flat tire AUDI S8 2016 Owner's Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2016, Model line: S8, Model: AUDI S8 2016Pages: 302, PDF Size: 75.68 MB

Page 265 of 302

c::> fig. 222 is located under the designated plas

tic mount

c::> A in AB: Raising the vehicle on

page

262 <=:>(D.

.. Align the jack so that its arm®

c::> fig. 222 en

gages in the designated lifting point in the door

sill and the movable base ® lies flat on the

ground . The base ® must be

vertical under the

li ft ing po int @ .

.,. Wind the jack up further unt il the fla t tire

c omes off the ground

c::> A in AB: Raising the

vehicle on page

262.

Position the veh icle jack

onl y under the designat

ed lifting points on the sill

<=:>page 261, fig. 219 .

There is exactly one locatio n for each wheel. The

jack must not be positioned at any other location

c::> .&. in AB: Raising the vehicle on page 262<=:> 0.

An

un stabl e surface under the jac k can ca use the

vehi cle to slip off the jack . Always provide a firm

base for the jack on the ground. If necessary

p lace a sturdy board or similar support under the

jack. On

hard , slippery surfaces (such as tiles)

use a rubber mat or similar to prevent the jack

from slipping

c::> .&. .

A WARNING

-

-You or your passengers could be injured

wh ile chang ing a wheel if you do not follow

these safety precautions :

- Position the vehicle jack only at the desig

nated lifting points and align the jack.

Otherw ise, the vehicle jack cou ld slip and

cause an injury if it does not have suffi

cient hold on the vehicle.

- A soft or unstable surface under the jack

may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on

the ground .

If necessary, use a sturdy

board under the jack.

- O n hard, s lippery surface (such as tiles)

use a rubber mat or s imilar to prevent the

jack from slipp ing.

- To help prevent inju ry to yourself and your

passenge rs:

- Do not raise the vehicle unt il you are sure

the jack is secure ly engaged .

Emergen cy a ssis tanc e

-Passengers must not remain in the vehicle

when it is jacked up.

- Make sure that passengers wait in a safe

place away from the vehicle and well away

from the road and traffic.

- Make sure jack position is correct, adjust

as necessary and then continue to raise

the jack .

- Changes in temperature or load can affect

the height of the veh icle.

(D Note

Do not lift the vehicle by the si ll. Position the

vehicle jack on ly at the designated lift ing

points on the sill. Otherwise, your veh icle w ill

be damaged.

@ Tips

The vehicle jack mode switches off automati

cally at speeds

above 10 km/h.

Taking the wheel off/installing the spare

Follow these instructions step-by-step for chang

ing the wheel .

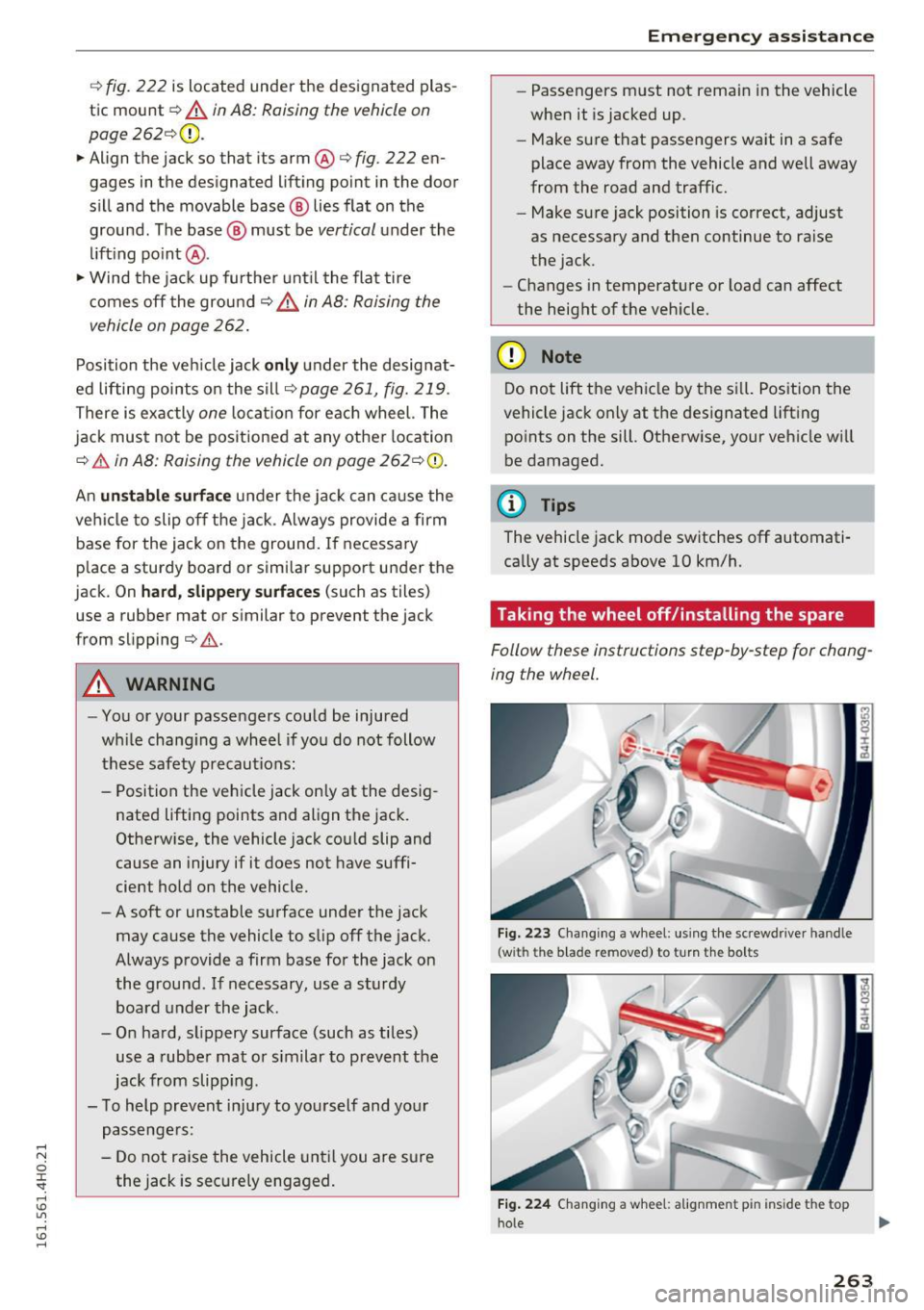

Fig . 223 Cha ngin g a w heel: us ing the screwdriver handle

(wit h the b lade removed) to turn th e bolts

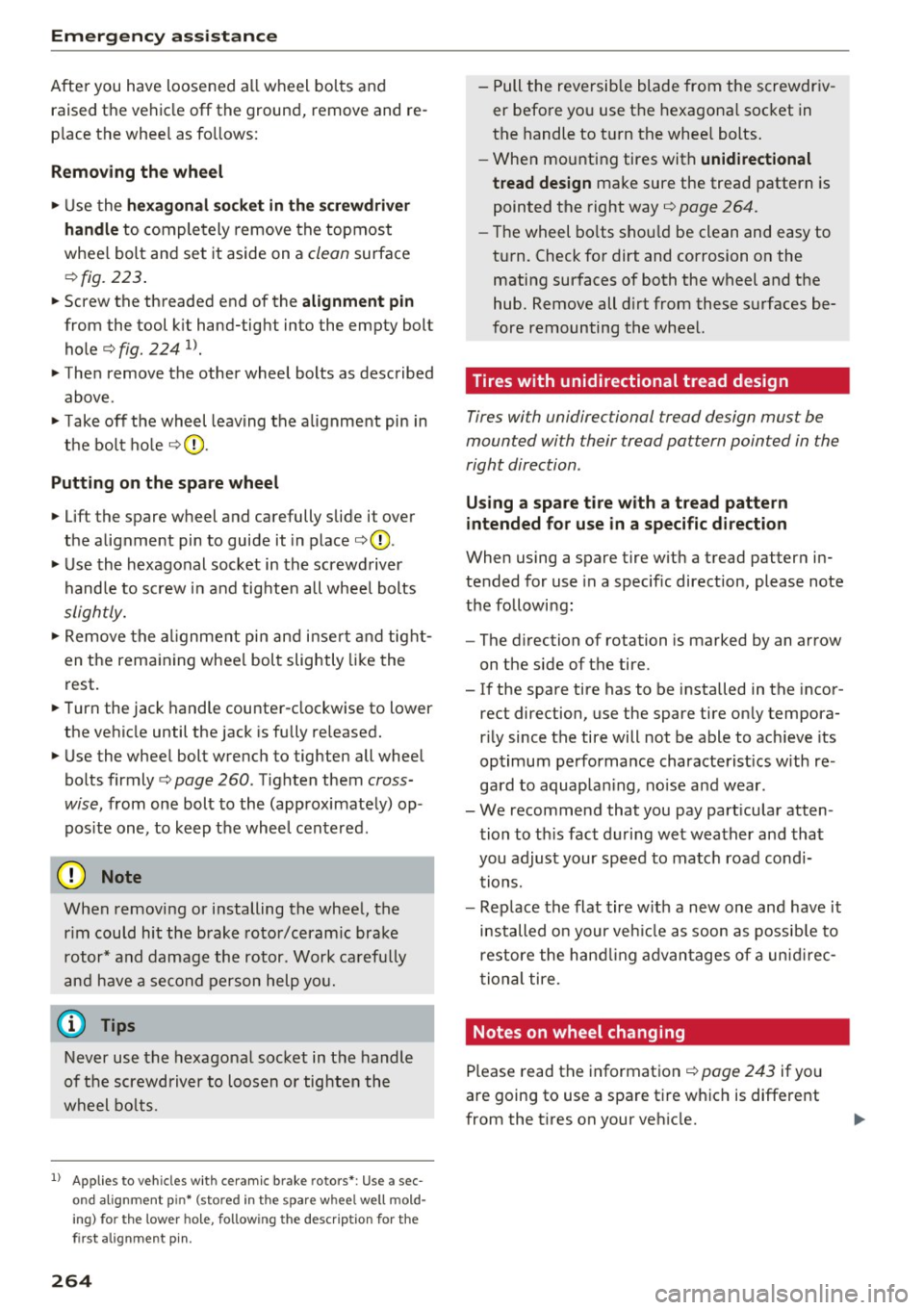

Fig. 224 Changing a w hee l: a lig nment p in in side the top

hole

263

Page 266 of 302

Emergency assistance

After you have loosened all wheel bolts and raised the vehicle off the ground, remove and re

place the wheel as follows:

Removing the wheel

.,. Use the hexagonal socket in the screwdriver

handle

to completely remove the topmost

wheel bolt and set it aside on a

clean surface

.::!> fig. 223.

.,. Screw the threaded end of the alignment pin

from the tool kit hand-tight into the empty bolt

hole¢

fig. 224 1> .

.,. Then remove the other wheel bolts as described

above.

.,. Take off the wheel leaving the alignment pin in

the bolt hole ¢0 .

Putting on the spare wheel

.,. Lift the spare wheel and carefully slide it over

the alignment pin to guide it in place ¢0 .

.,. Use the hexagonal socket in the screwdriver

handle to screw in and tighten all wheel bolts

slightly .

.,. Remove the alignment pin and insert and tight

en the remaining wheel bolt slightly like the

rest.

.,. Turn the jack handle counter-clockwise to lower

the vehicle until the jack is fully released.

.,. Use the wheel bolt wrench to tighten all wheel

bolts firmly ¢

page 260 . Tighten them cross

wise,

from one bolt to the (approximately) op

posite one, to keep the wheel centered.

0 Note

When removing or installing the wheel, the

rim could hit the brake rotor/ceramic brake

rotor* and damage the rotor . Work carefully

and have a second person help you.

Never use the hexagonal socket in the handle

of the screwdriver to loosen or tighten the

wheel bolts.

1

> A pp lies to vehicles with cer amic brake rotors*: Use a sec

o n d alignment p in* (sto re d in th e s pare w hee l well mold

in g) fo r the lower hole , fol low ing the descrip tion for the

fir st a lig nme nt pin .

264

-Pull the reversible blade from the screwdriv

er before you use the hexagonal socket in

the handle to turn the wheel bolts.

- When mounting tires with

unidirectional

tread design

make sure the tread pattern is

pointed the right way¢

page 264.

-The wheel bolts should be clean and easy to

turn. Check for dirt and corrosion on the

mating surfaces of both the wheel and the

hub. Remove all dirt from these surfaces be

fore remounting the wheel.

Tires with unidirectional tread design

Tires with unidirectional tread design mus t be

mounted with their tread pattern pointed in the

right direction .

Using a spare tire with a tread pattern

intended for use in a specific direction

When using a spare tire with a tread pattern in

tended for use in a specific direction, please note

the following:

- The direction of rotation is marked by an arrow

on the side of the tire.

- If the spare tire has to be installed in the incor

rect direction, use the spare tire only tempora

rily since the tire will not be able to achieve its

optimum performance characteristics with re

gard to aquaplaning, noise and wear.

- We recommend that you pay particular atten

tion to this fact during wet weather and that

you adjust your speed to match road condi tions.

- Replace the flat tire with a new one and have it

installed on your vehicle as soon as possible to

restore the handling advantages of a unidirec

tional tire.

Notes on wheel changing

Please read the information¢ page 243 if you

are going to use a spare tire which is different

from the tires on your vehicle.

Page 267 of 302

After you change a tire:

- Check the tire pressure on the spare immedi

ately after in stallation.

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as pos

s ible by your authorized Audi dealer or a

qualified servi ce stat ion .

- With steel and alloy wheel rims, the wheel

bolts are correctly tightened at a torque of 90

ft lb (120 Nm).

- If you notice that the wheel bolt s are corroded

and difficult to turn while changing a tire,

they should be replaced before you check the

tightening torque .

- Replace the flat tire with a new one and have

it installed on you r vehicle as soon as possi

ble. Remount the wheel cover .

Until then, drive with extra care and at reduced

speeds.

& WARNING

- If you are going to equ ip your vehi cle w it h

t ir es o r rims which differ f rom those which

we re factory installed, then be s ure to read

the info rmat io n ¢

page 243.

- Always ma ke sure the damaged whee l or

even a flat tire and the jack and tool kit a re

prope rly secured in the luggage com part

me nt and are not loose in t he passenger

compar tment.

- In an accident o r sudden maneuver they

cou ld fly forward, inju ring anyone in the ve

hicle.

- Always store damaged whee l, jac k and too ls

sec urely in the luggage co mpartment . Oth

erwise, in an accide nt or sudd en man euver

they could fly fo rw ar d, ca usin g injury to p as

sengers i n the vehicle .

-

Emergency assistance

265

Page 276 of 302

Emerg ency s it u ation s

_& WARNING

If you do not screw the towing loop complete

ly, it could come out of the threaded hole

wh ile the vehicle is be ing towed causing dam

age to the vehicle and poss ible serious per

sonal injury.

Rear towing loop

Only install the rear towing loop when it is need

ed .

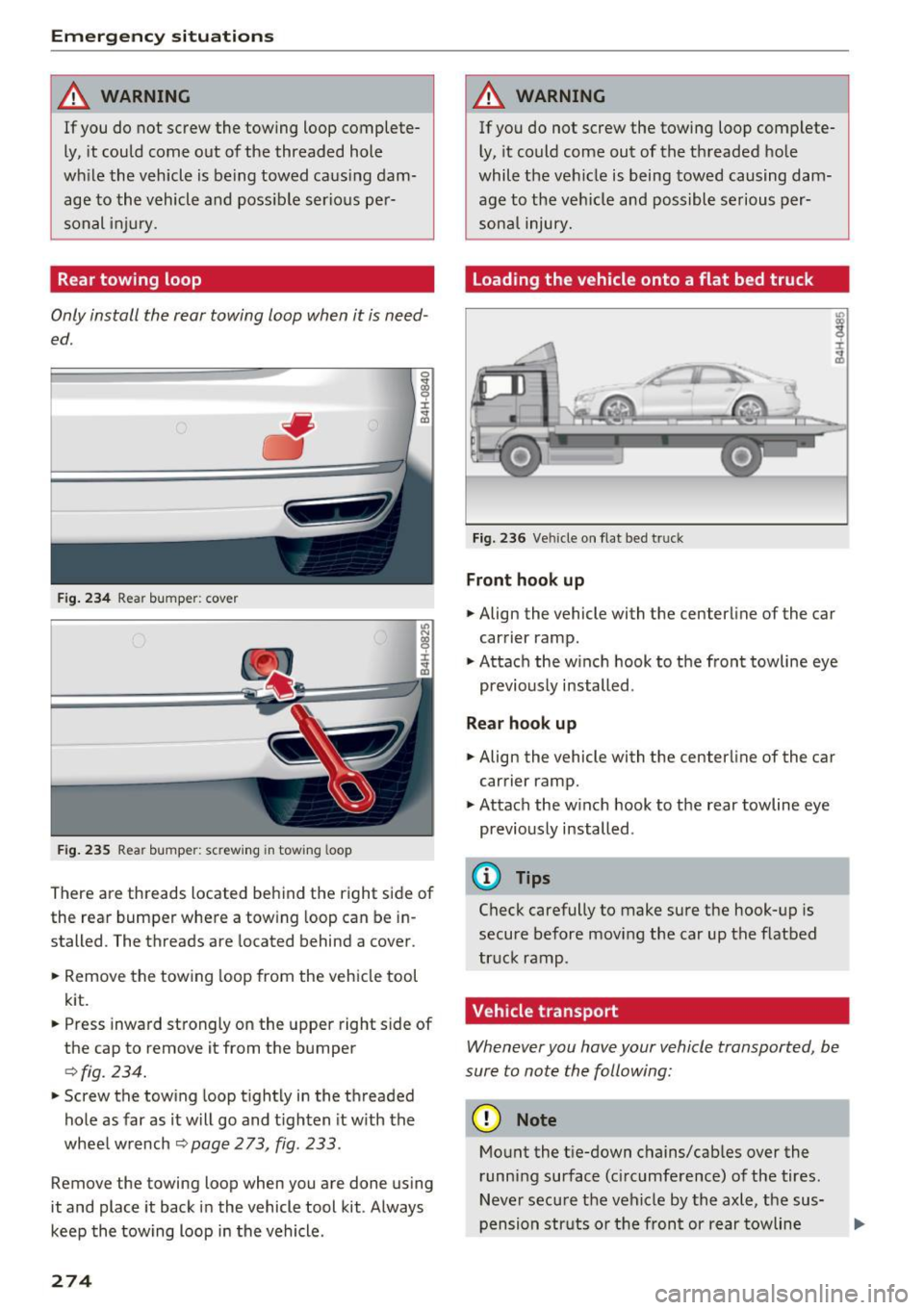

Fig . 234 Rea r bumper: cover

Fig . 235 Rear bumper: screwing in tow ing loop

There are threads located behind the right side of

the rear bumper where a tow ing loop can be in

stalled. The threads are located behind a cover.

" Remove the towing loop from the veh icle tool

kit.

" Press inward strongly on the upper right side of

the cap to remove it from the bumper

¢fig. 234.

"Screw the towing loop t ightly in the threaded

hole as far as it will go and t ighten it w ith the

whee l wrench

¢ page 273, fig . 233 .

Remove the towing loop when you are done us ing

it and place it back in the vehicle tool kit . Always

keep the towing loop in the vehicle .

274

_& WARNING

If you do not screw the towing loop complete

ly, it could come out of the threaded hole

while the vehicle is being towed causing dam

age to the veh icle and possible serious per

sonal injury.

Loading the vehicle onto a flat bed truck

Fig. 236 Ve hicle on flat bed t ruck

Fron t hook up

" Align the vehicle with the centerline of the car

carrier ramp .

.,. Attach the w inch hook to the front towline eye

previously installed .

Rear hook up

.,. Align the vehicle with the centerline of the car

carrier ramp .

.,. Attach the winch hook to the rear towline eye

previously installed .

@ Tips

Check carefully to make sure the hook-up is

secure before moving the car up the flatbed

tr uck ramp .

Vehicle transport

Whenever you hove your vehicle transported, be

sure to note the following:

(D Note

Mount the t ie-down chains/cab les over the

runn ing surface (c ircumference) of the tires .

Never secure the vehicle by the axle, the sus

pension str uts or the front or rear towline

Page 292 of 302

Index

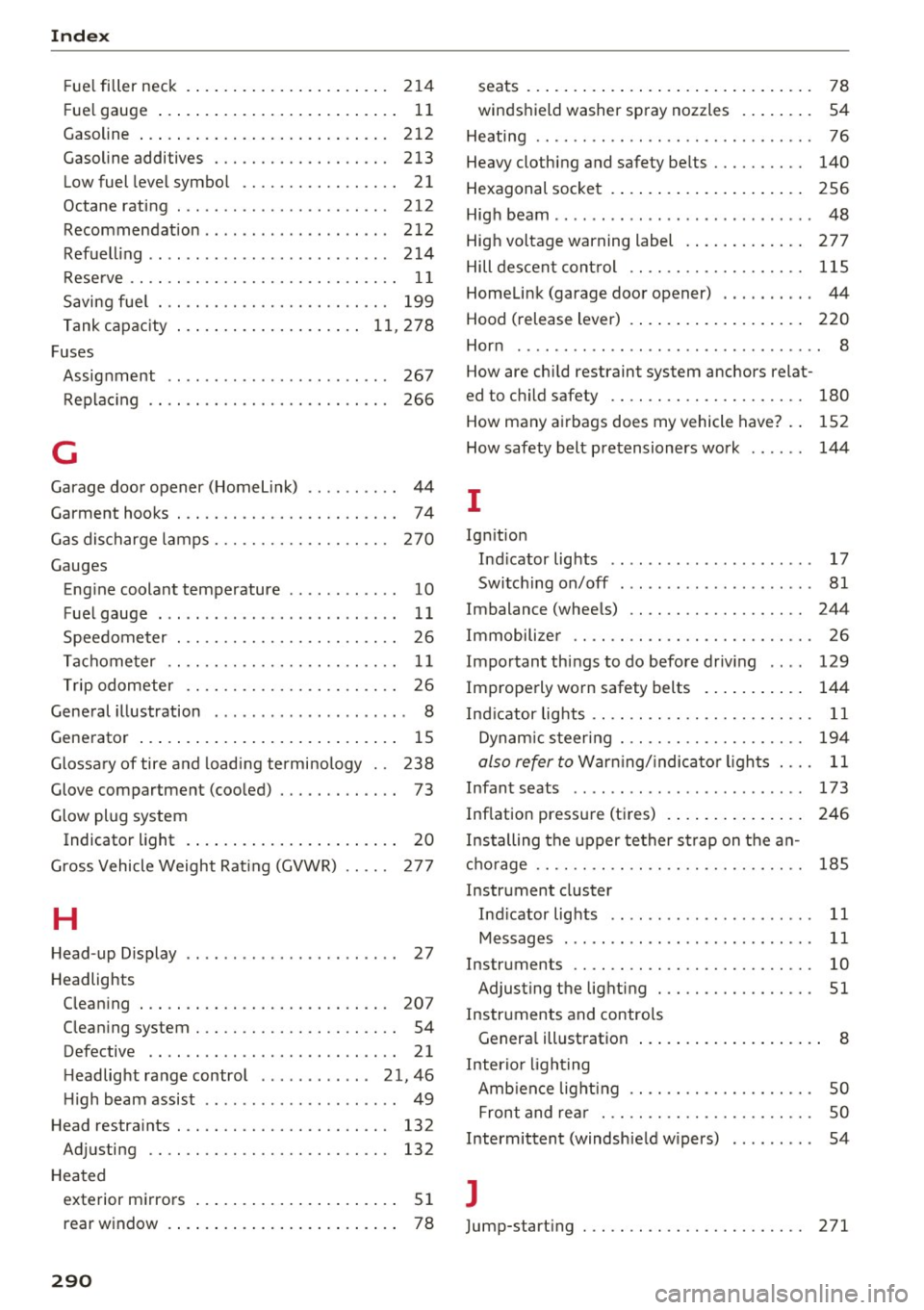

Fue l filler neck . . . . . . . . . . . . . . . . . . . . . . 214

F ue l gauge . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 12

Gasoline additives . . . . . . . . . . . . . . . . . . . 213

Low fuel level symbo l . . . . . . . . . . . . . . . . . 21

Octane rating . . . . . . . . . . . . . . . . . . . . . . . 212

Recommendation ... .... ...... ... ... . 212

Refuell ing . . . . . . . . . . . . . . . . . . . . . . . . . . 214

R ese rve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Saving fue l . . . . . . . . . . . . . . . . . . . . . . . . . 199

Tank capac ity ... .. . .. ..... ... .. .. 11,278

Fuses Assig nment . . . . . . . . . . . . . . . . . . . . . . . . 267

R ep lac ing . . . . . . . . . . . . . . . . . . . . . . . . . . 266

G

Garage doo r opener (Home Link) . . . . . . . . . . 4 4

Garment hooks . . . . . . . . . . . . . . . . . . . . . . . . 74

Gas discharge lamps. . . . . . . . . . . . . . . . . . . 270

Gauges Eng ine coolant temperature . . . . . . . . . . . . 10

Fue l gauge . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Speedometer . . . . . . . . . . . . . . . . . . . . . . . . 26

Ta chometer . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Trip odometer . . . . . . . . . . . . . . . . . . . . . . . 26

General illustration . . . . . . . . . . . . . . . . . . . . . 8

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Glossa ry of tire a nd loadi ng terminology . . 238

Glove compartment (coo led) . . . . . . . . . . . . . 73

Glow plug system Indicator light . . . . . . . . . . . . . . . . . . . . . . . 20

Gross Vehicle Weight Rat ing (GVWR) . . . . . 277

H

Head-up Display . . . . . . . . . . . . . . . . . . . . . . . 27

Headlights Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Clean ing system . . . . . . . . . . . . . . . . . . . . . . 54

Defective . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

H eadlig ht ra nge control ............ 21, 46

Hi gh beam assist . . . . . . . . . . . . . . . . . . . . . 49

Head restra ints . . . . . . . . . . . . . . . . . . . . . . . 132

Ad justing . . . . . . . . . . . . . . . . . . . . . . . . . . 132

H ea ted

exterior mirrors . . . . . . . . . . . . . . . . . . . . . . 51

rear window . . . . . . . . . . . . . . . . . . . . . . . . . 78

290

seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

winds hield washer spray nozzles . . . . . . . . 54

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Heavy clothing and safety be lts . . . . . . . . . . 140

Hexagonal socke t . . . . . . . . . . . . . . . . . . . . . 256

Hig h beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

High voltage warning label . . . . . . . . . . . . . 277

Hill descen t cont rol . . . . . . . . . . . . . . . . . . . 115

Homelink (garage door opener) . . . . . . . . . . 44

Hood (release lever) . . . . . . . . . . . . . . . . . . . 220

Hor n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How are child restraint system anchors relat-

ed to ch ild safety . . . . . . . . . . . . . . . . . . . . . 180

How many a irbags does my vehicle have? . . 152

How safety belt pre tensioners work 144

I

Ign ition

Ind icator lights . . . . . . . . . . . . . . . . . . . . . . 17

Swi tc hi ng on/off . . . . . . . . . . . . . . . . . . . . . 81

Imbalance (wheels) . . . . . . . . . . . . . . . . . . . 244

Immobili ze r . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Important things to do before driv ing . . . . 129

Imprope rly worn safety belts . . . . . . . . . . . 144

I nd icator lights .. .. .. .. ... ............ . 11

Dynam ic steering . . . . . . . . . . . . . . . . . . . . 194

also refer to War ning/ indica to r li ghts . . . . 11

Infan t seats . . . . . . . . . . . . . . . . . . . . . . . . . 173

Inflation pressure (ti res) . . . . . . . . . . . . . . . 246

I nstalling the upper tether st rap on the a n

c h o rage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Instrument cluster

Ind icator lights . . . . . . . . . . . . . . . . . . . . . . 11

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust ing the lighting . . . . . . . . . . . . . . . . . 51

I nstruments and contro ls

Genera l ill ustration . . . . . . . . . . . . . . . . . . . . 8

I nter io r lighting

Amb ien ce lig hting . . . . . . . . . . . . . . . . . . . . SO

Front and rea r . . . . . . . . . . . . . . . . . . . . . . . SO

Intermittent (windshie ld w ipers) . . . . . . . . . 54

]

Jump-start ing . . . . . . . . . . . . . . . . . . . . . . . . 271