The valves could get damaged.

@ For the sake of the environment

Dispose of old tires in accordance with the

local requirements.

Uniform tire quality grading

-Tread wear

- Traction AA A B C

- Temperature ABC

Quality grades can be found where applicable

on the tire side wall between tread shoulder

and maximum section width

~ fig. 200.

For example: Tread wear 200, Traction AA,

Temperature A.

All passenger car tires must conform to Feder

al Safety Requirements in addition to these

grades .

Tread wear

The tread wear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a specified

government test course.

Fo r example, a tire graded 150 would wear

one and one half (1 1/2) times as well on the

government course as a tire graded 100.

The relative performance of tires depends

upon the actual conditions of their use, how

ever, and may depart significantly from the

norm due to variations in driving habits, serv

ice practices and differences in road character

istics and climate.

Traction

The traction grades, from highest to lowest,

are AA, A, Band

C. Those grades represent the

tire's ability to stop on wet pavement as ..,.

Page 265 of 310

@ Tips

Where snow chains are mandatory oncer

tain roads, this normally also applies to

veh icles with all-wheel dr ive.

Wheel bolts

Wheel bolts must always be tightened to the

correct torque .

The design of whee l bolts is matched to the

factory insta lled rims . If different rims are fit

ted, the correct wheel bolts with the right

length and correctly shaped bolt heads must

be used. This ensures that wheels are f itted

securely and that the brake system functions

correctly .

In certain circumstances, you may not use

wheel bolts from a different vehicle -even if it

is the same model

<=> page 291.

.&_ WARNING

Improperly tightened or maintained wheel

bolts can becom e loose caus ing loss of

cont ro l, a co llision and serious persona l in

Jury .

- Always keep the wheel bolts and the

threads in the wheel hubs clea n so the

w heel bolts can t urn easily and be prop

erly t ightened .

- Never grease or oil the wheel bolts and

the threads in the wheel hubs. They can

become loose while d riving if greased or

oi led, even if tightened to the specif ied

torque.

- Only use whee l bolts that belong to the

rim being installed .

- Never use different whee ls bolts on your

vehicle.

- Always maintain the co rrect tighten ing

torq ue for the wheel bo lts to reduce the

risk of a wheel loss . If the tightening tor

que of the wheel bolts is too low, they

can loosen and come out when the vehi

cle is moving. If the tightening torque is

too high, the whee l bolts and threads

Tire s an d wheel s 263

can be damaged and the whee l can be

come loose.

(D Note

The specified torque for the whee l bolts is

90 ft lb (120 Nm) with a tolerance of± 7,4

ft lb(± 10 Nm) . Torq ue whee l bolts diago

nally. After changing a whee l, the torq ue

must be checked as soon as possible with a

torque wrench -preferably by an author

i zed Audi dealer or qualified workshop.

Low aspect ratio tires

You r Aud i is facto ry-equ ipped w it h low aspect

ra tio tires. These tires have been tho ro ughly

tested and been se lec ted spe cifically for you r

model for their superb perfo rmance, road fee l

and handling under a variety of driving condi

tions. Ask your authorized Audi dealer for

more details .

T he low aspect ratio of these t ires is ind icated

by a numera l of

55 or le ss in the tire's s ize

designation. The numera l represents the ratio

of the t ire's sidewa ll height in relation to its

tread width expressed in percentage. Conven

tiona l tires have a he ight/w idth rat io of 60 or

more .

The performance of low-aspect -ra tio tire s is

particularly sens it iv e to improper inflation

pressure. It is therefore important that low

aspect ratio t ires are inflated to the specified

pre ssure and that the inflation pressur e is

regularly che cked and maintain ed. Tire pre s

s ures should be checked at least on ce a

m onth and alwa ys before a long trip

¢ page 2 52, Checking tire pressure .

What you can do to avoid tire and rim

damage

Low aspect ratio tires can be damage d mo re

easily by impact w ith potholes, curbs, g ull ies

or ridges on t he road, partic ularly if the tire is

u nderinflated.

Ill>-

•

•

Page 271 of 310

Changing a wheel

Before changing a wheel

Observe the following precautions for your

own and your passenger's safety when chang

ing a wheel .

.,. After you experience a tire fai lure, pull the

car well away from moving traffic and try to

reach

le vel gro und before you stop¢.&_ .

.. All passengers shou ld

leav e the car and

move to a safe location (fo r instan ce, be hind

the guardra il)¢ .&_.

.. Engage the

parking br ake to prevent your

vehicle from ro lling unintentionally¢ .&_.

.. Move

selecto r leve r to posi tion P ¢ .&_ .

.. If you are tow ing a trai ler, unh itch the trai l

er from your veh icle.

.,. Take the

jack and the spare tire out of the

luggage compartment ¢

page 267,

¢page 268.

.8, WARNING

You or your passengers cou ld be injured

w hile changing a whee l if yo u do not fol

low t hese safety precautions:

- If you have a flat t ire, move a safe dis

t a nce off the ro ad. Tur n off the eng ine,

turn the emergency f lashers on an d use

other warning dev ices to alert other mo

torists.

- Make sure that passengers wait in a safe

place away from the ve hicle and well

away from the road and traff ic.

- To help p revent the vehicle from moving

sudden ly and possibly slipping off the

jack, always fu lly set the parking brake

and block the wheel diagonally opposite

the wheel being changed. Whe n one

front wheel is lifted off the ground, plac ing the A utomat ic Transm iss ion in P

(Park) will

not p revent the vehicle from

moving.

- Before you change a wheel, be su re the

ground is level and fi rm. If necessa ry,

use a sturdy board under the jack.

-

What do I do now? 269

- Always store the vehicle tool kit, the jack

and the replaced tire in the luggage com partment

¢page 136.

(D Tips

Before changing the whee l, you must acti

vate the jacking mode, so that the auto matic controls for the Adaptive Air Sus

pension* do not make it more d iff icult to

lift the vehicle with the jack

¢ page 271 .

Changing a wheel

When you change a wheel , follow these

quence described below step-by-step and in

exactly that order .

l. Activate the vehicle jack mode*

¢page 271 .

2. Remove the decorativ e whee l cover* . For

more details see also¢

page 2 70, Deco

rative wheel covers

or ¢ page 2 70,

Wheels with wheel bolt caps .

3. Loosen the wh eel bolt s ¢page 271.

4. Loca te the p roper moun ting poin t for the

jack and align the jack be low that point

¢ page 271 .

5. Rais e the car with the jack ¢ page 271.

6. Remove the wheel with the flat tire and

then install

the spare ¢page 273.

7. Tighten all whee l bolts lightly .

8.

Lo wer the vehicle with the jack .

9 . Use the wheel bolt w rench and

firmly

t ighten al l wheel bolts¢ page 2 71.

10. Rep lace the deco ra ti ve whe el c ove r*.

11. Deactivate the vehicle jack mode* in the

MMI:

ICARI f u nction button > (Car )* sy s

tems

contro l button > S ervici ng & check s

> Air s usp.: jack mod e > Off.

The vehicle jack mode * switches off automati

ca lly at speeds above 6 mph (10 km/h) .

.8, WARNING

-Always read and fo llow all WARNINGS and

i nformat ion¢

A in Raising the vehicle on

page

272 and ¢ page 274.

•

•

Page 273 of 310

Loosening and tightening the wheel

bolt s

The wheel bolts must be loosened before rais

ing the vehicle.

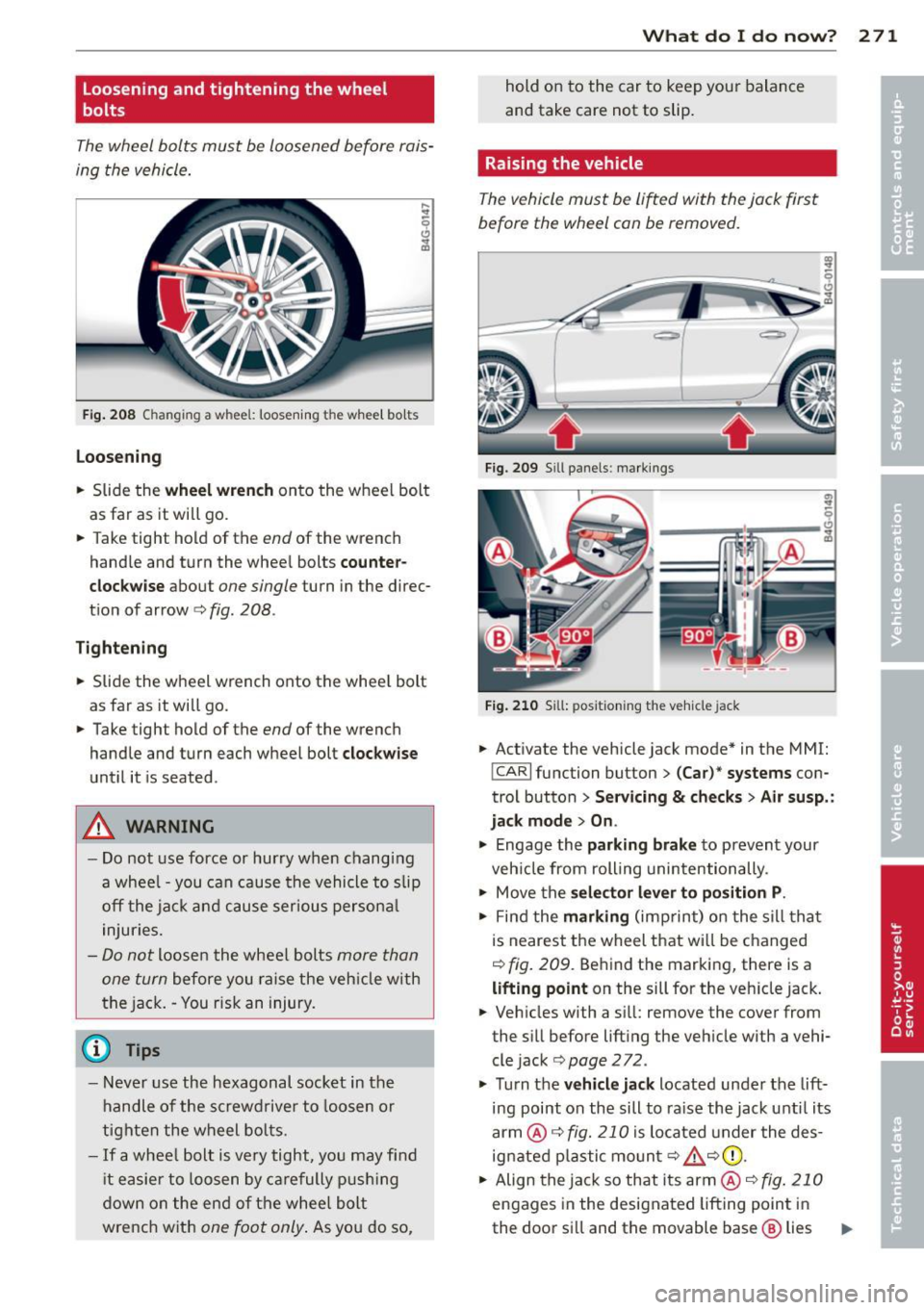

F ig. 208 Changing a whee l: loos enin g the wh eel bo lt s

Loo sening

.. Slide the whe el w re nch onto the wheel bolt

as far as it wi ll go .

.. Take tight hold of th e

end of the wrench

hand le and turn the whee l bolts

counte r

clock wis e

abou t one single turn in the direc

tion of arrow c:>

fig. 208 .

Tightening

.. Slide the wheel wrench onto the whee l bolt

as far as it will go.

.. Take tigh t hold of the

end of the wrench

handle and turn each wheel bolt

cl ockw ise

unt il it is seated .

A WARNING

-Do not use force or hurry when changing

a whee l -you can cause the vehicle to s lip

off the jack and cause ser ious persona l

injuries.

- Do not loosen the wheel bolts more than

one turn

before you ra ise the veh icle w ith

the jack. -You risk an injury.

(D Tips

- Never use the hexagonal socket in the

handle of the screwd rive r to loosen or

tighten the wheel bo lts.

- If a whee l bolt is very tight, you may find

i t easier to loosen by c arefully p ushi ng

down on the end of the whee l bolt

wrench with

one foot only . As you do so,

What do I d o now ? 271

hold on to the car to keep your balance

and take care not to slip .

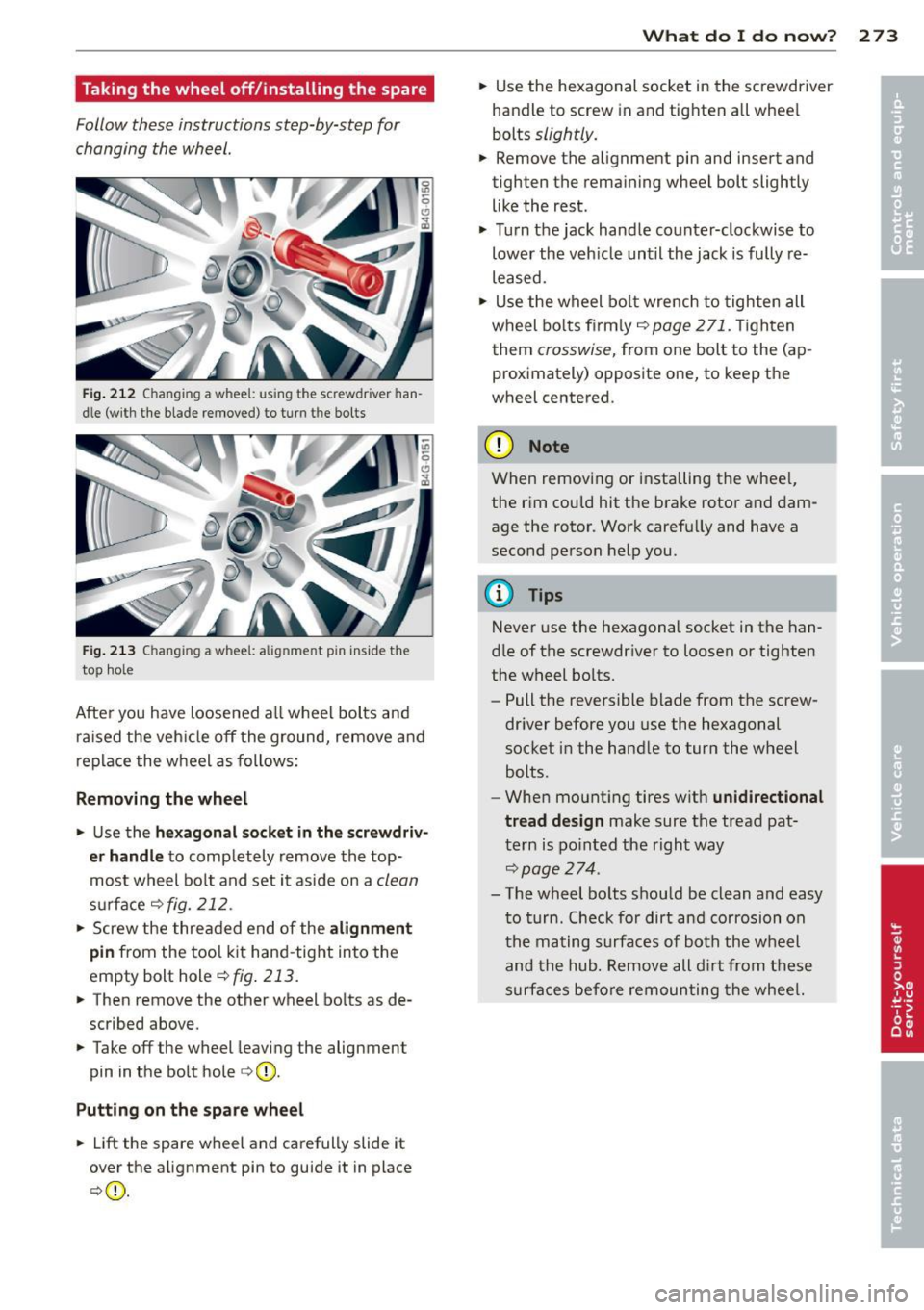

Raising the vehicle

The vehicle must be lifted with th e jack first

before the wheel can be removed.

F ig . 209 Sill panels : ma rki ngs

Fig . 210 Sill : p os it ion ing t he ve hicle jack

.. Act iv ate the vehicle jack mode* in the MMI:

!CAR I function button> (Car) * sy stems con

trol button>

S e rv icing & ch ecks > Air su sp .:

jack mode > On .

.,. Engage the park ing brake to prevent your

veh icle from rolling unintentionally .

.,. Move the

s elect or le ver to p osition P .

.,. Find the marking (imp rint) on the sill tha t

is nearest the wheel that wi ll be changed

r=> fig. 209 . Behind the marking, there is a

lifti ng p oint on the sill for the veh icle jack .

.. Veh icles wi th a s ill: remove the cover from

the sill before lift ing the veh icle wi th a vehi

cle jack

c:> page 272 .

.,. Turn the vehicl e ja ck located under the lift

ing point on the sill to ra ise the jack unti l its

arm @ c:>

fig. 210 is located under the des

ignated p lastic moun t c:> &, c:>(D .

.. Align the jack so that its arm@c:>

fig. 210

engages in the designated lifting point in

the door sill and the movable base @ lies

~

Page 275 of 310

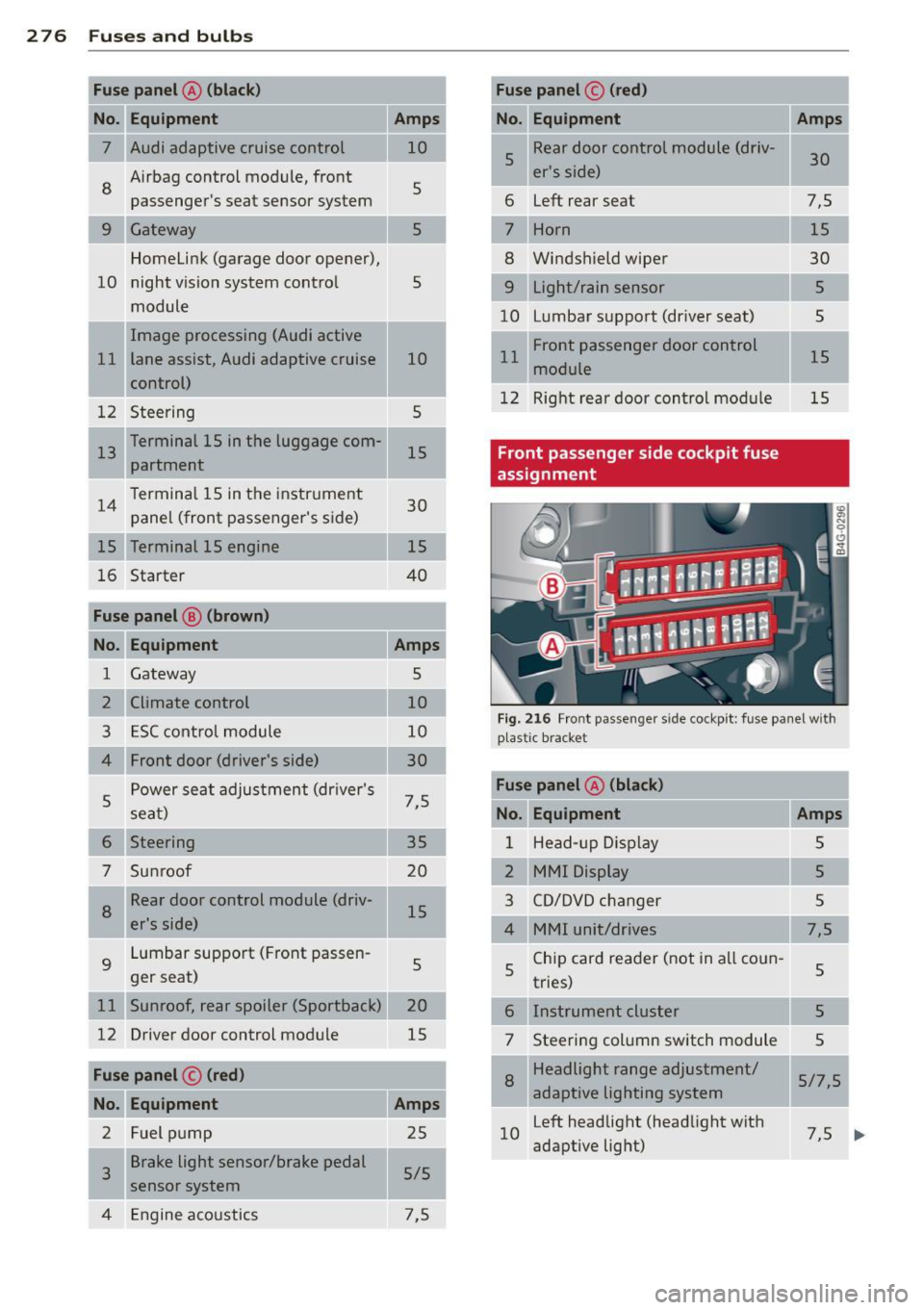

Taking the wheel off/installing the spare

Follow these instructions step-by-step for

changing the wheel.

Fig. 2 12 Changing a wheel: using the screwdriver han

dle (with the blade removed} to turn t he bo lts

F ig . 2 13 Changing a wheel: alignm en t pin ins ide the

top hole

After you have loosened a ll wheel bolts and

ra ised the veh icle off the ground, remove and

replace the wheel as follows:

R emoving the wheel

.. Use the hex agon al so ck et in th e scr ew dr iv

e r handle

to comp letely remove the top

most wheel bo lt and set it aside on a

clean

s u rface Q fig. 212 .

.. Screw the threaded end of the alignm ent

pin from the tool k it hand -tight into the

empty bolt hole

Qfig . 213.

.. Then remove the other wheel bo lts as de

scribed above .

.. Take off the wheel leaving the alignment

pin in the bolt hole

Q (D.

Putting on the spar e wheel

.. Lift the spare wheel and carefully slide it

over the alignment pin to guide it in place

Q (D.

What do I d o now ? 273

.. Use the hexagonal socket in the screwdriver

handle to screw in and tighten all wheel

bolts

slightly.

.. Remove the alignment pin and insert and

tighten the remaining wheel bolt slightly like the rest.

.. Turn the jack handle counter-clockwise to

lower the veh icle until the jack is fully re

leased .

.. Use the wheel bo lt wrench to tighten all

wheel bo lts firm ly

Q page 271. Tighten

them

crosswise, from one bolt to the (ap

proximately) opposite one, to keep the

wheel centered.

(D Note

When removing or installing the whee l,

the rim could hit the brake rotor and dam

age the rotor. Work carefully and have a

second person help you.

@ Tips

Never use the hexagonal socket in the han

dle of the screwdriver to loosen or tighten

the w heel bolts.

- Pull the reversible blade from the screw

dr iver before you use the hexagonal

socket in the hand le to turn the wheel

bolts.

- When mounting tires w ith

unidi rectional

tread design

make sure the tread pat

tern is po inted the right way

~page 274.

-The wheel bo lts shou ld be clean and easy

to turn . Check for dirt and corrosion on

the mating surfaces of both the wheel

and the hub. Remove all d irt from these

surfaces before remounting the whee l.

Page 278 of 310

2 76 Fuses and bulbs

Fuse panel

@ (bl ack )

No. Equ ipment

= 7 Audi adaptive cruise control

8 Airbag control module, front

passenger's seat sensor system

9 Gateway

Homelink (garage door opener),

10 night vision system contro l

module

Image processing (Audi active

11 lane assist, Audi adaptive cruise

control)

12 Steering

I 13 Terminal 15 in the luggage com-

partment

14 T

ermina l 15 in the instr ument

pane l (front passenger's s ide)

15 Terminal 15 engine

16 Starter

Fuse panel B (brown)

No. Equipment

1 Gateway

2 Climate control

3 E SC con trol module

Front door (driver's side)

5 Power seat adjustment (dr

iver's

sea t)

6 Steering

7 Sun roof

8

R ear door control module (driv-

er's side)

9

Lumbar support ( Front passen-

ger seat)

11 Sunroof, rear spoiler ( Sportbac k)

12 Driver door control mod

ule

Fuse panel c (red)

No. Equipment

2 Fuel p ump

.

3

Brake light sensor/brake pedal

sensor s ystem

4 Engine aco ustics

Amp s

10

5

5

10

5

15

30 15

40

Amps

5

10

10

30

7,5

35

20 15

5

20

15

Amps

25

5/5

7 ,5

-Fuse panel © (red )

No. Equipment Amps

=· Rear door control module (driv-

5 30

er's side)

6 Left rear seat ______ , 7,5

Ho rn 15

Windshield wiper ____ 30

Light/rain sensor ___ 5

10 Lumba r support (dr iver seat) 5

11 Front passenger door control

module

1 2 Rig ht rear door control mod ule

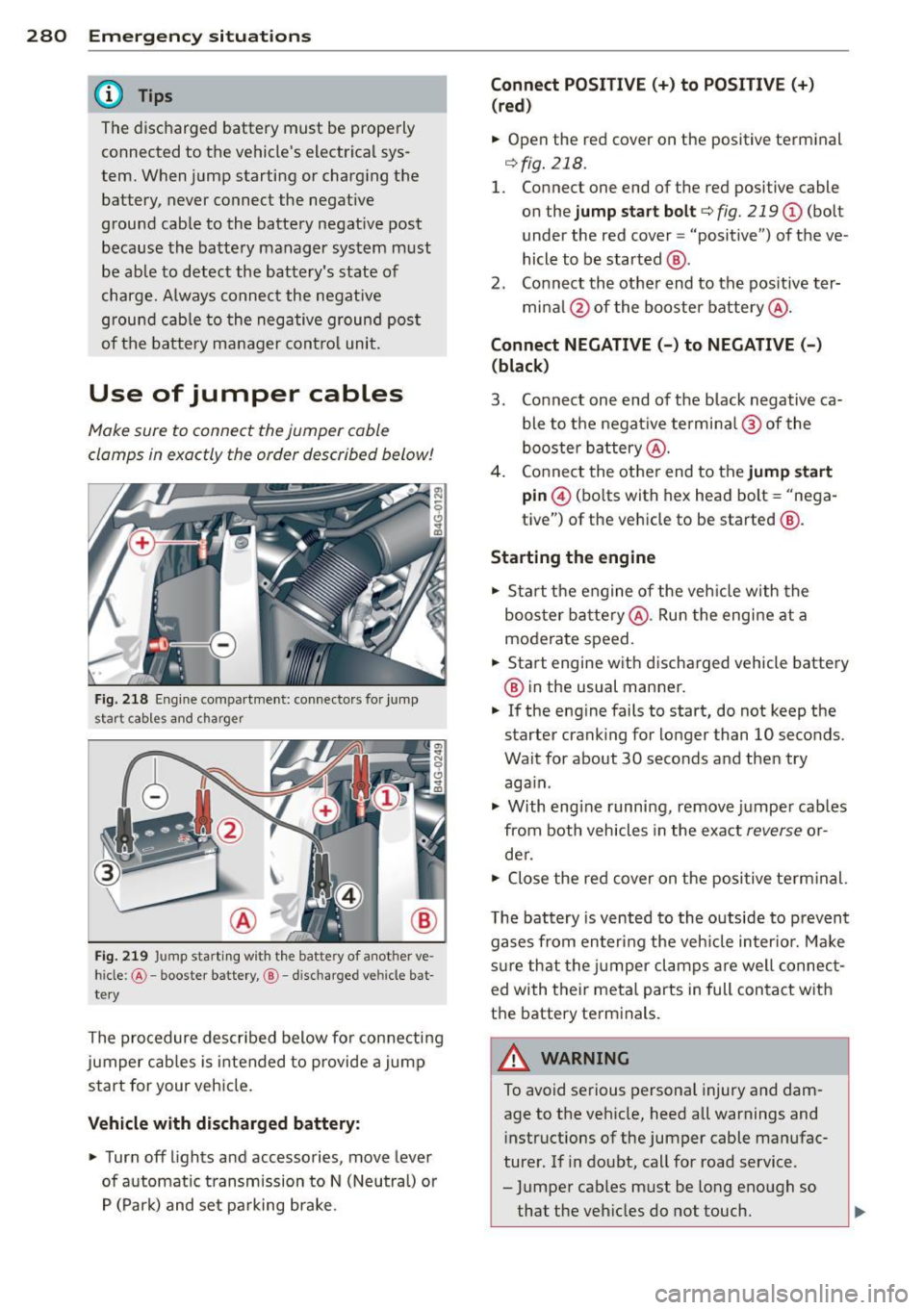

Front passenger side cockpit fuse

assignment

15

15

Fig. 21 6 Fro nt passen ger sid e co ckp it : fu se pa nel w it h

p last ic brac ket

Fuse panel @ (black)

No. Equipment Amps

1 Head-up D is p la y 5

2

MMI Display 5

3 C D/DVD changer 5

4 MMI unit/drives 7,5

5 Chi

p card rea der (not in a ll co un-

5

tries)

6 Instrument cluster 5

7 Stee

ring column switch module

5

8 Headlight range adjustment/

5/7,5

adaptive lighting sys tem

1 0 Left headlight (head

light wit h

7,5

adaptive light)

I

...

Page 279 of 310

Fuse s and bulb s 2 77

Fuse panel @ (brown) Fuse panel@ (red )

No. Equipment Amps No.

Equipment Amps

Climate control 10 1 Left belt tensioner 25

Climate control system blower 40 2 Right belt tensioner 25

3

Diagnost ic connec tor 10 3 Socke t 20

4

Electrical ignition lock 5 4 Socket 20

5

Power s teering colum n adj ust-

5 ment

5 Ele ctromechanical parking brake 5

6 adaptive air suspension 15

6 Steering column switch module 10

7

Power steering column adjust -

25

ment

7

Rear door (front passenger 's

30 side)

8 Rear e xterior lighting 30

8 Light switch 5

9

L u ggage compa rtment lid con-

30

trol modu le

Luggage compartment fuse assignment Telephone 5

11

Sound amplif ier 30

12

Rear spoiler (Sportback) 20

Fuse panel © (b rown )

No . Amps

1

Radio receiver, Sound amplifier/ 30/20

MMI unit/drives

2 Tank leak detection system 5

Fig. 2 17 Luggage co mpar tment: fuse panel w ith plas-

t ic b racke t 4

AEM co ntrol module/battery 10/15

module

Fuse p anel A (black )

Battery fan 35

Radio receive r 7,5

No. Equipment Amps 8 Rear Seat Entertainment 7,5

Electromechanical parking brake 30

Electromechanical parking brake 30 9

Automatic d imm ing interior 5/15

rearview mirror/battery mod ule

6

Front door (front passenger's

30 side)

10 Parking system 5

7

Rear exterior lighting 30 Fuse panel @ (green )

Rear sun shade, clos ing aid, lug-No .

Equipment Amps

8

gage compartment lock, con-

20 venience key, START ENGINE

1 Aud i pre sense 5

2

Electromechanical parking brake 5

STOP, fuel fi ller door 3 ad aptive air suspens ion 5

9 Power seat adjustment 15

4 Automatic transmission 7,5

10

Parking system 5 5 Parking system 5

11

Rear seat heating 30 6 Rear Seat Entertainment 5

7

Sta rt -Stop-Sys tem 5

8 Audi side assist 5

Page 282 of 310

280 Emergency situations

@ Tips

The discharged battery must be properly

connected to the vehicle's electrical sys

tem. When jump starting or charging the

battery, never connect the negative

ground cable to the battery negative post

because the batte ry manager system must

be able to detect the battery 's state of

charge. Always connect the negative

ground cab le to the negative ground post

of the battery manager control unit.

Use of jumper cables

Make sure to connect the jumper cable

clamps in exactly the order described below!

Fig. 218 Engine compartment: connecto rs for jump

start cables and charger

Fig. 219 Jump start ing with the battery of another ve·

hide: @-booster battery, @-discharged ve hicle bat

tery

The procedure described below fo r connecting

jumper cables is intended to provide a jump

start for your vehicle.

Vehicle with discharged battery:

.,. Turn off lights and accessories, move lever

of automatic transmission to N (Neutral) or

P (Park) and set parking brake.

Connect POSITIVE(+) to POSITIVE(+)

(red)

.,. Open the red cover on the positive terminal

¢fig. 218.

1. Connect one end of the red positive cable

on the

jump start bolt c::;, fig. 219 @ (bolt

under the red cover = "positive") of the ve

hicle to be started @.

2. Connect the other end to the positive ter-

mina l@ of the booster battery@.

Connect NEGATIVE (-) to NEGATIVE (-)

(black)

3. Connect one end of the black negative ca

ble to the negat ive terminal @ of the

booster battery @.

4. Connect the other end to the

jump start

pin © (bolts with hex head bolt= "nega

tive") of the vehicle to be started @.

Starting the engine

.,. Start the engine of the veh icle with the

booster battery@. Run the engine at a

moderate speed .

.,. Start engine with d ischarged vehicle battery

@ in the usual manner.

.,. If the engine fails to start, do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try aga in .

.,. With eng ine running,

remove jumper cables

from both vehicles in the exact

reverse o r

de r .

.,. Close the red cover on the positive term inal.

T he battery is vented to the outside to prevent

gases from entering the veh icle inter ior. Make

sure that the jumper clamps are well connect

ed with their metal parts in full contact with

the battery terminals.

_& WARNING

To avoid serious personal injury and dam

age to the vehicle, heed all warnings and

instructions of the jumper cable manufac

turer. If in doubt, call for road service .

- Jumper cables must be long enough so

that the veh icles do not touch.

-

Page 283 of 310

-When connecting jumper cables, make

sure that they cannot get caught in any

moving parts in the eng ine compart

ment .

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS ¢

page 224, Engine com

partment.

(D Note

Improper hook-up of jumper cables can r u

in the generator.

- Always connect POSITIVE(+) to POSI

TIVE(+), and NEGA TIVE( -) to NEGATIVE

( - ) ground post of the battery manager

control u nit .

- Check that all sc rew plugs on the battery

cells are screwed in firmly. If not, tighten

pl ugs p rior to connecting clamp on nega

tive batt ery terminal.

- P lease note that the procedure for con

nect ing a jump er cable as describe d

above applies spec ifically to the case of

your vehi cle be ing j ump s tarted. When

you are giving a jump star t to anothe r ve

hicle, do

not connec t the negative( -) ca

b le to the negat ive (-) term inal on the

discharged battery@¢

fig. 219. In

stead, securely connect the negative(-)

cable to e ither a solid metal component

that is firmly bolted to the engine block

or to the engine block itself.

If the bat

te ry tha t is being charged does not vent

to the ou tside, es ca ping b attery gas

could ignite and ex plode!

Emergency towing

with commercial tow

truck

General hints

Your Audi requires special handling for tow

ing .

The fo llow ing informa tion is to be used by

commercia l tow tr uck operators who know

how to ope rate thei r equipmen t sa fe ly.

Emergenc y situ ation s 281

-Ne ver tow your Audi. Towing will cau se

damage to the engine and tran smission.

- Never wrap the safety chain s or w inch ca

ble s around the brake lines.

- To prevent unnece ssary damage , your Audi

must be transported with a flat bed tru ck.

- To load the vehicle on to the fl at bed , use

the towing loop found in the vehicle tools

a nd attach to the front or rear anchora ge

¢page 281 and ¢page 282 .

_& WARNING

A vehicle being towed is not safe for pas

sengers. Never allow anyo ne to ride in a

vehicle be ing towed, for any reason.

Front towing loop

Only install the front towing loop when it is

needed.

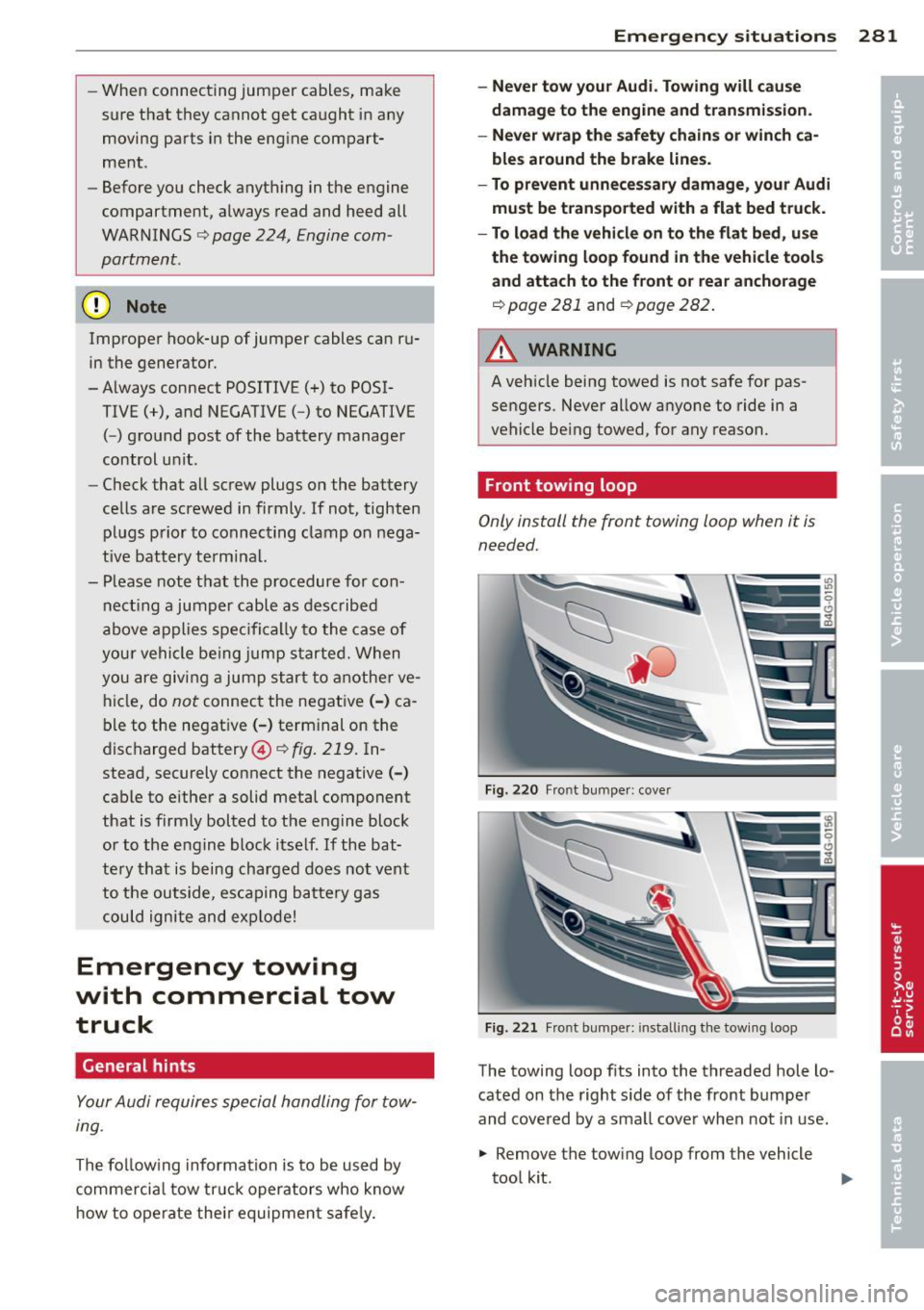

Fig. 22 0 Front bumpe r: cove r

Fig. 22 1 Front bu mpe r: in stall ing t he tow ing loop

-

The towing loop fits into the threaded hole lo

cated on the right s ide of the front bumpe r

and cove red by a sma ll cover when not in use.

.. Remove the tow ing loop from the vehicle

too l kit .