jack points AUDI TT 2012 Owners Manual

[x] Cancel search | Manufacturer: AUDI, Model Year: 2012, Model line: TT, Model: AUDI TT 2012Pages: 132, PDF Size: 89.43 MB

Page 115 of 132

Downloaded from www.Manualslib.com manuals search engine 226Whatdo1donO\N?.--------------------------------------

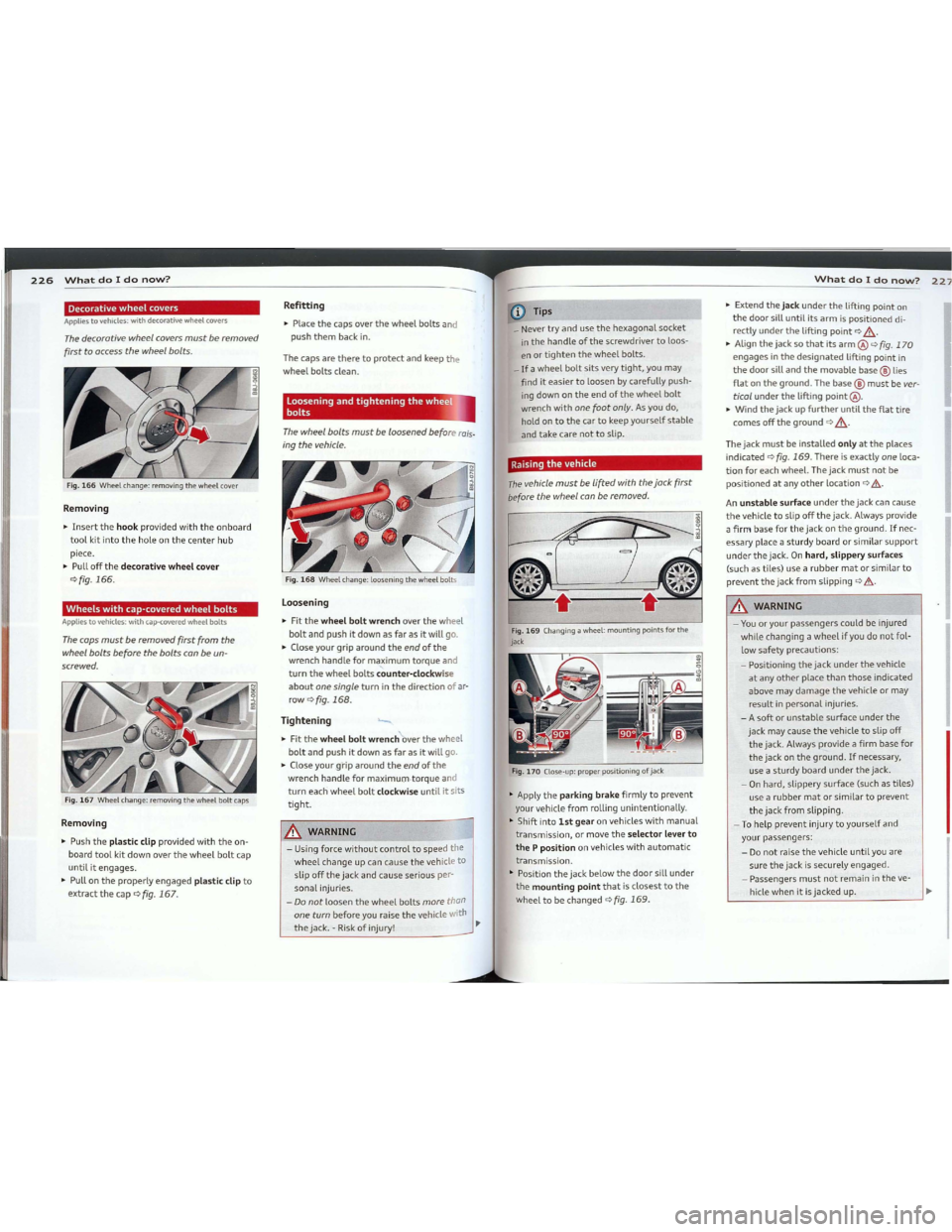

~Extendthejackundertheliftingpointon

thedoorsilluntil itsarmispositioneddi

rectlyundertheliftingpoint9A.

~Alignthejack50thatitsarm@~fig.170

engagesinthedesignatedliftingpointin

thedoorsillandthemovable base®lies

flatontheground.Thebase®mustbever

tical

undertheliftingpoint@.

~Windthejack upfurtheruntiltheflattire

comesofftheground~A.

AWARNING

-Vouoryourpassengerscould beinjured

while changing a

wheelifyoudonotfol

lowsafetyprecautions:

- Positioning

thejackunderthevehicle

atanyotherplacethanthoseindicated

above may

damagethevehicle ormay

resultinpersonalinjuries.

- A

softorunstablesurfaceunderthe

jack maycausethevehicletoslipoff

thejack. Always provide afirm basefor

thejackontheground.Ifnecessary,

use a

sturdyboardunderthejack.

-

Onhard, slipperysurface{suchastiles}

use a

rubbermatorsimilartoprevent

thejack from slipping.

-

Tohelppreventinjurytoyourself and

your

passengers:

-Donotraisethevehicle untilyouare

surethejackissecurelyengaged.

-Passengersmustnotremainintheve-

hicle when itisjacked up.~

Thejackmustbeinstalledonlyattheplaces

indicated

~fig.169.Thereisexactlyoneloca

tionfor each wheel. Thejackmustnotbe

positioned

atanyotherlocation~&..

Anunstablesurfaceunderthejack cancause

thevehicletoslipoffthejack. Always provide

a firm basefor

thejackontheground.Ifnec

essaryplace asturdyboard orsimilarsupport

underthejack.Onhard,slipperysurfaces

(suchastiles) usearubbermatorsimilarto

preventthejackfromslipping~&..

Fig.170Close-up: properpositioningofjack

iTips

_Nevertryandusethehexagonalsocket

inthehandleofthescrewdrivertoloos

en

ortightenthewheelbolts.

_If awheelboltsitsverytight,you may

find it

easiertoloosenbycarefully push

ing down

ontheendofthewheelbolt

wrench withonefootonly.Asyoudo,

hold

ontothecartokeepyourselfstable

andtakecarenottoslip.

Fig.169Changing awheel: mounting pointsforthejack

Raisingthevehicle

•Applytheparkingbrakefirmlytoprevent

yourvehicle fromrolling unintentionally.

•Shiftintolstgearonvehicles withmanual

transmission,ormovetheselectorleverto

thePpositiononvehicles withautomatie

transmission.

•Positionthejackbelowthedoorsillunder

themountingpointthatisc10sesttothe

wheeltobechanged~fig.169.

Thevehiclemustbeliftedwiththejockfirst

before

thewheel canberemoved.

The

wheel

boltsmustbeloosenedbeforerois

ingthevehicle.

Looseningandtighteningthewhee.!abolts•

Fig.168Wheel change: looseningthewheelbolts

Refitting

~Placethecapsoverthewheelbolts and

pushthembackin.

The

capsaretheretoprotectand keepthe

wheelboltsc1ean.

4.WARNING

-Using forcewithoutcontroltospeedthe

wheelchangeupcancausethevehicle to

slip off

thejack andcauseserious per

sonalinjuries.

-Donotloosenthewheelboltsmorethon

oneturnbeforeyouraisethevehicle with~thejack.-Riskofinjury!

Loosening

~FitthewheelboItwrenchoverthewheel

boltandpushitdownasfarasitwill go.

~Closeyourgrip aroundtheendofthe

wrenchhandleformaximumtorqueand

turnthewheelbolts counter-c1ockwise

aboutonesingleturninthedirectionofar

row~fig.168.

Tightening'-

~FitthewheelboItwrenchoverthewheel

boItandpushitdownasfarasitwill go.

~Close yourg·riparoundtheendofthe

wrenchhandleformaximum·torqueand

turneachwheelboltc10ckwise untilitsits

tight.

Fig.166Wheel change: removingthewheelcover

Wheelswithcap-coveredwheelboltsAppliestovehicles: withcap-covered wheelbolts

Fig.

167Wheel change: removingthewheelboltcaps

Removing

~Insertthehookprovided withtheonboard

toolkitintothehole onthecenterhub

piece.

~Pull offthedecorativewheelcoyer

~fig.166.

DecorativewheelcoversApplies tavehides: withdecorativewheel(avers

Thedecorative wheelcaversmustberemoved

firsttooccessthewheel bolts.

The caps

mustberemovedfirst fromthe

wheelboltsbeforetheboltscanbeun

screwed.

Removing

~Pushtheplasticclipprovided withtheon

boardtoolkitdown overthewheelboltcap

until it

engages.

~Pullontheproperlyengagedplasticclipto

extractthecap~fig.167.

Page 116 of 132

Downloaded from www.Manualslib.com manuals search engine Whatdo1donow?22!

Afteryouchangeatire:

Notesonwheelchange

andthehub. Remove alldirtfromthese

surfaces beforeremountingthewheel.

Aunidirectional tirecan be identified

byar

rows onthesidewall, whichpointinthedirec

tion

oftherotation.Youmustfollowthe

specified directionofrotation.Thisisnecessa

ryin·orderforthesetirestodeveloptheirop

timumcharacteristics regardinggrip,road

noise, wear,andhydroplaning.

Tireswith unidirectional treaddesignmustbe

mountedwiththeir tread pattern pointedthe

rightdirection.

sensorforthetirepressure monitoring

systemwillhavetobereplacedbyaquali

fied workshop.

Tireswithunidirectionaltreaddesign

-

JCDNote

.&.WARNING

-

Ifyou aregoingtoequip yourvehicle

with tires

orrims which differfromthose

whichwerefactory installed,thenbe

sure

toreadtheinformationqpage209,

New tires andreplacing tires

and

wheels.

-AlwaysstorethetooLssecurelyinLug

gagecompartment.Otherwise,inanac

cident or

suddenmaneuvertheycouldfly

forward, causing

injurytopassengersin

thevehicle.

Donotusecommercially availabletire

seaLants. Otherwise,

theelectrical compo

nentsofthetirepressure monitoring sys

temwillnolongerworkproperly andthe

Pleasereadtheinformationqpage209,New

tires andreplacing tiresandwheels,

ifyou are

going

touse aspare tirewhichisdifferent

fromthetiresonyour vehicle.

_ Check

thetirepressureonthespareimme

diatelyaftermounting.

- HavethewheelboIttighteningtorque

checkedwithatorquewrenchassoonas

possible byyourauthorizedAudidealeror

aqualified servicestation.

-Withsteelandalloywheelrims,thewheel

boltsarecorrectlytightenedatatorqueof

90ftlb(120Nm).

-

Ifyounoticewhitechangingatirethatthe

wheelboLtsarecorrodedanddifficultto

turn,then theyshouldbereplaced before

you check

thetighteningtorque.

-ReplacethefIattirewithanewoneand

have itinstalledonyourvehicleassoonas

possible.Remountthewheelcoyer.

Until

then,drivewithextracareandatre

duced

speeds.

CDNote

Whenremovingorinstallingthewheel,

therim could hitthebrakerotoranddam

agetherotor. Workcarefully andhave a

secondperson helpyou

iTips

Never usethehexagonalsocketinthehan

dle

ofthescrewdrivertoloosenortighten

thewheelbolts.

- Pull

thereversible bladefromthescrew

driver before youuse

thehexagonal

socketinthehandletoturnthewheel

bolts.

-

Whenmounting tireswith unidirectional

treaddesignmakesurethetreadpat

ternispointedtheright way

qpage229.

-The wheel boltsshould beclean andeasy

toturn.Checkfordirtandcorrosion on

thematingsurfacesofboththewheel

Puttingonthewheel

~Liftthesparewheelandcarefully slideit

over

thealignmentpintoguide itinplace

q(D.

~Usethehexagonalsocketinthescrewdriver

handletoscrewinandtightenallwheel

bolts

slightly.

~Unscrewthealignmentpin andinsertand

tightentheremainingwheelbolt slightly

like

therest.

~Turnthejack handle counter-clockwise to

lower

thevehicle untilthejackisfullyre

leased.

~Usethewheelboltwrenchtotightenall

wheelbolts firmlyqpage226.Tighten

themcrosswise,fromonebolttothe(ap

proximately)

oppositeone,tokeepthe

wheelcentered.

~Screwthethreadedendofthealignment

pin fromthetoolkithand-tightintothe

nowvacantbolt holeqfig.172.

~Then completely unscrewtheotherwheel

boltsasdescribed above.

~Takeoffthewheelleavingthealignment

pininthebolthole.

Taking

thewheeloff

Fig.171WheeL change: usingthescrewdriverhandLe(withthebLaderemoved)toturntheboLts

Fig.

172Wheel change: aLignment pininside thetophoLe

Removingthewheel

~Usethehexagonalsocketinthescrewdriv

erhandletocompletelyturnoutthetop

mostwheelboltandsetitaside onacleon

surfaceqfig.171.

Follow theseinstructions step-by-step for

changing

thewheel.

- Makesurethatpassengerswaitina

safeplace awayfromthevehicle and

well away from

theroadway andtraffie.

- Make

surejack positioniscorrect, ad

justasnecessary andthencontinueto

raisethejack.

After youhave loosened all

wheelboltsand

raised

thevehicle offtheground, performthe

followingstepstoremoveandreplacethe

wheel:

KDNote

Afloor jackorthepadsonthehoistarms

mustnotbepositionedatthepoints

shown

-arrows-.

Page 121 of 132

Downloaded from www.Manualslib.com manuals search engine Emergencysituations

Removethetowingloopwhen youaredone

using itand place itbackinthevehicletool

kit. Always keepthetowing loopinthevehi

cle.

When installing

theairintake grille,insertthe

tabsonthegrilleinthemountsonthevehicle

first. Then press

thegrilleintosecure it.

AWARNING

Ifthetowingloapisnottighteneduntilit

stopswhen installing,thethreadsmaybe

pulled

outwhen towingthevehicleand

thatcouldcauseanaccident.

Reartowingloop

Donotinsto/l therear towing{oopunti{itis

needed.

Fig.183Right rearsection

Fig.

184Rear bumper: screwing inthe towing loop

Ontherightsideundertherearbumperthere

isathreadedholeforthetowing loop.The

threadedholeispratectedbyacoyer.

~Removethetowing loopfromthevehicle

toolkit

Qpage222.

~Presstherightsideofthecoyer inward

forcefully

toremove itframthebumper.

Qfig.183.

~Screwthetowinglooptightly intothe

threadedholeasfarasitwill go.

When it

isnolongerneeded,unscrewthe

towing loopandputitback intothevehicle

toolkit.

Besuretohavethetowing loopstored

inthevehicleatalltimes.

AWARNING

Ifthetowing loopisnotscrewedinasfar

asitwill go,thethreadcanpulloutwhen

thevehicleistowed-potentialriskofan

accident.

Loadingthevehicleanteaflatbedtruc~

Fig.185Vehicle onflatbedtruck

Fronthookup

~Alignthevehicle withthecenterlineofthe

carcarrier ramp.

~Attachthewinchhooktothefronttowline

eye previously installed.

"--Rearhookup

~Alignthevehiclewiththecenterlineofthe

carcarrier ramp.

~Attachthewinchhooktothereartowline

eye previously installed.

(DTips

Checkcarefullytomakesurethehook-up

issecure beforemovingthecaruptheflat

bed truck ramp.

LiftingvehicLe

Liftingwithworkshophoistandwith

floorjack

Thevehiclemayonlybeliftedatthelifting

points i/lustrated.

Fig.186Rearliftingpoint(rightside)

Fig.

187Frontliftingpoint(rightside)

~ReadandheedWARNINGQ&'

~Locate liftingpointsQfig.186Qfig.187.

~Adjust liftingarmsofworkshop hoistor

floorjacktomatchvehicle liftingpoints.

~Insertarubber padbetweenthefloorjack!

workshop hoistand

thelifting points.

Ifyoumustliftyourvehiclewithafloorjack

toworkunderneath,besurethevehicle is

safelysupportedonstandsintendedforthis

purpose.

Frontliftingpoint

Thelifting pointislocated onthefloorpanre

inforcementaboutatthesamelevel asthe

jackmounting pointQfig.187.Donotlift

thevehicleattheverticalsillreinforcement.

Rearliftingpoint

Thelifting pointislocated onthevertical rein

forcementofthelowersillfortheonboard

jack

Qfig.186.

Emergencysituations2::

Liftingwithvehiclejack

RefertoQpoge227.

AWARNING

-

Toreducetheriskofseriousinjury and

vehicle

damage.

- Always liftthevehicleonlyatthespe

cialworkshophoistand floor jacklift

points illustrated

Qfig.186and

Qfig·187.

-Failuretoliftthevehicleatthese

points couldcausethevehicletotiltor

fall from alift

ifthereisachangeinve

hicle

weightdistribution andbalance.

This

mighthappen,for example, when

heavy

componentssuch astheengine

block or

transmissionareremoved.

- When removing heavy

componentslike

these,anchorvehicletohoistoraddcor

respondingweightstomaintainthecen

terofgravity. Otherwise,thevehicle

mighttiltorslip offthehoist, causing

serious personal

injury.

CDNote

-Beawareofthefollowing pointsbefore

lifting

thevehicle:

- The vehicle

shouldneverbeliftedor

jackedupfromunderneaththeengine

oilpan,thetransmissionhousing,the

frontorrearaxleorthebodyside

members.This could leadtoserious

damage.

-Toavoiddamagetotheunderbodyor

chassisframe,arubberpadmustbe

insertedbetweenthefloorjackand

theliftpoints.

-Before driving overaworkshophoist,

checkthatthevehicleweightdoesnot

exceedthepermissiblelifting capacity

ofthehoist.

- Before driving overa

workshophoist,

ensurethatthereissufficientclear

ancebetweenthehoistandlowparts

ofthevehicle.

Page 125 of 132

Downloaded from www.Manualslib.com manuals search engine 246ConsumerInformation

steadilyreducedthescopeofmaintenance

andrepairswhichcanbecarriedoutbyvehicle

owners. Also,

safetyandenvironmentalcon

cernsplaceverystrictlimitsonthenatureof

repairsandadjustmentstoengineandtrans

missionpartswhichanownercanperform.

Maintenance,adjustmentsandrepairs usually

require special

tools,testingdevicesandoth

erequipmentavailabletospeciallytrained

workshoppersonnelinordertoassureproper

performance,reliabilityandsafetyofthevehi

cle

anditsmanysystems.

Impropermaintenance,adjustmentsandre

pairs canimpair

theoperationandreliability

ofyourvehicleandeven voidyourvehicle war

ranty. Therefore,

proofofservicinginaccord

ancewiththemaintenanceschedulemaybea

condition

forupholdinga possiblewarranty

claim

madewithinthewarranty period.

Above all,

operationalsafetycanbeadversely

affected,creatingunnecessaryrisksforyou

andyourpassengers.

Ifindoubtaboutanyservicing, haveitdone

byyourauthorizedAudidealeroranyother

properlyequippedandqualified workshop.

We

stronglyurgeyoutogiveyourauthorized

Audidealertheopportunitytoperformall

scheduledmaintenanceandnecessaryrepairs.

Your

dealerhasthefacilities, originalparts

andtrainedspecialiststokeepyourvehicle

running properly.

Performinglimitedmaintenanceyourself

Thefollowingpagesdescribealimited num

berofprocedureswhichcanbeperformedon

your vehicle withordinary

tools,shouldthe

need ariseandtrainedpersonnelbeunavaila

ble. Before

performinganyoftheseproce

dures, always

thoroughlyreadalloftheappli

cable

textandcarefully followtheinstruc

tionsgiven.Always rigorouslyobservethe

WARNINGS provided.

Before

youcheckanythingintheengine

compartment,alwaysreadandheedail

WARNINGSc:>.&andc:>.&inWorkinginthe

engine

compartmenton page182.

AWARNING

- Serious

personalinjurymay occurasare

sultofimproperlyperformedmainte

nance,adjustmentsorrepairs.

- Always

beextremelyca refulwhenwork

ing on

thevehicle. Alwaysfollowcom

monlyacceptedsafetypracticesandgen

eralcommonsense.Neverriskpersonal

injury.

-

Donotattemptanyofthemaintenance,

checksorrepairs described onthefol

lowing

pagesif youarenotfully familiar

withtheseorotherprocedureswith re

specttothevehicle, orareuncertainhow

toproceed.

-

Donotdoany workwithouttheproper

toolsandequipment.Havethenecessary

work

donebyyourauthorizedAudi deal

eroranotherproperlyequippedand

qualified workshop.

- The

enginecompartmentofanymotor

vehicleisapotentiallyhazardousarea.

Never reachinto

theareaaroundor

touchtheradiatorfan.Itistemperature

controlledandcanswitch onsuddenly

evenwhentheengineisoffandtheigni

tionkeyhasbeenremoved. Theradiator

fanswitchesonautomaticallywhenthe

coolantreachesacertaintemperature

andwillcontinuetorununtilthecoolant

temperaturedrops.'--.

-Always removetheignition keybefore

anyonegetsunderthevehicle.

- Always

supportyourvehicle withsafety

standsifitisnecessarytowork under

neaththevehicle. Thejacksupplied with

thevehicleisnotadequateforthispur

poseandcouldcollapsecausing serious

personalinjury.

-

Ifyoumustworkunderneaththevehicle

withthewheelsontheground,always

makesurethevehicleison level ground,

thatthewheelsarealways securely

blocked

andthattheenginecannatbe

started.

- Always makesurethetransmissionse

lectorlever(automatictransmission)is

in"P"(Park position)(automatictrans

mission)orNeutral(manualtransmis

sion)andthehandbrakeisfirmly ap

plied.

•Forthesakeoftheenvironment

- Changingtheenginesettingswill ad

versely

affectemissionlevels. Thisisdet

rimentaltatheenvironmentandincreas

esfuelconsumption.

-Alwaysobserveenvironmentalregula

tionswhendisposingofoldengineail,

used brake fluid, dirty

enginecoolant,

spentbatteriesorwornouttires.

- Undeployed

airbagmodulesandpreten

sionersmightbe classifiedasPerchlo

rateMaterial-specialhandlingmay ap

ply,

seewww.dtsc.ca.gov/hazardous

waste/perchlorate.Whenthevehicle or

partsoftherestraintsystemincluding

airbag

modulessafetybeltswithpreten

sionersarescrapped,allapplicablelaws

andregulationsmustbeobserved.Your

authorizedAudidealerisfamiliarwith

theserequirementsandwerecommend

thatyou haveyourdealerperformthis

serviceforyou.

AdditionaLaccessories,

modificationsand

partsrepLacement

Additionalaccessoriesandpartsreplacement

Always consult anauthorized Audidealer be

forepurchasing accessories.

Yourvehicleincorporatesthelatestsafetyde

sign

featuresensuringa highstandardofac

tive

andpassive safety.

This

safetycouldbecompromisedbynon-ap

proved

changestothevehicle. Forthisreason,

if

partshavetabereplaced,pleaseobserve

thefollowingpointswheninstallingaddition

al accessories:

ConsumerInformation2L

Approved AudiaccessoriesandgenuineAudi

partsareavailablefromauthorizedAudi deal

ers.

Thesedealersalsohavethenecessaryfacili

ties,toolsandtrainedspecialiststoinstallthe

partsandaccessoriesproperly.

AWARNING

Using

thewrongsparepartsorusing non

approved

accessoriescancausedamageto

thevehicleandseriouspersonalinjury.

- Use only

accessoriesexpresslyapproved

byAudiandgenuineAudispareparts

-Thesepartsandaccessorieshavebeen

speciallydesignedtobeused onyour ve

hicle.

- Never install

accessoriessuchastele

phonecradlesorbeverageholders onair

bag covers orwithin

theairbag deploy

mentzones. Doingsawillincreasethe

riskofinjury ifairbagsaretriggeredinan

accident!

- Before youcheck

anythingintheengine

compartment,always readandheedall

WARNINGS

c:>page 176.

CDNote1

-IfitemsotherthangenuineAudispare

parts,add-onequipmentandaccessory

itemsareusedorifrepair workisnot

performedaccordingtospecifiedmeth

ods,thiscanresu ltinseveredamageta

your vehicle'sengineandbody (suchas

corrosion)andadverselyaffectyourvehi

cle's warranty.

- The innovative

aluminiumconceptof

your AudiTTmeansthatallservicing, re

pairs or

otherwork onthevehicle body

mustbecarriedoutexclusivelybyanAu

diworkshop.

-

Ifemergencyrepairsmustbeperformed

elsewhere,havethevehicleexaminedby

anauthorizedAudidealershipassoonas

possible.

- The

manufacturercannotbe held liable

fordamagewhich occursduetafailure

tacamplywiththesestipulations.